OLIMEX© 2012

PIC-IO User's Manual

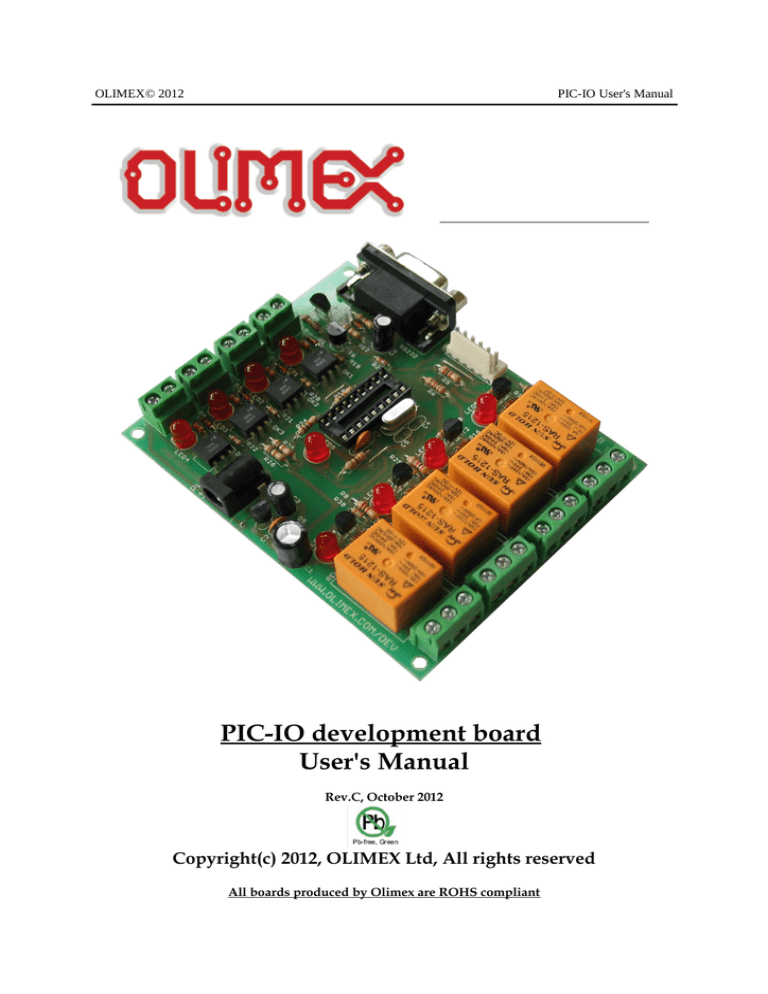

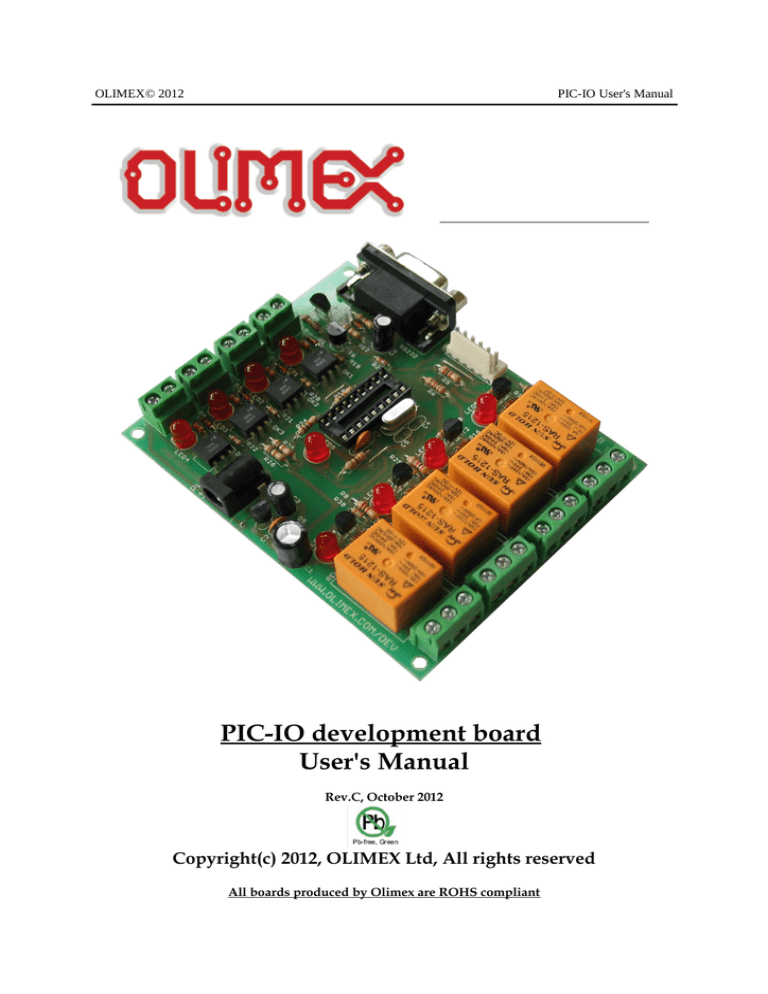

PIC-IO development board

User's Manual

Rev.C, October 2012

Copyright(c) 2012, OLIMEX Ltd, All rights reserved

All boards produced by Olimex are ROHS compliant

OLIMEX© 2012

PIC-IO User's Manual

INTRODUCTION:

PIC-IO board was designed as simple platform which to allow control of appliances and

devices with PIC, the idea was to build something like tiny PLC controller which is possible

to program in C or assembler instead of the weird PLC relay language.

Let’s see what we have on board:

Four High voltage/ High Current relays – with NO-NC-COM contacts available on terminal

block. The relay switching current is rated: 15A/125VAC, 10A/250VAC, 15A/24VDC. Note

that these relays are good for switching resistive loads, but if you have to commutate

inductive loads the relays will wear off quickly due to the sparking when disconnect the

inductive loads (like motors).

Each relay have status LED associated with it so you can easy see which relay is in ON and

which in OFF state.

O1 is connected to RA3 CMP1 and PIC CCP module can be used to generate ON/OFF pulses.

O2-O3-O4 are connected to RA2-RA1-RA0.

Four opto-isolated inputs will allow to detect voltages in range +5-24VDC. Opto-couplers are

fast and switch On/Off for 10 uS, so quick signals could be detected.

!NOTE for owners of MOD-IO prior to revision C1: the above information is correct

only for the opto-isolated couplers – the board is capable to handle up to 22VDC for

them. You need to swap R1, R2, R3, R4 - 330R resistors with 470R ones be able to use

24VDC! This has been fixed in the latest revision as seen in the schematics.

