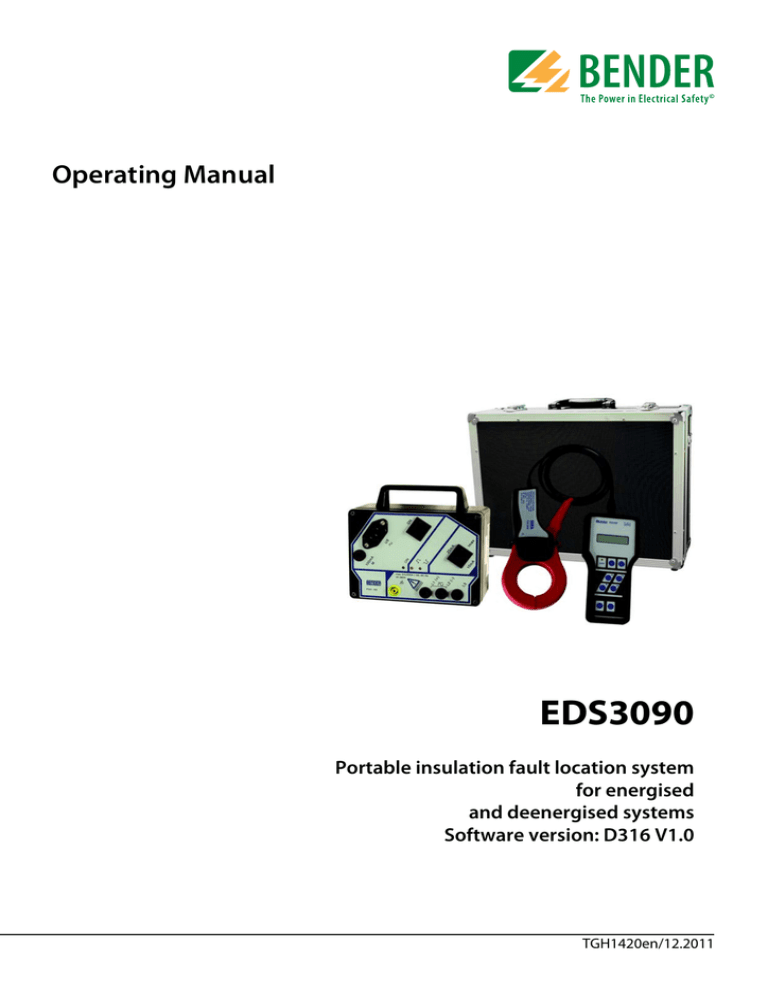

Operating Manual

EDS3090

Portable insulation fault location system

for energised

and deenergised systems

Software version: D316 V1.0

TGH1420en/12.2011

Dipl.-Ing. W. Bender GmbH & Co. KG

Londorfer Str. 65 • 35305 Grünberg • Germany

Postfach 1161 • 35301 Grünberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-mail: info@bender-de.com

Web: http://www.bender-de.com

© Dipl.-Ing. W. Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Table of Contents

1. How to use this operating manual effectively ................................................... 7

1.1

How to use this manual ......................................................................................................... 7

1.2

Explanations of symbols and notes ................................................................................... 7

1.3

Chapters at a glance ............................................................................................................... 8

2. Safety instructions .................................................................................................. 9

2.1

Intended use .............................................................................................................................. 9

2.2

Device-specific safety instructions .................................................................................... 9

2.3

General safety instructions ................................................................................................... 9

2.4

Skilled persons ....................................................................................................................... 10

3. System description .............................................................................................. 11

3.1

System components ............................................................................................................ 11

3.1.1 Overview system components ........................................................................................ 11

3.1.2 List of insulation fault location system types .............................................................. 12

3.1.3 Accessories .............................................................................................................................. 13

3.2

Function of the system components ............................................................................. 14

3.2.1 PGH18... insulation fault test device ............................................................................... 14

3.2.2 Insulation fault evaluator EDS190P ................................................................................ 14

3.2.3 Measuring clamps ................................................................................................................. 14

3.2.4 Coupling device AGE185 .................................................................................................... 15

3.3

Operating principle of insulation fault location (IΔs) ............................................... 15

3.3.1 Block diagram EDS system ................................................................................................ 16

3.3.2 Test cycle .................................................................................................................................. 16

3.3.3 Terms ......................................................................................................................................... 17

3.3.4 Currents in the EDS system ............................................................................................... 17

3.4

Operating principle of residual current measurement (IΔn) ................................. 18

4. Points to be considered before use .................................................................. 19

4.1

How does an insulation fault location system work? .............................................. 19

4.2

Requirements for reliable insulation fault location .................................................. 20

4.3

Reduced test current ........................................................................................................... 22

4.4

Characteristic curves on the response sensitivity of EDS190P ............................. 22

4.4.1 Response characteristic curves for main circuits in 3AC systems ........................ 23

TGH1420en/12.2011

3

Table of Contents

4.4.2 Response characteristic curves for main circuits in AC systems ........................... 24

4.4.3 Response characteristic curves for main circuits in DC systems ........................... 24

4.4.4 Response characteristic curves for control circuits in AC systems ...................... 25

4.4.5 Response characteristic curves for control circuits in DC systems ...................... 25

5. Commissioning and connection ....................................................................... 27

5.1

Decoupling the insulation monitoring device ............................................................ 27

5.2

Deenergised systems ........................................................................................................... 27

5.3

Connection to an IT system ............................................................................................... 28

6. Operation ............................................................................................................... 29

6.1

Brief description of insulation fault location (EDS mode) ....................................... 29

6.1.1 Commissioning of the PGH18... for test current supply .......................................... 29

6.1.2 Insulation fault location with EDS190P ......................................................................... 29

6.2

Operating elements of the PGH18... ............................................................................... 30

6.3

Display and operating elements of the EDS190P ...................................................... 31

6.4

Operation of the EDS190P .................................................................................................. 33

6.4.1 Switching the device on and off ...................................................................................... 33

6.4.2 Display illumination provides improved readability ................................................ 33

6.4.3 Switching between the operating modes insulation fault location IΔs

and residual current measurement IΔn ......................................................................... 33

6.4.4 Display elements and their meaning ............................................................................. 34

6.5

Standard displays of the EDS190P ................................................................................... 35

6.5.1 Standard display without enclosing the cable to be measured ........................... 35

6.5.2 Standard display in the EDS mode (IΔs) with the cable enclosed ....................... 35

6.5.3 Standard display in the RCM mode (IΔn) with the cable enclosed ..................... 35

6.6

Alarms in the EDS or RCM mode ...................................................................................... 35

6.7

Indication of device and measuring errors .................................................................. 36

6.8

Factory settings EDS190P (delivery condition) ........................................................... 36

6.9

Menu structure ....................................................................................................................... 37

6.10

Navigation within the menu .............................................................................................. 37

6.11

Menu item: Settings / General .......................................................................................... 38

6.12

Menu item: Settings / IΔs .................................................................................................... 38

6.13

Menu item: Settings / IΔn ................................................................................................... 39

6.14

Menu item: Settings / system ............................................................................................ 39

6.15

Menu item: View harmonics (Harmonics) ..................................................................... 39

6.16

Practical use ............................................................................................................................. 40

6.16.1 Use as a portable insulation fault location system .................................................... 40

6.16.2 Using the EDS190P within a permanently installed EDS system ......................... 42

6.16.3 EDS309... in diode-decoupled DC systems ................................................................... 44

4

TGH1420en/12.2011

Table of Contents

6.16.4 Using the EDS190P as a residual current monitor .................................................... 47

6.16.5 Measuring harmonics .......................................................................................................... 48

6.17

Coupling device AGE185 for higher voltages ............................................................. 49

6.18

Power supply of the EDS190P .......................................................................................... 50

6.18.1 Displaying the battery status ............................................................................................ 50

6.18.2 Replacing batteries or accumulators ............................................................................. 50

6.18.3 Power supply unit delivered with the system ............................................................ 50

7. Technical data ....................................................................................................... 51

7.1

Technical data of the EDS309... system ......................................................................... 51

7.2

Technical data PGH18... ...................................................................................................... 51

7.3

Technical data EDS190P ..................................................................................................... 52

7.4

Technical data measuring clamps .................................................................................. 53

7.5

Technical data AGE185 ....................................................................................................... 53

7.6

Dimension diagrams ............................................................................................................ 54

7.7

Standards ................................................................................................................................. 55

7.8

Ordering information ......................................................................................................... 56

7.9

List of components ............................................................................................................... 57

8. Frequently asked questions ............................................................................... 59

INDEX ........................................................................................................................... 61

TGH1420en/12.2011

5

Table of Contents

6

TGH1420en/12.2011

1. How to use this operating manual effectively

1.1 How to use this manual

This operating manual describes how to operate the portable insulation fault location system

EDS309... (with EDS190P, software version V1.0). It is designed for skilled personnel working in electrical engineering and electronics and in particular for those designing, installing and operating electrical systems.

