Part 1

advertisement

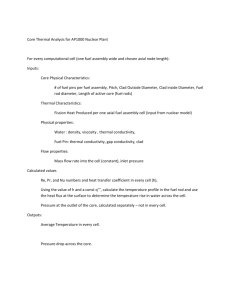

HEAT CONDUCTION

When a temperature gradient exist in a material, heat flows from the high temperature region to the low

temperature region. The heat transfer mechanism is referred to as conduction and the heat transfer rate has been

found to be proportional to the temperature gradient normal to the heat transfer surface. For a 1-dimensional

Cartesian geometry this may be written as

q

≡ q ′′ ∝

A

∂T

∂x

= −k

∂T

∂x

(1)

where:

k

A

q

q ′′

= Thermal conductivity

= Surface (heat transfer) area

= Heat transfer rate

= Heat flux

Note: The minus sign accounts for the fact that positive heat transfer occurs when the gradient is negative.

Equation 1 is called Fourier's Law of heat conduction. The thermal conductivity is a material specific property and

in general is a function of temperature, and therefore a function of position.

T

qx

x

Figure 1: Temperature Distribution and Heat Transfer Rate in a Conducting Medium

65

THE HEAT CONDUCTION EQUATION

Derivation of the Heat Conduction Equation in Cartesian Geometry

q

z+ Δz

qy

qx

q

x+ Δx

z

qy+

Δy

qz

x

y

Figure 1: Control Volume for Deriving the Heat Conduction Equation

Consider the volume ΔV = Δx ΔyΔz illustrated above. A heat balance on ΔV gives

The heat conducted into ΔV during a time interval Δt - the heat conducted out

of ΔV during a time interval Δt + the amount of heat generated in ΔV during

Δt = change in the stored (internal) energy in ΔV during Δt

Let

U = Internal energy

v

v

q rv = Heat conduction rate at an arbitrary location r in the r direction.

q ′′′ = Volumetric heat generation rate

In terms of these variables, and the heat conduction rates indicated on the diagram, the heat balance can be

expressed as

( q x + q y + q z )Δt − ( q x + Δx + q y + Δy + q z + Δz )Δt

+ Δx ΔyΔzq ′′′( x , y , z , t )Δt = U

t + Δt

−U

t

(1)

where x ∈[ x , x + Δx ] , y ∈[ y , y + Δy ], and z ∈[ z , z + Δz ] represent the location within the volume where the

function is equal to its average value.

Divide by Δt

66

( q x + q y + q z ) − ( q x + Δx + q y + Δy + q z + Δz )

+ Δx ΔyΔzq ′′′( x , y , z , t ) =

U

t + Δt

−U

(2)

t

Δt

and take the limit as Δt → 0. Recall the definition of a derivative

lim

U

t + Δt

−U

t

Δt

Δt →0

≡

∂U

(3)

∂t

such that the heat balance is now

( q x + q y + q z ) − ( q x + Δx + q y + Δy + q z + Δz )

+ Δx ΔyΔzq ′′′( x , y , z , t ) =

∂U

(4)

∂t

We can write the total internal energy U in terms of the specific internal energy and mass as U = Mu = Δx ΔyΔz ρu

where ρ is the density of the material. If the density is assumed constant

( q x + q y + q z ) − ( q x + Δx + q y + Δy + q z + Δz )

+ Δx ΔyΔzq ′′′( x , y , z , t ) = Δx ΔyΔz ρ

∂u

(5)

∂t

We can eliminate internal energy in favor of temperature by applying the chain rule from calculus

∂u

∂t

where C p ≡

∂u

∂T

=

∂u ∂T

∂T ∂t

= Cp

∂T

(6)

∂t

is the specific heat. Equation 5 is now

( q x + q y + q z ) − ( q x + Δx + q y + Δy + q z + Δz )

+ Δx ΔyΔzq ′′′( x , y , z , t ) = Δx ΔyΔz ρC p

∂T

(7)

