Red-I Joists

™

Including Red-I45™

, Red-I65™

, Red-I90™

,

Red-I90H™ and Red-I90HS™ Joists

Lightweight for Fast Installation

Download your free copy

of RedSpec™ here.

Specify Red-I™ Joists for

your next project using

RedSpec™ single-member

sizing software.

RedBuilt.com

1.866.859.6757

Compatible with

Standard Framing

Available in Long Lengths

FSC Chain-of-Custody

Now Available

Resists Bowing, Twisting,

and Shrinking

Works with Multiple Spans

Limited Product Warranty

introduction

Welcome to RedBuilt™

RedBuilt™ is an exciting business offering building solutions for a broad

range of commercial and custom residential applications; pioneering

unique manufacturing technologies; and providing world-class service and

technical support for architects, specifiers, and builders.

You’ll find reliable, innovative products including RedBuilt™ open-web

trusses, Red-I™ joists and RedLam™ LVL beams and headers. And you’ll

work with one service-oriented supplier to get all of these products and the

support you need to build smarter.

RedBuilt™: A family of brand-name building products…a source for

innovative ideas and solutions…a supplier that’s simpler to do business with.

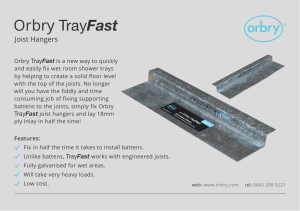

The RedBuilt™ Red-I™ Joist Advantage

Red-I™ joists are lightweight joists suitable for use in roofs and floors in

custom residential, multifamily, institutional, and commercial applications.

This product is available in multiple series so you can design the most costeffective system. Other Red-I™ joist benefits include:

■

■

TABLE OF CONTENTS

Introduction

2

Features and Benefits

3

Design Center Services

4

Red-I™ Joist Descriptions

4

Design Properties

5

6–9

Load Tables

8' On-Center Roof Span Table

9

Floor Details

10–12

Cantilevers and Outriggers

12­–13

Roof Details

14

15

Rim Board

Red-I™ Blocking Panels

15

Web Stiffeners

16

Nailing Information

16

Wind or Seismic Connections

17

Fire and Sound

18

Allowable Holes

19

Deflection Criteria

20

Snowdrift Loading

20

Technical Support and Analysis

21

Q&A22–23

Red-I™ Specifications24

Material Weights 25

Resources26

Product Warranty

28

2

■

■

ependable Delivery—RedBuilt™ plants are in key market areas enabling

D

us to deliver materials quickly. Each plant is staffed with experienced

personnel who can talk to you about any special requirements and help

solve problems.

Minimum Waste—Red-I™ joists are manufactured to resist twisting and

shrinking, and they can be cut to size at the factory so there’s virtually no

time or material waste prior to installation.

ompatibility—All Red-I™ joists fit into wood frame, masonry, or steel

C

construction, and they can accommodate a wide variety of decking and

ceiling materials—including wood, plywood, steel, and gypsum.

asy Mechanical Access—Knockout holes for ventilation and flexible

E

conduit are provided in the web of the Red-I™ joists. The web can also be

cut or drilled to accommodate larger ductwork (see pages 19), so costly

suspended ceilings can often be eliminated.

ABOUT THIS GUIDE

The RedBuilt™ Red-I45™

, I65, I90, I90H and I90HS Joist Specifier’s Guide is one

of several guides that offer technical information and design recommendations for

RedBuilt™ products. This guide provides architects, designers, and engineers with

information regarding Red-I™ joists for commercial and custom residential applications.

features and benefits

Product Selection

This guide provides specifiers with technical information

about the RedBuilt™ Red-I™ joist product line. However, you

will often find that a variety of products can work in many

applications when you consider span, wind or load-carrying

capacity, and design constraints. Your local RedBuilt™

technical representative, with support from our Design Centers,

can assist you in choosing the best system for your specific

application. Contact us for help with any of the following:

■

Product selection

■

Building department calculations

■

Complete cost analysis

■

ystem selection (system packages can

S

include horizontal framing, main carrying

beams, headers, wall framing, mansard

framing, and accessories)

Products for Every Application

In addition to Red-I™ joists, RedBuilt™ offers a variety of other engineered lumber products that are ideal for use in

commercial and custom residential projects. For more information, contact your RedBuilt™ technical representative

or visit www.RedBuilt.com to download literature for products such as tapered Red-I™ joists, open-web trusses and

RedLam™ LVL.

