Volume 54, Number 3-4, 2013

243

Hardware-software Application for

Monitoring and Diagnosis of Circuit

Breakers

Mihai ANDRUŞCĂ, Maricel ADAM, Razvan PANTELIMON, Adrian

BARABOI, Cătălin PANCU

Abstract: A method to diagnose circuit breakers is presented, which allowed accurate diagnosis of the monitored equipment, based

on the comparison of collected data with a similarly recording for detect possible anomalies, respective information on the kind of

fault. This paper presents a monitoring and diagnosis system for circuit breakers. Advanced processing and data analysis was

performed by using a software application developed in LabVIEW programming environment. A wavelet algorithm was applied to

acquired signals during circuit breaker operations for denoising and detrend the signals. The method can predict the early failure,

for maintenance of faulty components in order to reduce costs and improve quality in the electric service.

Keywords: monitoring, diagnosis, software application, wavelet transform, circuit breaker.

1.

INTRODUCTION

During operation, electrical equipment (circuit

breakers) is subjected to mechanical, thermal and

electrical stresses. To avoid some faults in their

incipient phase, it is important to monitor the relevant

parameters which characterize the technical condition

of the equipment. This field of research is in continuous

expansion having as a final objective to implement

some monitoring system for reduce the required time

for testing the circuit breaker, to achieve direct results

of the measurements, to compare these results with

previous records, to provide a large quantity of

information, to have the possibility to test circuit

breaker on-line.

Introduction of a large number of circuit breaker

parameters for monitoring and finding the best method

for establish the diagnosis are important research

directions in this area.

In this paper is presented a fault diagnosis method

by means of detects specific changes in acquired

parameters from a fingerprint recording, based on

differences between values and curves of those

parameters. If it is exceeded a predetermined limit

value it indicates that one of the characteristics of the

circuit breaker is in an unacceptable range.

In the paper is described a hardware-software

structure and parameters for monitoring and diagnosis

of the circuit breaker condition (operative voltage,

currents through solenoid coils, travel of contact mobile

etc.), and also a software application which is used for

advanced processing and analyzing the obtained data.

Finally, the experimental tests were performed

on a circuit breaker having different abnormal

situations that could have place on exploitation: faults

in solenoids, low, respective high operative voltage etc.

The analyzed circuit breaker was of medium

voltage with oil which has the operating mechanism

with springs accumulated energy.

Abnormal situations encountered in the

operation of this circuit breaker type that use

accumulated energy in springs can be generalized to

any type of medium, respectively high voltage circuit

breakers, with this kind of operating mechanism (SF6,

vacuum).

2.

