ISSN 2321-8665

Vol.03,Issue.04,

July-2015,

Pages:0640-0645

WWW.IJITECH.ORG

Power Factor Improvement using Single-Stage Balanced Forward

Flyback Converter

MADISHETTY VENKATESH KUMAR1, K. CHANDRA MOULI2

1

PG Scholar, Vaageswari College of Engineering, Ramakrishna Colony, Karimnagar, Telangana, India.

Assoc Prof, Vaageswari College of Engineering, Ramakrishna Colony, Karimnagar, Telangana, India.

2

Abstract: In this paper, a high efficiency and high power

factor single-stage balanced forward-flyback converter

merging a foward and flyback converter topologies is

proposed. The conventional AC/DC flyback converter can

achieve a good power factor but it has a high offset current

through the transformer magnetizing inductor, which results

in a large core loss and low power conversion efficiency.

And, the conventional forward converter can achieve the

good power conversion efficiency with the aid of the low

core loss but the input current dead zone near zero cross AC

input voltage deteriorates the power factor. On the other

hand, since the proposed converter can operate as the forward

and flyback converters during switch on and off periods,

respectively, it cannot only perform the power transfer during

an entire switching period but also achieve the high power

factor due to the flyback operation. Moreover, since the

current balanced capacitor can minimize the offset current

through the transformer magnetizing inductor regardless of

the AC input voltage, the core loss and volume of the

transformer can be minimized. Therefore, the proposed

converter features a high efficiency and high power factor. To

confirm the validity of the proposed converter, theoretical

analysis and experimental resultsfrom a prototype of 24W

LED driver are presented.

factor corrector and isolated DC/DC converter). The first

stage provides a near unity power factor and low total

harmonic distortion (THD) over an entire range of universal

inputvoltage (90-270 Vrms) and the second DC/DC stage is

used to provide a tight output regulation and galvanic

isolation between AC input and DC output. Even though the

two-stage configuration can provide the high power factor,

good output regulation and excellent ripple voltage, it has

several significant disadvantages such as a large system size,

high cost of production and low energy conversion efficiency.

Therefore, it is common that the two-stage driver is mainly

used for high power applications and single-stage driver is

adopted as a low power LED driver.

Keywords: Conventional AC/DC, Flyback Converter.

