™

The Torus - 3D Tank Cleaning Tool, up to 22 kpsi (TR-100)

Description:

The Torus 3D Tool is designed for cleaning tanks, vessels, autoclaves, ducts and reactor interiors. The tool is capable of working pressures up to 22,000 psi (1500 bar)

and flow rates of 17 to 80 gpm. The wide range of flow rates is accommodated by the use of four different manifolds: High Flow (HF), Medium Flow (MF), Low Flow

(LF) and Extra Low Flow (XLF). A maintenance-free magnetic brake is used to control rotation speed. Note that rotation speed may increase as the tool warms up to

operating temperature. The complete Torus cleaning cycle varies from about 4 to 30 minutes of operating time and 3 to 23 revolutions of the body per minute depending

on pressure, flow rate, nozzle diameter and manifold choice. The HP manifold revolves 2.36 times for each body revolution. When used in large vessels, extension

arms up to 36 inches long can be used to reduce the jet standoff distance. The Torus can be hung from the high pressure water hose or by the optional pulling ring

available for the tool. It is recommended to blow out all internal water passages (nozzles, weep holes, inlet) with compressed air after each use.

WARNING: The Torus contains several high-energy, rare-earth magnets that produce a magnetic field in excess of 10 Gauss. Persons with a pacemaker or other

electronic medical device must use extreme caution when handling, or in close proximity to the Torus. It is recommended that a minimum distance of 6 inches (152mm)

be maintained at all times between the Torus and any electronic medical devices.

CAUTION: The use of gloves when handling the tool after operation is recommended as the body and cover at the pulling ring end may reach temperatures of up to

160°F depending on operating conditions.

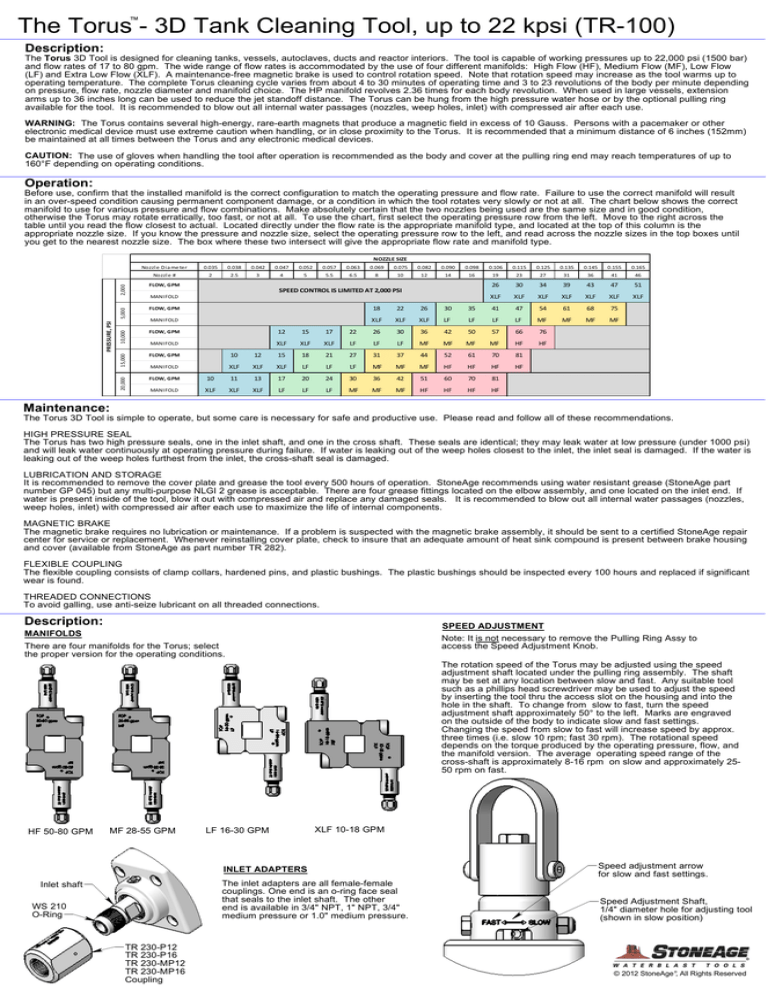

Operation:

Before use, confirm that the installed manifold is the correct configuration to match the operating pressure and flow rate. Failure to use the correct manifold will result

in an over-speed condition causing permanent component damage, or a condition in which the tool rotates very slowly or not at all. The chart below shows the correct

manifold to use for various pressure and flow combinations. Make absolutely certain that the two nozzles being used are the same size and in good condition,

otherwise the Torus may rotate erratically, too fast, or not at all. To use the chart, first select the operating pressure row from the left. Move to the right across the

table until you read the flow closest to actual. Located directly under the flow rate is the appropriate manifold type, and located at the top of this column is the

appropriate nozzle size. If you know the pressure and nozzle size, select the operating pressure row to the left, and read across the nozzle sizes in the top boxes until

you get to the nearest nozzle size. The box where these two intersect will give the appropriate flow rate and manifold type.

0.052

0.057

0.063

0.069

0.075

0.082

0.090

0.098

0.106

0.115

0.125

0.135

0.145

0.155

Nozzl e #

2

2.5

3

4

5

5.5

6.5

8

10

12

14

16

19

23

27

31

36

41

46

26

30

34

39

43

47

51

XLF

XLF

XLF

XLF

XLF

XLF

XLF

41

47

54

61

68

75

MF

MF

MF

2,000

0.047

FLOW, GPM

5,000

0.042

FLOW, GPM

10,000

0.038

FLOW, GPM

15,000

0.035

FLOW, GPM

20,000

PRESSURE, PSI

NOZZLE SIZE

Nozzl e Dia me ter

FLOW, GPM

10

11

13

17

20

24

30

36

42

51

60

70

81

MANIFOLD

XLF

XLF

XLF

LF

LF

LF

MF

MF

MF

HF

HF

HF

HF

SPEED CONTROL IS LIMITED AT 2,000 PSI

MANIFOLD

MANIFOLD

12

15

17

22

18

22

26

30

35

XLF

XLF

XLF

LF

LF

LF

LF

MF

26

30

36

42

50

57

66

76

HF

XLF

XLF

XLF

LF

LF

LF

MF

MF

MF

MF

HF

10

12

15

18

21

27

31

37

44

52

61

70

81

MANIFOLD

XLF

XLF

XLF

LF

LF

LF

MF

MF

MF

HF

HF

HF

HF

MANIFOLD

0.165

Maintenance:

The Torus 3D Tool is simple to operate, but some care is necessary for safe and productive use. Please read and follow all of these recommendations.

HIGH PRESSURE SEAL

The Torus has two high pressure seals, one in the inlet shaft, and one in the cross shaft. These seals are identical; they may leak water at low pressure (under 1000 psi)

and will leak water continuously at operating pressure during failure. If water is leaking out of the weep holes closest to the inlet, the inlet seal is damaged. If the water is

leaking out of the weep holes furthest from the inlet, the cross-shaft seal is damaged.

LUBRICATION AND STORAGE

It is recommended to remove the cover plate and grease the tool every 500 hours of operation. StoneAge recommends using water resistant grease (StoneAge part

number GP 045) but any multi-purpose NLGI 2 grease is acceptable. There are four grease fittings located on the elbow assembly, and one located on the inlet end. If

water is present inside of the tool, blow it out with compressed air and replace any damaged seals. It is recommended to blow out all internal water passages (nozzles,

weep holes, inlet) with compressed air after each use to maximize the life of internal components.

MAGNETIC BRAKE

The magnetic brake requires no lubrication or maintenance. If a problem is suspected with the magnetic brake assembly, it should be sent to a certified StoneAge repair

center for service or replacement. Whenever reinstalling cover plate, check to insure that an adequate amount of heat sink compound is present between brake housing

and cover (available from StoneAge as part number TR 282).

FLEXIBLE COUPLING

The flexible coupling consists of clamp collars, hardened pins, and plastic bushings. The plastic bushings should be inspected every 100 hours and replaced if significant

wear is found.

