don`t miss a beat. total compliance with equipment - Bender-UK

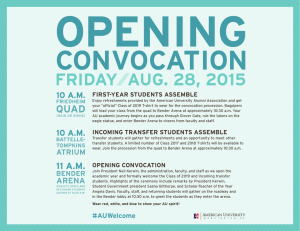

advertisement

DON’T MISS A BEAT. TOTAL COMPLIANCE WITH EQUIPMENT PACKAGES FROM BENDER. Our complete packages include… 4 IPS/UPS systems 4 Touch screen theatre panels 4 Surgical lights 4 Fixed and multi-movement pendants 4 Surgical Operating Tables 4 OR Integration Systems 4 MEIGaN products 4 Turnkey theatre packages 4 Annual and periodic inspection and verification inline with the requirements of HTM06-01 Part B and BS7671 17th Ed Amd 1 4 Maintenance and service contracts with 24hr call out cover BENDER UK Ltd Ulverston Cumbria e info@bender-uk.com t +44 (0)1229 480123 www.bender-uk.com THE POWER IN ELECTRICAL SAFETY PROTECTING YOUR EARTH Bender – The company that has been trusted by hospitals for over 70 years. Bender is an innovative, medium-sized company specialising in electrical safety and based in Grünberg in the German state of Hesse. Thanks to its entrepreneurial spirit, “can-do” attitude and collaborative management style, the company, which was founded in 1939 by Dipl.-Ing. Walther Bender, is now an international group with more than 400 employees. Having constantly expanded its range of products in consultation with customers, Bender is now in a position to offer practical solutions for all areas of electrical safety. 4 Industry leading efficient transformers in line with our ISO14001 environmental policy 4 Reduced cooling and running costs compared with standard transformers 4Up to 20% more efficient than other transformers available on the market 4Ultra reliable and suitable for use in all Group Two medical locations 4Available in sizes ranging from 3 -> 10kVA in accordance with HTM06-01 and BS7671 17th Edition Amendment 1 Key focus areas include the development, production, distribution and servicing of insulation monitoring devices (A-ISOMETER®), residual current monitors, supply monitoring systems, test engineering equipment, alarm indicator and operator panels, as well as complete power supplies. These systems serve as an early warning system for detecting faults in electrical and electronic installations and are primarily used in applications where high levels of operational reliability and protection against fire and explosion are required. In this context, our internationally recognised quality management system and flexible corporate culture, which is based on the principle of cooperation, provide the basis for our high-quality products and services. Bender – A worldwide presence Bender has subsidiaries and representatives worldwide, who provide users on all continents with the support they need. Our experienced application engineers are there to offer you expert advice when it comes to selecting, configuring and using your systems. BENDER UK Ltd Ulverston Cumbria e info@bender-uk.com t +44 (0)1229 480123 www.bender-uk.com BENDER – SPECIALIST FOR ELECTRICAL SAFETY IN HOSPITALS THERE FROM THE VERY START... 1960 In order for medical technical equipment to function, there has to be a reliable electricity supply. This, coupled with the fact that any power failure is likely to put people’s lives at risk, imposes stringent requirements as regards the reliability of power supplies for medical locations. Back in the 1960s, when the very first independent hospital standards were introduced in Germany, Bender was one of the first companies to launch an electronic insulation monitoring device for unearthed power supply systems (IT systems) within medical locations. Today, the company offers a universal solution for reliable medical locations power supplies in the form of its MEDICS® universal changeover and monitoring system. In 1962 the first independent VDE standard specifically relating to medical locations was published. The A-ISOMETER® 107TM2 was one of the world’s first electronic insulation monitoring devices to ever be launched for use in medical locations. Bender – All-round service The customer and the search for solutions to customer-specific requirements are at the heart of everything we do. Regardless of which phase you are at, whether it’s planning, configuration, commissioning or actual operation, our specialists will be happy to help. 1980 In the light of new discoveries and to take account of internationally binding specifications, in June 1981, standard DIN VDE 0107: 1981-06 entitled “Erection and testing electrical installations in medical locations” came into force. At this point, the A-ISOMETER® 107TM40 was introduced for the purpose of monitoring IT systems. In addition, series production of alarm indicator and operator panels for hospitals began, specifically those intended for use in operating theatres and on intensive care units. 