∂t

The heat transfer rates can be written in terms of temperature by application of Fourier's Law. Referring to Figure 1

q x = − k ΔyΔz

q y = − k Δx Δz

q z = − k ΔyΔx

∂T

∂x

(8a)

x, y, z

∂T

∂y

(8b)

x , y, z

∂T

∂z

(8c)

x , y,z

Similarly

67

q x + Δx = − k ΔyΔz

q y + Δy = − k Δx Δz

q z + Δz = − k ΔyΔx

∂T

∂x

(8d)

x + Δx , y , z

∂T

∂y

(8e)

x , y + Δy , z

∂T

∂z

(8f)

x , y , z + Δz

Note, the thermal conductivity is evaluated at the same location as the gradients, and in general can be different at

each surface. Substituting into Equation 7 and rearranging gives

⎛ ∂T

ΔyΔz⎜⎜ k

⎝ ∂x

⎛ ∂T

ΔxΔy ⎜⎜ k

⎝ ∂z

x + Δx , y ,z

∂T

∂x

x , y ,z + Δz

∂T

−k

∂z

−k

⎛

⎞

⎟ + ΔxΔz⎜ k ∂T

⎟

⎜ ∂y

x , y ,z ⎠

⎝

−k

x , y + Δy ,z

∂T

∂y

⎞

⎟+

⎟

r

x , y ,z ⎠

⎞

⎟ + ΔxΔyΔzq ′′′( x , y , z , t ) = ΔxΔyΔzρC ∂T

p

⎟

r

∂t

x , y ,z ⎠

(9)

Divide by Δx ΔyΔz

1 ⎛⎜ ∂T

k

Δx ⎜⎝ ∂x

1 ⎛⎜ ∂T

k

Δz ⎜⎝ ∂z

x + Δx , y ,z

∂T

∂x

x , y ,z + Δz

∂T

−k

∂z

−k

⎛

⎞

⎟ + 1 ⎜ k ∂T

⎟ Δy ⎜ ∂y

x , y ,z ⎠

⎝

−k

x , y + Δy ,z

∂T

∂y

⎞

⎟+

⎟

r

x , y ,z ⎠

⎞

⎟ + q ′′′( x , y , z , t ) = ρC ∂T

p

⎟

r

∂t

x , y ,z ⎠

(10)

and take the limit as Δx , Δy and Δz go to zero to give

∂ ⎛ ∂T ⎞ ∂ ⎛ ∂T ⎞ ∂ ⎛ ∂T ⎞

∂T

⎜ k ⎟ + ⎜ k ⎟ + ⎜ k ⎟ + q ′′′( x , y , z , t ) = ρC p

∂x ⎝ ∂x ⎠ ∂y ⎝ ∂y ⎠ ∂z ⎝ ∂z ⎠

∂t

(11)

which is the general form of the Heat Conduction Equation in Cartesian geometry. Equation 11 may be written in a

more convenient form by introducing the gradient operator in Cartesian geometry

v

∂

∂ $ ∂ $

j+ k

∇ ≡ i$ +

∂x

∂y

∂z

(12)

r

r

∂T

v

∇ ⋅ k (T )∇T + q′′′(r , t ) = ρC p

∂t

(13)

such that Equation 11 reduces to

It can be shown, that Equation 13 is valid not only for Cartesian geometries, but also cylindrical and spherical

v

geometries by substituting the appropriate definition for the gradient operator ∇ . Solution of the heat conduction

equation, subject to appropriate boundary and initial conditions gives the temperature distribution within the region

of interest.

68

Equation 13 is a nonlinear partial differential equation, and can only be solved analytically for special cases. One

common simplification is to assume the thermal conductivity to be constant. Under these conditions, Equation 13

reduces to

v

q ′′′(r , t ) 1 ∂T

∇2T +

=

(14)

k

α ∂t

k

2

where α ≡

is the thermal diffusivity and ∇ is the Laplacian Operator. The Laplacian is given below for

ρC p

several geometries of interest.