Before using the equipment, please read this operating manual, the supplement entitled “Important

safety instructions for Bender Products" and the instruction leaflets supplied with the individual system components. Please keep this documentation close at hand near to the equipment.

Should you have any questions, please do not hesitate to contact our technical sales team. We are

also happy to provide on-site services. Please contact our Service Department for more information.

Service-Hotline: 0700-BenderHelp (Telefon and Fax)

Carl-Benz-Straße 10 • 35305 Grünberg • Germany

Tel: +49 6401-807-760 • Fax: +49 6401-807-629

E-Mail: info@bender-service.com • www.bender-de.com

Although great care has been taken in the drafting of this operating manual, it may nevertheless

contain error and mistakes. The Bender Group cannot accept any liability for injury to persons or

damage to property resulting from errors or mistakes in this manual.

1.2 Explanations of symbols and notes

The following designations and symbols are used in this documentation for

hazards and warnings:

Information calling attention to hazards are marked with this warning symbol.

Information intended to assist the user to make optimum use of the product are

marked with the Info symbol.

TGH1420en/12.2011

7

How to use this operating manual effectively

1.3 Chapters at a glance

1. How to use this operating manual effectively:

This chapter provides tips and useful information on how to use this manual.

2. Safety instructions

This chapter describes the dangers during installation and when operating the device.

3. System description:

This chapter provides an overview of the system components, a description of their function

and the fundamentals of insulation fault location.

The last chapter describes the function of residual current measurement.

4. Points to be considered before use:

This chapter describes the practical aspects of insulation fault location and provides a number

of characteristic curves for evaluation of the response values to be set.

5. Commissioning and connection:

This chapter describes the connection of the EDS309... to a system to be tested.

6. Operation:

This chapter provides a description of the graphical user interface of the EDS190P. In addition,

you will find a representation of the menu structure and the graphical representation of various standard displays.

You will also find details about the power supply of the EDS190P.

7. Technical data:

In addition to the data in tabular form, you will be informed about standards and the dimensions of the system components.

8. Frequently asked questions:

This chapter will help you to recognise faults quickly which are likely to occur and provides

suggestions for trouble shooting.

9. INDEX:

Use the index to look up keywords quickly.

8

TGH1420en/12.2011

2. Safety instructions

2.1 Intended use

The EDS309... is a portable insulation fault location system designed to locate insulation faults in IT

systems. All versions are also suitable for measuring residual currents in TN and TT systems.

The EDS3096PG is particularly suitable for insulation fault location in de-energised systems.

Please take note of the limits for the application area specified in the technical data. Use

deviating from or beyond the scope of this is considered non-compliant.

System interferences and excessively high system leakage capacitances may influence the accuracy of the measurement negatively.

2.2 Device-specific safety instructions

If the test current of the PGH18...... is too high, sensitive loads (e.g. in control circuits) may be damaged or switching operations may be activated unintentionally. Therefore, it is recommended to select a lower test current (1 resp. 10 mA).

In systems with programmable controllers (PLC), only EDS3091 or EDS3091PG

may be used.

The test voltage of DC 50 V in the voltage source (PGH186) integrated in the insulation fault location system EDS3096PG may cause interferences on sensitive

system components. In case of doubt please consult Bender.

The test current of the PGH185 or PGH186 may trigger RCDs. The test current is

limited to max. 25 mA (resp. 10 mA), nevertheless, 30 mA RCDs may be triggered

between 15 and 30 mA.

Inside the measuring clamp, you should aim for the maximum possible symmetry of the conductors.

Due to an excessively high load current, the measuring clamp can reach a saturation state that may cause an alarm message IΔn >10A.

If electrical interferences occur during operation, the device may trip incorrectly

and may indicate incorrect values on the display.

2.3 General safety instructions

In addition to this data sheet, the documentation of the device includes a sheet entitled "Important

safety instructions for BENDER products“.

TGH1420en/12.2011

9

Safety instructions

2.4 Skilled persons

Only skilled persons may work on Bender products. Skilled means, persons

who are familiar with the assembly, commissioning and operation of the equipment and have undergone appropriate training. Such persons must have read this manual and understood all instructions relating to safety.

10

TGH1420en/12.2011

3. System description

3.1 System components

A detailed overview of the scope of delivery is given on page 57.

3.1.1

Overview system components

The main task of the EDS309... is insulation fault location in IT systems. For this purpose, the individual components of the EDS309... are used in combination.

2

1

20

ME

Da SSZA

ten NG

Du bla E /

rch tt

CL

Art.- me / Datas

AM

ss

ma Nr. / Ar er / heetP ON

Di

x. 1

PR

A t.-no. amete: TGH1 OB

E

:B

r

1000600 V

980 : 52 320

mA CAT

694 mm

/ 0,1 III

mA

~

Im

ax

L3

(+

)

L1

L2

3(N)AC 0...575V mit/with 500...790V

DC

0...504V AGE185 400...960V

(-)

10

0m

M A

ON

10

mA

25

mA

Us

PS

A30

ON

52

PSA30

PGH186

3

4

5

1

Aluminium case with carrying strap

2

Measuring clamp PSA3020 (main circuits) or PSA3320 (control circuits)

Inside diameter of the measuring clamp 20 mm

3

Insulation fault test device PGH18...

to generate a test current signal for insulation fault location

4

Insulation fault evaluator EDS190P

for the connection of measuring clamps and for the location of insulation faults

5

Measuring clamp PSA3052 (main circuits) or PSA3352 (control circuits)

Inside diameter of the measuring clamp 52 mm

TGH1420en/12.2011

11

System description

3.1.2

List of insulation fault location system types

All device versions listed below are suitable for residual current measurement in TT and TN systems

(earthed systems).

The different system types and the measuring tasks they can be used for are listed below:

Insulation fault location systems for main circuits

Permissible system voltage ranges for main circuits:

Insulation fault location in IT systems up to AC 42...460 Hz, 20...575 V and DC 20...504 V

Insulation fault location with AGE185 up to AC 42...460 Hz 500...790 V, DC 400...960 V:

EDS3090:

Applicable in IT systems where a PGH471 insulation fault test device or an IRDH575 is already

installed.

EDS3090PG:

Supply voltage of the PGH185 insulation fault test device delivered with the EDS system:

AC 50...60 Hz, 230 V

Applicable in IT systems where neither a PGH471 insulation fault test device nor an IRDH575 is

installed.

EDS3090PG-13:

Supply voltage of the PGH185-13 insulation fault test device delivered with the EDS system:

AC 50...60 Hz, 90…132 V

Applicable in IT systems where neither a PGH471 insulation fault test device nor an IRDH575 is

installed.