Unsurpassed Technical Support

RedBuilt™ has one of the largest networks of technical representatives

in the business. Their services include consultation, computer-assisted

design and layout, delivery coordination, and installation review. They

can suggest cost-reduction techniques and check special application

requirements. In addition, they’re backed by a staff of professional

engineers who provide comprehensive technical support when needed.

Special requests are accommodated wherever practical, and they

offer cost analysis, engineering analysis, assistance with building code

approvals—even the creation of special product applications for more

creative designs. The goal of RedBuilt™ technical support is to help

architects and engineers achieve quality design applications with the

most cost-efficient product selection possible.

Our network of technical representatives offers a wide

range of services to help guide your ­projects through

planning and construction.

Resource Efficiency

Consider all of the positive attributes of wood when selecting your building material

of choice. In addition to its structural properties, high strength-to-weight ratio, and

ease of construction, wood is a naturally occurring, renewable resource that requires

less energy to produce than steel or concrete. And it sequesters carbon–whether on

the stump or in your structure.

Our Red-I™ joists, as well as other RedBuilt™ products, are now available with FSC

credits. Whether you’re looking for LEED certification or simply because you want

to ensure efficient use of raw materials, we can help. By making better use of every

tree, RedBuilt™ produces cost-effective, consistently available engineered wood

products that reduce environmental impact. The result is a quality wood product that

offers superior strength and reliable performance.

3

design center Services

Installation Review

Upon request, RedBuilt™ can provide the following services for the products

described in this Red-I™ Joist Specifier’s Guide:

■

A complete design package including layout drawings (placement diagrams)

and detailed design ­calculations.

■

Review and analysis of the application.

■

Drawings or calculations sealed by a professional engineer.

Although responsibility for proper installation lies with the contractor-builder,

RedBuilt™ provides detailed suggestions and guidelines for installation. If

requested, a RedBuilt™ representative will visit the site to verify the contractor’s

understanding of proper installation. RedBuilt™ professional engineers also are

available to help solve jobsite application problems.

Engineering Responsibility Position Statement

RedBuilt™ is a manufacturer of proprietary structural components.

It employs a staff of professional engineers to aid in the development, manufacture, and marketing of its

products. RedBuilt™ does not replace or accept the responsibility of the design professional of record for

any structure.

RedBuilt™ accepts the delegation of engineering responsibility only for the products it manufactures,

provided that the application conditions are specified by the design professional of record, or other

responsible party when a design professional is not engaged. RedBuilt™ provides engineering in the

design of its products and does not displace the need on any project for a design professional of record.

Our technical support team offers professional capabilities in

the design and application of all RedBuilt™ products.

Red-I™ Joist Descriptions

, Red-I65™

, Red-I90™

, Red-I90H™ and Red-I90HS™. These joists are primarily intended for commercial applications

This guide covers five series of joists: Red-I45™

such as retail stores, office buildings, schools, restaurants, multi-family, hotels, warehouses, and nursing homes. They are typically designed, manufactured, and sold by

RedBuilt™ for each specific job. Contact your RedBuilt™ representative for more information.

Some series of Red-I™ joists are available with tapered profiles for use in certain roof applications. Contact your RedBuilt™ representative for determining availability and

for application assistance.

Red-I™ joists are normally produced without camber. However, camber is available at 2,250' radius as a special order for I45, I65, I90 and I90H series joists.

Camber is not recommended for floors, or for multiple-span or cantilever applications.

11⁄2"

(minimum)

11⁄2"

3⁄8"

31⁄2"

21⁄2"

13⁄4"

91⁄2",

117⁄8",

14"–16"

11⁄2"

(minimum)

7⁄16"

117⁄8",

14"–30"

21⁄2"

13⁄4"

7⁄16"

117⁄8",

14"–30"

31⁄2"

31⁄2"

7⁄16"

117⁄8",

14"–30"

⁄"

12

117⁄8",

14"–32"

Red-I45™

Red-I65™

Red-I90™

Red-I90H™

Red-I90HS™

Top and bottom flanges of

11⁄2" x 13⁄4" RedLam™ LVL

with 3⁄8" OSB web.

Top and bottom flanges of

11⁄2" (minimum) x 21⁄2"

RedLam™ LVL with 7⁄16"

OSB web.