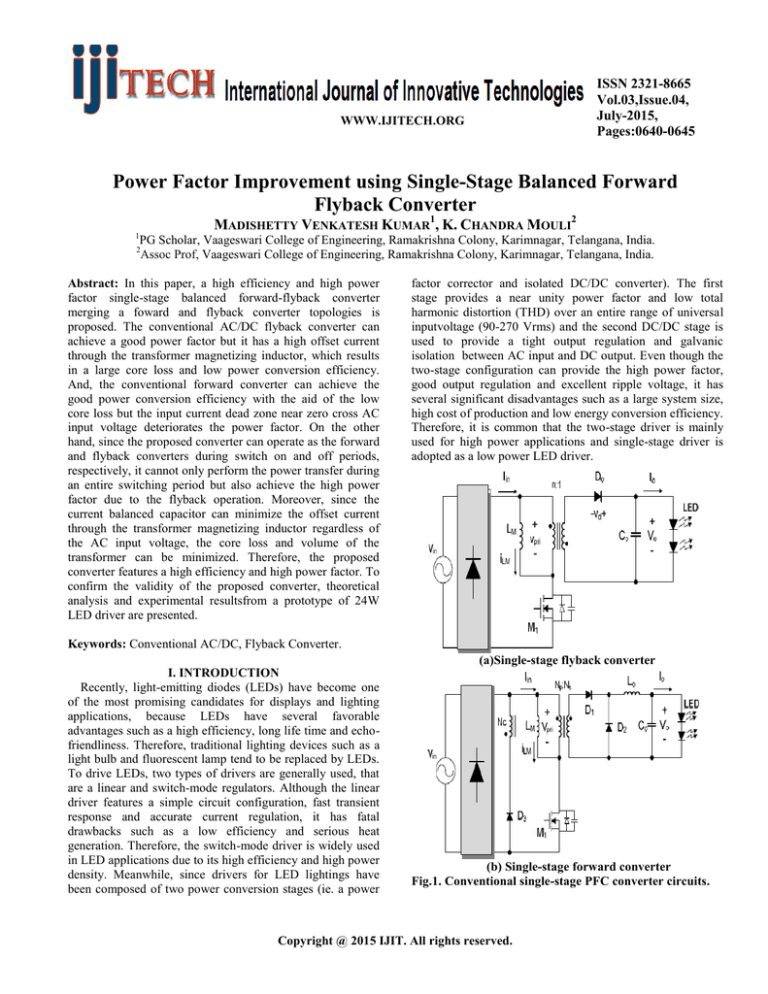

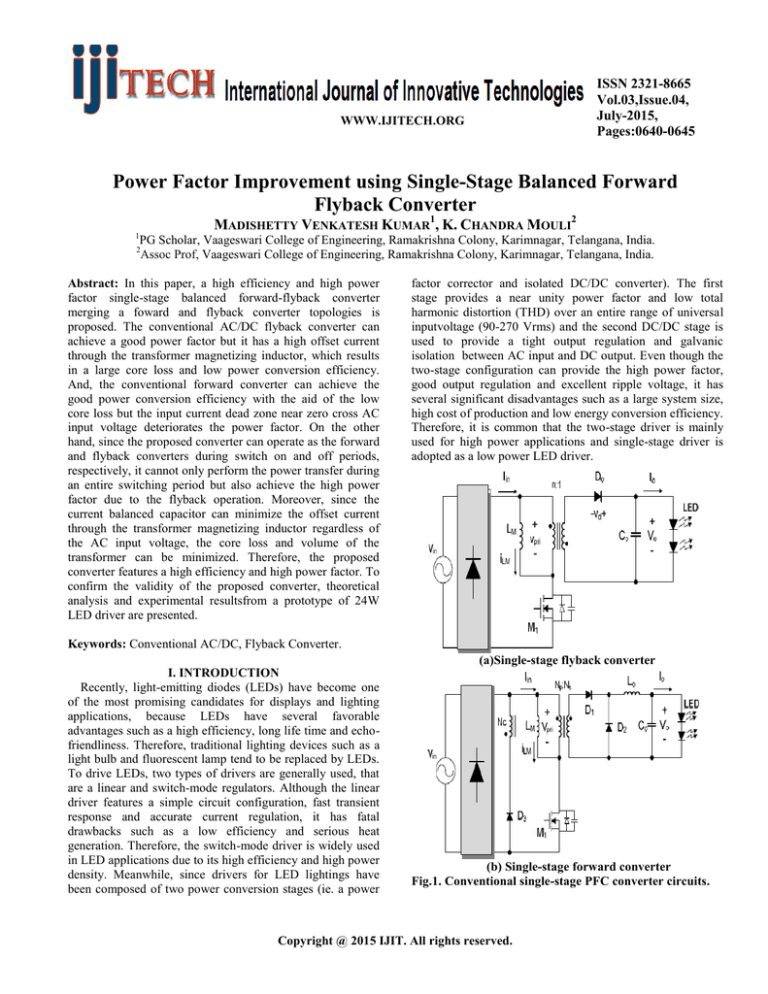

(a)Single-stage flyback converter

I. INTRODUCTION

Recently, light-emitting diodes (LEDs) have become one

of the most promising candidates for displays and lighting

applications, because LEDs have several favorable

advantages such as a high efficiency, long life time and echofriendliness. Therefore, traditional lighting devices such as a

light bulb and fluorescent lamp tend to be replaced by LEDs.

To drive LEDs, two types of drivers are generally used, that

are a linear and switch-mode regulators. Although the linear

driver features a simple circuit configuration, fast transient

response and accurate current regulation, it has fatal

drawbacks such as a low efficiency and serious heat

generation. Therefore, the switch-mode driver is widely used

in LED applications due to its high efficiency and high power

density. Meanwhile, since drivers for LED lightings have

been composed of two power conversion stages (ie. a power

(b) Single-stage forward converter

Fig.1. Conventional single-stage PFC converter circuits.

