C71P Compression Fire Hydrant - Terminal City Iron Works Ltd.

advertisement

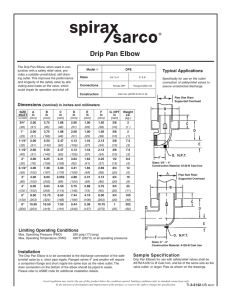

PART # QTY NAME MATERIAL TCH81-1 1 Barrel Cast Iron TCH81-1E 1 Barrel (Extended Alt. to TCH81-1 Cast Iron TCH81-2 1 Elbow Ductile Iron TCH3 1 “O” Ring Seal Plate Cast Iron TCH4 1 Bonnet Cast Iron H7 1 Valve Bottom Plate TCH8 1 Valve Top Plate Ductile Iron H9 1 Valve Seat Ring Bronze TCH81-9A 1 Subseat Bronze 863-10 2 2.5 inch ID Outlet Bronze TCH10 1 Operating Nut Cast Iron TCH10A 1 Revolving Nut Bronze H13 2 Drain Valve Face Rubber H14 2 Guide Plate Brass H15 6 Drain Valve Screw Stainless Steel H18 1 Travel Stop Nut TCH19 1 Hold Down Plate H21 1 Valve Rod Cap Nut TCH81-25 1 4 inch ID Pumper Outlet Bronze TCH25 1 Valve Rod Upper Section Type 416 Stainless Steel TCH25E 1 Valve Rod Upper Section for TCH81-1E Barrel Type 416 Stainless Steel TCH25A 1 Valve Rod Lower Section Hot Rolled Mild Steel TCH25M 1 Valve Rod Middle Section Hot Rolled Mild Steel H28 4 Hold Down Plate Capscrew Steel H31 1 Valve Rod Bottom Gasket Composition H33 28 1/2” x 2 3/4” Hex Bolt Grade 5 Steel 863-33 1 Independent “O” Ring Stuffing Box O Ring Bronze 28 1/2” Heavy Hex Head Nut Grade 5 36 863-40 Cast Iron Bronze Cast Iron Cast Iron 2 Independent Stuffing Box “O” Ring Buna N 863-41 2 2.5 inch ID Outlet “O” Ring Buna N 863-42 2 2.5 inch ID Outlet Lock Ring Ductile Iron TCH94-44 1 Valve Urethane H45 2 Valve Seat “O” Ring Buna N H45A 1 Subseat “O” Ring Buna N H45A1 1 Pumper Outlet “O” Ring Buna N H46 2 Drain Hole Liner Polyethylene H50 1 Top Flange Gasket Nitrile H51 2 Extension and Elbow Gasket NA-60 Fiber 52 1 Pumper Outlet Cap Cast Iron 53 2 Pumper Outlet Cap Gasket Red Rubber H54 1 Operating Nut & Lub Capscrew Grade 5 H55 2 “O” Ring Seal Plate “O” Ring Buna N TCH56 1 Hold Down Plate “O” Ring Buna N H57 1 Operating Nut Capscrew Gasket Vulcanized Fiber 59 2 2.5 inch ID Outlet Cap Cast Iron 60 4 2.5 inch ID Outlet Cap Gasket Red Rubber TCH61 C1 1 Valve Rod Coupling Upper Solid Cast Iron TCH61 D1 1 Valve Rod Coupling Lower Split Ductile Iron H66A 1 Valve Top Plate Gasket Vulcanized Fiber H70 2 3/8” x 3 1/4” Hex Head Bonnet Bolt Grade 2 H71 1 Thrust Bearing Assembly 2 Washers 1 Washer Polyethylene Stainless Steel 304 TCH92-72 1 Extension Ductile Iron TCH81-73 1 Pump Outlet Lock Ring Ductile Iron TCH81-74 1 Barrel Flange Cast Iron TCH92-75 2 Extension Flange Ductile Iron TCH81-76 1 Barrel Flange Retaining Ring Steel 91 1 2.5 inch ID Independent Outlet Bronze 92 1 Independent Gate Bronze 93 1 Independent Cut Off Screw Brass TCH41 3 Cap Attachment Chain Wire Rope 633 1 Insulating Gasket (if part # 633 required) 634 1 6 inch Extension (if part # 633 required) Cast Iron Coat the threaded section of the valve rod upper section (TCH25) with food grade grease for tempertures of -400C to +3000C Thread the bottom plate onto the valve rod. A small amount of food grade grease may be used on the bottom plate where it comes in contact with the urethane valve disk. This will allow the bottom plate to turn without binding against the urethane disc, tighten the bottom plate another HAND TIGHT against the disc. Using a wrench, tighten the bottom plate another 1/8 to 1/4 turn. DO NOT USE EXCESSIVE FORCE WHEN TIGHTENING BOTTOM PLATE, TO DO SO MAY DISTORT THE VALVE DISC, MAKING FUTURE REMOVAL DIFFICULT. To replace the valve seat “O” rings (H45), remove the old or worn “O” rings, clean the grooves that the “O” rings seat into and install the new “O” rings. Apply with a brush, a SMALL amount of food grade grease to the “O” rings. Avoid using too much grease as the excess grease can get under the “O” rings during reassembly causing them to jump from the groove that seats them and subsequently jam the assembly while it is being threaded back into the hydrant bottom end. Terminal City would like to go on record as stating that components used in the maintenance of our hydrants other than the “Original Equipment Manufacturer” parts may void any warranty offered for same. Typical 6” Elbow inlETs MEch JoinT TyTon JoinT FlangEd JoinT a 7 7 9 b 2 1/2 3 1/2 0 c 11 1/4 11 1/4 CODE C71 --- COMPRESSION HYDRANT 1971 WITH 2 PLAIN OUTLETS. C71P --- COMPRESSION HYDRANT 1971 WITH 2 PLAIN OUTLETS. PLUS 1 PUMPER OUTLET C71P1 --- COMPRESSION HYDRANT 1971 WITH 1 PLAIN OUTLET. PLUS 1 INDEPENDENT OUTLET PLUS 1 PUMPER OUTLET. NOTE: 2½" I.D. OUTLETS ARE TO B.C. ST’D 2½" FIRE HOSE THREAD OR TO CUSTOMERS SPECIFICATION. PUMPER OUTLET TO CUSTOMERS SPEC. – 11 – * * * * part no quan CAST IRON H31 1 VALVE ROD BOTTOM GASKET COMPOSITION EXTENSION DUCTILE IRON H33 28 ½NC X 2¾ L HEX HD ELECTRO-GALV.BOLT GRADE 2 STEEL 1 ELBOW CAST IRON 36 28 ½NC HEAVY HEX NUT STEEL TCH3 1 O RING SEAL PLATE CAST IRON 863-41 2 2½" I.D. OUTLET O RING NITRILE TCH4 1 BONNET-(ANTIQUE HYD’T H4) CAST IRON 863-42 2 2½" I.D. OUTLET LOCK RING DUCTILE IRON H7 1 VALVE BOTTOM PLATE CAST IRON TCH94-44 1 VALVE URETHANE TCH8 1 VALVE TOP PLATE DUCTILE IRON H45 2 VALVE SEAT O RING NITRILE H9 1 VALVE SEAT RING BRONZE H46 2 DRAIN HOLE LINER NYLON TCH98-9A 1 SUBSEAT BRONZE TCH81-74 1 BARREL FLANGE CAST IRON 863-10 2 2½" I.D. OUTLET BRONZE H50 1 TOP FLANGE GASKET NITRILE TCH10 1 OPERATING NUT -(T-H10) CAST IRON H51 2 EXTENSION (AND OR) ELBOW GASKET NA-60 FIBER TCH10A 1 REVOLVING NUT -(TCH10A-H105) BRONZE 52 1 4" I.D. PUMPER OUTLET CAP (HGA) CAST IRON H13 2 DRAIN VALVE FACE RUBBER 53 1 4" I.D. PUMPER OUTLET CAP GASKET RED RUBBER H14 2 GUIDE PLATE BRASS ASTM B16 H 54 1 HEX. SOC. HD. OPERATING NUT & LUB CAPSCREW STEEL H15 6 DRAIN VALVE SCREW STAINLESS STEEL TCH 56 1 HOLD DOWN PLATE O RING NITRILE H18 1 TRAVEL STOP NUT BRONZE H57 1 OPERATING