Technical Focus Sound of Music, Sightline

advertisement

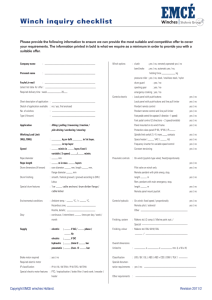

22 Sightline Summer 2007 Technical Focus The Sound of Music Over 80 ABTT and ALD members visited the London Palladium to take a detailed look at the staging of The Sound of Music Stage Technologies make the ‘hills come alive’ in the new production of The Sound of Music at the London Palladium, literally move a mountain which is one of the focal pieces of scenery in this highly acclaimed production in London’s West End. Mark Agar from Stage Technologies and production stage manager Jo Miles hosted the visit. The scenery movement was demonstrated in real show time, without actors but with lighting cues. The interest was very much focused on how it moved and looked. The most spectacular was the disc for the Alps, which flies in and vertically turns while covering the whole stage. Stage Technologies worked with set building company Scena to create this scenic piece which is lowered from the grid and has to rotate along horizontal axes, all of which is controlled by an Acrobat control console. Left: BT 200 winches fixed to counterweight frame Right: Stage tower showing the Mountain haulage chain and control and power cables. The flown Mountain is a multi-axis scenic piece weighing approximately eight tonnes. The movement of each axis has had to be carefully considered in how it affects the other two and the relationship between the Mountain and its surrounding scenery. There is a Servomotor and Mayr electromagnetic brake on the input shaft of the gearbox and two electromagnetic brakes on the output shaft of the gearbox. The motor/gearbox drives a heavy duty chain which is double-purchased top and bottom around the gimbals to which the Mountain is attached. The rotating component of the flown Mountain motor is attached directly to the input shaft of the gearbox, with dual-caliper hydraulic disk brakes on the output shaft of the gearbox. The motor and gearbox are contained within the stage-left gimbal and travel with the Mountain. Installed within the Mountain piece are foldback speakers and scenic gravestones which rise up to provide a dramatic visual effect. The whole Mountain is suspended on two towers positioned either side of the stage. This loading exceeded the Palladium stage’s safe working load. Concerned engineers decided to prop up the underside of the stage to the concrete floor below, which took the weight. No one dared ask how far below is the Central tube line! As well as beautiful mountain backdrops, the story of the problematic Maria unfolds amidst the stone walls of an abbey and the beautiful Von Trapp family mansion house. Large automated trucks bring the house onto stage in four sections. The synchronisation and millimetre positioning of these trucks is vital to bring each piece together in full view of the audience. Stage manager Jo Miles told members that there was “some intake of breath for the first few runs but the system soon settled down… as confidence grew. Positional stops are few and show stops – hardly ever.” Occasionally dirt in the tracks causes a bit of trouble – so sucking up the dirt is an important job; if not done properly it would stall thousands of pounds’ worth of machinery. Onboard drive systems enable each truck to rotate, turning the sections to transform the interior into the exterior in fast fluid moves, Sightline Summer 2007 achieved by each having a Servomotor attached directly to the input shaft of the gearbox. The output shaft drives a rackand-pinion slew ring. With the drive cabinets located on board the truck, they are fed by power from Profibus and switched at 24Vdc via a cable reeler and slip ring assembly which enables simultaneous endless rotation and tracking. Big Tow winches are used to fly wall backdrops onstage to create the abbey and a bedroom where the children take refuge from a thunderstorm. Cloths, gauze and banners are pulled into position and life size birch trees fly and track into view all done by the Big Tow. The Big Tow winch is a multi-purpose scenery-moving winch, which will lift loads of up to 500 kg at speeds of up to 3 m/s. The Big Tow winch incorporates patented ‘zero fleet’ technology which ensures that the take off point for the cable on the drum remains static. This allows the winch to be easily mounted in any position without the concerns of fleet angle normally associated with drum winches. The Big Tows operate virtually silently, do not suffer from vibration and can be used as a point hoist, counterweight assist, power flying winch, a performer-flying winch or as a floor track winch. The winch has two brake systems: primary