Copyright @ 2015 IJIT. All rights reserved.

MADISHETTY VENKATESH KUMAR, K. CHANDRA MOULI

Fig.1(a) shows conventional single-stage PFC (power

Fig.2 shows the basic topology of a fly-back circuit. Input

factor correction) LED drivers, which are well known as most

to the circuit may be unregulated dc voltage derived from the

cost effective solutions. Fig1(b) shows their transformer

utility ac supply after rectification and some filtering. The

magnetizing inductor currents. As shown in this figure, the

ripple in dc voltage waveform is generally of low frequency

magnetizing inductor offset current of flyback converter is

and the overall ripple voltage waveform repeats at twice the

larger than that of forward converter as followings

ac mains frequency. Since the SMPS circuit is operated at

much higher frequency (in the range of 100 kHz) the input

voltage, in spite of being unregulated, may be considered to

(1)

have a constant magnitude during any high frequency cycle.

A fast switching device („S‟), like a MOSFET, is used with

fast dynamic control over switch duty ratio (ratio of ON time

to switching time-period) to maintain the desired output

(2)

voltage. The transformer, in Fig.2, is used for voltage

Moreover, from equations(1) and (2), while the magnetizing

isolation as well as for better matching between input and

inductor offset current of flyback converter is dependent on

output voltage and current requirements.

the load current Io, that of forward converter is not.

Therefore, as the load current is more increased, the offset

III. AC –DC CONVERTER

current of flyback converter becomes larger, which might

A. Introduction

result in the larger core loss and volume of transformer. For

A rectifier is an electrical device that converts alternating

these reasons, the forward converter is superior to the flyback

current (AC), which periodically reverses direction, to direct

converter in terms of the transformer size and energy

current (DC), which flows in only one direction. The process

conversion efficiency.

is known as rectification. Physically, rectifiers take a number

of forms, including vacuum tube diodes, mercury-arc valves,

II. FLY BACK CONVERTER

copper and selenium oxide rectifiers, semiconductor diodes,

A. Introduction

silicon-controlled rectifiers and other silicon-based

Fly-back converter is the most commonly used SMPS

semiconductor switches. Historically, even synchronous

circuit for low output power applications where the output

electromechanical switches and motors have been used. Early

voltage needs to be isolated from the input main supply. The

radio receivers, called crystal radios, used a "cat's whisker" of

output power of fly-back type SMPS circuits may vary from

fine wire pressing on a crystal of galena (lead sulfide) to

few watts to less than 100 watts. The overall circuit topology

serve as a point-contact rectifier or "crystal detector".

of this converter is considerably simpler than other SMPS

Rectifiers have many uses, but are often found serving as

circuits. Input to the circuit is generally unregulated dc

components of DC power supplies and high-voltage direct

voltage obtained by rectifying the utility ac voltage followed

current power transmission systems. Rectification may serve

by a simple capacitor filter. The circuit can offer single or

in roles other than to generate direct current for use as a

multiple isolated output voltages and can operate over wide

source of power. As noted, detectors of radio signals serve as

range of input voltage variation. In respect of energyrectifiers. In gas heating systems flame rectification is used to

efficiency, fly-back power supplies are inferior to many other

detect presence of a flame. Because of the alternating nature

SMPS circuits but its simple topology and low cost makes it

of the input AC sine wave, the process of rectification alone

popular in low output power range. The commonly used flyproduces a DC current that, though unidirectional, consists of

back converter requires a single controllable switch like,

pulses of current. Many applications of rectifiers, such as

MOSFET and the usual switching frequency is in the range of

power supplies for radio, television and computer equipment,

100 kHz. A two-switch topology exists that offers better

require a steady constant DC current (as would be produced

energy efficiency and less voltage stress across the switches

by a battery). In these applications the output of the rectifier

but costs more and the circuit complexity also increases

is smoothed by an electronic filter (usually a capacitor) to

slightly. The present lesson is limited to the study of fly-back

produce a steady current. A more complex circuitry device

circuit of single switch topology.

that performs the opposite function, converting DC to AC, is

called an inverter.

