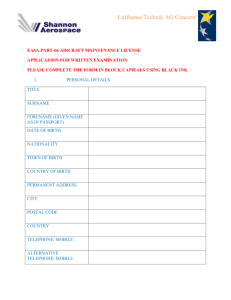

Technik Connection - Lufthansa Technik AG

advertisement