Installation Manual

IOM-HEPA-RT-00

725343-01

09-30-04

HEPALERT™ LED LIGHT Kit

Installation, Operation, and Maintenance Manual

for the RadiaTec Diffuser

Contents

Observe all precautions and warnings in product

data or attached to the unit.

Page

Introduction.............................................................1

General ....................................................................1

Follow all safety codes. Wear eye protection and gloves.

Have a fire extinguisher readily available.

Safety .......................................................................1

Caution: Disconnect all power supplies before

accessing equipment.

Inspection................................................................1

Disconnecting more than one power supply may

be required to de-energize some equipment.

Product Description ...............................................1

Tools and Equipment .............................................1

Preparation..............................................................1

DANGER

Installation...............................................................2

ELECTRIC SHOCK CAN CAUSE DEATH.

Startup and Operation............................................5

Calibration ...............................................................5

Inspection

Appendix - Bill of Materials ...................................6

Thoroughly inspect all packages upon receipt. Ensure

carton(s) have not been dropped, crushed or punctured.

Inspect all contents for damage. If damage is found,

immediately file a claim with the delivering carrier.

Introduction

Product Description

Maintenance ............................................................5

Abbreviations..........................................................6

This document provides installation, operation, and

maintenance information for the Titus HEPALERT™ LED

Light Kit installed on RadiaTec diffusers, specifically.

Additional information may be found at the Titus website,

www.titus-hvac.com.

General

The following information is to be used by the installer as a

guide. Since each installation is unique unto itself, only

general topics are covered. Topic order may not be the

same as required by actual installation.

The HEPALERT™ LED Light Kit provides an easy and

visible verification for HEPA filter cleanliness from the

occupied space. The kit uses pressure sensors and light

emitting diodes (LED) indicators to alert clean room users

when filter replacement is needed.

Tools and Equipment

In addition to the HEPALERT LED light kit the following

items (supplied by others) assist the installation process.

•

Transformer (Class 2 – 120 Vac to 24 Vac

transformer, rated 40 VA)

•

Power cord for transformer

•

Silicon sealant

•

Rubber tubing – 3/8-inch OD

•

Screw drivers (various sizes of Phillips and flat

blades)

The installer MUST read the entire contents of this guide

and develop a thorough understanding before beginning

installation.

•

Drill and drill bits (sizes needed are 3/16-, ¼-, 3/8-,

and 5/8-inch)

Due to a continuing program of product research, Titus

reserves the right to discontinue or change without notice,

any or all specifications or designs without incurring

obligations.

•

Unpack HEPAlert LED Light Kit and check contents

against Bill of Materials.

•

Sort contents, especially wire, screws, nuts according

to color, size, and type as listed on the Bill of

Materials.

•

Keep Bill of Materials readily available for reference.

•

Remove HEPA filter and back pan before attempting

installation.

This guide is not intended to supersede or circumvent any

applicable national, state, or local codes.

The installation is to be performed only by individuals

whose experience meets or exceeds the requirements of

the work involved.

Safety

The installation and / or servicing of comfort conditioning

equipment can be hazardous due to system pressures

and electrical devices.

Preparation

Caution: Only trained and qualified personnel

should perform service and/or installation.

605 Shiloh Road • Plano, Texas 75074 • 972-212-4800

All rights reserved. No part of this work may be reproduced or transmitted in any form or any means, electronic or mechanical, including photocopying and recording, or by any information storage retrieval system without permission in writing from Air Distribution Technologies.

HEPALERT Kit Installation Manual

Installation

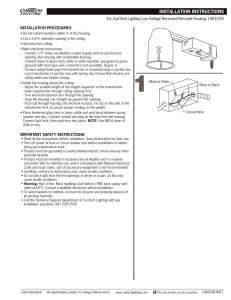

1.

Determine and mark hole locations in back pan

(see Figure 1). Before drilling holes, position the

base bracket on back pan to verify alignment of

marked holes to bracket openings. Drill holes and

insert grommet into the 5/8-inch diameter hole.

2.

Determine and mark hole locations on HEPA filter

frame (see Figure 2). Before drilling frame holes,

verify the marked holes align directly under the

back pan holes in final installation. Insert grommet

into the 5/8-inch diameter hole.

3.

Determine LED bracket placement on the back

pan. Drill mounting holes on the side of back pan

(see Figure 3). The holes should be on the side of

the back pan adjacent to the holes drilled in Steps

1 and 2.