FAULTS, PARAMETERS AND

TECHNIQUES FOR CIRCUIT BREAKERS

MONITORING AND DIAGNOSIS

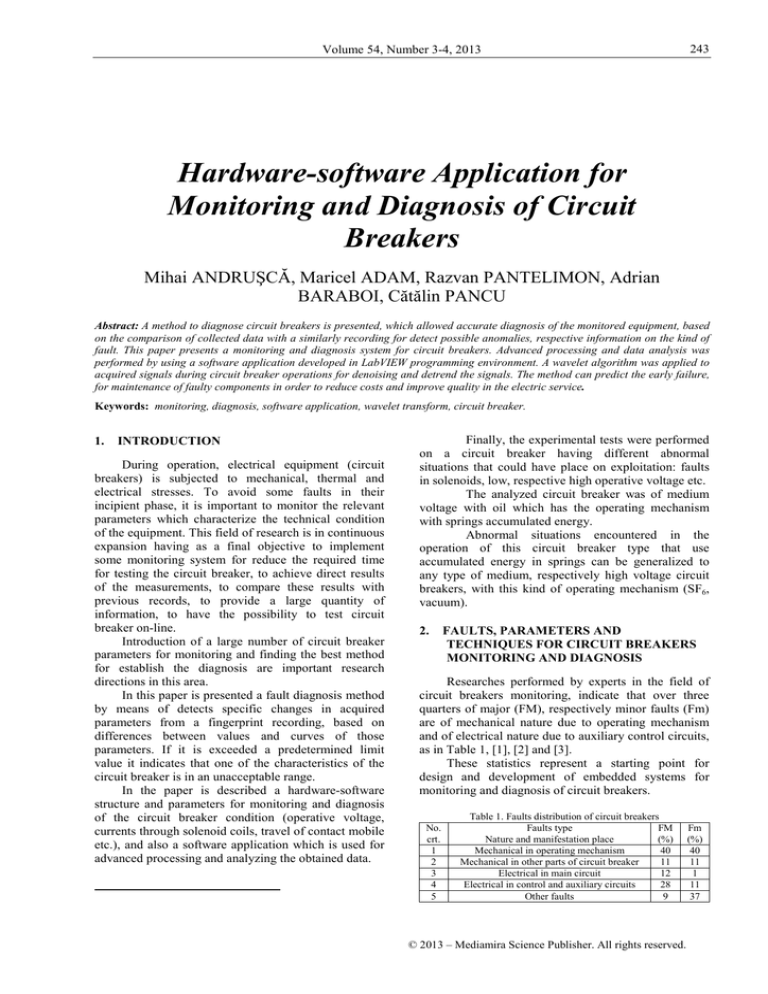

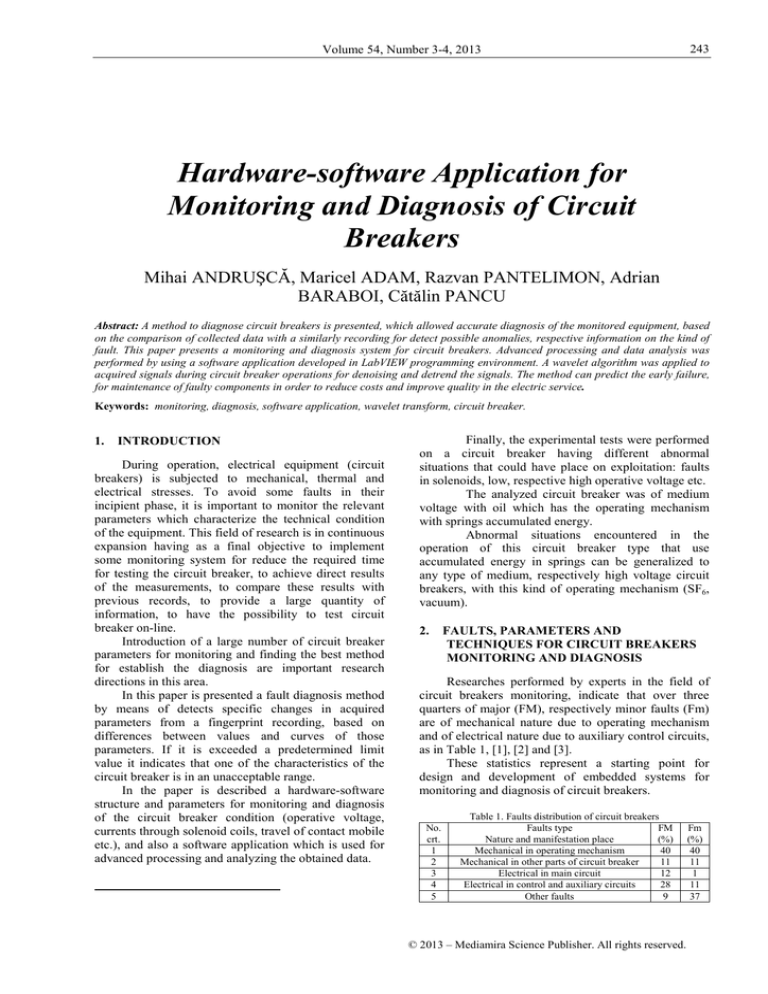

Researches performed by experts in the field of

circuit breakers monitoring, indicate that over three

quarters of major (FM), respectively minor faults (Fm)

are of mechanical nature due to operating mechanism

and of electrical nature due to auxiliary control circuits,

as in Table 1, [1], [2] and [3].

These statistics represent a starting point for

design and development of embedded systems for

monitoring and diagnosis of circuit breakers.