B. Rectifier devices

Before the development of silicon semiconductor rectifiers,

vacuum tube thermionic diodes and copper oxide- or

selenium-based metal rectifier stacks were used.[1] With the

introduction of semiconductor electronics, vacuum tube

rectifiers became obsolete, except for some enthusiasts of

vacuum tube audio equipment. For power rectification from

very low to very high current, semiconductor diodes of

various types (junction diodes, Schottky diodes, etc.) are

widely used (fig 3 to5).

Fig 2. Basic Topology of Fly-Back Converter.

International Journal of Innovative Technologies

Volume.03, Issue No.04, July-2015, Pages: 0640-0645

Power Factor Improvement using Single-Stage Balanced Forward-Flyback Converter

A power factor of 0.7 requires approximately 40% more

current; and a power factor of 0.5 requires approximately

100% (twice as much) to handle the same load. The answer to

these problems is to reduce the reactive power drawn from

the supply by improving the power factor. If an AC motor

were 100% efficient it would consume only active power.

However, since most AC motors are only 75% to 80%

efficient, they operate at a lower power factor. This means

inefficient and even "wasteful" energy usage and cost

efficiency because most electric utilities charge penalties for

poor, inefficient power factor. Simply installing capacitors

will improve a commercial or industrial company's power

Fig 3. Half-wave rectifier.

factor and will result in savings on their electricity bill every

month. An additional potential benefit for correcting poor

power factor includes. Reduction of heating losses in

transformers and distribution equipment Longer equipment

life

Fig 4. Graetz bridge rectifier: a full-wave rectifier using 4

diodes.

A. Operational principles

Fig.6 shows the circuit diagram of the proposed forward

flyback converter. As shown in this figure, its primary side is

exactly same as that of the conventional flyback converter

consisting of one power switch (M1) and one transformer. On

the other hand, its secondary side consists of one output

inductor (Lo) for forward operation, one DC blocking

capacitor (Cb) for balancing operation and three output

Diodes (D1, D2, D3). When M1 is conducting, the proposed

converter operates as a forward converter as shown in Fig 7.

On the other hand, when M1 is blocked, the proposed

converter operates as a flyback converter.

Fig 5. Full-wave rectifier using a center tap transformer

and 2 diodes.

IV. SINGLE STAGE PFC CONVERTER

A. Power Factor Correction (PFC)

An electric utility's power load on an electrical distribution

system fall into one of three categories; resistive, inductive or

Fig.6. Proposed single stage PFC forward flyback

capacitive. In most industrial facilities, the most common

converter circuit.

power usages are "inductive." Examples of inductive loads

include transformers, fluorescent lighting and AC induction

However, if it is assumed that the proposed converter has no

motors. Most inductive loads use a conductive coil winding

balancing capacitor Cb, abovementioned forward operation is

to produce an electromagnetic field which permits the motor

possible only when the reflected primary voltage Vin/n to the

to function. All inductive loads require two different types of

transformer secondary side is higher than the output voltage

power for the motor to operate: Active power (measured in

Vo. This is because the forward converter is originated from

kW or kilowatts) - this power produces the motive force

the buck converter. Therefore, the forward-flyback converter

Reactive power (kvar) - this energizes the magnetic field of

operates only as a flyback converter over the range of Vin/n <

the motor. The operating power from the distribution system

Vo. Especially, at the minimum input voltage near Vin=

is composed of both active (working) and reactive (non90Vrms, Vin/n is lower than Vo during most of periods and

working) elements. The active power does useful work in

thus, the transformer has a large magnetizing offset current

driving the motor whereas the reactive power only provides

similar to the conventional flyback converter. In this case, the

the magnetic field. Unfortunately, electric utility's customers

transformer core loss and according to the input voltage. (a)

are charged for both active and reactive power. Example: A

without balancing capacitor (b) with balancing capacitor

customer's power factor drops, the system becomes less

volume are also as large as those of the conventional flyback

efficient. A drop from 1.0 to 0.9 results in 15% more current

converter.

being required for the same load.

