Strain Gage Calculations

advertisement

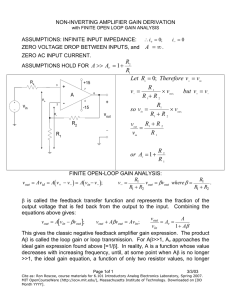

PRACTICAL STRAIN GAGE MEASUREMENTS APPENDICES AND BIBLIOGRAPHY AVERAGE PROPERTIES OF SELECTED ENGINEERING MATERIALS EXACT VALUES MAY VARY WIDELY MATERIAL ABS (unfilled) Aluminum (2024-T4) Aluminum (7075-T6) Red Brass, soft Iron-Gray Cast Polycarbonate Steel-1018 Steel-4130/4340 Steel-304 SS Steel-410 SS Titanium alloy APPENDIX A: TABLES WIRE RESISTANCE SOLID COPPER WIRE AWG Ω/FOOT (25°C) DIAMETER (IN) 18 20 22 24 26 28 30 32 0.0065 0.0104 0.0165 0.0262 0.0416 0.0662 0.105 0.167 0.040 0.032 0.0253 0.0201 0.0159 0.0126 0.010 0.008 ELASTIC STRENGTH (*) TENSION (psi) 4500-7500 48000 72000 15000 — 8000-9500 32000 45000 35000 40000 135000 (*) Elastic strength can be represented by proportional limit, yield point, or yield strength at 0.2 percent offset. APPENDIX B: BRIDGE CIRCUITS Equations compute strain from unbalanced bridge voltages: Vr = [(VOUT /VIN)strained – (VOUT /VIN)unstrained]: sign is correct for VIN and VOUT as shown GF = Gage Factor MODULUS OF ELASTICITY, E psi X 106 0.2-0.4 10.6 10.4 15 13-14 0.3-0.38 30 30 28 29 14 POISSON'S RATIO, — 0.32 0.32 0.33 — 0. 285 0.285 0.28-0.29 0.25 0.27-0.29 0.34 = Strain: Multiply by 10 = Poisson’s ratio: 6 for microstrain: tensile is (+) and compressive is (–) Quarter-Bridge Configurations Rl Rl R1 + – V IN – VOUT Rl + R2 + OR – V IN – Rl R3 Half-Bridge Configurations R1 Rg ( ) VOUT Rl + Rg (Dummy) R2 = –4Vr GF(1 + 2Vr ) • ( 1+ Rl ) Rl Rg (AXIAL) (BENDING) Rl Rl R1 + – V + OUT V IN – R2 = GF[(1 + ) -2Vr( – 1)] R1 Rg ( + ) Rl + – V • IN – Rg ( – ) Rl –4Vr Rg ( ) ( 1+ Rl VOUT Rl + R2 ) Rg = Rl –2Vr GF • ( 1+ © Agilent Rl Rg ( + ) Rg (– ) ) Rg Technologies, Inc. 1999. Reproduced with Permission, Courtesy of Agilent Technologies, Inc. E-103 PRACTICAL STRAIN GAGE MEASUREMENTS Full-Bridge Configurations – V – VOUT + (AXIAL) + – + IN (BENDING) + IN – – VOUT GF + + + –Vr = – V IN – – + –2Vr = – V + OUT V – + – + – + GF( + 1) –2Vr = GF[( + 1) – Vr ( – 1)] APPENDIX C: EQUATIONS BIAXIAL STRESS STATE EQUATIONS x = y = X – E y – E y z = E x E E x = E X – 1- y – E ( x + 2 y = y ) E 2 1- ( x + x) z = 0 ROSETTE EQUATIONS Rectangular Rosette: 3 1 p,q = E 2 45° 2 2 [ [ 1 1 + + 3 3 ( 1 – 3) ± 1 ± 1+ 1– 2 + (2 2 – 1 – 3 ) 2 ( 1 – 3) 2 ] + (2 2 – 1 – 3 ) 2 ] STRAIN GAGES p,q = p,q = 1 TAN -1 2 2 – 1 – 3 45° 1 2 1 – 3 Delta Rosette: 2 3 60° 60° 1 p,q = 1 p,q = E 3 [ [ 1 1 + 2 + 3 ± + 2 + 3 1– p,q = 1 TAN -1 3 ( 2 2 ± 2[( 1 – 2) 1 1+ 2 + ( 2 – 3 ) 2 + ( 3 – 1) 2] 2[( 1 – 2) 2 ] + ( 2 – 3 ) 2 + ( 3 – 1) 2] E ] 3 ) 2 1 – 2 – 3 © Agilent Technologies, Inc. 1999. Reproduced with Permission, Courtesy of Agilent Technologies, Inc. WHERE: p,q = p,q = 3 Principal strains Principal stresses p,q = the acute angle from the axis of gage 1 to the nearest principal axis. When positive, the direction is the same as that of the gage numbering and, when negative, opposite. NOTE: Corrections may be necessary for transverse sensitivity. Refer to gage manufacturer’s literature. E-104