No.

crt.

1

2

3

4

5

Table 1. Faults distribution of circuit breakers

Faults type

FM

Nature and manifestation place

(%)

Mechanical in operating mechanism

40

Mechanical in other parts of circuit breaker

11

Electrical in main circuit

12

Electrical in control and auxiliary circuits

28

Other faults

9

© 2013 – Mediamira Science Publisher. All rights reserved.

Fm

(%)

40

11

1

11

37

244

ACTA ELECTROTEHNICA

Monitoring is the continuous process of gathering

relevant information about the monitored equipment

while diagnosis is a process that uses information

obtained during monitoring in order to verify if the

measured values are in accordance with those specified

by the manufacturer or with some records determined

previously according to which alerts, alarms,

recommendations are emitted.

Thus, diagnosis is the next step representing the

interpretation of on-line and off-line data measured.

Monitoring is the basis of diagnosis, but without a

diagnosis, the measured data would not have the same

value.

Monitoring and diagnosis of circuit breakers is

orientated on function or/and subassembly (operating

mechanism, auxiliary and control circuits, switching

function, insulating). In Table 2 are presented the

parameters and techniques used in monitoring and

diagnosis of operating mechanism, respective auxiliary

and control circuits of circuit breakers.

Table 2. Parameters and techniques for monitoring and diagnosis

Function/

Parameter

Techniques and

Subassembly

device

Acting number

Counters

Operation time

Accumulated

energy

Operating

mechanism

Auxiliary and

control

circuits

Recording opening / closing time in

the primary circuit. Special sensors.

Oil pressure, nitrogen pressure,

micro-switches position

Kinematics

Magneto-resistive position sensor,

characteristics potentiometer, bar codes technique

etc.

(travel, velocity)

Motor condition Current, voltage and temperature of

motor, the number of pump starts,

pump recharging time, pump

operating total time

Vibratory

Fourier transform, the frequency

fingerprint

spectrum and peak frequency.

Accelerometers.

Operative

Voltage sensor

voltage

Current through

Current duration and evolution.

coil

Shunts, current transformer etc.

Circuits

continuity

Continuity verification by passing a

small current or in impulse

Auxiliary

contacts status

Verify the integrity by sequence of

the operation, position etc.

Those components are responsible for the largest

number of faults. Embedding a large number of these

parameters, it will allow a more accurate report of the

real technical condition of equipment, [3], [4] and [5].

New tendency in circuit breakers maintenance is

to pass from the maintenance based on predetermined

criteria through maintenance based on condition, which

involves introduction of embedded systems for

monitoring and diagnosis of their technical condition,

[3] and [6].

3.

HARDWARE-SOFTWARE SYSTEM FOR

MONITORING AND DIAGNOSTIC

The intelligent system of monitoring and

diagnostic (SIMDE) of electrical equipment it uses for

monitoring and diagnostic of circuit breakers from high

and medium voltage electrical installations with onephase and three-phase operation, [6], [7].

The system can be installed on new circuit

breakers as well as on existing circuit breakers and

allows to obtain information necessary to establish their

technical state.

The monitoring and diagnostic system can be

mounted in the enclosure of operating mechanism or

attached on it introducing the system into an exterior

enclosure, and it connects in parallel with operating

circuits of circuit breaker. On duration of a trip or

closing operation of circuit breaker, the system allows

to acquisition of the following information about it:

- main currents on each phase;

- currents through the trip and closing coils;

- the displacement of mobile contact;

- operating voltage;

- status of circuit breaker;

- sulfur hexafluoride (SF6) pressure;

- motor starting of operating mechanism;

- the behaviour of motor protection;

- contacts electroerosion;

- other 3 analog signals having the range 0-10 V

DC, established by the user.

The same information can be acquired also in the

case of some multiple operations like as rated operating

sequence: O-0,3 s-CO-3 min.-CO.

The records realised by SIMDE after a trip/closing

operation of circuit breaker are sent to PC (through

direct connection, GSM modem or SD card) where are

analysed, with the help of an adequate software,

through comparison with the results of some similar

records, and also with the limits anterior programmed.