Top and bottom flanges of

11⁄2" (minimum) x 31⁄2"

RedLam™ LVL

with 7⁄16" OSB web.

Top and bottom flanges of

13⁄4" x 31⁄2" RedLam™ LVL

with 7⁄16" OSB web.

Top and bottom flanges of

21⁄2" x 31⁄2" RedLam™ LVL

with 1⁄2" OSB web.

■

Available in a tapered profile.

(Red-I65T™) Check with

your technical representative

for availability

Joist depths from 14" to 32" are available in 2" increments.

Building Codes and Product Acceptance: See ICC-ES ESR-2993, ICC-ES ESR-2994

L.A. City RR #25832 and #25833, DSA IR 23-9

4

■

■

For heavy loads and 8'

on-center roof systems

Increased bending strength

and stiffness

Joist

Depth

Joist

Weight

(lbs/ft)

Moment (1)

Mr (ft-lbs)

Shear (2)

Vr (lbs)

91 ⁄ 2 "

117⁄ 8"

14"

16"

2.2

2.5

2.8

3.0

3,620

4,685

5,570

6,390

1,590

1,785

1,960

2,120

185

319

474

653

117⁄ 8"

14"

16"

18"

20"

22"

24"

26"

28"

30"

3.6

3.9

4.2

4.4

4.7

5.0

5.3

5.5

5.8

6.1

6,750

8,030

9,210

10,380

11,540

12,690

13,830

14,960

16,085

17,205

2,255

2,540

2,810

3,080

3,345

3,615

3,200

3,200

3,200

3,200

450

666

913

1,205

1,545

1,934

2,374

2,868

3,417

4,025

117⁄ 8"

14"

16"

18"

20"

22"

24"

26"

28"

30"

4.6

4.9

5.2

5.4

5.7

6.0

6.3

6.5

6.8

7.1

9,605

11,430

13,115

14,785

16,435

18,075

19,700

21,315

22,915

24,510

2,255

2,540

2,810

3,080

3,345

3,615

3,400

3,400

3,400

3,400

621

913

1,246

1,635

2,085

2,597

3,172

3,814

4,525

5,306

117⁄ 8"

14"

16"

18"

20"

22"

24"

26"

28"

30"

4.6

4.9

5.2

5.4

5.7

6.0

6.3

6.5

6.8

7.1

10,960

13,090

15,065

17,010

18,945

20,855

22,755

24,645

26,520

28,380

2,300

2,600

2,880

3,160

3,445

3,725

3,800

3,800

3,800

3,800

687

1,015

1,389

1,827

2,331

2,904

3,549

4,266

5,059

5,930

117⁄8"

14"

16"

18"

20"

22"

24"

26"

28"

30"

32"

6.0

6.3

6.6

7.0

7.3

7.6

7.9

8.2

8.5

8.8

9.1

16,050

19,425

22,550

25,640

28,695

31,725

34,730

37,715

40,680

43,630

46,560

2,320

2,565

2,790

3,020

3,250

3,480

3,710

3,940

4,165

4,375

4,375

900

1,355

1,876

2,488

3,195

3,998

4,901

5,905

7,014

8,230

9,555

EI x 10 6

(in. 2-lbs)

Reference Design Values

End Reaction (lbs) (4) (5)

Intermediate Reaction (lbs) (4) (5)

EI(3) x 10 6

EI(3) x 10 6

Bearing Length

Bearing Length

Red-I™ Joist

Red-I™ Joist with

13⁄4"

with Nailed

Glue-Nailed Floor (21/2" for I90HS)

31⁄2"

31⁄2"

51⁄4"

Floor Sheathing

Sheathing

(6) Web Stiffeners (6) Web Stiffeners (6) Web Stiffeners (6)

2

2

Web

Stiffeners

(in. -lbs)

(in. -lbs)

