PRODUCT - HUWA International Pipeline Products

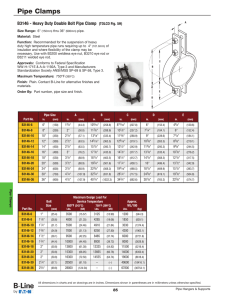

advertisement