2000 The proliferation of modern bus systems and the desire for more information culminated in the development of the MEDICS® system at the end of the 1990s. The buzzwords associated with this development were: increased reliability for power supplies in medical locations, data exchange via bus systems, display of information in plain-text format and user-friendliness. In November 2002 standard DIN VDE 0100710 (VDE 0100-710): 2002-11 came into force, superseding DIN VDE 0107 (VDE 0107): 1994-10. This national standard, which is based on international draft standard IEC 60364-7710, takes account of the latest advances within the field of medical engineering and higher levels of safety awareness. The MEDICS® system also meets these new requirements, thereby providing clear proof of Bender’s forward-thinking strategy. 1990 Work continued on German standard DIN VDE 0107 to ensure that it remained in line with the current state of the art. A new edition was published in 1994. The key points covered by this standard were the requirements and use of standalone changeover equipment for redundant power supplies. The UM107ETU changeover and monitoring module was the first complete solution for Group 2 rooms to be made available on the market. In addition, the first alarm indicator and operator panels with plain-text display were launched. 3 4 ...AND STILL HERE IT SYSTEM FLOOR STANDING DISTRIBUTION CABINET SERIES IPS-F Application The IT system distribution cabinet in the IPS-F series supply electrical power to group 2 medical locations. In such locations, according to the requirements of IEC 60364-7-710 for circuits supplying medical electrical Equipment and systems intended for life support, surgical applications and other electrical equipment located in the “patient environment” the use of the IT system with insulation monitoring and load current monitoring (IEC 60364-7-710) is recommended. This requirement applies for example for anaesthetic rooms, operating theatres, operating preparation rooms, operating plaster rooms, operating recovery rooms, heart catheterisation rooms, intensive care rooms, angiographic examination rooms, premature baby rooms. The distribution cabinet of the IPS-F series feature all necessary components and are supplied prewired to terminals, thereby drastically reducing the time needing to be spent on installation and commissioning. The completely factory tested cabinets do comply with our high quality and safety requirements and ISO9001 standard. Built-in components in accordance with IEC 60364-7710 BS7671:2008, HTM 06-01 and MEIGaN The IPS-F series distribution cabinet feature the following components: Device features – Complete standardized IT system featuring 3.15…8 kVA Isolating transformer – Insulation, load, temperature and connection monitoring – Main isolator switch – 6 subcircuits with 2-pole circuitbreakers / IT system (max. 18) – Power supply unit for alarm indicator and operator panels – Time saving as the floor-standing distribution cabinets are supplied prewired and factory tested – Versions for 1…4 IT systems in one enclosure – Designed in accordance with the requirements of applicable standards – In and out going wires are terminated by screwless type/cage clamp spring terminals or as per customers specification – Exchange of information via bus technology – Short delivery times 4 4 4 4 4 4 4 4 3.15…8 kVA Isolating transformer (10 kVA optional) Insulation, load, and temperature monitoring device 107TD47 Main isolator switch 6 x 2-pole circuit breakers / IT system (max. 18 breakers / IT system) 1 Load current transformer 1 Equipotential bonding terminals Power supply for 2 MK2430 or 1 MK800 alarm indicator and operator panel(s) Ventilation filters and fans are mounted into the cabinet door Insulation, load and temperature monitoring The 107TD47 insulation monitoring device continuously monitors the insulation