THREADED CONNECTIONS

To avoid galling, use anti-seize lubricant on all threaded connections.

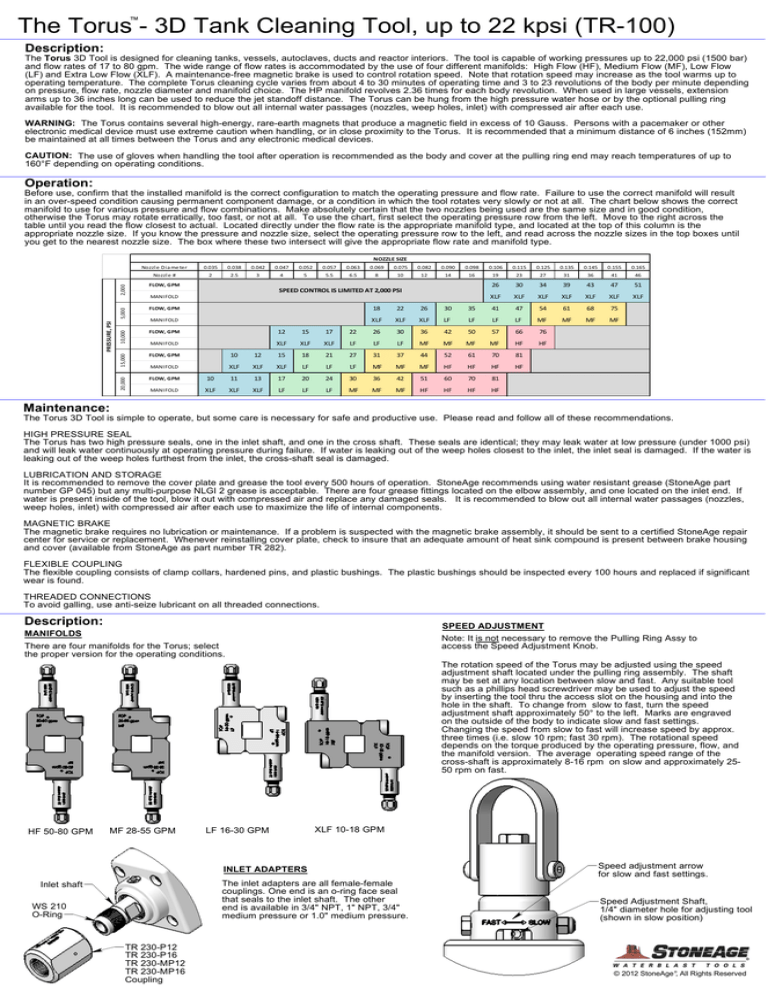

Description:

SPEED ADJUSTMENT

Note: It is not necessary to remove the Pulling Ring Assy to

access the Speed Adjustment Knob.

MANIFOLDS

There are four manifolds for the Torus; select

the proper version for the operating conditions.

The rotation speed of the Torus may be adjusted using the speed

adjustment shaft located under the pulling ring assembly. The shaft

may be set at any location between slow and fast. Any suitable tool

such as a phillips head screwdriver may be used to adjust the speed

by inserting the tool thru the access slot on the housing and into the

hole in the shaft. To change from slow to fast, turn the speed

adjustment shaft approximately 50° to the left. Marks are engraved

on the outside of the body to indicate slow and fast settings.

Changing the speed from slow to fast will increase speed by approx.

three times (i.e. slow 10 rpm; fast 30 rpm). The rotational speed

depends on the torque produced by the operating pressure, flow, and

the manifold version. The average operating speed range of the

cross-shaft is approximately 8-16 rpm on slow and approximately 2550 rpm on fast.

HF 50-80 GPM

MF 28-55 GPM

LF 16-30 GPM

XLF 10-18 GPM

INLET ADAPTERS

The inlet adapters are all female-female

couplings. One end is an o-ring face seal

that seals to the inlet shaft. The other

end is available in 3/4" NPT, 1" NPT, 3/4"

medium pressure or 1.0" medium pressure.