If a limit is exceeded then an alarm signal is released

which indicates the fact that one of the circuit breaker’s

features is into an unacceptable range.

The main technical features of hardware-software

system are:

- 3 AC channels, galvanic insulated, dedicated to

measure the main currents through the current

transformers (the load is maximum 0,01 VA);

- 13 DC channels, galvanic insulated, dedicated to

measure the currents through the trip and closing coils,

the operating voltage and the displacement of the

mobile contacts (shunts resistance: 0,2 Ω (5 A), 0,1 Ω

(10 A), 0,05 Ω (20A));

- 12 digital inputs galvanic insulated, having:

6 channels with one of the following ranges 3-7 V,

or 20-60 V, 80-150 V with exterior resistor, the

voltages being in DC or AC;

6 channels with ranges 170-250 V DC or AC;

- 9 outputs of relay type having contacts NO/NC

with features 5 A at 30 V DC, or 5 A at 250 V AC;

- serial interfaces:

Volume 54, Number 3-4, 2013

-two asynchronous interfaces on RS232

transceiver;

-one serial interfaces having TTL logic signals;

-one module UART 16C550 for GSM

communication;

- SD card with storage memory of 2 GB;

- alphanumeric display LCD 4x20 characters or

graphic display LM24014H;

- keyboard with 4 keys;

- recording: sampling rate 2 kHz;

- external SRAM memory of 1Mb;

- EEPROM memory of 512Ko;

- triggering of data acquisition: the state changing

of any digital inputs;

- heating resistance (optional);

- voltage supply: 85-265 V AC; 110-330 V DC;

- operating temperature: -20 °C ... +40 °C.

The Figure 1 shows the block diagram of

monitoring and diagnostics system, structure realised

with the help of the microcontroller ATMEL

ATmega2560 AVR.

4.

245

EXPERIMENTAL INSTALLATION

In Figure 2 is presented the electrical diagram

used for monitoring and diagnosis of medium voltage

circuit breakers from medium voltage installation. This

includes: a circuit breaker, respectively a monitoring

and diagnosis system consists of sensors/transducers

and dedicated hardware-software structure.

Circuit breaker, on which data were acquired for

diagnosis is with springs operating mechanism.

During of closing/closing operations of circuit

breaker, the system allows to acquire of following

information about it:

- main currents on each phase;

- currents through the trip and closing coils;

- travel of mobile contacts;

- operating voltage.

To determine the travel is used a resistive sensor

(potentiometer) which is reliable and easy to use,

ensuring accurate precision. Resistive sensor was

attached to a mobile part of the movement transmission

system from the operating mechanism to mobile

contacts of circuit breaker.

Fig.1. Block diagram of system

246

ACTA ELECTROTEHNICA

Fig. 2. Electrical diagram of monitoring and diagnosis system for circuit breaker

5.

SOFTWARE APPLICATION

For an easy interface with the users, a software

application was developed in LabVIEW programming

environment, [8].

In Figure 3 is represented the architecture for

monitoring and diagnosis system of circuit breakers and

also the software application structure.

After acquire some parameters of circuit breakers

with monitoring and diagnosis system, the acquired

data are transmitted to a PC, where are subject to a

process for processing, analyzing data, visualization in

graphical form of signals etc.

The software application algorithm developed

offers the following features, [7]:

- initialization of the application;

- uploading data for analysis;

Phase currents

Circuit breakers

Monitoring of current through coils of closing,

respectively opening solenoid is performed with shunts.

Acquisition of the 3-phase currents is achieved with

current transformers, and also for operative voltage is

used a voltage sensor.

Recordings performed with hardware-software

structure

for

monitoring

at

the

connection/disconnection of the circuit breaker are

transmitted to a computer (through direct connection,

GSM modem or SD card) where are analyzed using an

adequate software, by comparing with the results of

similar records, as well as previous limits by

programming. In the case when data are transmitted on

the memory card of SD type, the monitoring system

performs their automatic save after acquisition.

The signal acquisition was performed at a

sampling rate of 2 kHz, with a resolution to 12 bits,

while the recorded signal duration was 260 ms.

