Bulletin 71.8:6350

June 2009

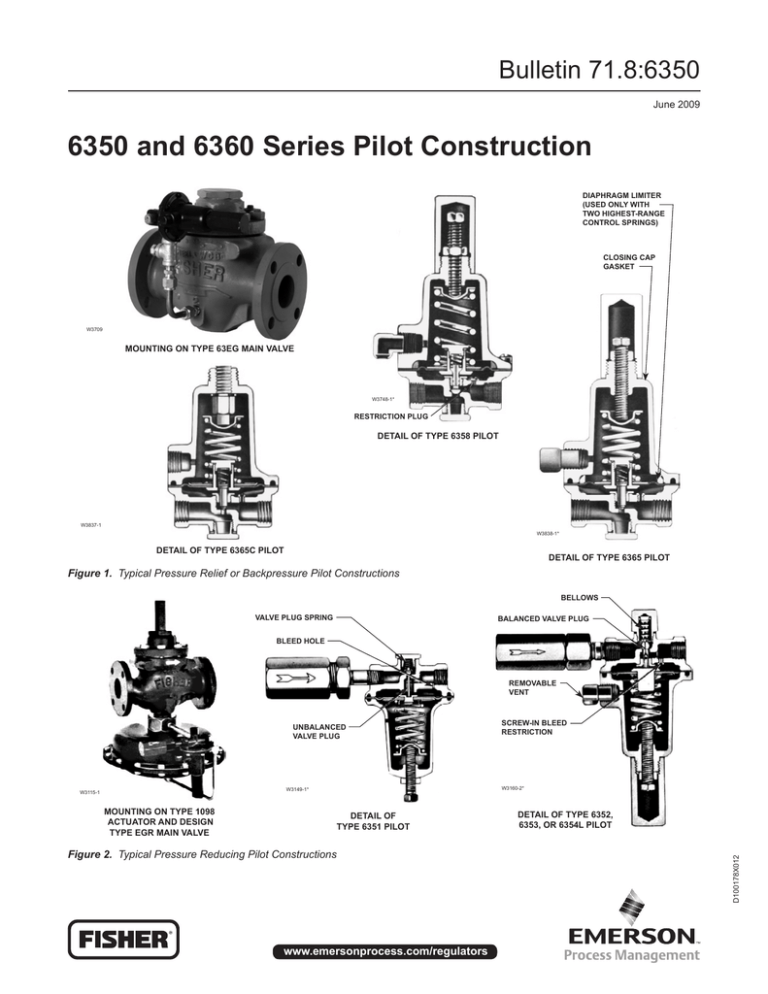

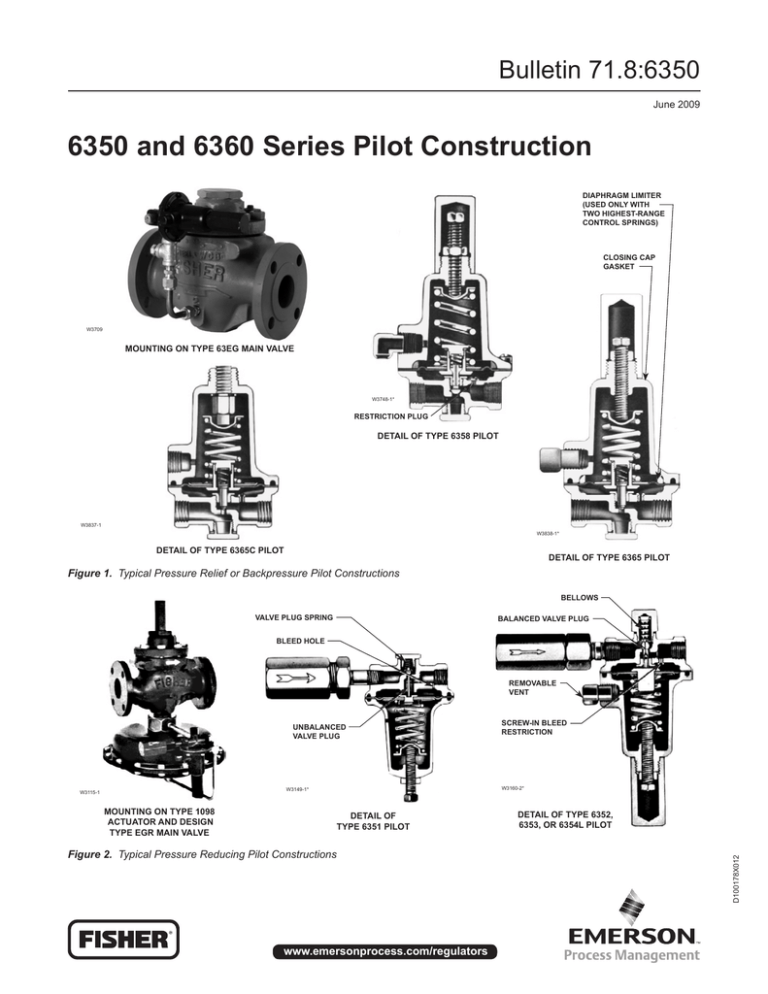

6350 and 6360 Series Pilot Construction

DIAPHRAGM limiter

(used only with

two highest-range

control springs)