and secondary. Essential winch maintenance checks are required every week and include inspection of the lead screw and end nut, end of travel hard limits, gearbox chain, all control cables, and the haulage cable. A full stage width travelator is also used to whisk furniture and performers on and off stage quickly and safely. This rubber conveyor belt is friction driven from a drum at the stageleft end of the belt. The servo-motor is bolted directly to the gearbox and linked by chain to the drive drum. The belt has a centre guide fin that slots into a gap on the passive drums as well as in the supporting floor. A large scenic banner is revealed during the concert scene, and made up of three segments, one over the stalls, and two are revealed, one each side of the auditorium. All the mechanics, drives and motors for these were supplied and installed by Howard Eaton Lighting. Control is provided by Stage Technologies in the form of ‘dry contacts’ which remotely switch the HEL control gear. The power supply is also incorporated into the overall e-stop system providing additional safety. The rose window, the abbey backing, the crucifix and large stage masking flats are all flown using power assisted counterweight sets, using BT 200 winches fixed to the counterweight frame with steel wire ropes attached to the top and bottom of each counterweight cradle. These winches were also supplied by Stage Technologies and installed by Stage Services. The automation control was programmed by Alex Hitchcock, who has automated many large West End productions with Stage Technologies including Oliver!, The Witches of Eastwick and Mary Poppins. The Acrobat console is the interface and translator between the operator and the Programmable Transmission System (PTS). Waltz scene “Lonely goatherd” 23 24 Sightline Summer 2007 This system has twelve pushbuttons which provide two key features which help ensure safety, dual channel redundancy, which ensures that a single fault does not lead to loss of safety function, and cyclic monitoring, which provides detection of the first fault by monitoring correct operation of the safety component at each cycle. The e-stop system complies with BS EN 418: Safety of machinery – emergency stop equipment. The full installation takes an hour to check out every day plus hours of maintenance every week. Geoffrey Joyce Information kindly supplied by Stage Technologies. Stuart Porter, Associate Lighting Designer The Acrobat allows the operator to move the winches as required to meet the desired effect during the performance. The Acrobat can move one or more motors at different speeds/times and show the operator the details the movement of each axis. The operator knows what each scenic element or attached performer is doing. The operator can stop one or all motors immediately if required. The Maxis provides control for up to 24 separate axes. It is designed to form a central part of the Acrobat control system. The Maxis rack contains an electrical interface and a sophisticated computer control system to provide positioning and synchronisation functions for each axis. The control system allows individual or groups of motors to be run accurately to a position, at a pre-determined speed. The rack also provides synchronisation between motors allowing more than one motor to move a piece of scenery as required. Critical to all of this is the fully digital IRT 1300 series drive which controls the supply to the motor thus giving smooth operation of motor allowing minute adjustment in speed. Rotation is transmitted through the winch gearboxes to drive the drums of the winches by the HD115 and HR142 series motors. An internal feedback device returns positional data; in this installation all devices are resolvers. The motors are also fitted with failsafe magnetic brakes. The emergency stop system when activated will bring all axes to a rapid and controlled stop. Typical lighting specification see plan on pages 20/21 Moving lights 19 x VL1000 AS 34 x MAC 700 Wash 39 x Martin TW1 16 x Martin MAC 700 Profile Generic rig 44 x Source 4 10 98 x Source 4 profile 12 x PAR 64 60 x Source 4 PAR 750W 12 x 2 CRT M16 Batten 75 watt 26 x 3 CRT M16 Batten 75 watt 20 x various birdie fittings Scrollers (all fitted with heat shields) 76 x Rainbow Pro scrollers Smoke machines 2 x smoke machines 2 x haze machines DMX controllable fans Dimmers and control 1 x Hog IPC (8 Streams DMX) 1 x 8 universe City Theatrical DMX Sound of Music Producer: Really Useful Theatre Company Production manager: Matt Towell Venue: London Palladium Lighting designer: Mark Henderson Associate lighting designer: Stuart Porter Production LX: Fraser Hall