No

Yes

No

Yes

No

Yes

No

Yes

Red-I45™ Joist

221

250

1,015

NA

1,560

NA

2,025

NA

2,575

NA

375

420

1,015

1,225

1,560

1,785

2,025

2,385

2,575

2,930

553

615

1,015

1,225

1,560

1,915

2,025

2,385

2,575

2,930

756

839

1,015

1,225

1,560

1,915

2,025

2,385

2,575

2,930

Red-I65™ Joist

512

561

1,375

1,745

1,885

2,255

2,745

3,120

3,365

3,735

752

821

1,375

1,750

1,885

2,505

2,745

3,365

3,365

3,985

1,025

1,116

1,375

1,750

1,885

2,625

2,745

3,490

3,365

4,105

1,348

1,462

1,375

1,750

1,885

2,750

2,745

3,615

3,365

4,230

1,722

1,864

NA

1,750

NA

2,875

NA

3,740

NA

4,355

2,149

2,322

NA

1,750

NA

3,000

NA

3,860

NA

4,480

2,632

2,838

NA

1,750

NA

3,125

NA

3,875

NA

4,605

3,172

3,416

NA

1,750

NA

3,200

NA

4,725(7)

NA

5,345(8)

3,772

4,056

NA

1,750

NA

3,200

NA

4,850(7)

NA

5,470(8)

4,434

4,762

NA

1,750

NA

3,200

NA

4,975(7)

NA

5,590(8)

Red-I90™ Joist

687

741

1,400

1,715

1,885

2,200

3,350

3,665

3,965

4,285

1,005

1,079

1,400

1,875

1,885

2,355

3,350

3,825

3,965

4,440

1,366

1,462

1,400

2,030

1,885

2,515

3,350

3,980

3,965

4,600

1,786

1,908

1,400

2,030

1,885

2,515

3,350

3,980

3,965

4,600

2,272

2,422

NA

2,190

NA

2,675

NA

4,140

NA

4,755

2,824

3,006

NA

2,345

NA

2,830

NA

5,090

NA

5,705

3,442

3,659

NA

2,345

NA

2,830

NA

5,405

NA

6,020

4,132

4,387

NA

2,450

NA

2,990

NA

6,180(7)

NA

6,795(8)

4,895

5,191

NA

2,450

NA

3,145

NA

6,335(7)

NA

6,800(8)

5,732

6,073

NA

2,450

NA

3,145

NA

6,655(7)

NA

6,800(8)

Red-I90H™ Joist

755

810

1,400

1,715

1,885

2,200

3,495

3,810

4,100

4,420

1,109

1,185

1,400

1,875

1,885

2,355

3,495

3,970

4,100

4,575

1,512

1,610

1,400

2,030

1,885

2,515

3,495

4,130

4,100

4,735

1,982

2,106

1,400

2,030

1,885

2,515

3,495

4,130

4,100

4,735

2,522

2,676

NA

2,190

NA

2,675

NA

4,285

NA

4,890

3,136

3,321

NA

2,345

NA

2,830

NA

5,235

NA

5,840

3,825

4,046

NA

2,345

NA

2,830

NA

5,425

NA

6,155

4,590

4,850

NA

2,450

NA

2,990

NA

6,315(7)

NA

6,920(8)

5,436

5,737

NA

2,450

NA

3,145

NA

6,470(7)

NA

7,080(8)

6,363

6,710

NA

2,450

NA

3,145

NA

6,790(7)

NA

7,395(8)

Red-I90HS™ Joist

974

1,034

1,835

2,320

2,150

2,320

3,995

4,650

4,690

5,345

1,457

1,538

1,835

2,565

2,150

2,565

3,995

4,980

4,690

5,670

2,008

2,113

1,835

2,790

2,150

2,790

3,995

4,980

4,690

5,670

2,654

2,787

1,835

3,020

2,150

3,020

3,995

5,310

4,690

6,000

3,399

3,562

NA

3,250

NA

3,250

NA

5,425

NA

6,330

4,244

4,442

NA

3,475

NA

3,480

NA

5,425

NA

6,330

5,194

5,428

NA

3,500

NA

3,710

NA

5,425

NA

6,655

6,249

6,523

NA

3,500

NA

3,940

NA

6,985(7)

NA

7,675(8)

7,412

7,730

NA

3,500

NA

4,165

NA

6,985(7)

NA

7,675(8)

8,687

9,052

NA

3,500

NA

4,375

NA

7,310(7)

NA

8,005(8)

10,075

10,490

NA

3,500

NA

4,375

NA

7,640(7)

NA

8,335(8)

The stated allowable design properties are for loads of normal duration. Adjustments to the

allowable design values shall be in accordance with the applicable code.

(1)Do not increase joist resistive moment properties by a repetitive-member-use ­factor.