Geometry

3-Dimensional Cartesian

1-Dimensional Cartesian

2-Dimensional Cylindrical

(r, z )

1-Dimensional Cylindrical

(Radial)

1-Dimensional Spherical

(Radial)

Laplacian

∂ T

2

2

∇ T=

∂x

2

2

∂ T

2

+

∇ T=

∂y

2

∂ T

2

+

∂z

2

∂ 2T

∂x 2

1 ∂ ⎛ ∂T ⎞ ∂ 2 T

∇2T =

⎜r ⎟ +

r ∂r ⎝ ∂r ⎠ ∂z 2

1 ∂ ⎛ ∂T ⎞

∇2T =

⎜r ⎟

r ∂r ⎝ ∂r ⎠

1 ∂ ⎛ 2 ∂T ⎞

∇2T = 2

⎜r

⎟

r ∂r ⎝ ∂r ⎠

Table 1: Laplacian Operator for Selected Geometries

69

STEADY STATE SOLUTIONS OF THE ONE-DIMENSIONAL HEAT CONDUCTION EQUATION

We have shown, that in general the heat conduction equation is given by

r

r

∂T

v

∇ ⋅ k (T )∇T + q′′′(r , t ) = ρC p

∂t

At steady-state, the volumetric heat generation rate is independent of time, and

∂T

∂t

≡ 0 . The steady-state Heat

Conduction Equation is then

r

r

v

∇ ⋅ k (T )∇T + q′′′(r ) = 0

(1)

In this section we concentrate on solutions of Equation 1 for conditions typical of nuclear power systems.

Solution of the Heat Conduction Equation in Plate Type Fuel Elements

Consider the plate type fuel element illustrated below.

S

x

c

T

T

z

y

x=0

Figure 1: Plate Fuel Element

The steady-state conduction equation in Cartesian geometry is

∂ ⎛ ∂T ⎞ ∂ ⎛ ∂T ⎞ ∂ ⎛ ∂T ⎞

⎜ k ⎟ + ⎜ k ⎟ + ⎜ k ⎟ + q ′′′( x , y , z ) = 0

∂x ⎝ ∂x ⎠ ∂y ⎝ ∂y ⎠ ∂z ⎝ ∂z ⎠

(2)

The thickness of the plate in the x direction, is much smaller than the dimensions in the y and z directions. This

implies

70

∂T

∂T

<<

∂y

∂x

and

∂T

∂T

<<

∂z

∂x

such that the conduction equation is approximately

∂ ⎛ ∂T ⎞

⎜ k ⎟ + q ′′′( x , y , z ) = 0

∂x ⎝ ∂x ⎠

(3)

or

d ⎛ dT ⎞

⎜k

⎟ + q ′′′( x , y , z ) = 0

dx ⎝ dx ⎠

(4)

where we have taken advantage of the fact that the partial derivatives reduce to total derivatives for a 1-dimensional

steady-state problem. Note, that this equation does not assume the temperature is invariant in the y and z directions.

It does however assume that any variation in the temperature in these directions can by accommodated by simply

varying the source term. For this example, we will further assume the volumetric heat generation rate to be

uniform, such that

d ⎛ dT ⎞

⎜k

⎟ + q ′′′ = 0

dx ⎝ dx ⎠

(5)

Equation 5 is valid whether the thermal conductivity is constant or varies with position, and will provide the basis

for determining the temperature distribution in the fuel element. Equation 5 is a second order differential equation,

and its solution requires boundary conditions. We assume the solution is symmetric about x = 0, such that

dT

dx

=0

(6)

0

Solution in the Fuel Region x ∈[0, S ]

The temperature distribution is obtained by integrating Equation 5 twice. While a number of approaches are

possible, the technique chosen here is to integrate the conduction equation from the left, or inner most boundary,

outward. For this example, we integrate from x = 0, to some arbitrary x ′ contained within the fuel material.

∫

x′

0

k

d ⎛ dT ⎞

⎜k

⎟ dx ′′ +

dx ′′ ⎝ dx ′′ ⎠

dT

dx ′′

−k

x′

∫

x′

q ′′′dx ′′ = 0

(7)

0

dT

x′

+ q ′′′x ′′ 0 = 0

dx ′′ 0

(8)

Applying the boundary condition at x = 0

k

dT

+ q ′′′x ′ = 0

dx ′

(9)

71

Equation 9 is valid for any x ′ ∈[0, S ] and provides information about the heat flux within the fuel. This is seen

more clearly by evaluating Equation 9 at x ′ = S and rearranging to give

−k

dT

= q ′′′S .

dx ′

(10)

S

Multiplying by surface area As gives

− kAs

dT

dx ′

= q = q ′′′SAs

(11)

S

which is a simple energy balance stating that the total heat transferred across the fuel surface is equal to the heat

generated within the fuel.