IOM-HEPA-RT-00

725343-01

09-30-04

4.

Secure the pressure switch and terminal barrier

strip to base bracket using pan head screws and

hex nuts (see Figure 4).

5.

Secure base bracket to back pan using self-tapping

screws (see Figure 5).

Figure 3. RadiaTec Hole Placement for LED Bracket

Figure 4. Base Bracket with Pressure Switch and

Terminal Barrier Attached

Figure 1. HEPALERT Kit Hole Placement

Contaminants

Figure 2. HEPA Filter Frame Hole Locations

Figure 5. HEPALERT Base Attached to Back Pan

2 of 7

HEPALERT Kit Installation Manual

09-30-04

Secure the LED assemblies to LED bracket using

self-tapping screws (see Figure 6).

Connect spade-tongue terminal on the white LED

assembly wire to the terminal barrier strip (see

Figure 8).

12.

Feed quick-connect terminals of LED assemblies

through the grommets on HEPA filter frame and

back pan (see Figure 6).

Connect the quick-connect terminal on the blue

LED assembly wire to the low-pressure terminal on

the pressure switch (see Figure 8).

13.

Connect the quick connect terminal on the red LED

assembly wire to high-pressure terminal on the

pressure switch (see Figure 8).

14.

Ensure all drilled holes and gaps in grommets and

tubing ports in back pan and HEPA filter frame are

sealed with silicon sealant.

15.

Connect quick-connect terminal of 8-inch red wire

assembly to pressure sensor power terminal.

Connect spade-tongue terminal to the terminal

barrier strip adjacent to white wire (see Figure 9).

Secure LED bracket to inside of back pan using

self-tapping screws (see Figure 6).

7.

8.

Insert 9-inch rubber tube through the 3/8-inch

diameter holes in back pan and HEPA filter frame.

Connect tube to the high-pressure port of the

pressure switch (see Figure 7).

10.

725343-01

11.

6.

9.

IOM-HEPA-RT-00

Insert 3-inch rubber tube through the hole on back

pan and connect tube to the low-pressure port of

pressure switch (see Figure 7). Use silicon sealant

to seal both sides of the back pan hole to prevent

leakage.

Figure 6. HEPAlert Base Bracket and LED Bracket

Placement

Figure 8. LED to Pressure Switch Wiring Connections

Note: Seal inside and outside of backpan with silicon

sealant.

Figure 7. Rubber Tube and Pressure Port Connections

Figure 9. LED to Pressure Switch Wiring Connections

3 of 7

HEPALERT Kit Installation Manual

16.

Secure a class 2 – 120 Vac to 24 Vac transformer

(rated for 40 VA. Transformer supplied by others.)

to back pan using self-tapping screws (see Figure

10).

17.

Connect spade-tongue terminal of 14-inch red wire

assembly to terminal barrier strip across from

previously connected red wire (see Figure 11).

18.

Connect spade-tongue terminal of 14-inch white

wire assembly to terminal barrier strip across from

previously connected white wire (see Figure 11).

19.

Feed quick-connect terminals of red and white wire

assemblies through grommet in side of base

bracket. Connect to transformer (see Figure 11).

NOTE: A single transformer may be used to

power multiple HEPAlertTM Kits. The 60-inch

red and white wire assemblies are supplied to

interconnect terminal barrier strips of

TM

HEPAlert Kits on adjacent diffusers.

20.

Place and align top cover to base bracket and

secure using self-tapping screws to secure (see

Figure 12).

21.

Connect AC supply power wires to transformer

(see Figure 13).

22.

Install clean HEPA filter with wing nuts. Restore the

face screen to diffuser.

Note: Refer to RadiaTec Installation Manual

available on www.Titus-hvac.com

IOM-HEPA-RT-00

725343-01

09-30-04

Figure 11. HEPALERT Kit and Transformer Wiring

Figure 12. Securing Top Cover

Note: Use a Class 2 – 120 Vac to 24 Vac transformer

(rated for 40 VA).

Figure 10. Transformer Placement

Figure 13. Power Cord Connection

4 of 7

HEPALERT Kit Installation Manual

IOM-HEPA-RT-00

725343-01

09-30-04

Startup and Operation

When power is supplied, the green LED comes on,

indicating the system is functioning.

The red LED comes on when a pressure differential of

50% is reached, indicating that filter needs to be replaced.