Permissible system voltage ranges for main circuits:

Insulation fault location in IT systems up to AC 42...460 Hz, 0...575 V and DC 0...504 V

Insulation fault location with AGE185 up to AC 42...460 Hz 500...790 V, DC 400...960 V:

EDS3096PG:

Supply voltage of the PGH186 insulation fault test device delivered with the EDS system:

AC 50...60 Hz, 230 V

Insulation fault location, also in IT systems with all poles disconnected

Applicable in IT systems where neither a PGH471 insulation fault test device nor an IRDH575 is

installed.

EDS3096PG-13:

Supply voltage of the PGH186-13 insulation fault test device delivered with the EDS system:

AC 50...60 Hz, 90…132 V

Insulation fault location, also in IT systems with all poles disconnected

Applicable in IT systems where neither a PGH471 insulation fault test device nor an IRDH575 is

installed.

12

TGH1420en/12.2011

System description

Insulation fault location systems for control circuits

Permissible system voltage for control circuits:

Insulation fault location in IT systems up to AC 42...460 Hz, 20...265 V and DC 20...308 V.

EDS3091:

Applicable in IT systems where a PGH473 insulation fault test device or an IRDH575 is already

installed.

EDS3091PG:

Supply voltage of the PGH183 insulation fault test device delivered with the EDS system:

AC 50...60 Hz, 230 V

Applicable in IT systems where neither a PGH473 insulation fault test device nor an IRDH575 is

installed.

EDS3091PG-13:

Supply voltage of the PGH183-13 insulation fault test device delivered with the EDS system:

AC 50...60 Hz, 90…132 V

Applicable in IT systems where neither a PGH473 insulation fault test device nor an IRDH575 is

installed.

Insulation fault location system for main circuits and control circuits

EDS3092PG:

It consists of the same components as EDS3090PG and EDS3091PG and combines the features

of the two devices.

3.1.3

Accessories

For details about optional accessories also refer to ordering information and the list of components

on page 56 and page 57.

When working with the EDS309... only use those components which are delivered with the system.

In particular, do not use any other measuring clamps! This also applies to additional measuring clamps or measuring current transformers from the Bender

range which are not exclusively designed for use with EDS309..... .

TGH1420en/12.2011

13

System description

3.2 Function of the system components

3.2.1

PGH18... insulation fault test device

The PGH18... generates a defined test current signal. The test current generated in this manner depends on the size of the present insulation fault and the system voltage.

Depending on the switch position of the PGH185 or PGH186 the test current is limited to a maximum of 25 mA or 10 mA respectively,

the PGH183 limits the test current to a maximum of 2.5 mA or 1 mA respectively.

In deenergised IT systems or in IT systems with a system voltage of < 50 V, the PGH186 drives a

test current through an integrated voltage source (DC 50 V). In IT systems with a system voltage

of > 50 V, the currently available in the system is used to drive the test current.

3.2.2

Insulation fault evaluator EDS190P

The insulation fault evaluator EDS190P provides the following measuring functions:

Insulation fault location IΔS (EDS mode) for use in IT AC systems or DC systems:

–

within the portable EDS309... insulation fault location system or

–

within a permanently installed EDS46.../49.... insulation fault location system.

Residual current measurement IΔn (RCM mode) for use in TN or TT AC systems. The response

value range is listed in the Tabelle 3.1 auf Seite 14.

Response value

The response value is determined by the sensitivity of the EDS190P evaluator. In DC, AC and 3AC IT

systems, this is an arithmetic average value that can be set according to Tabelle 3.1 auf Seite 14. System interferences and excessively high system leakage capacitances may have a negative influence

on the accuracy.

3.2.3

Measuring clamps

Measuring clamps detect the test current signal resp. the residual current. The measuring lead has a

length of approximately 2 m. The connection to the EDS190P is made via a BNC connector.

The most important data of the different measuring clamps are listed in the table below.

Measuring

clamps

Measuring range

IT system

Response value

TN/TT system

Measuring

clamps

Measuring range

Response value

Main circuit

(EDS3090..., 3096...)

Control circuit

(EDS3091...)

PSA3020, PSA3052, PSA3165

PSA3320, PSA3352

2...50 mA

0....5 mA

2...10 mA, ±30 % / ±2 mA

0.2...1 mA, ±30 % / ±0.1 mA

PSA3020, PSA3052, PSA3165

PSA3320, PSA3352

5 mA...10 A

10 mA...10 A

2 mA...2 A

5 mA...1 A

Tab. 3.1: Measuring clamps and response values for EDS190P

If measuring current transformers are to be used instead of measuring clamps, you will need the

adapter delivered with the system: BNC/4 mm plug. See table on page 57.

14

TGH1420en/12.2011

System description

3.2.4

Coupling device AGE185

The coupling device AGE185 extends the nominal voltage range of the insulation fault location system EDS309... . It allows connection to nominal voltage ranges up to

AC 790 V resp. DC 960 V.

3.3 Operating principle of insulation fault location (IΔs)

When a first insulation fault occurs in IT systems, a residual current flows which is essentially determined by the system leakage capacitances. The basic concept in fault location is therefore to close

the fault current circuit for a short period over a defined resistance. As a result of this principle, the

system voltage itself drives a test current containing a signal that can be evaluated.

The test current is generated periodically by the PGH18... insulation fault test device (which is a component of the EDS309...PG system).

Optionally, the test current can also be generated by an IRDH575 or PGH47... insulation fault test device.

The test current is limited in amplitude and time. As this happens, the system conductors are connected alternately to earth via a defined resistance. The test current generated in this manner depends on the value of the present insulation fault and the system voltage.

The test current of the EDS3090 is limited to a maximum of 25 mA, and when Imax = 10mA is set, it is

limited to 10 mA. For planning purposes, it should be noted that no system components are present

in which this test current can bring about a damaging reaction, even in unfavourable cases.

The test current pulse flows from the insulation fault test device via the live parts, taking the shortest

path to the location of the insulation fault. From there, it flows via the insulation fault and the earth

conductor (PE) back to the insulation fault test device. This test current pulse is then detected by the

measuring clamps or measuring current transformers located in the insulation fault path, and is signalled by the connected insulation fault evaluator EDS190P.

You must ensure that all live conductors are routed through the measuring

clamp. Do not route any PE conductors or shields of shielded conductors through

the measuring clamp! Normal commercial measuring clamps are not suitable

for the EDS309... and must not be used.

Only if these notes are observed will you obtain a true measurement result.

Additional information is available in our "Transformer installation" technical

information.

TGH1420en/12.2011

15

System description

3.3.1

Block diagram EDS system

Un

IT-System

L1(L+)

L2(L-)

PSA...

3

2

1

EDS190P

PGH...

RF

PE

3.3.2

EDS190P

Insulation fault evaluator

PGH...

Insulation fault test device

Un

System voltage IT system

PSA...

Measuring clamp

RF

Insulation fault

PE

Protective earth conductor

Test cycle

The duration of the test current pulse cycle is 6 seconds. The PGH... alternately sends positive and

negative test current pulses. The test cycle of the PGH... is shown in different switch positions (1, 2,

3) in the block diagram below (also see block diagram of the EDS system above).

Position

PGH...

1

2 sec

3

4 sec

2

2 sec

3

1

4 sec

EDS Start

16

TGH1420en/12.2011

System description

3.3.3

Terms

IΔs

IΔn

Measured value of the selective fault current of the evaluator unit (EDS mode).

Residual current created by an insulation fault (RCM mode).

3.3.4

Currents in the EDS system

In addition to the block diagram on page 16, the path of the residual currents and the test current is

illustrated in the diagram below:

Un

PSA...

IT-System

IDn, IT

3

1

PGH...

EDS190P

2

CE-V

RF-V

CE-N

RF-N

PE

.............

Test current loop IT

.. .. .. ..