To obtain the temperature distribution within the fuel, we assume for this example that the thermal conductivity is a

constant. Dividing by k, Equation 9 is integrated again from x ′ = 0, to some arbitrary x contained within the fuel

material

∫

x

0

dT

dx ′ +

dx ′

∫

T ( x ) − T ( 0) +

x

0

q ′′′x ′

dx ′ = 0

k

q ′′′x ′

2 x

2k

T ( x ) = T ( 0) −

(12)

=0

(13)

0

q ′′′x

2

(14)

2k

The fuel surface temperature is obtained by evaluating Equation 14 at x = S

T ( S ) = T ( 0) −

q ′′′S

2

(15)

2k

and the temperature drop across the fuel is

T ( 0) − T ( S ) =

q ′′′S

2

(16)

2k

Solution in the cladding region x ∈[S , S + c ]

Assuming constant thermal conductivity in the clad, the conduction equation in the cladding is

d ⎛ dTc ⎞

⎜ kc

⎟ =0

dx ⎝ dx ⎠

(17)

where it is assumed that the volumetric heat generation rate in the cladding is zero. Boundary conditions are

required at the fuel/clad interface. Since there is no heat sink at the fuel/clad interface, we require that no heat is

lost within the interface. The heat transfer rate out of the fuel is then equal to the heat transfer rate into the cladding.

72

Since the surface areas are equal at the interface, this is equivalent to requiring conservation of heat flux. By

Fourier's Law this implies

−k

dT

= − kc

dx

dTc

s

(18)

dx

s

In addition, for this problem we will assume the cladding is bound to the fuel such that good thermal contact exists

at the interface and the interface temperature is the same for the fuel and clad, i.e.

T ( S ) = Tc ( S )

We again integrate the conduction equation from the left, or inner most boundary, outward. For the cladding, the

left or inner most boundary is at x = S.

∫

x′

S

kc

d ⎛ dTc ⎞

⎜k

⎟ dx ′′ = 0

dx ′′ ⎝ c dx ′′ ⎠

dTc

dx ′′

x′

− kc

dTc

dx ′′

=0

(19)

(20)

S

To apply the boundary condition at x ′ = S , note

− kc

dTc

dx

=−k

s

dT

dx

s

However, from Equation 10

−k

dT

= q ′′′S

dx ′

S

such that

− kc

dTc

dx

= q ′′′S

(21)

dTc

+ q ′′′S = 0

dx ′

(22)

s

Substituting into Equation 20

kc

Equation 22 is valid for any x ′ ∈[S , S + c ] and provides information about the heat flux within the clad.

The temperature distribution within the clad is obtained by assuming the thermal conductivity within the clad is

constant, and integrating Equation 22 from x ′ = S, to some arbitrary x contained within the clad material

∫

x

S

dTc

dx ′ +

dx ′

∫

x

S

q ′′′S

dx ′ = 0

kc

(23)

73

Tc ( x ) − Tc ( S ) +

q ′′′Sx ′

Tc ( x ) = Tc ( S ) −

k

x

=0

(24)

S

q ′′′S ( x − S )

(25)

k

The clad surface temperature is obtained by evaluating Equation 25 at x = S + c

Tc ( S + c ) = Tc ( S ) −

q ′′′Sc

(26)

kc

and the temperature drop across the clad is

Tc ( S ) − Tc ( S + c ) =

q ′′′Sc

(27)

kc

Heat Transfer from the Clad to the Coolant x = S + c

Heat transfer from a solid to a flowing fluid is said to be transferred by convection. The convective heat transfer

rate to a fluid of temperature T∞ , is given by Newton's Law of Cooling which states

v

v

q ′′(rs ) = hc [T (rs ) − T∞ ]

where:

v

q ′′(rs )