Operative voltage

Currents through

solenoids coil

Travel of mobile

contacts

Acquired Upload data

data

Intelligent

System for

monitoring

and diagnosis

of electrical

equipment

Data Reading

LabVIEW

software

application

Calculate monitored

parameters

Data processing

Values and curves

visualization

Data analysis

Alarms,

Warnings

Reports

Fig. 3. Monitoring and diagnosis system of circuit breakers and

software application structure

- calculate and display the monitored parameters

in different graphs or in the same graphs for an easy

interpretation;

- extracting the characteristic values of the

parameters (minimum, maximum etc.);

- processing and analyzing data;

- generate the alarms and reports.

In Figure 4 is presented the front panel of software

application that allows uploading the files, both from

normal situation and abnormal situation, visualizations

the values and curves of obtained data for analyzing

them, [9].

Volume 54, Number 3-4, 2013

By compare obtained curves and values of the

parameters on the circuit breaker operation in abnormal

situations, with the parameters considered normal it can

observe the difference between those signals.

In Figure 5 is presented a part of block-diagram of

the software application, namely the diagram of the

subprogram for determination the travel, respective the

velocity of mobile contacts.

This part of diagram performs:

- reading data from the corresponding column for

travel of mobile contacts from both saved files current

and that considered normal;

- removing the offset;

- transforming the rotary motion of the

displacement transducer into the linear motion of

mobile contacts;

- performing the signal denoising and detrending;

- extracting the minimum and maximum value of

the travel of mobile contacts;

Fig. 4. Front panel of monitoring and diagnosis system for circuit

breaker

247

monitored parameters (maximum, minimum, average

etc.), graphical visualization etc.

An advanced software component developed by

wavelet algorithms for signal processing was designed

and implemented in order to extract information from

the acquired parameters.

The data analysis, in accordance to variable scales

in the time and frequency domain, constitutes the basic

idea to use the Wavelet theory. The Wavelet Transform

(WT) is a mathematical tool for signal analysis.

Wavelets are functions that are used to decompose

signals. The WT presents local representations in the

time and frequency domain of a given signal, [10] and

[11].

One of the most effective application of wavelets

in signal processing is denoising, or reducing noise in a

signal. The wavelet transform-based method can

produce much higher denoising quality than

conventional methods. Furthermore, the wavelet

transform-based method retains the details of a signal

after denoising, [12].

For applications that require signal reconstruction,

the LabVIEW Wavelet Analysis Tools provide the

following wavelet transforms tools:

- Discrete wavelet transforms (DWT);

- Undecimated wavelet transforms (UWT).

Also, the Wavelet Analysis Tools provide the

following commonly used discrete wavelets:

- Orthogonal wavelets - Haar, Daubechies (dbxx),

Coiflets (coifx), and Symmlets (symx);

- Biorthogonal wavelets - FBI, and Biorthogonal

(biorx_x);

where x indicates the order of the wavelet, the

higher, the order, the smoother of wavelet. Orthogonal

wavelets are suitable for applications such as signal

denoising.

Fig. 5. Part of block diagram of monitoring and diagnosis system for

circuit breaker

- derivation the signal of the travel of mobile

contacts to obtain the velocity of mobile contacts;

- extracting the maximum velocity;

- graphical visualization of the acquired

parameters.

Regarding the other parameters acquired by the

monitoring system (operative voltage, phase currents,

currents through opening and closing coils) are subject

to the same process of signal processing, namely:

reading data from files, performing the signal

denoising, extracting the characteristic values of

Fig. 6. Phase R current with noise and the denoised signal using the

wavelet transform-based method.

248

ACTA ELECTROTEHNICA

In Figure 6 is presented the denoising case of

phase R current signals. It can see the original signal

obtained with monitoring system with noise, respective

the denoised signal with UWT, respective DWT. The

denoising result of the UWT has a better balance

between smoothness and accuracy than the DWT. For

better denoising, in developed software application it

was used the UWT.

