Instructions - Edison Price Lighting

LED Square XSM DL/4, LED Square XSM DL/5

LED Square XSM wL/4, LED Square XSM wL/5

installation instructions

mounting bars

Three kinds of mounting bars may be purchased as accessories from

Edison Price Lighting.

Standard mounting bars are

27” long, 3 /

4

” high C channels for use in suspended ceiling systems.

Residential mounting bars are

18” and 26” long telescoping bars for use in wood joist construction.

Caddy #517A bars are 26” long telescoping bars which attach easily to many kinds of suspended T-bar.

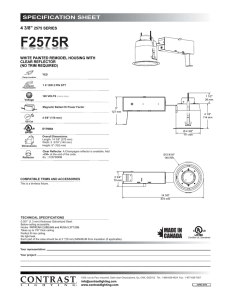

installation: housing

This fixture is listed, suitable for use in a fire rated ceiling, and should be installed in accordance with the National Electrical Code and local regulations.

SPACING REQUIREMENTS

Luminaires with L10A or L15S engines must be spaced 24” apart and 12” from walls, and must have ½” clearance above housing.

Luminaires with L13A, L20S or L30S engines must be spaced

36” apart and 18” from walls, and must have ½” clearance above housing.

• Insert mounting bars through the adjustable mounting brackets on either side of the fixture.

7

This fixture can be attached to ceiling runners which extend no less than

/

8

” and no more than 3 3 /

8

” above the finished ceiling surface.

• Position the fixture so that its mounting bars lie on top of the ceiling runners.

• When the fixture is correctly located, fasten the mounting bars securely to the ceiling runners.

• Adjust the fixture to the proper height by loosening the wing nuts on both adjustable brackets and setting the fixture so that the bot- tom edge of the circular plaster ring will be flush with the surface

of the finished ceiling. Tighten the wing nuts.

WARNING: Do not install ceiling insulation within 3 inches of fixture sides nor above fixture in such a way to entrap heat.

• Wire the fixture following the instructions on the reverse side of this sheet.

After all ceiling finishing work is complete, install the reflector.

installation: reflector

Insert the reflector into the housing.

LED XSM DL/4, LED XSM DL/5

LED XSM WL/4, LED XSM WL/5

© Edison Price Lighting 41-50 22 nd Street Long Island City, NY 11101 www.epl.com

wiring

This fixture is listed and is approved for eight #12 wire 90°C branch circuit pull-through wiring.

• Remove inner cover of junction box by releasing spring clip on top of box.

• Splice incoming black wire to black thermal protector (TP) lead. Splice incoming white wire to white leads from TP and ballast. Splice blue TP lead to black ballast lead. Splice incoming ground to box ground.

• Put wire nuts on all open splices.

• Snap junction box cover back into place.

standard 120-volt, non-dimming, service shown

servicing

LED engines and drivers are replaced at end-of-life as follows:

• interrupt electrical circuit by which luminaire is powered; and

• remove reflector or reflector assembly

LED ENGINE REPLACEMENT:

• Remove the mixing reflector by removing two screws.

• Remove the LED engine by removing three screws.

• Attach the new LED engine.

• Re-attach the mixing reflector.

DRIVER REPLACEMENT:

Downlights: LED Square XSM DL/4 and LED Square XSM DL/5

1. Disengage the LED engine assembly from its support stands by

loosening its two nuts and rotating the assembly clockwise.

2. Place the LED engine assembly to the side of the luminaire away

from the junction box.

3. Press up on the junction box spring to release the driver box

assembly.

4. Loosen wire nuts. Break splices. Withdraw the driver box

assembly through the aperture of luminaire.

5. Open driver box by untwisting, with pliers, the twisted steel tab

holding the box to the plate.

6. Attach new driver box to the driver box plate and secure it by

twisting the steel tab.

7. Re-splice wires; apply wire nuts and snap the junction box closed

with the new driver box assembly.

8. Replace the LED engine assembly in its support stands and secure

by re-tightening two nuts.

Wallwashers: LED Square XSM WL/4 and LED Square XSM WL/5

1. Disengage LED engine assembly by removing two wing nuts

and lifting the assembly off its support stands.

2. – 7. Same steps as above

8. Replace the LED engine assembly in its support stands and

secure with the two wing nuts.

DRIVER bOx PLATE

JUNCTION bOx

SPRING TWISTED STEEL TAb

(hidden from view)

JUNCTION bOx

DRIVER

DRIVER bOx LED ENGINE

SCREW (3)

(hidden from view)

LED Square XSM DL/4, LED Square XSM DL/5

JUNCTION bOx

DRIVER bOx PLATE

JUNCTION bOx SPRING

LED

ENGINE

SUPPORT STAND

LED ENGINE

ASSEMbLy

LED ENGINE

ASSEMbLy NUT (2)

MIxING

REfLECTOR

SCREW (2)

LED ENGINE

ASSEMbLy

SUPPORT STAND

LED ENGINE

ASSEMbLy

WING NUT (3)

LED ENGINE

SCREWS (3)

(hidden from view)

reflector maintenance

Reflector may be cleaned of dust with a damp, soft lint-free cloth. To remove fingerprints or dirt, wash with a solution of dishwashing detergent and water, rinse, and dry with a soft lint-free cloth. Avoid wiping when reflector surface is dry.

TWISTED

STEEL TAb

(hidden from view)

DRIVER bOx

DRIVER

LED ENGINE

LED Square XSM WL/4, LED Square XSM WL/5

MIxING

REfLECTOR

SCREW (2)