closing cap

gasket

W3709

mounting on type 63eg main valve

W3748-1*

restriction plug

detail of type 6358 pilot

W3837-1

W3838-1*

detail oF TYPE 6365c pilot

detail of TYPE 6365 pilot

Figure 1. Typical Pressure Relief or Backpressure Pilot Constructions

bellows

valve plug spring

balanced valve plug

bleed hole

removable

vent

unbalanced

valve plug

W3160-2*

mounting on type 1098

actuator and design

TYPE egr main valve

detail of

type 6351 pilot

Figure 2. Typical Pressure Reducing Pilot Constructions

www.emersonprocess.com/regulators

detail of type 6352,

6353, or 6354L pilot

D100178X012

W3149-1*

W3115-1

screw-in bleed

restriction

Bulletin 71.8:6350

Specifications

Available Configurations

See Table 1

Maximum Inlet Pressure(1)

See Table 2 or 3, but cannot exceed maximum inlet

pressure for complete regulator or relief valve, whichever is less

Outlet (Control) Pressure Ranges For Pressure

Reducing Pilots

See Table 2

Set Pressure Ranges For Relief or

Backpressure Pilots

See Table 3

Construction Materials

Body, Body Plug, and Spring Case

Type 6351 Pilot: Aluminum

Types 6352 through 6365C Pilots: Aluminum (standard), brass, or stainless steel

Closing Cap (Except Types 6351 and

6365C Pilots): Same material as spring case

Control Spring: Plated steel

Valve Plug Assembly

Type 6351 Pilot: Nitrile (NBR) seat with brass

stem (standard), Nitrile (NBR) seat with stainless

steel stem, Fluorocarbon (FKM) seat with brass stem,

or Fluorocarbon (FKM) seat with stainless steel stem

Type 6358 Pilot: Polyethylene with Nitrile (NBR) O-ring

All Other 6350 and 6360 Series Pilots: Nitrile (NBR)

seat with stainless steel stem

Other Metal Trim Parts: Steel, aluminum, nickel, and stainless steel

Diaphragm

Type 6351 Pilot: Nitrile (NBR) (standard) or

Fluorocarbon (FKM)

Type 6352 Pilot: Natural rubber

Types 6353, 6358, and 6365C Pilots: Nitrile (NBR) rubber

Types 6354L, 6354M, and 6354H Pilots: Neoprene

Type 6365 Pilot: See Table 3

Gaskets

Connector Cap Gasket: Fluorocarbon (FKM)

All Others: Asbestos

Filter (if used): Brass (Type P594-1 standard) or aluminum (Type P593-1), except cellulose for filter element and asbestos for gasket

Vents: Plastic

Material Temperature Capabilities(1)

Standard Elastomers: -20° to 150°F (-29° to 66°C)

High-Temperature Elastomers: 0° to 300°F

(-18° to 149°C), except 0° to 180°F (-18° to 82°C) for water service

Connections(2)

NPS 1/4 female

Approximate Weight

2 pounds (1 kg)

Additional Options

See Table 1

1. The pressure/temperature limits in this Bulletin, and any applicable standard or code limitations should not be exceeded.

2. Connections threaded to various national or international standards can usually be supplied. Contact your local Sales Office.

Introduction

Ordering Information

A 6350 or 6360 Series pilot (Figure 1 or 2) is typically

used with one of several different main valves in a

pressure reducing, pressure relief, or backpressure

application (see Table 1). All of these pilots can be

used in gas service, and all except the Type 6351 pilot

can be used in liquid service. All pilots described in

this bulletin have an easily-installed valve plug that

can be removed without removing the valve plug

stem guide.

Application

When ordering, specify:

2

1. Type of service—pressure reducing, pressure

relief or backpressure application; liquid or

gas service

2. Nature and specific gravity of controlled fluid

(including chemical analysis of possible)

3. Fluid temperature

4. Range of flowing inlet pressures and pressure drops

5. Desired set pressure

Bulletin 71.8:6350

Table 1. Available Configurations

type number

construction feature

Gas

Gas or Liquid

Pressure

Pressure

Reducing

Reducing

Application Application

6351

Unbalanced valve plug

Its set pressure is above main

valve outlet pressure

Pilot bleeds only when

X

Gas or Liquid

Backpressure

Application

6365

6352,

2

Lowest

3

Middle

2 Highest

6354M

6353,

6365C

6354H Control Control Control

6354L

Spring

Spring

Spring

Ranges Ranges Ranges

X

Balanced valve plug (specify when rapidly changing loads or

varying supply pressures are anticipated)