NUT CAP SCREW GASKET COMPOSITION TCH 19 1 HOLD DOWN PLATE CAST IRON 59 2 2" I.D. OUTLET CAP - (H5) CAST IRON H21 1 VALVE ROD CAP NUT CAST IRON 60 2 2" I.D. OUTLET CAP GASKET part no quan name TC H81-1E 1 BARREL - (ANTIQUE HYD’T - HI.) TCH92-72 1 TCH98-2 material * * name material RED RUBBER UPPER LOWER CAST IRON DUCTILE IRON TCH81-25 1 4" I.D PUMPER OUTLET BRONZE TCH 61 TCH 61 2 VALVE ROD COUPLINGS TCH 25 1 VALVE ROD UPPER SECTION TYPE 416 STAINLESS STEEL H66A 1 VALVE TOP PLATE GASKET COMPOSITION TCH 25A 1 VALVE ROD LOWER SECTION HOT ROLLED MILD STEEL H70 2 ³/8NCX 3¼ L HEX HD BONNET NOLT ELECTRO-GALX STEEL H28 4 HOLD DOWN PLATE CAPSCREW STEEL H55 2 O RING SEAL PLATE O RING NITRILE 2 WASHER 1 WASHER PENLON ST. STEEL TCH 25M 1 VALVE ROD MIDDLE SECTION HOT ROLLED MILD STEEL H71 1 THRUST BEARING TCH 81-76 1 BARREL FLANGE RETAINING RING STEEL H45A 2 SUBSEAT TOP O RING NITRILE TCH 81-73 1 PUMPER OUTLET LOCK RING DUCTILE IRON 91 1 2½" I.D. INDEPENDENT OUTLET BRONZE H45-AI 1 PUMPER OUTLET ORING NITRILE 92 1 INDEPENDENT GATE BRONZE EXTENSION FLANGE DUCTILE IRON 93 1 INDEPENDENT CUT-OFF SCREW TOBIN OR CAST BRONZE TCH 92-75 4 *REQUIRED FOR H105 *REQUIRED FOR H105 – 12 – ENGINEERING DATA (IMPERIAL) PrEssurE in LBs. PEr squarE inCH and EquivaLEnT HEad OF WaTEr in FEET, aLsO HEad OF WaTEr in FEET and EquivaLEnT PrEssurE in i.B. PEr squarE inCH EquivaLEnT EquivaLEnT EquivaLEnT LB or FT. HEad FT. PrEssurE Psi LB or FT. HEad FT. PrEssurE Psi LB or FT. HEad FT. PrEssurE Psi 1 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 2.31 11.56 23.12 34.68 46.24 57.80 69.36 80.92 92.48 104.04 115.60 127.16 138.72 150.28 161.84 173.40 184.96 196.52 208.08 .4325 2.16 4.32 6.48 8.65 10.81 12.97 15.13 17.31 19.46 21.62 23.78 25.95 28.11 30.27 32.43 34.60 36.76 38.92 105 110 115 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 242.77 254.33 265.89 277.45 289.01 300.57 312.13 323.69 335.25 346.81 358.37 369.93 381.49 393.05 404.61 416.17 427.73 439.29 450.85 45.41 47.57 49.73 51.90 54.06 56.22 58.38 60,55 62.71 64.87 67.03 69.20 71.36 73.52 75.68 77.85 80.01 82.17 84.33 205 210 215 220 225 230 235 240 245 250 255 260 265 270 275 280 285 290 295 473.98 485.54 495.10 508.66 520.22 531.78 543.34 554.90 566.46 578.02 589.58 601.14 612.70 624.26 635.82 647.38 658.94 670.50 682.06 88.66 90.82 92.98 95.15 97.31 99.47 101.63 103.80 105.96 108.12 110.28 112.45 114.61 116.77 118.93 121.10 123.26 125.42 127.58 95 219.64 41.08 200 462.42 86.50 300 693.63 129.75 100 231.25 43.25 FirE HYdranT HEad LOssEs TC-C71P TC-1 TC-20 TC-1G = = = = Compression Hydrant 2-21/2 - inch and 1 - pumper outlet. no. 1 slide Gate Hydrant 2 - 21/2 - inch and 1 - pumper outlet. no. 20 slide Gate Hydrant 2 - 21/2 - inch outlet. no. 1 slide Gate Hydrant 2 - 21/2 - inch and 1 - pumper outlet (1 - 21/2 c/w independent cut-off