International Journal of Innovative Technologies

Volume.03, Issue No.04, July-2015, Pages: 0640-0645

MADISHETTY VENKATESH KUMAR, K. CHANDRA MOULI

Table I: Specifications of Laboratory Prototype

Fig.7. Primary and magnetizing currents of forwardflyback converter

On the other hand, if the balancing capacitor Cb is serially

inserted with the transformer secondary side, it can make the

average current through Cb during forward operation become

exactly same as that during flyback operation by the charge

balance principle of Cb. In other words, since the voltage

across Cb charged by flyback operation is added to the

Vsec=Vin/n during forward operation, Vin/n+Vcb becomes

higher than Vo and thus, the forward operation is possible

even at Vin/n<Vo. Therefore, the proposed forward-flyback

converter with the balancing capacitor Cb can always operate

as both forward and flyback converters regardless of the input

voltage. Fig. 4.2 shows the primary and magnetizing current

waveforms of the proposed converter operating in the

boundary conduction mode (BCM). And, Fig.7 (a) and (b)

show current waveforms without and with balancing

capacitor Cb according to the input voltage, respectively. As

mentioned earlier, the proposed converter with Cb can

operate as both forward and flyback converters over an entire

range of input voltage with the aid of Vcb. On the other hand,

while the proposed converter without Cb can transfer the

input energy to the output side at Vin/n>Vo, it cannot at

Vin/n<Vo. As a result, the proposed converter with balancing

capacitor Cb features a smaller magnetizing offset current,

resultant smaller core loss and more reduced transformer

volume.

Fig.8. Simulation model diagram.

As shown in this figure, the proposed converter has the

high power factor above 95% over a wide range of input

voltage. Especially, its efficiency along wide input voltage

range is above 88.51% and higher than the conventional

converter by maximum 8.05% at 264Vrms. This high

efficiency is due primarily to the small transformer offset

current and resultant reduced core loss.

V. SIMULATION RESULTS AND DISCUSSIONS

To confirm the validity of the operational principles and

theoretical analysis of the proposed converter, a laboratory

prototype applicable to the LED driver was implemented and

tested with the following specifications. Fig.9 shows the

experimental waveforms of transformer primary current and

switch voltage at Vin=90 and 264Vrms. As can be seen in

this figure, the measured waveform of Iin(=Ip) has a near

sinusoidal waveform. Fig.10 show the experimental

waveforms of output inductor current ILo and output diode

current ID3 at 90Vrms and 264Vrms, respectively, where ILo

corresponds to the forward operating current and ID3 flyback

operating current. As can be seen in these figures, ILo and

ID3 continuously flow even at the low input voltage, which

proves that the proposed forward-flyback converter can

always operate as both forward and flyback converters

regardless of the input voltage.

International Journal of Innovative Technologies

Volume.03, Issue No.04, July-2015, Pages: 0640-0645

Power Factor Improvement using Single-Stage Balanced Forward-Flyback Converter

91.21% respectively. Moreover, the proposed circuit can be

perform the power transfer during an entire switching period.

Therefore, the proposed circuit having these favorable

advantages is expected to be well suited to various LED

driver applications.

VII. REFERENCES

[1] F. Xiaoyun, L. Xiaojian, and W. Yan, “Research and

analysis of the design development and perspective

technology for LED lighting products,” in Proceeding of

CAID&CD, pp. 1330-1334, Nov. 2009.

[2] Huang-Jen Chiu Yu-Kang Lo, Jun-Ting Chen, Shih-Jen

Cheng, Chung- Yi Lin, and Shann-Chyi Mou, “A HighEfficiency Dimmable Driver for Low-Power Lighting

Applications” , IEEE Trans. on Industrial Electronics, Vol.

