Presentation - 2016 Energy Exchange

advertisement

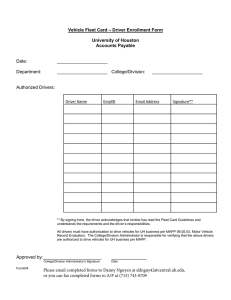

“But the OEM said 0‐10’s free…” But the Fixture OEM said 0‐10’s “Free”… Purpose: Explore the Top 10 reasons why, in reality, 0‐10V LED Drivers are NOT Free Codes Comparisons This image cannot currently be display ed. Designing with Digital vs. 0-10V Occupancy Daylight Zone 1 1 3 3 4 5 6 Daylight Zone 2 Personal Control Zone 1 Personal Control Zone 2 Designing with Digital vs. 0-10V 0‐10V Lighting Control “Box” 1 3 3 4 5 6 How many “boxes” do I need for the entire job? Designing with Digital vs. 0-10V EcoSystem “Box” Where is the power wiring? How many “boxes” do I need? Top 10 Reasons 0‐10 isn’t “Free”… Sink or source. Which method does the driver use for the control? 10. IEC 60929 for General Lighting – The driver sources the current – The control sinks the current – At 10 Volts, lights go to full – At 1 Volt or below, lights go to minimum ESTA E1.3 for theatrical lighting – The control sources the current – The driver sinks the current – At 10 Volts, lights go to full – At 0 Volts, lights go off Are you sure your driver is sourcing current? One more item to coordinate and a callback if you are wrong! Top 10 Reasons 0‐10 isn’t “Free”… 9. Inrush Current. Does it comply with NEMA 410? What is NEMA 410? NEMA 410 is a standard for testing of lighting controls used with electronic drivers, ballasts, and lamps • Defines worst case inrush current expected in installations and establishes test criteria for compatibility • What is Inrush Current? And why do I care? On a 5A load at 277V, during turn‐on one could expect a peak inrush of 320A! Fried Dimmer! Fried Relay What is Inrush Current and Why do I care? What is Inrush Current? • –Maximum (peak) input current drawn by an electrical device when first turned on Why does it occur? • –Electronics which use capacitors in power supplies when first turned on require large currents to flow to charge those capacitors What is the impact? • –Causes excessive wear on switch or relay contacts, Electro / Mechanical wear –Can result in tripping breaker, do you have access (high inrush) leading to premature failure (welding) of switch or relay to reset breaker? Most often maintenance or the EC is called Relay contacts 120VAC, 16A 50k cycles Top 10 Reasons 0‐10 isn’t “Free”… Brand X With most 0‐10V LED Drivers, every time you turn them on (occupancy sensor, daylight sensor, blink‐warn from a timeclock, …) they experience this Inrush Current Some LED driver makers provide inrush current specs, but not whether this meets NEMA 410 requirements • Lutron LED Drivers meet NEMA 410 at initial power up • With Lutron’s Electronic off – there is NO Inrush Current • Inrush Current compliance – another item to coordinate Top 10 Reasons 0‐10 isn’t “Free”… Battery‐back up Emergency fixtures require an extra wire (HOT) run to all EM fixtures with 0‐10V drivers to charge the battery 8. - Some Digital Systems do not need this extra wire(s) for EM battery packs Extra $ cost to run additional wire for EM fixtures – another item to coordinate Top 10 Reasons 0‐10 isn’t “Free”… Power line noise interference. What happens if the control wires are too close to the power wires? 7. “Standards” do not specify whether 0‐10 control wires should be run as UL Class 1 (Line Voltage) or Class 2 – up to Driver manufacturer •Long wire runs of 0‐10 can affect performance (dimming range, accuracy) How long is too long? •Running 0‐10 wires in the same conduit as power wiring (Class 1 option) can capacitively couple noise on to the 0‐10 lines and affect performance • Utilizing digital communication, not analog 0‐10 and is immune to this noise. Wires can be run in the same conduit (check local codes) • More coordination – how do LV control wires get run to perform OK? Top 10 Reasons 0‐10 isn’t “Free”… 6. Polarity free? Topology free? Miswire protected? No. 0‐10 volt control wiring must: •Maintain polarity •Follow the line voltage zoning •Some 0‐10 LED Drivers do not survive if the 0‐10V wires are miswired with the line voltage wiring • Digital Controls help prevent line / low voltage miswires, can be run in any configuration (star, T‐tap, daisy chain, etc) and can swap polarity without issue • Extra cost to wire 0‐10V zones compared to Ecosystem, maybe in conduit! Top 10 Reasons 0‐10 isn’t “Free”… UL requires a failed LED driver be replaced with the exact make and model of driver otherwise the UL Listing is voided 5. Today, if an LED driver fails, the entire fixture needs to be replaced… •Since an LED fixture is UL Listed with a specific LED driver, you can replace a failed driver with the same brand & model to maintain UL. You will need a UL FIELD INSPECTION •Locked into using a particular brand & model •0‐10V LED Drivers are not as “Open” as they sound • Is your LED Driver UL 1598C recognized which means they can be part of UL Listed LED field retrofit kits • Myth of the Open nature of 0‐10 Drivers is busted by UL requirements Top 10 Reasons 0‐10 isn’t “Free”… 4. No guarantee of compatibility between driver + control • Do you know the maker of the LED driver? •Can you easily get answers from the LED driver manufacturer on all the topics covered here? •Sink vs. Source? •Meet IEC 60629 or ESTA1.3? •Inrush Current NEMA 410 compliant? •UL 1598C listed? •Input vs. Output curve? •Turn‐on Time? •Can you get this in a timely fashion? • Does your manufacturer guarantee compatibility between Drivers / Ballasts and controls? • Top 10 Reasons 0‐10 isn’t “Free”… Variation between models – control input vs. light level output and turn on time 3. 0‐10V “Standards” do not specify performance – so each manufacturer has their own interpretation of things like input to output, turn on time, etc. • Lutron Ecosystem LED Drivers turn on together, go to the same levels, and track together when dimming • You need to evaluate all LED driver dimming curves to get lights to track together ! Top 10 Reasons 0‐10 isn’t “Free”… Making changes to zones requires rewiring, both in design and in the field 2. 0‐10V dimming requires the EC to re‐circuit and rewire when a change in space layout is needed. •In the design phase, changes in zoning requires the designer to change drawings. • Digital Drivers can defer zoning decisions until later. •Easy to use software and iPad to make changes in zoning. • Changes in design and in the field will add extra cost with 0‐10 LED drivers; higher project life cycle cost! Top 10 Reasons 0‐10 isn’t “Free”… LED driver company has little presence to stand behind its performance. Will they be able to resolve field issues? 1. Will there be performance issues to deal with post installation – pop‐on, flicker, sub‐standard quality dimming •Can you get someone from the 0‐10 LED driver company out to your jobsite? •Can you even get them to answer the phone or an email? • The extended Lutron organization has vast knowledge and resources, as well as commitment to get to the root cause of a problem and fix it. • Will you have somebody to call anytime of the day (24/7/365), if you have an issue with your LED driver?