(2)For possible increases in shear capacity see below.

(3)For deflection calculation only. Assumes 24" joist spacing with a 24" span-rated panel.

(4)Interpolation between bearing lengths is permitted for allowable design ­reactions.

■

(5)Reaction capacity has been determined based on RedBuilt™ products.

Allowable bearing on supporting members shall be checked.

(6)Refer to page 16 for web stiffener details.

(7)51⁄4" bearing length is required at intermediate reactions.

(8)7" bearing length is required at intermediate reactions.

Red-I™ Joist Shear Design

When joists are used as simple-span members, the design shear is equal to the

shear at the face of the support.

When joists up to 24" in depth are used as multiple-span ­members, the design

shear is the calculated shear at the interior support reduced by the following:

Where: R is the percent reduction

W is uniform load in plf

R = W ≤ 18% V12

V12 is the reference design shear for

100

an 117⁄ 8" deep joist (lbs.)

5

Load Tables

Load Table Instructions

General Notes

To size floor joists:

Values shown are maximum allowable load capacities based on the following

assumptions:

– Simple span; horizontal clear distance between supports.

–Uniformly loaded conditions with 21⁄2" bearing length. Web stiffeners are

assumed for joist depths greater than 91⁄2". Other capacities may be possible

with d­ ifferent ­criteria; contact your RedBuilt™ representative.

–Positive drainage in roof applications (1⁄4" per foot slope ­minimum).

–Composite action is not considered for deflection.

–Floor Total Load deflection limit is L/240.

–Floor Live Load deflection limit is based on commercial deflection criteria

shown on page 20.

– Roof Total Load deflection limit is L/180.

■

■

■

Calculate total load and live load in pounds per linear foot (plf).

Check both total load (100% TL) and live load (100% LL). Live load (100%

LL) values may be increased with a glue-nailed floor system, contact your

RedBuilt™ representative for assistance.

To size roof joists:

■

Calculate total load in pounds per linear foot (plf).

Check the appropriate snow load area (115% TL) value or non-snow load area (125% TL) value to determine the maximum allowable total load.

■

Consult local codes to verify deflection limits required for

specific applications.

■

Camber (2,250' radius) is available for simple-span applications only (not

available for I90HS). Contact your RedBuilt™ representative

for availability.

■

Visit www.RedBuilt.com to find your local representative.

For span or loading conditions not covered by these tables (such as

multiple spans or concentrated loads), contact your RedBuilt™ representative

for assistance.

100% TL (Total Load)

Use this and the 100% LL to select

floor member. This is the ­maximum

allowable total load in pounds per linear

foot of joist. Values are limited by deflection

equal to L/240 at total load.

115% TL (Total Load)

117 ⁄ 8"

Span

100% LL (Live Load)

12'

14'

Use this and the 100% TL to select floor member. This

number is the maximum allowable live load capacity 16'

in pounds per linear foot of joist. Value is based on the

Commercial Floor Deflection Limit shown on page 20.

6

14"

16"

100% TL 115% TL 100% TL 115% TL 100% TL 115% TL

100% LL 125% TL 100% LL 125% TL 100% LL 125% TL

320 368 354 407 388 446

252 401 350 442 * 485

316 303

332

Use this to select roof member in snow load

areas. This is the maximum allowable total

load in pounds per l­inear foot of joist. Values

are limited by deflection equal to L /180 at

total load.

125% TL (Total Load)

Use this to select roof member in non-snow load areas.

This is the maximum allowable total load in pounds per

linear foot of joist. Values are limited by deflection equal to

L /180 at total load.

Load Tables

Red-I45™ Allowable Uniform Load (PLF)

Depth

91 ⁄ 2 "

Span

10'

12'

14'

16'

18'

117⁄ 8"

14"

16"

100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL

100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL

245

160

195

98

129

64

89

44

64

28

20'

22'

282

307

224

244

165

173

119

119

85

85

63

63

48

48

288

257

240

162

186

107

143

74

107

47

80

32

331

360

276

301

214

233

164

179

130

141

105

106

81

81

299

*

249

230

214

154

170

106

135

69

109

46

89

35

344

373

287

312

246

268

196

213

155

168

126

136

104

113

299

*

249

*

214

205

188

143

154

92

125

63

104

48

344

373

287

312

246

268

216

235

178

193

144

157

119

130

* Indicates that total load (TL) value controls.