I1 is connected to RA4 and is good for counting as this pin is connected to PIC T0CKI.

I2 is connected to RB0 which is INT and generates interrupts.

I3 is connected to CCP1 and is good for pulse width measurement.

I4 is connected to RB4.

The inputs have status LEDs so easy could be seen which input have voltage. Note that the

optocouplers inverse the levels i.e. when on the input have +5V the PIC pin will read “0” and

vice versa.

Status LED is connected to RB5.

PIC-IO have RS232 connector, but the driver is made by tricky level shifter which uses the

other side RS232 negative levels to generate the PIC-IO levels, so on the other side you must

OLIMEX© 2012

PIC-IO User's Manual

have real RS232 driver (like PC) if you try to connect two PIC-IO boards by RS232 the

connection will fail as no one of the boards will generate the negative levels.

The on-board ICSP connector allow you to program the PIC on the board without pulling it of

the socket, by ICSP programmer like PIC-MCP, PIC-MCP-USB, PIC-PG1, PIC-PG2, PICPG3, PIC-PG4 or to program and debug it with PIC-ICD2, PIC-ICD2-POCKET or PICICD2-TINY. IMPORTANT: all programmers provide power supply through ICSP connector

during the programming PIC-IO should not be powered via the external power jack!

The power supply circuit have protection diode for reverse connection. The positive point is

the internal pin of the power jack. The input voltage could be in range 12–14V DC.

The oscillator circuit is made with 20 Mhz crystal oscillator, so you can run your PIC at

maximum performance.

The RESET is connected with 10K to +5V and allow safe use of PIC-ICD2 or PIC-MCP

programming.