57, No. 2, pp. 735, Feb. 2010.

[3] Jin-Bong Choi, Kwan Woo Kim, Young Cheol Lim,

“LED Driver for the isolated LED Lighting using Flyback

Fig.9.Simulation waveforms of transformer primary

converter” , KIPE Power Electromics Annual conference, pp.

current and switch voltage.

167-169, 2009.

[4] Ming-Shian Lin, Chem-Lin Chen, "A Driver Based on

Pulse Current Modulator", IEEE Trans. on Power Electronics,

Vol. 26, pp. 2054-2058, Apr. 2011.

[5] Hua-Min Xu, Xin-Bo Ruan, Yang-Guang Yan “ A novel

forward single-stage single-switch power factor correction

AC/DC converter”, in Proceeding of PESC, vol.2, pp. 754759, 2001.

[6] Huai Wei “Comparison of basic converter topologies for

power factor correction” Southeastcon Proceedings. IEEE,

pp. 348-353, 2008.

[7] Yoshito Kusuhara, Tamotsu Ninomiya and Shin

Nakagawa, "Steady-State Analysis of a Novel ForwardFlyback-Mixed Converter", Proceeding of the EPE-PEMC,

pp. 60-65, Aug. 2006.

[8] Yonghan Kang, Byungcho Choi and Wonseok Lim,

"Analysis and Design of a Forward-Flyback Converter

Employing Two Transformers", Proceeding of the IEEE, Vol.

1, pp. 357-362, June. 2001.

[9] Yungtaek Jang and Milan M. Jovanovic, "Bridgeless

Buck PFC Rectifier", Proceeding of the APEC2010, pp. 2329, Feb. 2010.

[10] F. Chen, H. Hu, J. Shen, I. Batarseh and K. Rustom,

"Design and Analysis for ZVS Forward-Flyback DC-DC

Converter", Proceeding of the ECCE2011, pp. 116-121, Sept.

Fig.10. Simulation waveforms of proposed circuit

2011.

measured at 90Vrms.

Author’s Profile:

Madishetty Venkatesh Kumar received

VI. CONCLUSION

B.Tech degree in Electrical & Electronics

A single stage power-factor-correction balanced forward

Engineering from Jyothishmathi Institute

flyback converter for LED application is presented, and its

of Technology and Science, Nustlapur,

operation principle analyzed in this paper. The proposed

Karimnagar, T.S. currently pursuing

forward-flyback converter with the balancing capacitor can

M.Tech in Power Electronics at

always operate as both forward and flyback converters

Vaageswari College of Engineering,

regardless of the input voltage. Therefore, it has a smaller

Ramakrishna Colony, Karimnagar, T.S. my areas of Interest

magnetizing offset current, resultant smaller core loss and

are Power Electronics, Power Systems.

more reduced transformer core volume. For this reason, the

K.Chandra Mouli, DECE, B.Tech,

proposed converter can be obtained high efficiency and high

M.Tech,

MISTE, working as Associate

power factor. To verify the validity of proposed circuit,

Proffessor & HOD in the dept. of EEE

experimental results from a prototype of 24W single stage

from Vaageswari College of Engineering,

power factor correction balanced forward-flyback converter

Ramakrishna colony, Karimnagar-District,

for LED application are provided, which shows that the

Telangana, INDIA. Worked in various

measured maximum power factor and efficiency is 0.996 and

Engineering Colleges and have 13 years of

International Journal of Innovative Technologies

Volume.03, Issue No.04, July-2015, Pages: 0640-0645

MADISHETTY VENKATESH KUMAR, K. CHANDRA MOULI

Teaching experience. Currently doing research in Multilevel

Inverters, cascaded H-Bridge Inverters (15, 11, 9, 5 levels),

diode clamped 7 level inverter, He has presented 4 National,

5 International Conference Papers . He has published 3

research papers in National and International Journals.

International Journal of Innovative Technologies

Volume.03, Issue No.04, July-2015, Pages: 0640-0645