T∞

hc

v

T (rs )

(28)

v

= local heat flux at a position rs on the solid surface

= local bulk fluid temperature

= Convective heat transfer coefficient

v

= local temperature at a position rs on the solid surface

v

v

In our problem, rs is at the clad/coolant interface, T (rs ) = Tc ( S + c) and the heat flux at the clad/coolant interface is

given by Fourier's Law as

dT

v

q ′′(rs ) = q ′′( S + c) = − k c c

dx

(29)

S +c

giving

− kc

dTc

dx

S +c

= hc [Tc ( S + c ) − T∞ ]

(30)

where the gradient is given directly by Equation 22

− kc

dTc

dx

= q ′′′S

S +c

q ′′′S = hc [Tc ( S + c ) − T∞ ]

(31)

The clad temperature can then be written in terms of the coolant temperature as

74

Tc ( S + c ) = T∞ +

q ′′′S

(32)

hc

and the temperature drop from the clad to the coolant is

Tc ( S + c ) − T∞ =

q ′′′S

(33)

hc

Examine the temperature drops across each region

1) Fuel

T ( 0) − T ( S ) =

q ′′′S

2

2k

2) Clad

3) Coolant

Tc ( S ) − Tc ( S + c ) =

Tc ( S + c ) − T∞ =

q ′′′Sc

kc

q ′′′S

hc

In many applications, the intermediate surface temperatures are not needed, and these three equations can be added

to yield the total drop from the centerline of the fuel plate to the coolant.

⎡S

c

1⎤

T (0) − T∞ = q ′′′S ⎢

+

+ ⎥

⎣ 2 k k c hc ⎦

(34)

or

⎡S

c

1⎤

T (0) = T∞ + q ′′′S ⎢

+

+ ⎥

⎣ 2 k k c hc ⎦

(35)

Equation 35 gives the fuel centerline temperature given the physical dimensions and characteristics of the fuel plate

and the local bulk fluid temperature. Alternatively, given the centerline temperature, the required coolant

temperature could be determined. The convective heat transfer coefficient is governed by the fluid velocity, and the

physical properties of the fluid (e.g. density, viscosity, specific heat, etc.). By setting constraints on any of the

above parameters, the others may be adjusted to give the desired result.

Equation 35 may also be written as

q = q ′′′SAs =

q=

T (0) − T∞

c

1 ⎡S

1⎤

+ ⎥

⎢ +

As ⎣ 2 k k c hc ⎦

T (0) − T∞

R

(36)

(37)

where

75

R=

⎡S

c

1⎤

+

+ ⎥

⎢

⎣ 2 k k c hc ⎦

1

As

(38)

is called the thermal resistance and represents the total resistance to heat transfer from the centerline of the fuel out

to the coolant. Equation 37 suggests, that the smaller the thermal resistance, the smaller the temperature difference

necessary to drive the heat transfer, and therefore lower centerline temperatures. From Equation 38 it should be

obvious, that the thermal resistance can be reduced by increasing the thermal conductivity of a conducting region,

decreasing the thickness of a conducting region, or increasing the convective heat transfer coefficient. It should

also be noted, that even if the convective heat transfer coefficient were infinite, such that 1 / hc → 0 , the minimum

thermal resistance is still

c⎤

1 ⎡S

+ ⎥

⎢

As ⎣ 2 k k c ⎦

Rmin =

(39)

which implies that for a given coolant temperature, the minimum fuel centerline temperature is dictated by the fuel

dimensions and material properties, regardless of how much cooling is available.

Non Uniform Heat Generation

In reality, the volumetric heat generation rate within the fuel plate is not uniform, but as shown previously, is

proportional to the fission rate. In thermal reactors the volumetric heat generation rate is then proportional to the

thermal flux distribution within the fuel material. We again consider the plate type fuel element of the previous

example, but now impose a realistic spatial dependence on the heat generation rate. If we assume a thermal reactor,

then it is reasonable to assume there are no thermal neutron sources in the fuel as fission neutrons undergo relatively

few interactions in the fuel material, reaching thermal energies in the moderator. If we assume all thermal neutrons

are produced in the moderator, then we can write the neutron diffusion equation for the thermal flux within the fuel

as

D∇ φ − φΣ a = 0

2

(40)

or

∇ φ − φ / L = 0.