resistance, load current and the temperature of the IT system transformer. If one or a number of response values have been reached (insulation resistance, load current, temperature), the alarm relay will switch and a corresponding message will appear. The connecting cables to the system and PE, as well as to the measuring current transformer and temperature sensor, are permanently monitored. In the event of wire breakage or short circuit, of the current transformer an alarm will come on. The patented AMP measuring technique is used in order to exclude the possibility of insulation monitoring being impaired by DC components. Messages displayed in plain text The unique status, warning and fault messages are displayed in plain text. The MK2430/MK800 alarm indicator and test combination or TM alarm indicator and operator panel must to be installed in a suitable location in the medical location and permanently monitored by medical staff. A twisted pair shielded bus cable is used to connect the IPS distribution cabinet to the alarm indicator panels. 5 6 IT system floor-standing distribution cabinet Series IPS-F 7 IT system floor-standing distribution cabinet Series IPS-F 8 IT system floor-standing distribution cabinet Series IPS-F 9 IT system floor-standing distribution cabinet Series IPS-F 10 IT system floor-standing distribution cabinet Series IPS-F 11 IT system floor-standing distribution cabinet Series IPS-F 12 PREVENTION REALLY IS BETTER THAN CURE 4Provides quick and easy alerts for estates staff 4Provides a gateway between the Bender components and any PC/smartphone via a web browser 4Can be used to convert Bender-BMS-bus data to TCP/IP protocols with Ethernet or Modbus 4PDF report function 4Email & text alerts 4Fast & simple remote parameterisation 4Can be used in conjunction with professional visualisation software BENDER UK Ltd Ulverston Cumbria e info@bender-uk.com t +44 (0)1229 480123 www.bender-uk.com IPS/UPS SYSTEMS AND THE NEED FOR A SERVICING PLAN Isolated Power Systems and Uninterrupted Power Supplies are highly specialised pieces of equipment, which if correctly verified and maintained, will provide excellent service protecting the critical systems for many years. Any failure in these systems may result in serious consequences for industrial operations as well as for patients and staff in the medical sector. In order to maintain precise operational performance, maximise reliability and minimise operational costs each IPS should receive regular preventative maintenance and verification inspections in line with BS7671710.6, 710.61, 710.62, HTM06-01 Part B and MEIGaN. Bender UK’s service agreements can be tailored to each client’s specific needs and are renewable for either annual or multiyear contracts. The IPS verification would involve the following checks: – 24/7 365 telephone support The IPS verification options include all of the manufacturer verification inspections, and telephone support 24/7, 365 days a year. These options can include for any spares required during the arranged visit. The IPS Systems are backed by UPS systems. In order to optimise operational reliability of the UPS systems, and hence provide maximum power protection to the critical load, it is strongly recommended that all UPS systems are also comprehensively maintained under an extended warranty agreement. Third party equipment UNINTERRUPTIBLE POWER SUPPLIES (UPS) In critical Healthcare Group Two areas it is essential that the supply to life support equipment is maintained at all times and as such Bender UK offer a wide range of highly efficient and reliable uninterruptible power supplies (UPS) as part of their electrical safety package. Key features include: 4 Online Double Conversion (VFI) 4 Compliance with IEC 62040-3 and HTM 06-01 4 High Efficiency (up to 96.5%) 4 Input Power Factor > 0.99 4 Output Power Factor of 0.9 (3ph) 4 Input Current Distortion < 3% 4 Single Module, Cascade & Parallel Systems available 4 Power ‘Walk’ in & ‘Delay’ facilities 4 USB, RS232 & 2 x Comms Card Slots 4 Dual Input Capability In addition, our unrivalled level of expertise allows us to service and maintain third party equipment, realising the benefits this may offer to our clients with a single maintenance contract covering all equipment on site. – Minimum of 1 IPS PPM visit per year – Minimum of 2 UPS PPM visits per year – Critical spares carried with each engineer – Guaranteed rapid response to site – Inclusive of spare part options 15 – Onsite training packages available – Expertise extends to third party equipment EQUIPMENT SERVICE AND MAINTENANCE CONTRACTS ARE AVAILABLE FOR ALL THE SYSTEMS WE SUPPLY TO OUR MEDICAL AND INDUSTRIAL SECTOR CLIENTS. 