OLIMEX© 2012

PIC-IO User's Manual

FEATURES:

•

•

•

•

•

•

•

•

•

•

•

ICSP/ICD connector for programming and debugging

RS232 interface

DIL18 socket

Quartz crystal 20Mhz

LED to RB5 through jumper

Four opto-isolated inputs with status LEDs

Four Relays 10A/250VAC with status LEDs

Power plug-in jack, accept AC and DC input

Four mounting holes 3,3 mm (0,13")

FR-4, 1.5 mm (0,062"), green soldermask, white silkscreen component print

Dimensions 100x80 mm (3,9x3,15")

OLIMEX© 2012

PIC-IO User's Manual

HARDWARE:

+12V

PWR+

IN

-2

-1

C1

1N4004

+12VDC

6

5

2

4

R19

470K

R2

IN2-2

LED2

1

6

5

D2

1N4148

2

4

R20

470K

4N37

R3

IN3-1

IN3-2

LED3

6

5

2

4

R21

470K

4N37

R4

IN4-1

IN4-2

LED4

10K

C4

20p

C5

20p

+5V

16

Q1

20MHz

R9

15

RESET

4

10K

VDD

6

5

2

4

5

R26

I4

R22

470K

4N37

10K

GND

RB7/T1OSI

RB6/T1CKI

RB5

RB4/PGM

RB3/CCP1

RB2/TX/CK

RB1/RX/DT

RB0/INT

RA7/OSC1

RA6/OSC2

RA5/MCLR

RA4/T0CKI/CMP2

RA3/AN3/CMP1

RA2/AN2/VREF

RA1/AN1

RA0/AN0

OK4

1

470

D4

1N4148

U1

14

C7

100n

R25

I3

GND

+5V

10K

OK3

1

470

D3

1N4148

RESET

+5V

R24

I2

R5

T1

2N3904

2K

OUT1-2

OUT1-1

10K

OK2

470

OUT1-3

REL1

O1

100uF/16VDC

GND

R23

I1

4N37

IN2-1

100n

R27

1

220uF/25VDC

C3

VSS

PICICSP

+12V

1

2

3

4

5

6

REL2

H200

D7

1N4004

R16

1.5K

ICSP

13

12

11

10

9

8

7

6

I4

I3

T XD

RXD

I2

3

2

1

18

17

I1

O1

O2

O3

O4

R14

PIC_18pin

OUT2-3

REL2

O2

330

R6

T2

2N3904

2K

LED9

OUT2-2

OUT2-1

GND

+12V

REL3

H200

D8

1N4004

+5V

LED6

10K

IN1-2

LED1

D1

1N4148

C2

LED5

R15

1.5K

OUT

GND

+5V

OK1

470

D6

1N4004

R28

R1

IN1-1

+5V

10K

D5

REL1

H200

VR

78L05

+12V

LED7

R17

1.5K

+5V

OUT3-3

REL3

RXD

R11

4,7K

GND

D10

R12

1N4148

10K

C6

10uF/25VDC

+

1

2

3

4

5

GND

T3

2N3904

2K

R13

10K

10K

R7

OUT3-1

T6

2N3904

+12V

D11

1N4148

GND

OUT3-2

10K

RS232

6

7

8

9

O3

T XD

R29

R10

T5

PNP2N3906

REL4

H200

D9

1N4004

LED8

R18

1.5K

OUT4-3

REL4

Copyright (C) 2002, OLIMEX Ltd

http://www.olimex.com/dev

T4

2N3904

2K

OUT4-2

10K

PIC-IO_rev_C1

R8

R30

O4

OUT4-1

OLIMEX© 2012

PIC-IO User's Manual

SOFTWARE:

DEMO1:

PIC16F628-I/P

CONTROL SOFTWARE

This is demo code, which allow control of the PIC-IO inputs/outputs via PC

with Hyper terminal.

Connect PIC-IO RS232 with cable to your PC and run Hyper terminal with

these settings: 9600,8,N,1,NONE. When you apply power this will be seen

on the Hyper terminal window:

***************************

* PIC-IO CONTROL

*

* (C) 2007, OLIMEX Ltd*

***************************

>_

To read the inputs in binary format type “r”, PIC-IO will respond with

something like:

%0000

if all inputs are 0 or

%1111

if all inputs are 1 (i.e. +5V is applied)

the inputs are with right less significant bit i.e. the order is: I4 I3 I2 I1

To read the inputs in HEX format type “R”, PIC-IO will respond with

something like:

$0

if all inputs are 0 or

$F

if all inputs are 1

To change the outputs type “w0101”, this will switch on relay 1 and relay 3

and will switch off relay 2 and relay 4.

If you want to use HEX value you can write “W5” for instance which will

switch on relay 4 and relay 1 and will switch off relay 2 and relay 3.