2

2

(41)

If we assume a one-dimensional, cartesian geometry

d φ

2

dx

2

−

φ

2

=0

(42)

L

which has solution

φ( x ) = φ 0 cosh( x / L )

(43)

Since the volumetric heat generation rate is proportional to the flux

q ′′′( x ) = q0′′′cosh( x / L )

(44)

d ⎛ dT ⎞

⎜ k ⎟ + q0′′′cosh( x / L) = 0

dx ⎝ dx ⎠

(45)

The conduction equation in the fuel is now

76

We assume the same boundary conditions, i.e.

dT

dx

=0

0

The solution procedure is identical to that for a uniform volumetric heat generation rate. We integrate from x = 0, to

some arbitrary x ′ contained within the fuel material

∫

x′

0

k

d ⎛ dT ⎞

⎜k

⎟ dx ′′ +

dx ′′ ⎝ dx ′′ ⎠

dT

dx ′′

−k

x′

∫

x′

q0′′′cosh( x ′′ / L)dx ′′ = 0

(46)

0

dT

x′

+ q0′′′ L sinh( x ′′ / L) 0 = 0

dx ′′ 0

(47)

Evaluating the integrals at the limits, and applying the boundary condition at x = 0

k

dT

+ q0′′′ L sinh( x ′ / L) = 0

dx ′

(48)

Equation 48 is valid for any x ′ ∈[0, S ] . The heat flux at the fuel/clad interface is obtained by evaluating Equation

48 at x ′ = S and rearranging to give

−k

dT

= q0′′′L sinh( S / L) ≡ q′s′ .

dx ′ S

(49)

To obtain the temperature distribution within the fuel, we again assume the thermal conductivity to be constant, and

Equation 48 is integrated from x ′ = 0, to some arbitrary x contained within the fuel material

∫

x

0

dT

dx ′ +

dx ′

∫

x

0

q0′′′ L sinh( x ′ / L)

dx ′ = 0

k

q ′′′ L2 cosh( x ′ / L)

T ( x ) − T (0) + 0

k

T ( x ) = T (0) +

(50)

x

=0

(51)

q0′′′ L2

{1 − cosh( x / L)}

k

(52)

0

The fuel surface temperature is obtained by evaluating Equation 52 at x = S

T ( S ) = T (0) +

q0′′′ L2

{1 − cosh( S / L)}

k

(53)

and the temperature drop across the fuel is

T (0) − T ( S ) = −

q0′′′ L2

{1 − cosh( S / L)}

k

(54)

77

It is relatively easy to show, that the temperature drops across the cladding and the clad/coolant interface can be

written in terms of the heat flux q′s′ as

Clad:

q′′c

Tc ( S ) − Tc ( S + c) = s

kc

Coolant:

q′′

Tc ( S + c) − T∞ = s

hc

78

CYLINDRICAL FUEL ELEMENTS

We next consider a cylindrical fuel element as illustrated below.

Cladding

Coolant

Coolant

Fuel

r=0

Ro

R

Figure 1: Cylindrical Fuel Element

We again begin by assuming steady-state heat conduction, with uniform heat generation. We further assume the

thermal conductivity is constant. If the diameter of the fuel rod is small compared to the length, then heat

conduction is predominately in the radial direction, and we can assume the one-dimensional conduction equation in

cylindrical geometry is valid

1 ∂ ⎛ ∂T ⎞

⎜ rk

⎟ + q ′′′ = 0 .

r ∂r ⎝ ∂r ⎠

(1)

We assume similar boundary conditions to those for the plate fuel element, i.e. symmetry about the origin,

1)

dT

dr

=0

0

conservation of energy (heat flux) at the fuel/clad interface,

2) − k

dT

dr

= − kc

R

dTc

dr

R

good thermal contact between fuel and cladding,

79

3) T ( R ) = Tc ( R )

and the fuel rod is convectively cooled by a fluid of temperature T∞ .