16 MEDICAL SECTOR Bender UK’s experienced and sector specific expert technicians offer a carefully tailored service package designed to give all our clients precisely the level of support they require. Having a service package for numerous products all under one Bender Contract can significantly reduce clinical downtime and admin costs for the end user. A safe electrical infrastructure is clearly crucial in a medical environment where critical system issues can literally be a matter of life or death. Additionally there are clear guidelines within the health sector’s electrical installation regulations that dictate the level and frequency of equipment testing and verification, so as not to expose the hospital to undue risk. This risk can be reduced by incorporating a carefully planned preventative maintenance schedule. With Bender UK currently supplying maintenance for critical power systems to over 170 hospitals throughout the UK, and with a network of factory-trained engineers offering a rapid response to any eventuality. A Bender UK maintenance agreement could be the answer to all your needs. Surgeon’s Control Panels As well as our specialist services in verifying and maintaining all our IPS and UPS systems, Bender has specific expertise in servicing Surgeons Control Panels. As designers and manufacturers we have unrivalled knowledge of SCPs and their servicing requirements. The control of various devices such as UCV Control and Surgical Lighting are commonly integrated with the SCP’s. It is imperative that these panels are checked annually to ensure the theatre area continues to function to the highest standards available. 17 UltraClean canopies All servicing works are carried out in accordance with HTM 03-01 Part B and can be carried out on weekdays or weekends depending on customer requirements. Surgical lighting and pendants Pre-planned maintenance and regular servicing are essential for safety and to ensure the surgical lights deliver optimum performance throughout their lifespan. Fully comprehensive service packages including spares and repairs are available on all Steris operating lights and pendants. Surgical Tables Pre-planned maintenance and regular servicing are essential for safety and to ensure the surgical tables deliver optimum performance throughout their lifespan. Fully comprehensive service packages including spares and repairs are available on all Steris operating tables. BENDER UK CURRENTLY SUPPLY MAINTENANCE FOR CRITICAL POWER SYSTEMS TO OVER 170 HOSPITALS THROUGHOUT THE UK THE BEST JUST GOT BETTER 4Market leading 22 inch touch screen control panels 4 67% more viewing area when compared to other products available on the market 4Smart phone connectivity for onsite or offsite remote monitoring 4Anti-bacterial front foil to facilitate infection control 4Bespoke graphic design to suit user requirements 4Service back up from a network of factory trained engineers 419”, 22” and 42” PACS monitors and medical PC’s, either incorporated into the TCP’s or as stand-alone units. BENDER UK Ltd Ulverston Cumbria e info@bender-uk.com t +44 (0)1229 480123 www.bender-uk.com CHANGE OVER TO ATiCS ENHANCED RESILIENCE AND/OR SAFETY FOR CRITICAL MEDICAL AREAS 4 Smart & compact space saving design 4 Unique rotary cam arrangement for increased reliability and performance 4 Full monitoring of incoming supplies including built in insulation monitor (optional) 4Fully automatic changeover between power sources in the event of failure 4Manual bypass arrangement allows replacement without any interruption 4Quick and easy to test/replace during maintenance works 4Compatible with all other Bender devices and perfect for retrofitting 4Compliant with IEC 61508 and suitable for use in safety systems according to the SIL Level 2 standard HARMONY vLED OPERATING LIGHTS PRIMARY POWER SOURCE SECONDARY POWER SOURCE SINGLE SOURCE – CRITICAL INCUBATOR UNIT BENDER UK Ltd Ulverston Cumbria e info@bender-uk.com t +44 (0)1229 480123 www.bender-uk.com 4Cool White Light 4Excellent Colour Rendition 4Shadow Free 4Exceptional Deep Cavity Illumination 4Adjustable illumination intensity (7 different levels), available with future proofing integration system including cameras & flat panel monitors BENDER UK Ltd Ulverston Cumbria e info@bender-uk.com t +44 (0)1229 480123 www.bender-uk.com AIRPORT EQUIPMENT MANAGEMENT STERIS OPERATING TABLES 4For Surgery, Aneasthesia & Critical Care 4Ergonomically Designed Equipment Handling 4Modular & Adaptable 4Complete with Multiple Accessories 4Ideal for Anyone’s Integration System 4Flexibility – accommodate any clinical procedure/ position 4 Durability – engineered for extensive clinical use 4 Future Proof – upgradeable mobile system to motorised transfer system 4 Ease Of Use – informative operative control with Bluetooth technology 4 Ergonomic – allows easy cleaning and gives maximum comfort for patients 21 22 CORPORATE PROFILE FACT FILE Since our founder, Mr Walther Bender, patented the absolute isometer in 1939 Bender has grown to become the recognised world leader in the field of earth-fault monitoring and electrical safety. To this day Mr Bender’s ambition ‘to make electrical power safe’ remains the fundamental objective of the familyowned company. Bender is dedicated to protecting people, processes and assets against the hazards of electrical power. Products: ► Insulation monitors for (IT) AC, DC and AC/DC systems up to 7.2kV In addition to operating audited international management systems in line with ISO 9001:2008 and ISO 14001:2004 Bender’s reputation for compliance and technical competence is backed by representation on both national and international standards committees. With product compliance to IEC, EN, UL, Lloyds, Germanischer Lloyd and Railtrack, customers can rely on Bender to deliver a technically sound solution. ► Online earth fault location systems for IT power supplies ► Portable earth fault location systems for IT power supplies ► Offline insulation monitoring systems for back up motors/drives ► Type A Residual Current Monitors for AC or Pulsed DC supplies 10mA-10A ► Type B Residual Current Monitors for DC TN/TT supplies 10mA-3A ► Multi-Channel AC, Pulsed DC and DC Residual Current Monitors 6mA- 20A ► Portable Residual Current Monitoring systems Over the past 70 years the company has established an enviable reputation for the development of innovative products designed to meet our clients’ needs. The emphasis from the beginning has been on performance, compliance and quality - and today these factors have become synonymous with the Bender brand. Today Bender employs more than 600 staff worldwide and is represented globally by a network of distributors in addition to wholly-owned subsidiaries in the USA, UK, China, India, Russia, Holland, Spain and Italy. Our efficient company structure promotes agility and facilitates the problem-solving attitude for which Bender is renowned. Our ability to identify and understand the complex technical issues faced by customers is backed by a strategy of continual investment in Research and Development, a department which currently represents around 10% of our global work force. ► True RMS voltage relays for AC and DC systems ► Phase sequence relays ► Frequency relays ► Restart relays ► Current relays Looking ahead Bender anticipates its strategy of collaboration, continued R&D investment and close ties with customers will help deliver the company’s principal objective ‘to protect people, processes and assets against the hazards of electrical power’. Main Market Sectors: Offshore Oil and Gas, Healthcare, Subsea robotics, Ships, Power Plants, Automation and Control, Mining Developing the most technically advanced products and systems in order to achieve this goal has been at the heart of our business for over 70 years and our innovative approach to achieving this will continue. Parent Company: Dipl.-Ing. W. Bender GmbH + Co. KG founded in Grunberg, Germany in the 1930s. Bender UK was incorporated as the UK subsidiary in 1997 ► Touch-screen control panels Bender UK Ltd Low Mill Business Park Ulverston Cumbria LA12 9EE T: 01229 480123 E: admin@bender-uk.com www.bender-uk.com www.bender-uk.com BENDER UK Ltd Ulverston Cumbria e info@bender-uk.com t +44 (0)1229 480123 www.bender-uk.com