The wavelet type used for denoising was

Symmlets (sym8). The functions WA Detrend, WA

denoise and Wavelet Denoise Express from LabVIEW

Advanced Signal Processing toolkit was used, [12]. The

Wavelet Denoise Express enables to specify parameters

and settings for an analysis, to select the wavelet type,

specify a threshold and visualization the results

immediately.

6.

EXPERIMENTAL RESULTS

In Table 4 are presented the circuit breaker

condition, possible causes of abnormal situation,

respective the nature and manifestation place.

Table 4. Circuit breaker conditions

No

crt.

Circuit breaker

condition

1

2

Normal condition

Abnormal condition,

circuit

low voltage in

interruption, the

auxiliary circuit

occurrence of

short circuits on

the solenoid coils

or relay

Abnormal condition, circuit interruption

high voltage in

auxiliary circuit

Abnormal condition, incorrect settings,

low or high

respectively

changes in

accumulated energy

in springs

physical properties

of springs

Abnormal condition,

inadequate

low or high free

adjustment of

solenoids

travel of solenoid air

gap

Abnormal condition, lack of lubrication,

low or high current operative voltage

of solenoids

out of range

3

4

6

7

On a circuit breaker have been simulated various

types of faults that could occur in exploitation and with

the help of the software application for monitoring

and diagnosis of circuit breakers described above, it can

observe the variations of acquired parameters.

In Table 3 are presented some parameters

considered for diagnosis and their variation range in

order to establish circuit breakers technical condition.

Table 3. Parameters considered for monitoring and diagnosis of

circuit breakers

Range

No.

Considered parameters

Unit

crt.

Minim

Maxim

1

Current through opening

A

0.7

0.8

solenoid coil

2

Current through closing

A

0.7

0.8

solenoid coil

3

Opening coil current

A·s

0.55

0.63

profile area

4 Closing coil current profile

A·s

0.55

0.63

area

5

Mean operative voltage

V

210

220

6

Travel of contact mobile

mm

211

218

7

Opening velocity of

m/s

4.5

6

contact mobile

8 Closing velocity of contact

m/s

3.7

5.2

mobile

9

Opening time

ms

44

70

10

Closing time

ms

93

123

Possible causes of

abnormal situation

8

Other abnormal

condition

transducers

incorrect mounting

Nature and

manifestation

place

electrical faults in

the control and

auxiliary circuit

electrical faults in

the control and

auxiliary circuit

mechanical faults

in operating

mechanism

electrical faults in

the control and

auxiliary circuit

(fault in solenoid)

mechanical or

electrical faults in

the control and

auxiliary circuit

fault in transducers

Further, the cases which were selected for

presenting are:

- electrical faults in the control and auxiliary

circuit: faults in solenoid.

- faults on travel transducer.

6.1. Solenoid faults

Monitoring the current through solenoid coil

provides information on start time and end time of

mobile armature movement and also on start time of

open the auxiliary contacts. From changes of coil

current timings can be deduced the occurrence of some

problems (lack of lubrication, inadequate adjustment of

solenoids) in control system of the operating

mechanism, [4].

Ib (A)

0.9

A

C

0.7

0.5

B

The proper analyses of these parameters may

identify some abnormal situations in circuit breaker

operation; respective may detect a fault of the circuit

breaker.

If the value of one or more of the presented

parameters in Table 3 exceeds the allowable limits it

indicates that one of the circuit breaker characteristics is

into an unacceptable domain.

0.3

0.1

0

20

40

60

80

Time (ms)

Fig. 7. Evolution of current through opening coil

249

Volume 54, Number 3-4, 2013

In Figure 7 is given the current evolution from

opening coil recorded for a 24 kV circuit breaker with

spring-operated mechanism. It can be seeing the three

timings as follows: A- armature starts, B-armature

stops, C-auxiliary contact opens).

In Figure 8 are presented the records of current

through opening coil, operative voltage and travel,

respectively velocity of mobile contact for values

adjusted of the air gap armature of opening solenoid of

3 mm, 7 mm, 9 mm and 12 mm. The reference value is

considered of 9 mm.