Residual currents IΔn (example)

CE-V

Upstream capacitances, system leakage capacitances upstream the measuring current transformer

CE-N

Downstream capacitances, system leakage capacitances downstream the

measuring current transformer

RF-V

Insulation fault upstream the measuring current transformer

RF-N

Insulation fault downstream the measuring current transformer

The following residual currents flow through the measuring current transformer of the EDS... :

The test current IΤ caused by the insulation fault RF-N

Residual currents IΔn flowing through the system leakage capacitances CE-V and

CE-N resp. caused by RF-V and RF-N,

Transient leakage currents caused by switching and control activities in the system,

Low-frequency leakage currents caused by the use of converters

TGH1420en/12.2011

17

System description

3.4 Operating principle of residual current measurement (IΔn)

In the RCM mode, the EDS309... operates according to the principle of residual current measurement. In this case, only the evaluator unit EDS190P with the measuring clamp is used, the PGH18...

insulation fault test device is not required.

In accordance with Kirchhoff's Law, the sum of the inflowing currents at every intersection in a system is equal to the sum of the outflowing currents.

I from

Ito

P

ME

Da SS

Du ten ZA

Ar rch bla NG

t.- me tt

Nr

/ E

. / ss Da / CL

Ar er tas AM

t.- / Di he

no am et P

ON

.:

B ete : TG PR

98 r H1

OB

0 : 52

3x

xx

x mm x E

S

A

30

52

ID=0

PE

Fig. 3.1: The two currents Ito and Ifrom are equal in quantity but have different directions,

so that the resultant sum is zero. The EDS190P recognises this, no message is generated.

Ito

I from

P

ME

Da SS

Du ten ZA

Ar rch bla NG

t.- me tt

Nr

/ E

. / ss Da / CL

Ar er tas AM

t.- / Di he

no am et P

ON

.:

B ete : TG PR

98 r H1

OB

0 : 52

3x

xx

x mm x E

S

A

30

52

ID =0

RF

PE

Fig. 3.2: A portion of the current is flowing away via an insulation fault RF. The sum of the currents is

no longer zero. If the residual current is equal to or greater than the response value,

the EDS190P will generate a message.

In the RCM mode, residual currents can be measured in one and three-phase TT

or TN systems. If the system leakage capacitance upstream of the measuring

clamp is sufficiently high, the EDS190P can also be used for measurements in one

and three-phase IT systems. Its suitability for this purpose must be checked in

each individual case.

18

TGH1420en/12.2011

4. Points to be considered before use

4.1 How does an insulation fault location system work?

An insulation fault location system consists of a PGH18...insulation fault test device and an EDS190P

insulation fault evaluator in combination with a PSA3.... measuring clamp.

Functional sequence

Start insulation fault location by activating the PGH18... insulation fault test device

The PGH18... insulation fault test device for a short period connects the live conductors to earth

via an electronic current limiting device.

A test current IT which is dependent on the system voltage and on the value of the insulation

fault flows and closes the fault current circuit. The test current is limited to a maximum value of

25 mA resp. 10 mA (PGH185/186) or 2.5 mA resp. 1 mA (PGH183).

The test current pulse flows from the insulation fault test device via the live conductors, the

insulation fault RF and the earth conductor (PE conductor) back to the insulation fault test

device.

This current pulse can be detected by enclosing the outgoing conductors of the distribution

point, located in the current circuit, with the measuring clamp and can be evaluated with the

EDS190P insulation fault evaluator.

By measuring along the cable with the measuring clamp, the point of the fault can be located

precisely.

PSA...

PGH18...

EDS190P

Fig. 4.1: Function of the EDS system

TGH1420en/12.2011

19

Points to be considered before use

4.2 Requirements for reliable insulation fault location

The task of the insulation fault evaluator is to detect insulation faults downstream of the measuring

clamp RF-N. It is designed to recognise reliably the test current caused by the insulation fault for this

purpose.

Requirements:

The insulation fault must be present for at least 30 seconds.

The test current range:

– for main circuits with EDS3090, EDS3090PG, EDS3090PG-13, EDS3096PG is: It = 2...50 mA

– for control circuits with EDS3091, EDS3091PG, EDS3091PG-13 is: It = 0.2...5 mA

The upstream capacitances CE-V must be at least as large as the downstream capacitances CE-N.

The total system leakage capacitance must not exceed the following values:

– for main circuits with EDS3090, EDS3090PG, EDS3090PG-13, EDS3096PG: up to 30.000 μFV

(product of the system leakage capacitance and nominal system voltage)

– for control circuits with EDS3091, EDS3091PG, EDS3091PG-13: up to 1.000 μFV (product of

the system leakage capacitance and nominal system voltage)

The sum of the test current and residual current flowing through the measuring clamp and the

measuring current transformer must not exceed the following values:

– for main circuits with EDS3090, EDS3090PG, EDS3090PG-13, EDS3096PG-13: 10 A

– for control circuits with EDS3091, EDS3091PG, EDS3091PG-13: 1 A

There must not be any connections to other sub-distributions downstream a measuring clamp

or an installed measuring current transformer, see the illustration below.

Fig. 4.2: Connections between sub-distributions lead to measuring errors

Not only does the value of the residual current influence the reliable detection of the test current but also the respective frequency of the residual current. Residual currents deviating from

the system frequency may be caused by the use of frequency converters, for example. The

behaviour of the EDS309... is described in the fault curve illustrated below:

– When the measured residual current values exceed a value of 10 A in main circuits, the

EDS190P outputs the alarm message „IΔn>10A“.

This applies to nominal system frequencies of 50/60/400 Hz

for EDS3090, EDS3090PG, EDS3090PG-13, EDS3096PG and EDS3096PG-13.

20

TGH1420en/12.2011

Points to be considered before use

– When the measured residual current exceeds a value of 1 A in control circuits, the EDS190P

outputs the alarm message IΔn>1A“.

This applies to nominal system frequencies of 50/60/400 Hz

forEDS3091, EDS3091PG and EDS3091PG-13.

– When residual currents of nominal system frequencies below 50 Hz occur, the message

"Fault" will be generated.

Example:

When a residual current of 2 A with a frequency of 20 Hz occurs (red dot in the diagram), the

insulation fault location system is outside the permissible measuring range and the message "Fault" appears on the display of the EDS190P.

Fig. 4.3: A residual current value of 2 A is outside of the permissible frequency range (red dot)

Sub-distributions downstream of the measuring clamp must not be galvanically

connected with each other, because such connections create disturbing residual

currents.

As a result, the message "Fault" or "IΔn>10A“ may be output, for example.

Symmetrical insulation faults downstream of the measuring current transformer may not be recognised under certain circumstances. Low-frequency residual

currents (caused by converters, for example) may have the effect that insulation

faults cannot be found when their frequency is equal or nearly equal the test cycle frequency of the PGH186.

Cables leading to the same load in parallel are to be passed together through the

measuring clamp during the measurement.

TGH1420en/12.2011

21

Points to be considered before use

4.3 Reduced test current

Especially in DC control voltage systems in the power station and energy supply utility sector, relays

or SPCs might be installed which switch already in case of relatively low currents. In such a case, the

switch Imax on the PGH18... must be moved to 10/1 mA position. The test current limiting values

10 mA and 25 mA indicated on the switch only applies to DC systems.

Prior to measurements with the EDS3090.. with reduced test current (switch position 10/1 mA), it is

also necessary to check whether any sensitive system components can be caused to operate unintentionally.

4.4 Characteristic curves on the response sensitivity of EDS190P

The type of supply system, system voltage, system frequency, leakage capacitance and test current

have an effect on the response sensitivity of the EDS system. The value of the test current can be set

at the PGH18... insulation fault test device. Resulting from the type of supply system, the real test current in AC systems is lower than the setting. In comparison to DC systems, the factor is 0.5 in AC systems respectively 0.67 in 3AC systems. For use in AC and 3AC systems, set the response value at the

EDS190P as follows:

Application

Insulation fault location system

Setting EDS190P

Maximum test current Menu

2.5: IΔs max

Setting PGH18...

