Workplace Health and Safety in Contemporary Dental

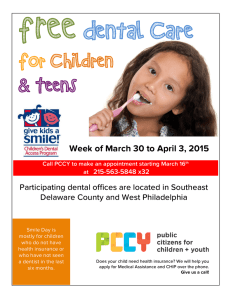

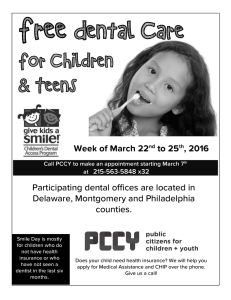

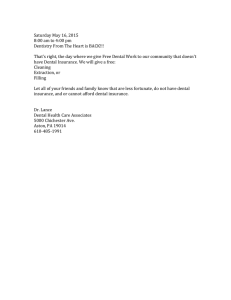

advertisement