Inlet shaft

WS 210

O-Ring

TR 230-P12

TR 230-P16

TR 230-MP12

TR 230-MP16

Coupling

Speed adjustment arrow

for slow and fast settings.

Speed Adjustment Shaft,

1/4" diameter hole for adjusting tool

(shown in slow position)

© 2012 StoneAge ®, All Rights Reserved

™

The Torus - 3D Tank CleaningTool

HC 090

PULLING RING

TR-100 ASSEMBLY

GB 337-12

HEX BOLT .37-16 X 3.00 SS

TR 152

INSERT, PULLING RING

TR 200

BRAKE ASSEMBLY

TR 220

COUPLING ASSEMBLY

(6) TR 116

SEALING SCREW

SBHCS .31-18 X .50 SS

TR 170

CROSS SHAFT ASSEMBLY

GN 337-L

NUT, HEX LOCK SS

TR 121

PLATE,

COVER

(6) TR 115

SEALING SCREW

SHBCS .19-24 X .38 SS

TR 240-HF

TR 240-MF

TR 240-LF

TR 240-XLF

MANIFOLD ASSEMBLY

TR 102

BODY WELDMENT

TR 120

INLET ASSEMBLY

TR 130

ELBOW ASSEMBLY

TR 230-MP16

TR 230-MP12

TR 230-P16

TR 230-P12

COUPLING, O-RING FACE

GS 319-015

SHCS .19-24 X .38 SS

TR 107

O-RING , COVER PLATE

TR 240-XX MANIFOLD ASSEMBLY

TR 250

SHAFT CAP

MJ 011-C

SEAT

(2) TR 247

SOCKET HEAD CAP SCREW

HC 012-TO

HP SEAL AND O-RING

(2) TR 260-HF

(2) TR 260-MF

(2) TR 260-LF

(2) TR 260-XLF

HALF MANIFOLD

TR 126

GEAR, BEVEL 27T

CJ 009

BEARING

TR 245

SEAL, HP MANIFOLD

SA 059

O-RING

TR 577.3

FLOW STRAIGHTENER

TR 577-XX

NIPPLE ASSEMBLY

TR 170 CROSS SHAFT ASSEMBLY

TR 173

CAP, OUTLET

TR 175

O-RING

TR 172

CROSS SHAFT

TR 113

SEAL

BJ 007

BEARING

wide outer race

(2) AP4-XXX

NOZZLE

FS 004-45-SS

ZERK, 45°

(2) FS 004-0-SS

ZERK, STRAIGHT

(4) GS 337-03

SHCS .375-16 X .75 SS

HC 012-TO

HP SEAL AND O-RING

TR 118

RETAINING RING

TR 122 INLET SHAFT

TR 120 INLET ASSEMBLY

TR 250

SHAFT CAP

WS 210

O-RING

FS 004-0-SS

ZERK, STRAIGHT

spring side in

(2) BJ 007

BEARING

(2) GS 319-015

SHCS .19-24 X .38

MJ 011-C

SEAT

TR 220 COUPLING ASSEMBLY

TR 103

END INLET

TR 104

GEAR, INLET SHAFT

wide outer race

TR 113

SEAL

TR 223

BUSHING, PEEK

wide inner race

TR 124

LOCK NUT

TR 222

DOWEL PIN

TR 105

O-RING, INLET END

spring side in

TR 118

RETAINING RING

(4) TR 117

SEALING SCREW

SHCS .37-16 X 1.25 SS

TR 221

COLLAR ASSEMBLY

®

© 2012 StoneAge , All Rights Reserved

™

The Torus - 3D Tank Cleaning Tool

FS 004-0-SS

ZERK, STRAIGHT

(2) TR 138 RETAINING RING

TR 130 ELBOW ASSEMBLY

TR 140

GEAR 8T

(2) TR 134 SEAL

open side of

seal towards

elbow

TR 135

NEEDLE BEARING

TR 144

GEAR, BEVEL 18T

open side of

seal towards

elbow

TR 139

GEAR 23T

(2) TR 143

KEY, PRIMARY SHAFT

TR 131

PRIMARY SHAFT

(2) TR 142

KEY, PINION SHAFT

TR 132

ELBOW

TR 146

RETAINING RING

(4) TR 127

O-RING

TR 133

GEAR 21T

(2) TR 136

NEEDLE BEARING

(2) GP 025-P4

PLUG, P4

TR 141

WASHER, PINION SHAFT

TR 145

BEARING

DT 032

RETAINING RING

GS 325-02

SHCS .25-20 X .50 SS