Any other commands will not be recognized and PIC-IO will respond with

“ERR”

OLIMEX© 2012

PIC-IO User's Manual

ORDER CODE:

PIC-PIO – assembled and tested (no kit, no soldering required)

How to order?

You can order directly from us or from any of our distributors.

Check our web https://www.olimex.com for more info.

Revision history:

REV.A

- created June 2007

REV.B

- added info about the maximum voltage possible on the opto-couplers, 22VDC by default

REV.C

- changed schematic with the latest one, revision C1 of the board has adjusted resistors on the

relay inputs (330R were replaced with 470R); added a note about differences in different

revisions; updated disclaimer; added support and warranty info

OLIMEX© 2012

PIC-IO User's Manual

DISCLAIMER

© 2012 Olimex Ltd. Olimex®, logo and combinations thereof, are registered trademarks of Olimex Ltd.

Other product names may be trademarks of others and the rights belong to their respective owners.

The information in this document is provided in connection with Olimex products. No license, express

or implied or otherwise, to any intellectual property right is granted by this document or in connection

with the sale of Olimex products.

The Hardware project is released under the Creative Commons Attribution-Share Alike 3.0 United States

License. You may reproduce it for both your own personal use, and for commercial use. You will have to

provide a link to the original creator of the project https://www.olimex.com on any documentation or

website.

You may also modify the files, but you must then release them as well under the same terms. Credit can be

attributed through a link to the creator website: https://www.olimex.com

The software is released under GPL.

It is possible that the pictures in this manual differ from the latest revision of the board.

The product described in this document is subject to continuous development and improvements. All

particulars of the product and its use contained in this document are given by OLIMEX in good faith.

However all warranties implied or expressed including but not limited to implied warranties of

merchantability or fitness for purpose are excluded. This document is intended only to assist the reader in the

use of the product. OLIMEX Ltd. shall not be liable for any loss or damage arising from the use of any

information in this document or any error or omission in such information or any incorrect use of the

product.

This evaluation board/kit is intended for use for engineering development, demonstration, or evaluation

purposes only and is not considered by OLIMEX to be a finished end-product fit for general consumer use.

Persons handling the product must have electronics training and observe good engineering practice

standards. As such, the goods being provided are not intended to be complete in terms of required design-,

marketing-, and/or manufacturing-related protective considerations, including product safety and

environmental measures typically found in end products that incorporate such semiconductor components or

circuit boards.

Olimex currently deals with a variety of customers for products, and therefore our arrangement with the user

is not exclusive. Olimex assumes no liability for applications assistance, customer product design, software

performance, or infringement of patents or services described herein.

THERE IS NO WARRANTY FOR THE DESIGN MATERIALS AND THE

COMPONENTS USED TO CREATE PIC-IO. THEY ARE CONSIDERED

SUITABLE ONLY FOR PIC-IO.

OLIMEX© 2012

PIC-IO User's Manual

Product support

For product support, hardware information and error reports mail to: support@olimex.com. Note

that we are primarily a hardware company and our software support is limited.

Please consider reading the paragraph below about the warranty of Olimex products.

Warranty and returns:

Our boards have lifetime warranty against manufacturing defects and

components.

During development work it is not unlikely that you can burn your programmer

or development board. This is normal, we also do development work and we have

damaged A LOT of programmers and boards during our daily job so we know how it

works. If our board/programmer has worked fine then stopped, please check if

you didn't apply over voltage by mistake, or shorted something in your target

board where the programmer was connected etc. Sometimes boards might get

damaged by ESD shock voltage or if you spill coffee on them during your work

when they are powered.

Please note that warranty do not cover problems caused by unproper use,

shorts, over-voltages, ESD shock etc.

If the board has warranty label it should be not broken. Broken labels void

the warranty, same applies for boards modified by the customer, for instance

soldering additional components or removing components - such boards will be

not be a subject of our warranty.

If you are positive that the problem is due to manufacturing defect or

component you can return the board back to us for inspection.

When we receive the board we will check and if the problem is caused due to

our fault and we will repair/replace the faulty hardware free of charge,

otherwise we can quote price of the repair.

Note that all shippings back and forth have to be covered by the customer.

Before you ship anything back you need to ask for RMA. When you ship back

please attach to it your shipping address, phone, e-mail, RMA# and brief

description of the problem. All boards should be sent back in antistatic

package and well packed to prevent damages during the transport.