Uop

X (mm)

v ·0.06(m/s)

X

Uop·0.83(V)

Ib·0.005(A)

v

Ib

δ=12 mm

δ=9 mm

δ=7 mm

δ=3 mm

Fig. 8. Evolution of opening travel (X), respectively velocity (v) of

mobile contact, operative voltage (Uop), current through solenoid coil

(Ib) at different values of solenoid air gap

In Table 5 are presented the parameter values that

are influenced by the changes of free travel of air gap of

opening solenoid.

- mean operative voltage values decreases with

higher free travel of air gap, respectively increases with

lower free travel of air gap.

6.2. Fault in sensors/transducers

During the experiments, due to many manoeuvres

and high vibration produced on them duration, it was

observed a fault to the displacement transducer.

In case of such anomalies, after analysis the

monitored parameters it can conclude following, Table

6 and Figure 9:

- important changes are observed between the

abnormal travel evolution of the mobile contact and the

record considered normal;

- a significant decrease of maximum velocity is

noticed which is less than 60% from than reference

value, being on below of the limit specified by the

equipment manufacturer;

- the other values of the monitored parameters

were found in specified ranges by the manufacturer.

Table 6. Monitored parameters of circuit breaker on displacement

transducer faults

Current

Profile area

Mean

Travel, Velocity,

through

of solenoid

No. operative

solenoid coil, coil current,

X

v

voltage,

U

opm

crt.

Ib

PA

(V) (%) (mm) (m/s) (%) (A)

(%) (A·s) (%)

1

216.4

100

214

5.58 100

0.76

100

0.62

100

2

216.6

100

214

3.24

0.76

100

0.60

97.8

58

Table 5. Monitored parameters of circuit breaker at different values of solenoid air gap

Free travel of

Mean

Profile area of

Travel, Velocity, Current through

operative

solenoid coil

No. solenoid air gap,

X

v

solenoid coil, Ib

δ

voltage, Uopm

current, PA

crt.

(mm)

(%)

(V)

(%)

(mm) (m/s) (%)

(A)

(%)

(A·s)

(%)

1

9

100 216.7 100

216.8 5.23 100 0.77

100

0.579

100

2

12

133.3 215.7 99.45 216.2 5.39 103 0.77

100

0.7058 121.9

3

7

77.7 218.4 100.69

212 5.79 110 0.75

97.2

0.5329

92

4

3

42.8

221 101.9

218 4.98 95.2 0.77

100

0.463

80

Experimental results obtained provides following

information:

- delays in the appearance of specified timing for

12 mm air gap, which leads to a movement to the right

of the travel of mobile contact, respectively its velocity;

- for the lower values than the reference value of

air gap is observed that specified timings occur more

quickly, resulting in a movement to the left of the travel

of mobile contact, respectively their velocity;

- profile area of coil current increase with higher

free travel of solenoid, respectively decreases with

lower free travel;

- maximum values of the current through solenoid

coil in the analyzed cases have close values;

- maximum values of velocity and travel of mobile

contact are in the specified range by the manufacturer;

Uop

v ·0.06(m/s)

X

Uop·0.83(V)

Ib·0.005(A)

X (mm)

v

Ib

normal

abnormal

due

transducer

Fig. 9. Evolution of opening travel (X), respectively velocity (v) of

mobile contact, operative voltage (Uop), current through solenoid coil

(Ib) with faults on displacement transducer

250

7.

ACTA ELECTROTEHNICA

CONCLUSIONS

The paper presents an online monitoring and

diagnosis system for circuit breakers which have the

role to acquire, to transfer and to process information

about the monitored equipment. The main objective of

such systems is to detect any change in the monitored

parameters based on differences between values and

curves of those parameters.

The monitoring an diagnostic system, on duration

of a trip or closing operation of circuit breaker, allows

to acquisition of analog measurements (main currents

on each phase; currents through the trip and closing

coils; the displacement of mobile contact; operating

voltage), respectively event information (opened/closed

position of circuit breaker; sulfur hexafluoride (SF6)

pressure; motor starting of operating mechanism; the

behaviour of motor protection), quantities necessary to

establish the technical state of monitored equipment.