TR 200 BRAKE ASSEMBLY

TR 212

O-RING

TR 202

PLATE, BASE

(8) GS 313-02

SHCS .13-32 X .50 SS

(2) TR 210

MAGNET ASSEMBLY

TR 205

SHAFT, BRAKE

RJ 009

BEARING

spring side

TR 201

PLANETARY GEARBOX

RJ 010

SEAL

GC 313-025

SHCS .13-32 X .62 SS

key not required

TR 215

O-RING

TR 206

SHAFT, SPEED CONTROL

(2) TR 208

SHOULDER BOLT

(2) TR 214

WAVE SPRING

TR130 233

O-RING

TR 204

PLATE, STOP

TR 207

DISC, CU

GN 337-L

LOCKNUT

TR 203

COVER, BRAKE GS 319-08

SHCS .19-24 X 2.0 SS

TR 213

WAVE SPRING

GP 025-P4

PLUG, P4

TORUS INSTALLATION IN TR 408-SS CAGE

One set of ribs on the cage

have a slightly larger gap

which allows easier installation

of the Torus into the cage.

Insure that the end plate of the cage is installed

as shown over the Pulling Ring Housing and

NOT over the Insert; otherwise the Torus will

not rotate correctly during operation.

Pulling Ring Housing

Note that the short

2" nipples must be

installed when using

the Torus in the cage.

Pulling Ring Insert

© 2012 StoneAge®, All Rights Reserved

The Torus - 3D Tank Cleaning Tool

™

TR-100 HIGH PRESSURE SEAL MAINTENANCE

(2) SHCS

The Torus has 2 high pressure seals. These seals may leak at

tap pressure, but should seal at pressures above 1000 psi.

To access the Torus internals:

TR 250 Shaft Cap

H.P. Half Manifolds

(2) TR 247

SHCS

TR 121 Cover Plate

1. Remove the (2) Socket Head Cap Screws

holding the Shaft Cap (TR 250) in place. Loosen

the (2) Socket Head Cap Screws (TR 247) on the

High Pressure Half Manifolds & slip the Manifolds

off the Cross Shaft.

2. Remove the (6) Sealing Button Head Cap

Screws (TR 115) from the Cover Plate (TR 121)

and remove the Cover Plate.

(6) TR 115 Sealing BHCS

To access the Inlet Shaft Seal:

! SEE CAUTION !

1. Remove the (4) Sealing Socket Head Cap

Screws holding the Inlet Assy (TR 120) to the

Body and the Elbow Assy. The Inlet Assy may

then be slid out of the Elbow Assy to gain access

to the Seal. The Seal is located in the end of the

Inlet Shaft. No more disassembly is required.

To access the Cross Shaft Seal:

1. Remove the (4) Socket Head Cap Screws that

hold the Cross Shaft Assy to the Elbow Assy. Lift

the Cross Shaft Assy out of the Main Elbow. The

Seal is located in the end of the Cross Shaft. No

more disassembly is required.

(4) SHCS

MJ 011-C Seat

TR 170

Cross Shaft Assy

HC 012-TO

H.P. Seal & O-Ring

HC 012-TO

H.P. Seal & O-Ring

MJ 011-C Seat

To maintain H.P. Seat & Seal:

1. Remove the Carbide Seat (MJ 011-C) and

the H.P. Seal (HC 012-TO). Inspect the Seat

for chips on edges. Replace if damaged.

Inspect the related face of the Elbow Assy for

dings or pits. If damaged, it must be faced or

replaced, otherwise the Seal will leak.