Test current IT

Response range EDS190P

Menu 3.2

Setting PGH18...

Reduced test current IT

Response range EDS190P

Reduced test current

Menu 3.2

Main circuit

Control circuit

EDS3090

EDS3090PG

EDS3090PG-13

EDS3096PG

EDS3091

EDS3091PG

EDS3091PG-13

max. 50 mA

max. 5 mA

25 mA

(PGH185/186)

2.5 mA

(PGH183)

2...10 mA

0.2...1 mA

10 mA

(PGH185/186)

1 mA

(PGH183)

2...5 mA

0.2...0.5 mA

Tab. 4.1: Settings on the insulation fault location system

For details on the setting of the response value, refer to “Setting menu 3: (Settings IΔs) on page 37.

The response values are shown as characteristic curves. The maximum deviation can be +/- 30 %, including the tolerances of the measuring clamps. The characteristic curves apply to the respective

nominal voltage indicated in the diagram.

If the nominal voltage of the system being monitored is different from the nominal voltage shown

in the diagram, the response values may change proportionally. Nominal voltages changing dynamically during operation or in case of superimposed alternating currents that deviate from the system

frequency (e.g. caused by frequency converters) or superimposed direct currents may result in response values that are outside the range displayed in the diagram.

The following curves makes light work of determining a correct and practical response value for this

EDS190P. When the insulation monitoring device shows an alarm message in a system being monitored, manual insulation fault location can be started. Proceed as follows:

1. Select the characteristics (3 AC, AC, DC) that are appropriate for your type of distribution system.

22

TGH1420en/12.2011

Points to be considered before use

2. From these, select the diagram that best matches the desired system voltage.

3. Calculate the anticipated leakage capacitance of the system being monitored. Insulation monitoring devices of the IRDH... series can display the value of the leakage capacitance (press the

INFO key). Apply this value to the diagram in the form of a vertical line.

If it is not possible to query the leakage capacitance, the respective highest value is to be taken

from the characteristic curve.

4. The curves show the response sensitivity values 2 mA, 5 mA and 10 mA set for the EDS190P for

main circuits and 0.2 mA, 0.5 mA and 1 mA for control circuits. Values above the respective

curve cannot be detected. Values and characteristics that fall between the top and bottom

characteristics can be roughly determined on the basis of those actually provided.

5. Set the respective response value on the EDS190P.

6. The curves for DC 24 V and AC 42 V do not apply to the EDS3096 because the insulation fault

test device works with its own test voltage of DC 50 V. For this reason, the curves for DC 60 V

and AC 110 V are valid for these nominal voltages.

Response characteristic curves for main circuits in 3AC systems

3AC 230 V

80

2mA

5mA

10mA

70

60

50

Re [kOhm]

Re [kOhm]

4.4.1

2mA

5mA

10mA

120

100

80

40

60

30

40

20

20

10

0

0

0

0

50

100

40

60

80

2mA

5mA

10mA

100

Ce [µF]

3AC 500 V

200

180

160

140

120

100

80

60

40

20

0

20

150

Ce [µF]

Re [kOhm]

Re [kOhm]

3AC 400 V

140

3AC 690 V

250

2mA

5mA

10mA

200

150

100

50

0

0

10

20

30

40

50

60

Ce [µF]

TGH1420en/12.2011

0

10

20

30

40

50

Ce [µF]

23

Points to be considered before use

4.4.2

Response characteristic curves for main circuits in AC systems

Re [kOhm]

Re [kOhm]

AC 42 V

8

2mA

5mA

10mA

6

AC 110 V

25

2mA

5mA

10mA

20

15

4

10

2

5

0

0

50

100

150

200

250

0

300

0

50

100

150

200

250

Ce [µF]

300

Ce [µF]

2mA

5mA

10mA

60

20

0

50

100

150

Ce [µF]

0

20

40

60

80

100

Ce [µF]

Response characteristic curves for main circuits in DC systems

DC 24 V

10

9

8

7

6

5

4

3

2

1

0

Re [kOhm]

Re [kOhm]

2mA

5mA

10mA

80

40

4.4.3

2mA

5mA

10mA

DC 60 V

30

2mA

5mA

10mA

25

20

15

10

5

0

100

200

300

400

0

500

Ce [µF]

0

2mA

5mA

10mA

100

90

80

70

60

50

40

30

20

10

0

100

200

300

Ce [µF]

DC 110 V

60

50

40

30

20

10

0

0

50

100

150

200

250

300

Ce [µF]

24

100

Re [kOhm]

Re [kOhm]

50

45

40

35

30

25

20

15

10

5

0

0

Re [kOhm]

Re [kOhm]

AC 400 V

AC 230 V

DC 230 V

2mA

5mA

10mA

0

50

100

150

Ce [µF]

TGH1420en/12.2011

Points to be considered before use

Response characteristic curves for control circuits in AC systems

AC 42 V

80

Re [kOhm]

Re [kOhm]

4.4.4

0,2mA

0,5mA

1,0mA

60

0,2mA

0,5mA

1,0mA

150

40

100

20

50

0

AC 110 V

200

0

0

5

10

15

20

25

Ce [µF]

0

2

4

6

8

10

Ce [µF]

Re [kOhm]

AC 230 V

600

0,2mA

0,5mA

1,0mA

500

400

300

200

100

0

0

1

2

3

4

5

6

Ce [µF]

4.4.5

Response characteristic curves for control circuits in DC systems

DC 60 V

250

0,2mA

0,5mA

1,0mA

200

150

100

50

0

0

Re [kOhm]

Re [kOhm]

0,2mA

0,5mA

1mA

10

20

30

40

50

60

Ce [µF]

0

5

10

20

DC 230 V

DC 110 V

500

15

Ce [µF]

0,2mA

0,5mA

1,0mA

400

300

Re [kOhm]

Re [kOhm]

DC 24 V

100

90

80

70

60

50

40

30

20

10

0

800

0,2mA

0,5mA

1,0mA

600

400

200

200

100

0

0

0

2

TGH1420en/12.2011

4

6

8

10

Ce [µF]

0

1

2

3

4

5

6

Ce [µF]

25

Points to be considered before use

26

TGH1420en/12.2011

5. Commissioning and connection

Prior to commissioning make sure that the supply voltage of the PGH18... and of

the power supply unit (as appropriate) corresponds to the voltage of the supplying system. When the devices are operated with wrong supply voltage, the devices may be damaged.

Prior to commissioning, please check that all system components are connected

to each other.

5.1 Decoupling the insulation monitoring device

While insulation fault location is being undertaken with the EDS309..., an existing insulation monitoring device must be disconnected from the system for the duration of the fault location, if its internal resistance Ri is < 120 kΩ. This must be done by effecting an all-pole interruption of the system

coupling, it is not sufficient to switch off the supply voltage to the insulation monitoring device.

When a device is used with an Ri of ≥ 120 kΩ, the influence is negligible, and in this case there is no

need to disconnect. However, take into consideration that the PGH influences the measurements of

the insulation monitoring device.

5.2 Deenergised systems

For insulation fault location in deenergised systems with EDS3096PG, the integrated voltage source

(G) of the PGH186 provides a test voltage of DC 50 V.

The test voltage DC 50 V supplied by the PGH186 is available at the socket L1(+). Make sure that this

socket is connected to the system to be monitored. Only in this way, the integrated voltage source

of PGH186 will be available.

Please note that all live conductors of the system to be searched must be connected to each other via loads or the deenergised power supply.

US = 0 V

IT-System

L1(L+)

L2(L-)

PSA...

