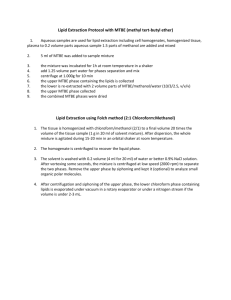

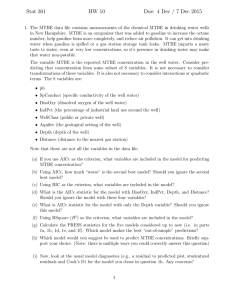

SAFETY DATA SHEET

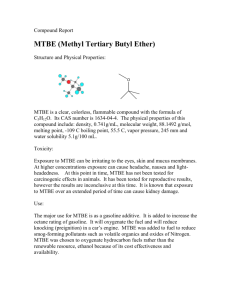

advertisement