2. Apply grease to new H.P. Seal and install

into bore. Place the Seat on the Seal with the

flat side against the Seal. The chamfered side

should face towards the Elbow Assy.

Elbow Assy

chamfered face

MJ 011-C

Carbide Seat

(4) Sealing SHCS

TR 120 Inlet Assy

flat face

towards seal

! CAUTION !: The use of gloves when handling the

tool after operation is recommended as the body and

cover at the pulling ring end may reach temperatures

of up to 160°F depending on operating conditions.

HC 012-TO

H.P. Seal & O-Ring

Body

! SEE CAUTION !

TR-100 ASSEMBLY SEQUENCE & DETAILS

Note: Always use anti-seize lubricant

on all threaded connections to

prevent galling.

1. Apply heat-conducting grease

(StoneAge part number TR 282) to

bottom surface of Brake Assy (the

surface that will be in contact with the

inside bottom of the Body) and insert

Brake Assy into Body by first tilting and

inserting under web of Body and then

sliding forward as shown; use care to

insure that the Speed Adjust Knob with

O-Ring starts into the hole in the end of

the Body while sliding the Assy forward.

Loosely start (2) Sealing Button Head

Cap Screws thru bottom of Body and

into Brake Assy.

Body

Brake

Assy

2. Insert Elbow Assy (may include Cross Shaft Assy) into

Body and loosely start (4) Sealing Button Head Cap Screws

thru bottom of Body and into Elbow.

Elbow Assy

Pulling Ring

Assy

6. Install the H.P. Manifolds onto the

Cross Shaft and hand tighten the (2) large

Socket Head Cap Screws.

7. Install the Shaft Cap using (2) small

Socket Head Cap Screws and tighten

them to 24 in/lbs. Then tighten the (2)

large Cap Screws on the H.P. Manifolds

to 50 ft/lbs.

(4) Sealing

SHCS

Hex Bolt & Hex Lock Nut

Inlet Assy

Brake Assy top surface

(4) Elbow Sealing BHCS

3. Insert Inlet Assy into end of Body and tighten (4)

Sealing Socket Head Cap Screws thru end of Body and

into Elbow. Take care to insure O-Ring is properly

seated in groove. Next, tighten the (4) Sealing Button

Head Cap Screws at the bottom of the Body into the

Elbow Assy.

(2) Brake

Sealing BHCS

5. Apply heat-conducting grease

(StoneAge part number TR 282) to top

surface of Brake Assy and install the

Cover Plate using (6) Sealing Button

Head Cap Screws. Take care to insure

the O-Ring is properly seated in the

groove of the Cover Plate.

Cover Plate

start shaft

into hole

4. Once the Elbow Assy is firmly mounted and the Brake Assy is loosely in place, the (2) Coupling Assys need

to be installed. Note that keys are NOT required in the shafts. The easiest way to install the Couplings are to

couple (1) Male Half and (1) Female Half together, place a rag in the bottom of the Body cavity under where

the couplings are to be, and slip them into place underneath the bottom of the shafts (resting on top of the rag).

The rag will help hold them in place and up against the shafts while starting the Socket Head Cap Screws in

the opposite pair of Coupling Halves. Note that there should be a .03" gap between the Elbow and the

Coupling face abutting the Elbow. Tighten the (2) Elbow Coupling screws evenly to 50 in/lbs. Next, allow a

.03" gap between the Elbow Coupling and the Brake Coupling as shown. Tighten the (2) Brake Coupling

screws to 50 in/lbs. Finally, tighten the (2) remaining Sealing Button Head Cap Screws holding the Brake Assy

to the Body. Also grease the (4) Zerks on the Elbow if necessary.

Grease Zerks

H.P. Manifolds

Grease Zerks

Shaft

Cap

8. Finally, install the Pulling Ring

Assy onto the Body with the Hex Bolt

and Hex Lock Nut.

Male

Coupling Half

Elbow Coupling

.03 gap

.03 gap

Female

Coupling Half

Note: It is not necessary to remove

the Pulling Ring Assy to access the

Speed Adjustment Shaft.

Brake Coupling

®

© 2012 StoneAge , All Rights Reserved