+

L1

G

-

EDS190P

RF

3

PE

TGH1420en/12.2011

1

2

PGH186

27

Commissioning and connection

5.3 Connection to an IT system

Connect the EDS309... as described below:

3 AC - System

3/N AC - System U

n

PE

L1 L2 L3

AC - System

L1

L2

L3

N

PE

L1

Un

L2

PE

PE

L1

L2

DC - System

L+

Un

LL1 L2

If the terminals L1, L2, L3 (resp. L1, L2) of the device are connected to a live system

under operation, the terminal must not be disconnected from the protective

conductor (PE).

28

TGH1420en/12.2011

6. Operation

6.1 Brief description of insulation fault location (EDS mode)

6.1.1

Commissioning of the PGH18... for test current supply

1. First, connect the PGH18... to the PE of the system to be checked, see page 28

2. Then connect the PGH18... to active conductors

3. Connect the device to US and switch it on

If the test current IT is to be generated by an IRDH575, its menu item EDS-Setup has to be set to

EDS=On.

6.1.2

Insulation fault location with EDS190P

1. Connect the measuring clamp to the EDS190P

2. Switch the device on with the On/off button

3. A self test is carried out, wait until the message OK appears

4. Check whether the right measuring clamp has been set on the EDS190P

5. Enclose the PE conductor between PGH18... (IRDH575) and/or the PE bar with the measuring

clamp in order to prove the test current IT

6. Enclose the functionally related active conductors of the respective sub-distributions with the

measuring clamp.

Warning! Do not enclose the PE!

7. Read and evaluate the measured value.

If the set response value has been exceeded, the message alarm appears on the display

with the alarm LED flashing.

TGH1420en/12.2011

29

Operation

6.2 Operating elements of the PGH18...

1

1

Im

ax

2

10

ON

(-)

L2

L1

(+

)

3(N)AC 0...575V mit/with 500...790V

DC

0...504V AGE185 400...960V

L3

10

6

0m

M A

mA

25

7

mA

Us

ON

8

PGH186

3

5

30

4

1

ON/OFF switch, activates the test current

2

Selector switch for the maximum test current 25 / 10 mA or 2.5 / 1 mA

3

Not visible: Magnetic adhesive strip at the back of the enclosure for fixing to metal parts

(e.g. switchboard cabinet)

4

3 sockets for system coupling

5

Socket for PE connection

6

LED indicators:

Power ON LED

Indication of the positive test cycle of the test current

Indication of the negative test cycle of the test current

7

Microfuse 100 mA

8

Panel plug for supply voltage

TGH1420en/12.2011

Operation

6.3 Display and operating elements of the EDS190P

1

2

3

4

5

6

12

11

7

8

10

9

1

Connection for external power supply unit DC 6 V

2

BNC connection for the measuring clamp

3

LC display, illuminated

3 lines a 16 characters

4

Alarm LED, lights when the response value is exceeded

5

Button for the selection of the operating mode:

IΔS = Insulation fault location in IT systems (EDS mode)

IΔn = Residual current measurement in TN-S systems (RCM mode)

IDs

IDn

6

Button to select the measuring current transformer

for ITmax = 50 mA:

for ITmax = 5 mA:

P20

= PSA3020 = PSA3320

P52

= PSA3052 = PSA3352

P165 = PSA3165 --------------W/WR = W.... / WR.... = W...-8000

WS

= WS....

= W...-8000

7

INFO key:

- Device type

- Software version

- Current response values IΔS and IΔn

- Setup status

ESC key:

Exits the menu function without changing parameters

ESC

TGH1420en/12.2011

INFO

31

Operation

8

MENU

9

On-Off button

10

32

MENU key:

To start the Menu mode

Enter key:

To confirm changed parameter values or the selected menu items

Illumination button: On /Off switching of the display illumination

11

RESET

RESET button: To clear the fault memory

DOWN key: To move down in the menu, to decrease the parameter value

12

HOLD

HOLD button: To save the measured value

UP key: To move up in the menu, to increase the parameter value

TGH1420en/12.2011

Operation

6.4 Operation of the EDS190P

6.4.1

Switching the device on and off

1. Prior to commissioning, connect a measuring clamp (e.g. PSA3052) to the EDS190P!

2. Switch the device on by means of the On/Off button.

Once the device is switched on, the self test is started.

When the self test runs correctly, the message "Test OK“ appears on the display.

The device is factory set to the EDS mode.

Press the On/Off button for approximately 2 seconds to switch the device off.

1. Display indication

EDS190P

when starting

BENDER GmbH&CoKG

D-35305 Grünberg

for approx. 3 s

2. Display indication

when starting

for approx. 10 s

3. Display indication

when starting

for approx. 3 s

EDS190P

Self-test

>> >> >> >>

EDS190P

Self-test

TEST OK

Fig. 6.1: Starting sequence of the EDS190P

6.4.2

Display illumination provides improved readability

Press the illumination button on the bottom left in order to improve the readability of texts and symbols.

By pressing the button again the illumination can be switched off.

6.4.3

Switching between the operating modes insulation fault location IΔS and residual current measurement IΔn

Here, the measuring functions can be selected. IΔn for residual current measurement preferably for

TN-TT systems. IΔs for insulation fault location in IT systems.

Avoid changing the operating mode during insulation fault location.

TGH1420en/12.2011

33

Operation

6.4.4

Display elements and their meaning

Insulation fault location is carried out in the EDS mode, as illustrated in the figure below.

12

1

2

11

3

10

9

8

7

6

5

4

1

Progress bar to show the measurement progress in the EDS mode

2

Indication of the test current pulse:

= positive impulse,

idle time,

= negative impulse

3

Type of distribution system: AC, DC

4

Hold function activated; Measured value indication "frozen“

5

Charge status of the accumulators

6

Alarm output activated via LED

7

Loudspeaker symbol visible:

An existing alarm will also be output acoustically.

8

Fault memory M is activated

9

Selected measuring current transformer

for ITmax = 5 mA:

for ITmax = 50 mA:

P20

= PSA3020

= PSA3320

P52

= PSA3052

= PSA3352

P165

= PSA3165

--------------W/WR

= W.... / WR....

= W...-8000

WS

= WS....

= W...-8000

10

Selection of the measuring sensitivity

= Control circuit = ITmax = 5 mA

= Main circuit = ITmax = 50 mA

34

11

IΔn = Indication of the currently flowing residual current

12

IΔS = Indication of the currently flowing test current

TGH1420en/12.2011

Operation

6.5 Standard displays of the EDS190P

6.5.1

Standard display without enclosing the cable to be measured

The device is in the EDS mode (IΔS ).

IΔS will not be indicated, because no conductor is enclosed with the measuring clamp.

>> >> >>

I s = 0mA

I n < 100mA

P52

M

H

AC

Standard display in the EDS mode (IΔS) with the cable enclosed

The display shows a measured fault current IΔS of 10 mA. A new measurement is being carried out.

This is indicated by the progress bar represented as an angle.

6.5.2

I s = 10mA >> >> >>

I n < 100mA

P52

M

H

AC

Please note that only 50% of the value of the test current IT created by the PGH18... in AC systems is

indicated by the EDS190P. One-way rectifiers used in the PGH18... decreases the indicated value in

AC systems to 50 %, in 3AC systems to 67 %.

Standard display in the RCM mode (IΔn) with the cable enclosed

The display shows a measured residual current IΔn of 160 mA.

The set residual current response value is 1000 mA.

6.5.3

I n = 160mA

Resp. = 1000mA

P52

M

H

AC

The following display shows a standard indication with menu item

"4.Harmonics on“ activated. This setting is only possible for systems with a frequency of 50 Hz and

60 Hz. The display shows a measured current of 4 mA as well as harmonic distortion of 64 % for the

first harmonics.

I n = 6.0mA

H1=4mA

P52

M

THD=64%

H

50Hz

6.6 Alarms in the EDS or RCM mode

When one of the set response values IΔs or IΔn are exceeded, the message alarm appears on the display.