It was developed a LabVIEW software application

used for processing and analyzing the data acquired by

the monitoring system which enable advanced data

processing and visualization of the monitored

parameter waveforms, both for normal, respective

abnormal condition for an easy interpretation of data.

Calculation of monitored parameters and display

the waveforms was performed after wavelets-based

adaptive filtering of the acquired signals, filters that are

used to perform denoising and detrending of the

original signal.

After the analysis of acquired parameters, in the

case of fault in solenoids, respective faults in

transducers, it can conclude following:

- at a fault in solenoid is observed that all

monitored parameters are changed by the reference

record.

- on displacement transducer fault is observed a

significant difference on travel evolution of mobile

contact, respectively of its velocity values from the

reference.

The obtained results can be used to analyze

other circuit breakers with similar characteristics.

Acknowledgment. This paper was realised with

the

support

of

POSDRU

CUANTUMDOC

“DOCTORAL

STUDIES

FOR

EUROPEAN

PERFORMANCES

IN

RESEARCH

AND

INOVATION” ID79407 project funded by the

European Social Found and Romanian Government.

REFERENCES

M. Andruşcă, M. Adam, R. Pantelimon, A. Baraboi, “About

diagnosis of circuit breakers from electricity company”, 8th

International Symposium on ADVANCED TOPICS IN

ELECTRICAL ENGINEERING - ATEE 2013, Bucureşti,

România, 2013.

2. J.E. Silva, M. Aguiar, P. Costa, “Computational intelligence to

fault diagnosis in gas SF6 circuit breakers”, 2006.

3. IEEE Guide for Selection of Monitoring for Circuit Breaker,

IEEE Standard C37.1O.1-2000, 2001.

4. M. Adam, A. Baraboi, C. Pancu “About the monitoring and

diagnostic of the circuit breakers”, The XIII International

Symposium on High Voltage Engineering, Delft, Holland, 2003.

5. M. Adam, A. Baraboi, C. Pancu, T. Plesca, “Reliability Centered

Maintenance of the Circuit Breakers”, International review of

electrical engineering-IREE, Vol.5, 2010.

6. M. Adam, A. Baraboi, C. Pancu, M. Andruşcă, “System for

monitoring and diagnostics of the electrical equipment”, Acta

Electrotehnica, Cluj, 2011.

7. M. Andruşcă, M. Adam, A. Baraboi, D. F. Irimia, “Embedded

system and software application for monitoring and diagnosis of

high voltage circuit breakers”, 7th International Conference and

Exposition on Electrical and Power Engineering, Iaşi, România,

2012.

8. E. Lunca, S. Ursache, O. Neacsu, Graphical Programming Tools

for Electrical Engineering Higher Education, International

Journal of Online Engineering (iJOE), Vol. 7, Nr. 1, pp 19-24,

2011.

9. M. Andruşcă, M. Adam, R. Pantelimon, A. Baraboi, C. Pancu,

“LabVIEW Software Aplication for Monitoring and Diagnosis

of Circuit Breakers”, Proceedings of 5th International

Conference on Modern Power Systems – MPS 2013, ClujNapoca, România, 2013.

10. G. Fazio, F. Muzi, S. Ricci, G. Sacerdoti, “Circuit-Breaker

Diagnostics Based on Continuous Wavelet Transform”, IEEE

Bologna Power Tech Conference, Bologna, Italy, 2003.

11. M. S. Silva, J. A. Jardini, L. C. Magrini, A. Corvo, L.A. Solis and

F. Veiga, “Determination of the Circuit breaker Operation times

using the Wavelet Transform”, Power Engineering Society

General Meeting, IEEE, 2004.

12. Advanced Signal Processing Toolkit, Wavelet Analysis Tools

User Manual, National Instruments, 2005.

1.

PhD. student Mihai ANDRUŞCĂ

Prof. dr. eng. Maricel ADAM

PhD. student Răzvan PANTELIMON

Prof. dr. eng. Adrian BARABOI

Lecturer dr. eng. Cătălin PANCU

Faculty of Electrical Engineering,

“Gheorghe Asachi” Technical University of Iasi

Bd. D. Mangeron, nr. 21- 23, 700050 Iaşi,

ROMÂNIA