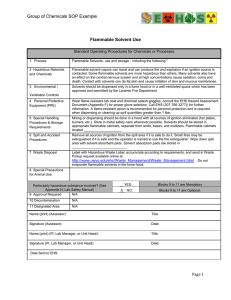

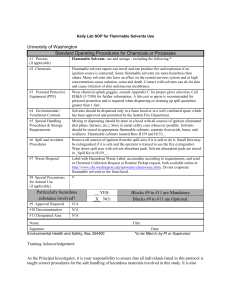

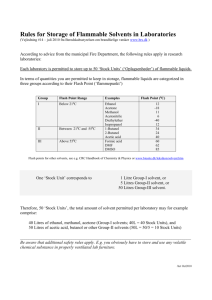

Flammability : A safety guide for users

advertisement