I s = 10mA Alarm

Next Measurement

P52

M

H

AC

I n = 160mA Alarm

Resp. = 100mA

P52

TGH1420en/12.2011

M

H

Alarm during insulation fault location

Alarm during an RCM measurement

AC

35

Operation

6.7 Indication of device and measuring errors

Fault messages possible to occur are explained in the table below.

No CT connected

P52

M

H

AC

Short Circuit CT

P52

M

H

AC

No measuring clamp or no measuring current

transformer at the measuring input or wrong measuring current transformer connected

Actions:

Connect the appropriate measuring clamp or

measuring current transformer

Short circuit in the measuring clamp or measuring

current transformer or wrong transformer type

connected.

Actions:

Connect intact and appropriate measuring clamp

A fault occurred during insulation fault location

(EDS mode).

Possible causes:

The measuring clamp is not held steady.

Fault

I s = 0mA

I n < 100mA

P52

M

H

AC

A residual current is flowing through the measuring clamp which disturbs the measurement.

A magnetic field exists in the vicinity of the measuring clamp which disturbs the EDS measurement.

6.8 Factory settings EDS190P (delivery condition)

Most of the parameters are set in the menu. If this is not the case, the setting is market with (button).

Button operating mode:

Button transformer selected:

Button illumination:

Memory:

Alarm LED:

Buzzer:

Test current ITmax:

Response value (for IΔs):

Type of distribution system (for IΔs):

System with converter (for IΔs):

Response value (for IΔn):

System frequency (for IΔn):

Measurement of the harmonics (for IΔn):

Language in the display:

Time:

36

IΔs (EDS mode = insulation fault location)

Measuring clamp PSA3052 (EDS3090 and 3096)

Measuring clamp PSA3352 ( EDS3091)

off

off

on

on

50 mA (EDS3090 and 3096)

5 mA (EDS3091)

5 mA (EDS3090 and 3096)

500 μA (EDS3091)

AC

no

100 mA

50 Hz

off

English

CET

TGH1420en/12.2011

Operation

6.9 Menu structure

A schematic sketch of the menu structure is shown below.

Level 1

Level 2

Level 3

1. Exit

2. Settings

3. View harmonics

4. Service

1. Exit

2. General

1. Exit

2. Memory: on/off

3. Buzzer: on/off

4. AlarmLED: on/off

5. ITmax: 5mA / 50mA

3. IΔs

1. Exit

2. Resp.: 2...10mA / 200...1000μA

3. System type: AC/DC

4.Inverter: yes / no

4. IΔn

1. Exit

2. Resp: 10...10000mA

3. Freq: 50Hz / 60Hz / up to 2kHz

4. Harmonics: on/off

5. System

1. Exit

2. Language: German / English / French

3.Clock

1. Exit

2. H1= 0 mA

3. H2= 0 mA

.....

9. H8= 0 mA

10. H9= 0 mA

This menu item exclusively serves the purpose of

displaying the harmonics from H1 to H9.

If you want to view the occurring harmonics in

the standard display outside the menu, you have

to activate the menu item "4. Harmonics:

For

service purposes

only

6.10 Navigation within the menu

TGH1420en/12.2011

- Starting the menu mode with MENU

- Selection of the menu item

or confirming a a value with Enter

MENU

- Navigating up or down in the menu

- increasing or decreasing values

HOLD

ESC:

- To exit the selected menu item

- To exit the modified setting without

saving

INFO

RESET

ESC

37

Operation

All menu descriptions below are based on the factory settings. These settings are given in brackets

after the menu items of level 3.

6.11 Menu item: Settings / General

Alarms are always signalled on the display. In delivery condition, alarms are also signalled by an

alarm LED and a buzzer.

You can use these menu items to set whether:

alarms are to be saved

alarms are not to be signalled acoustically

alarms are not to be signalled by an alarm LED

the measuring sensitivity of the EDS190P is to be adapted to the test current of a control or

main circuit.

A maximum test current IT of 5 mA is to be used for control circuits, and maximum test current

of 50 mA for main circuits.

Level 1

Level 2

2. Settings

1. Exit

2. General

Level 3

1. Exit

2. Memory: on / off (off )

3. Buzzer: on / off (on)

4. AlarmLED: on / off (on)

5. ITmax: 5mA / 50mA (50mA), (EDS3090/3096)

(5mA), (EDS3091)

6.12 Menu item: Settings / IΔs

Use this menu item to set all relevant parameters for insulation fault location:

the IΔS response value for control circuits in the range of 200...1000 μA.

This value range is specified by the value ITmax = 5 mA.

Or the IΔS response value for main circuits in the range of 2...10 mA.

This value range is specified by the value ITmax = 50 mA.

Adaption to the system to be monitored: AC or DC.

Select yes, if a converter is operated in the system to be monitored.

Level 1

2. Settings

Level 2

1. Exit

3. IΔs

38

Level 3

1. Exit

2. Response value: 2...10mA / 200...1000μA

3. Supply system: AC/DC

4. Inverter: yes / no

TGH1420en/12.2011

Operation

6.13 Menu item: Settings / IΔn

Use this menu item to set all relevant parameters for residual current measurement:

Set the IΔn response value between 10 mA and 10 A.

Set the frequency of the system being monitored here.

If you want to view the currents of the occurring harmonics on the standard display, activate

the menu item "4. Harmonics“. When the Harmonics menu has been activated, please note that

only system frequencies of 50 Hz and 60 Hz can be selected.

Level 1

Level 2

Level 3

1. Exit

2. Settings

1. Exit

4. IΔn

1. Exit

2. Resp.: 10...10000mA

3. Freq.: 50Hz / 60Hz / up to 2kHz

4. Harmonics: on/off

6.14 Menu item: Settings / system

Use this menu item to select the appropriate display language and set the correct date and time. For

setting the date, different formats can be selected.

Level 1

Level 2

Level 3

1. Exit

2. Settings

1. Exit

5. System

1. Exit

2. Language: German / English / French

3.Clock

6.15 Menu item: View harmonics (Harmonics)

This menu item exclusively serves the purpose of displaying the harmonics from H1 to H9.

Level 1

Level 2

Level 3

1. Exit

2. H1= 0 mA

3. H2= 0 mA

.....

9. H8= 0 mA

10. H9= 0 mA

This menu item exclusively serves the purpose of

displaying the harmonics from H1 to H9.

If you want to view the occurring harmonics in

the standard display outside the menu, you have

to activate the menu item "4. Harmonics: on/off“.

1. Exit

3. View Harmonics

TGH1420en/12.2011

39

Operation

6.16 Practical use

6.16.1 Use as a portable insulation fault location system

The primary application of the EDS309... is as a portable insulation fault location system in IT systems.

After all the information of the chapter “Points to be considered before use” auf Seite 19 has been

considered, the actual fault location operation may be started. Proceed as follows:

1. Check that the nominal system voltage is within the permissible limits.

2. Connect up the PGH18... near the supply input. When you do this, you must comply with the

general guidelines for live work!

– Before making a connection to the system to be checked, connect the green-yellow conductor over the PE socket of the PGH18... with the PE of the system.

– Only then, connect the PGH18... to the system to be checked using the connecting cable

supplied with the device

Three-phase system

Connect the sockets L1, L2 and L3.

Single-phase system AC or DC

Connect the sockets

L1 and L2.

3. Connect the PGH18... to a suitable supply voltage (see nameplate) using the power supply

cable supplied with the device.

4. If the insulation monitoring device which is present in the IT system has an internal resistance

of < 120 kΩ, effect an all-pole interruption of the system coupling. It is not sufficient to switch

off the supply voltage to the insulation monitoring device.

5. Set the switch position Imax on the PGH18.... Refer to the instructions in the chapter “Reduced

test current” auf Seite 22.

6. Switch the PGH18... on. The "ON" LED must light up, the two LEDs "

" and "

" must

light up in time with the cycle and then go out again. If the LEDs fail to show any activity whatsoever, the supply voltage and the microfuse installed in the PGH18... should be checked.