4) − k c

dTc

dr

= hc [Tc ( Ro ) − T∞ ]

Ro

Solution in the Fuel Region r ∈[0, R]

Solution for the temperature distribution follows directly from our solution in the plate type fuel element. The

temperature distribution is obtained by integrating Equation 1 twice, starting from the left or inner most boundary

and working outward. For this example, Equation 1 must first be multiplied by r, such that the left and right hand

sides of the equation are directly integrable.

∂ ⎛ ∂T ⎞

⎜ rk

⎟ + q ′′′r = 0

∂r ⎝ ∂r ⎠

(2)

We integrate from r = 0, to some arbitrary r ′ contained within the fuel material.

∫

r′

0

d ⎛

dT ⎞

⎜ r ′′k

⎟ dr ′′ +

dr ′′ ⎠

dr ′′ ⎝

∫

r′

q ′′′r ′′dr ′′ = 0

(3)

0

dT

dT

q′′′r ′′ 2

− r ′′k

+

r ′′k

2

dr ′′ r′

dr ′′ 0

r′

=0

(4)

0

Evaluating Equation 4 at the limits, and applying the boundary condition at r = 0

r ′k

dT q ′′′r ′ 2

+

=0

dr ′

2

(5)

Equation 5 is valid for any r ′ ∈[0, R] and can be used to determine the heat flux at the fuel/clad interface.

Evaluating Equation 5 at r ′ = R and rearranging gives

− r ′k

dT

dr ′

=

q ′′′R 2

2

(6)

=

q ′′′R

.

2

(7)

R

or

−k

dT

dr ′

R

To obtain the temperature distribution within the fuel, we assume the thermal conductivity is constant and divide

Equation 5 by r ′k to obtain integrable terms on both sides of the equation. Integrate again from r ′ = 0, to some

arbitrary r contained within the fuel material

∫

r

0

dT

dr ′ +

dr ′

∫

r

0

q ′′′r ′

dr ′ = 0

2k

(8)

80

q ′′′r ′ 2

T ( r ) − T (0) +

4k

T ( r ) = T (0) −

r

=0

(9)

0

q ′′′r 2

4k

(10)

The fuel surface temperature is obtained by evaluating Equation 10 at r = R

T ( R) = T (0) −

q ′′′R 2

4k

(11)

T (0) − T ( R) =

q ′′′R 2

4k

(12)

and the temperature drop across the fuel is

Solution in the cladding region r ∈[ R, Ro ]

The conduction equation in the cladding is

∂ ⎛ ∂Tc ⎞

⎟ =0

⎜ rk

∂r ⎝ c ∂r ⎠

(13)

where it is again assumed that the volumetric heat generation rate in the cladding is zero. Integrate the conduction

equation from the left, or inner most boundary, outward. For the cladding, the left or inner most boundary is at r =

R.

∫

r′

R

r ′′k c

dTc ⎞

d ⎛

⎜ r ′′k

⎟ dr ′′ = 0

dr ′′ ⎝ c dr ′′ ⎠

(14)

dTc

dTc

− r ′′k c

dr ′′ r ′

dr ′′

(15)

=0

R

To apply the boundary condition at r ′ = R , note

− kc

dTc

dr

=−k

R

dT

dr

⇒ − kcr

R

dTc

dr

= − kr

R

dT

dr

R

However, from Equation 6

− kr

dT

dr ′

=

q ′′′R 2

2

=

q ′′′R 2

2

R

such that

− rk c

dTc

dr

R

(16)

81

Substituting into Equation 15

r ′k c

dTc q ′′′R 2

+

=0

dr ′

2

(17)

Equation 17 is valid for any r ′ ∈[ R, Ro ] and provides information about the heat flux within the clad. The heat

flux at the clad/coolant interface can be obtained by evaluating Equation 17 at r ′ = Ro

− r ′k c

dTc

dr ′

=

Ro

q ′′′R 2

2

(18)

The temperature distribution within the clad is obtained by assuming the thermal conductivity constant, dividing

Equation 17 by r ′k c and integrating from r ′ = R, to some arbitrary r contained within the clad material