Gas or Liquid

Pressure Relief

Applications

X

X

X

X

Its set pressure is below main

valve inlet pressure

X

X

X

X

X

X

X

X

X

X

X

Main valve is stroking open

Adjustable control spring

X

X

X

X

Used singly on main valve

X

X

X

X

X

X

Reduces buildup required for main valve to go wide open when

used along with Type 6365 pilot at 20 psig (1,4 bar) and

higher set pressures

Fixed restriction and no letter code

on body

X

X

X

Field-changeable green-coded

restriction screw and S stamped

on body

X

X

Field-changeable yellow-coded

restriction screw and H stamped

on body

X

Field-changeable red-coded

restriction screw and S stamped

on body

X

X

X

Plugged restriction with bleed

through valve plug

X

Optional lower gain (field-changeable red-coded restriction

screw and S stamped on body)

Optional low gain for liquid

service and/or broader

proportional bands

Optional high gain for

narrower proportional bands

(such as with low-differential

boiler fuel service)

X

Field-changeable blue-coded

restriction screw and L stamped

on body

X

Threaded restriction without screw

and with L stamped on body

X

X

Field-changeable red-coded

restriction screw and H on body

X

X

Diaphragm limiter

P590 Series filter

X

Standard

X

X

X

X

X

Optional

Drilled no vent or closing cap

Standard spring case

X

X

X

X

X

X

X

X

X

1/4-inch (6,4 mm) tapped with

removable vent and gasketed

closing cap for remote venting or

for pressure loading applications

X

X

1/4-inch (6,4 mm) tapped without

vent or closing cap

Adjusting screw

Standard

Handwheel

Optional

Spring case for Type 661 Kixcel®

pilot drive unit mounting

Optional

Sour gas service constructions

X

X

X

Nonadjustable control spring

Standard gain

(will be provided unless

otherwise specified) 6358

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

3

Bulletin 71.8:6350

Table 2. Outlet (Control) Pressure Ranges for Pressure Reducing Pilots

maximum inlet

pressure(1)

Psig

bar

type number

6351

600

41,4

6352

600

41,4

6353

600

41,4

6354L

6354M

6354H

600

600

600

41,4

41,4

41,4

Without diaphragm

limiter

With diaphragm limiter

outlet (control)

pressure range

3 to 20 psig

5 to 35 psig

35 to 100 psig

14-inches w.c. to 2 psig

2 to 10 psig

3 to 40 psig

35 to 100 psig

85 to 200 psig

175 to 220 psig

200 to 300 psig

(0,21 to 1,4 bar)

(0,34 to 2,4 bar)

(2,4 to 6,9 bar)

(35 mbar to 0,14 bar)

(0,14 to 0,69 bar)

(0,21 to 2,8 bar)

(2,4 to 6,9 bar)

(5,9 to 13,8 bar)

(12,1 to 15,2 bar)

(13,8 to 20,7 bar)

pilot control spring

data

Color Code

Part Number

Green

1B986027212

Cadmium

1B788327022

Red

1K748527202

Yellow

14A9672X012

Black

14A9673X012

Yellow

1E392527022

Red

1K748527202

Blue

1L346127142

Blue

1L346127142

Green

15A9258X012

1. Maximum inlet pressure for complete regulator, if less than this value, cannot be exceeded.

Table 3. Set Pressure Ranges for Relief or Backpressure Pilots

type number

6358

6365(2)

Without diaphragm

limiter

With diaphragm limiter

maximum inlet pressure

(including buildup)(1)

Psig

bar

150

10,3

50

3,45

150

10,3

360

24,8

360

24,8

set pressure range

Psig

3 to 40

3 to 125

0.5 to 2

2 to 10

3 to 40

35 to 125

85 to 200

175 to 220

200 to 300

bar

0,21 to 2,8

0,21 to 8,6

0,03 to 0,14

0,14 to 0,69

0,21 to 2,8

2,4 to 8,6

5,9 to 13,8

12,1 to 15,2

13,8 to 20,7

pilot control

spring data

Color Code

Part Number

Yellow

1E392527022

Red

1K748527202

Yellow

14A9672X012

Black

14A9673X012

Yellow

1E392527022

Red

1K748527022

Blue

1L346127142

Blue

1L346127142

Green

15A9258X012

diaphragm

material

Nitrile (NBR)

rubber

Natural rubber

Nitrile (NBR)

rubber

Neoprene

Neoprene

1. Maximum inlet pressure for complete relief valve, if less than this value, cannot be exceeded.

2. Addition of Type 6365C cascade pilot does not affect set pressure range.

Construction

Refer to the Specifications section on page 2. Review

the description to the right of each specification and

in the referenced tables; specify the desired selection

wherever there is a choice to be made.

Always specify the type number of other desired

equipment as well as the pilot. The standard-gain

pilot restriction will be provided automatically unless

an optional-gain restriction is ordered.

Industrial Regulators

Natural Gas Technologies

TESCOM

Emerson Process Management

Regulator Technologies, Inc.

Emerson Process Management

Regulator Technologies, Inc.

Emerson Process Management

Tescom Corporation

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Asia-Pacific

Shanghai, China 201206

Tel: +86 21 2892 9000

Asia-Pacific

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

©Emerson Process Management Regulator Technologies, Inc., 1983, 2009; All Rights Reserved