7. Connect a suitable measuring clamp or a measuring current transformer to the EDS190P.

8. Switch on the EDS190P by pressing the On/Off button.

9. Make the following settings:

– Select the function IΔS (EDS mode) by pressing the button

– Set the maximum sensitivity:

50 mA for main circuits for EDS3090, EDS3090PG, EDS3090PG-13, EDS3096PG-13, the measuring clamps PSA3020, PSA3052, PSA3165 and the measuring current transformers W/

WR…, WS… .

5 mA for control circuits for EDS3091, EDS3091PG, EDS3091PG-13, the measuring clamps

PSA3320, PSA3352 and the measuring current transformers W…8000, WS…8000

– Select the measuring clamp or the measuring current transformer to be used with the button.

– Set the supply system of the system to be monitored in the menu 2.3 (setting IΔs).

– Select yes in menu 3 (setting IΔs) if frequency converters are connected to the sub-distributions to be checked.

10. When using measuring clamps please note:

– Do not connect the core of the measuring clamp to system voltages above the nominal

insulation voltage.

– Keep the contact surfaces of the measuring clamp clean.

40

TGH1420en/12.2011

Operation

– The measuring clamp should not be used in the immediate vicinity of devices which generate magnetic fields, such as transformers or throttles, nor in the vicinity of adjacent conductors with high operating currents.

– Do not disconnect the measuring clamp from the EDS190P when live conductors are routed

through the measuring clamp. Failure to observe this can destroy the measuring clamp!

– Inside the measuring clamp, you should aim for the maximum possible symmetry of the

conductors.

Due to excessive load current, the measuring clamp can reach a saturation state that may

cause an alarm message IΔn >10 A.

– Keep the measuring clamp steady during the measurement!

– Make sure that you do not exert any pressure on the measuring clamp arms.

11. Enclose the green-yellow conductor with the measuring clamp between the PGH18... and

earth. When the EDS190P does not react, the insulation fault is too high and cannot be found.

Recognised test current pulses are indicated by the symbol

.

12. Start insulation fault location at the main distribution point in the IT system. Enclose all system

conductors, but not the PE conductor, with the measuring clamp. For each measurement, wait

for one test cycle (approx. 30 seconds). An alarm message on the EDS190P display signals an

insulation fault downstream of the measuring clamp. It is recommended to carry out fault location with the buzzer activated.

The EDS190P can display the following messages during insulation fault location:

– No CT connected:

Measuring clamp or measuring current transformer not connected or defective.

– Fault:

The measuring clamp is not held steady.

A residual current disturbing the EDS measurement is flowing through the measuring

clamp.

A magnetic field exist in the vicinity of the measuring clamp which disturbs the EDS measurement.

In these cases, the insulation fault cannot be located in the respective sub-distributions

resp. at the location of measurement.

– IΔn >10A / >1A:

A residual current of > 10 A bzw. >1A flows through the measuring clamp. In this case, the

insulation fault cannot be located in the respective sub-distribution. Residual currents of

this size occurring in an IT system can be caused by high system leakage capacitances or by

multiple insulation faults. Therefore, it is possible that this alarm message also signals an

insulation fault in this sub-distribution.

– >>>>:

Measurement is running, this display shows the progress of the measurement. This process

will be completed after approximately 30 seconds.

– Next measurement:

No insulation fault found in this sub-distribution. The measuring clamp or the measuring

current transformer can be moved to the next sub-distribution.

– Alarm ...mA:

An insulation fault has been detected in this sub-distribution. Measurement should be continued along this conductor.

13. Measure along the conductor with the EDS190P until the fault is found. Penetrate radially into

the sub-distributions as you do this. The fault location is found when the test current generated by the PGH18... downstream of the measuring clamp at least exceeds the preset response

TGH1420en/12.2011

41

Operation

value of the EDS190P.

For operating currents < 10 A, it is also possible to enclose one conductor only.

For currents > 10 A, this may produce the effect that the measuring clamp can no

longer be opened. This danger is particularly present in DC systems. If this behaviour occurs, under no circumstances use force, since this would destroy the measuring clamp. Instead, you must disconnect the respective system. After this has

been done, the measuring clamp can be opened without the application of

force.

6.16.2 Using the EDS190P within a permanently installed EDS system

The EDS190P can also be used in a permanently installed EDS system (EDS460/490 resp. EDS461/

491). In extended IT systems with a number of sub-distributions, often only the main distributions

are monitored by a permanently installed EDS system. When the main distribution where the insulation fault exists is recognised, the search will be continued from that point using the EDS190P.

For this purpose, the EDS190P uses the test current pulse of the permanently installed EDS system

(IRDH575, PGH47...). The PGH18... is not required for this application. The scope of delivery of the

EDS3090 and EDS3091 systems does not include a PGH18.... Insulation fault location can only be carried out in energised IT systems. Also observe the operating instructions of the permanently installed

EDS system.

Example: The insulation monitoring device has signalled an insulation fault below its response value

and has started the permanently installed EDS system. The main distribution affected by an insulation fault has been recognised. Continue insulation fault location as follows:

1. Set the EDS system mode to permanent insulation fault location:

– IRDH575: Set "EDS on"

– PGH471: Press the "Start/Stop" button

2. Connect a suitable measuring clamp to the EDS190P.

3. Switch on the EDS190P by pressing the On/Off button.

4. Make the following settings:

–Select function IΔs (EDS mode) with the button

–Set the maximum sensitivity:

50 mA for main circuits for EDS460/490 for the measuring clamps PSA3020, PSA3052,

PSA3165 and the measuring current transformers W/WR…, WS…

5 mA for control circuits for EDS461/491 for the measuring clamps PSA3320, PSA3352 and

measuring current transformers W…8000, WS…8000

– Select the measuring clamp or the measuring current transformer to be used with the button.

– Set the supply system of the system to be checked in the menu 2.3 (setting IΔs).

– Select yes in menu 2.3 (setting IΔs) if frequency converters are connected to the sub-distributions to be tested.

5. When using measuring clamps, please note:

– Do not connect the core of the measuring clamp to system voltages above the nominal

insulation voltage.

42

TGH1420en/12.2011

Operation

– Keep the contact surfaces of the measuring clamp clean.

– The measuring clamp should not be used in the immediate vicinity of devices which generate magnetic fields, such as transformers or throttles, nor in the vicinity of adjacent conductors with high operating currents.

– Do not disconnect the measuring clamp from the EDS190P when live conductors are

enclosed by the measuring clamp. Otherwise the measuring clamp may be destroyed!

– Inside the measuring clamp, you should aim for the maximum possible symmetry of the

conductors. Due to excessively high load current, the measuring clamp can reach a saturation state that may cause an alarm message IΔn >10A.

– Keep the measuring clamp steady during the measurement!

– Make sure that you do not exert any pressure on the measuring clamp arms.

– Enclose the green-yellow conductor with the measuring clamp between the IRDH575 resp.

PGH47... and earth. When the EDS190P does not react, the insulation fault is too high and

cannot be found. Recognised test current pulses are indicated by the symbol

.

6. Start insulation fault location in the sub-distribution of the IT system recognised to be faulty.

Enclose all system conductors, but not the PE conductor, with the measuring clamp. For each

measurement, wait for one test cycle (approx. 30 seconds). An alarm message on the EDS190P

display signals an insulation fault downstream of the measuring clamp. It is recommended to

carry out fault location with the buzzer activated.

The EDS190P can display the following messages during insulation fault location:

– No CT connected:

Measuring clamp or measuring current transformer not connected or defective.

– Fault:

Measuring clamp is not held steady. A residual current flows through the measuring clamp

affecting the EDS measurement.

A magnetic field exist in the vicinity of the measuring clamp which disturbs the EDS measurement.

In these cases, the insulation fault cannot be located in the respective sub-distributions