∫

r

dTc

dr ′ +

R dr ′

q′′′R 2 dr ′

=0

R 2k c r ′

∫

r

(19)

r

Tc ( r ) − Tc ( R) +

q ′′′R 2

ln( r ′) = 0

2kc

R

(20)

q ′′′R 2 ⎛ r ⎞

ln⎜ ⎟

⎝ R⎠

2kc

(21)

Tc ( r ) = Tc ( R) −

The clad surface temperature can then be obtained by evaluating Equation 21 at r = Ro

Tc ( Ro ) = Tc ( R ) −

q ′′′R 2 ⎛ Ro ⎞

ln⎜ ⎟

⎝ R⎠

2kc

(22)

q ′′′R 2 ⎛ Ro ⎞

ln⎜ ⎟

⎝ R⎠

2kc

(23)

such that the temperature drop across the clad is

Tc ( R ) − Tc ( Ro ) =

Heat Transfer from the Clad to the Coolant r = Ro

Heat transfer from the cladding to the coolant is given by Newton's Law of Cooling

q ′′( Ro ) = − k c

dTc

dr

= hc [Tc ( Ro ) − T∞ ]

(24)

Ro

or multiplying by Ro

q′′( Ro ) Ro = −rkc

dTc

= hc Ro [Tc ( Ro ) − T∞ ]

dr R

o

(25)

82

From Equation 18

− r ′k c

dTc

dr ′

=

Ro

q ′′′R 2

2

such that

q′′′R 2

= hc Ro [Tc ( Ro ) − T∞ ]

2

(26)

The clad temperature can then be written in terms of the coolant temperature as

Tc ( Ro ) = T∞ +

q ′′′R 2

2 Ro hc

(27)

q ′′′R 2

2 Ro hc

(28)

and the temperature drop from the clad to the coolant is

Tc ( Ro ) − T∞ =

Examine the temperature drops across each region

q ′′′R 2

4k

1) Fuel

T (0) − T ( R) =

2) Clad

Tc ( R ) − Tc ( Ro ) =

3) Coolant

Tc ( Ro ) − T∞ =

q ′′′R 2 ⎛ Ro ⎞

ln⎜ ⎟

⎝ R⎠

2kc

q ′′′R 2

2 Ro hc

The total temperature drop from the fuel centerline to the coolant is obtained by adding these three equations to give

T (0) − T∞ =

q ′′′R 2 ⎡ 1

1 ⎛ Ro ⎞

1 ⎤

⎢ + ln⎜⎝ ⎟⎠ +

⎥

2 ⎣ 2k kc

R

hc Ro ⎦

(29)

q ′′′R 2 ⎡ 1

1 ⎛R ⎞

1 ⎤

+ ln⎜ o ⎟ +

⎢

⎥

2 ⎣ 2 k k c ⎝ R ⎠ hc Ro ⎦

(30)

or in terms of the fuel centerline temperature

T (0) = T∞ +

Equation 30 gives the fuel centerline temperature given the physical dimensions and characteristics of the fuel rod

and the local bulk fluid temperature. For this example of a uniformly heated rod, q = q′′′πR 2 H = q′H and

As = 2πRo H . Equation 30 may then be written in terms of the linear heat rate and the thermal resistance as

q′H =

T (0) − T∞

R

83

where

R=

1

As

⎡ Ro Ro ⎛ Ro ⎞ 1 ⎤

+

ln⎜ ⎟ + ⎥

⎢

⎣ 2 k k c ⎝ R ⎠ hc ⎦

(31)

The corresponding minimum thermal resistance ( 1 / hc → 0 ) is

Rmin =

1 ⎡ Ro Ro ⎛ Ro ⎞ ⎤

+

ln⎜ ⎟ ⎥

⎢

As ⎣ 2 k k c ⎝ R ⎠ ⎦

(32)

which again implies that for a given coolant temperature, the minimum fuel centerline temperature is dictated by the

fuel dimensions and material properties, regardless of how much cooling is available. In addition, if we assume the

maximum fuel centerline temperature is equal to the fuel melt temperature, then the maximum linear heat rate is

T

− T∞

′ H = melt

qmax

R

(33)

84