valve). When flowing 1500 Imp. gal./min. – Head Loss through the hydrant TC-C71P = 13 p.s.i. TC20 = 181/2 p.s.i. -- 13 -- TC-1 = 171/2 TC-1G = 21 p.s.i. ENGINEERING DATA (METRIc) PRESSURE IN kPa AND EQUIVALENT HEAD OF WATER IN METRES, ALSO HEAD OF WATER IN METRES AND EQUIVALENT PRESSURE IN kPa kPa kPa kPa EQUIVALENT EQUIVALENT EQUIVALENT or or or HEAD PRESSURE HEAD PRESSURE HEAD PRESSURE METRES METRES METRES METRES METRES METRES kPa kPa kPa 0.5 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 •18 19 20 21 0.051 0.102 0.204 0.306 0.408 0.510 0.612 0.714 0.816 0.918 1.020 1.122 1.224 1.326 1.428 1.530 1.632 1.734 1.836 1.938 2.040 2.142 4.896 9.791 19.582 29.373 39.164 48.955 58.746 68.537 78.328 88.119 97.910 107.701 117.492 127.283 137.074 146.865 156.656 166.447 176.238 186.029 195.820 205.611 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 2.244 2.346 2.448 2.550 2.652 2.754 2.856 2.958 3.060 3.162 3.264 3.366 3.468 3.570 3.672 3.774 3.876 3.978 4.080 4.182 4.284 4.386 215.402 225.193 234.984 244.755 254.566 264.357 274.148 283.939 293.730 303.521 313.312 323.103 332.894 342.685 352.476 362.267 372.058 381.849 391.640 401.431 411.222 421.013 FIRE HYDRANT CAPACITIES FIG.1 TC-C71P = Compression Hydrant 2 - 65mm and 1 pumper outlet. TC-1 = No. 1 Slide Gate Hydrant 2 - 65mm and 1 pumper outlet. TC-20 = No. 20 Slide Gate Hydrant 2 - 65mm outlets. 44 45 46 47 48 49 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 4.488 4.590 4.692 4.794 4.896 4.998 5.100 6.120 7.140 8.160 9.180 10.200 11.220 12.240 13.260 14.280 15.300 16.320 17.340 18.360 19.380 20.400 430.804 440.595 450.386 460.177 469.968 479.759 489.550 587.460 685.370 783.280 881.190 979.100 1077.010 1174.920 1272.830 1370.740 1468.650 1566.560 1664.470 1762.380 1860.290 1958.200 FIRE HYDRANT HEAD LOSSES FIG.2 When flowing 6000 litres/min. – Head loss through the hydrant TC-C71P = 74.5 kPa TC-1 = 96.2 kPa TC-20 = 96.2 kPa Created Pressure Drop Across Hydrant kPa Hydrant Flow 1000 min Hydrant Capacity 1000 min Head Loss kPa 6.90 24.15 48.3 79.35 127.65 186.30 255.30 338.10 427.80 517.50 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 3.45 9.66 20.70 33.80 51.75 74.52 100.05 131.10 167.00 207.00 Created Pressure Drop Across Hydrant kPa Hydrant Flow 1000 l min Hydrant Capacity 1000 l min Head Loss kPa 6.90 22.08 51.75 93.15 141.45 200.10 267.03 351.90 460.92 555.45 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 3.45 10.35 24.15 41.40 65.55 89.70 120.75 158.70 203.55 251.85 Created Pressure Drop Across Hydrant kPa Hydrant Flow 1000 l min Hydrant Capacity 1000 l min Head Loss kPa 6.90 24.15 60.37 96.60 145.97 207.00 272.50 365.70 462.30 572.70 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 4.83 13.80 20.70 44.85 67.62 96.25 130.41 171.12 216.66 265.65 -- 14 -- notes notes notes