Once a clean filter is inserted in the filter frame, the green

LED comes on.

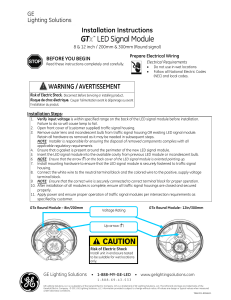

Calibration

Each HEPAlert kit sensor must be set based on the

module and inlet size. Use the information in the following

steps to calibrate the setscrew.

1.

Turn the setscrew clockwise to ensure it is in the fully

closed position. See Figure 14.

2.

Based on the module and inlet size, twist the

setscrew counter-clockwise the prescribed number of

turns from the fully closed position. See Table 1.

Figure 15 shows the setscrew at the fully open

position.

Figure 16 is a chart showing the pressure from supply

side of the HEPA filter.

Figure 14. Setscrew at Fully Closed Position

Table 1. RadiaTec-AL and RadiaTec-SS

Calibration Settings

Module and

Inlet Size

1- or 2-way

Pattern

CFM

Number of CCW Turns

from Fully Closed

Position

(50% Full Filter Setting)

24 x 24

inches

8-inch inlet

200

2¾

300

2½

400

2

24 x 24

inches

8-inch inlet

300

2½

400

2¼

500

2

48 x 24

inches

10-inch inlet

400

2½

48 x 24

inches

12-inch inlet

600

2¼

800

2

600

2½

800

2¼

1000

2

Figure 15. Setscrew at Fully Open Position

Maintenance

Components of the HEPAlert require no regular

maintenance. However, if neither LED is on, check the

following items.

•

Power supplied to unit.

•

Wiring and tubing connections are secure.

•

Transformer is operational (use a voltmeter).

Contact a Titus representative if service or replacement is

required.

Note: Replace filter when filter is 50% full.

5 of 7

IOM-HEPA-RT-00

# of CCW Turns on Setting Screw from the

Closed (Bottomed-Down) Position

HEPALERT Kit Installation Manual

725343-01

# of CCW Turns from the

bottomed-down position

4 1/2

4

Power (# of CCW Turns

from the bottomed-down

position)

3 1/2

3

2 1/2

2

1 1/2

y = 3.0026674924016900000000000x -0.1873089407736940000000000

R2 = 0.9932736534985160000000000

1

1/2

0

0

1

2

3

4

5

6

Ps, in. wg. (HEPA-Supply Side)

Figure 16. Setscrew Position Versus Filter Pressure

Abbreviations

The following abbreviations were used in this document.

Abbrev.

Term

AC

Alternating Current

CCW

counter-clockwise

DP

Differential Pressure

HEPA

High Efficient Particulate Air

ID

Inside Diameter

LED

Light Emitting Diode

OD

Outside Diameter

Vac

Volts alternating current

Vdc

Volts direct current

6 of 7

7

8

09-30-04

HEPALERT Kit Installation Manual

IOM-HEPA-RT-00

725343-01

Appendix - Bill of Materials

The following table provides a bill of materials list for

the HEPALERT kit.

Table 1. Bill of Materials

Part / Assembly

No.

Description

Unit of

Measure

Quantity

724939-01

Base

EA

1

724940-01

Cover

EA

1

724809-01

Bracket, LED Indicator

EA

1

103533-01

Switch, DP Air

EA

1

103544-01

LED Assembly

EA

1

103520-01

Wire Assembly, Red, 14-inch

EA

1

103520-02

Wire Assembly, White, 14-inch

EA

1

103520-03

Wire Assembly, Red, 8-inch

EA

1

103520-04

Wire Assembly, Red, 60-inch

EA

1

103520-05

Wire Assembly, White, 60-inch

EA

1

103534-01

Terminal Barrier Strip, 2 Position

EA

1

102215-01

Rubber Tube, 0.16 ID, 3/8-inch OD, 9-inch

IN

1

102215-01

Rubber Tube, 0.16 ID, 3/8-inch, 3-inch

IN

1

Screw, Self-Tapping, #8 X 0.50

EA

10

103574-01

Screw, Pan Head, 6-32 X 0.75

EA

10

103569-01

Nut, Hex, 6-32

EA

10

101796-01

Grommet, 0.50 ID

EA

4

725343-01

HEPALERT™ LED Light Kit Installation Manual

EA

1

00TCBE

7 of 7

09-30-04