■

Red numbers refer to 115% total load (TL).

Red-I65™ Allowable Uniform Load (PLF)

Depth

117⁄ 8"

Span

10'

12'

14'

16'

18'

20'

22'

24'

26'

28'

30'

32'

34'

36'

38'

40'

14"

16"

18"

20"

22"

24"

26"

28"

30"

100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL

100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL

386

347

322

220

269

147

206

102

149

65

111

44

85

34

444

482

371

403

309

336

237

258

188

199

148

148

113

113

88

88

70

70

56

56

46

46

38

38

32

32

407

*

340

310

292

210

245

146

194

94

157

64

123

49

96

38

77

30

469

509

391

426

336

365

282

307

223

243

181

197

150

163

126

129

102

102

83

83

68

68

56

56

47

47

40

40

34

34

29

29

418

*

349

*

300

277

262

194

223

126

181

86

149

66

126

52

104

41

84

33

480

522

401

436

345

375

302

328

256

279

208

226

172

187

145

157

123

134

106

112

92

92

77

77

64

64

54

54

46

46

40

40

428

*

358

*

307

*

269

249

239

163

204

112

168

86

142

68

121

54

104

44

90

36

75

30

492

535

411

447

353

384

309

336

275

299

234

255

194

211

163

177

139

151

120

130

104

114

92

100

81

84

71

71

61

61

52

52

439

*

366

*

315

*

276

*

245

204

221

140

187

108

158

85

134

68

116

55

101

46

89

38

79

32

504

548

421

458

362

393

317

345

282

307

254

276

216

234

181

197

155

168

133

145

116

126

102

111

90

98

81

88

72

78

65

67

449

*

375

*

322

*

282

*

251

248

226

172

206

133

173

105

148

84

127

69

111

57

98

47

86

40

77

34

69

29

517

562

432

469

371

403

325

353

289

314

260

283

237

257

199

217

170

185

147

159

128

139

112

122

100

108

89

97

80

87

72

78

460

*

384

*

330

*

289

*

257

*

231

206

211

161

189

127

161

102

139

83

121

69

106

57

94

48

84

41

75

35

68

30

529

575

442

480

379

412

332

361

296

321

266

289

242

263

217

236

185

201

160

174

139

151

122

133

108

118

97

105

87

94

78

85

466

*

389

*

334

*

293

*

261

*

235

*

213

190

196

151

174

122

150

100

131

82

115

69

102

58

91

49

82

42

74

36

536

583

448

487

385

418

337

366

300

326

270

293

246

267

225

245

201

218

173

188

151

164

133

144

117

128

105

114

94

102

85

92

466

*

389

*

334

*

293

*

261

*

235

*

213

*

196

177

181

143

162

117

141

97

124

81

110

68

98

58

88

50

79

43

536

583

448

487

385

418

337

366

300

326

270

293

246

267

225

245

208

226

186

202

162

176

143

155

126

137

113

122

101

110

91

99

466

*

389

*

334

*

293

*

261

*

235

*

213

*

196

*

181

166

168

136

151

113

133

95

117

80

105

68

94

58

85

50

536

583

448

487

385

418

337

366

300

326

270

293

246

267

225

245

208

226

193

210

173

189

152

166

135

147

121

131

108

118

98

106

* Indicates that total load (TL) value controls.

■

Red numbers refer to 115% total load (TL).

7

Load Tables

Red-I90™ Allowable Uniform Load (PLF)

117⁄ 8"

Span

14'

16'

18'

20'

22'

24'

26'

14"

16"

18"

20"

Depth

22"

24"

26"

28"

30"

100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL

100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL

271

192

237

134

198

87

148

59

114

45

89

35

71

28

28'

30'

32'

34'

36'

38'

312

339

273

297

243

264

198

198

152

152

119

119

95

95

77

77

63

63

52

52

44

44

37

37

31

31

293

268

257

189

229

124

206

85

164

65

129

51

103

41

83

33

40'

42'

337

367

296

321

263

286

237

257

214

219

172

172

137

137

111

111

91

91

76

76

64

64

54

54

46

46

40

40

34

34

315

*

276

249

246

164

221

113

201

87

172

69

138

55

112

45

92

37

77

30

363

394

318

346

283

307

255

277

232

252

206

224

176

184

150

150

123

123

103

103

86

86

73

73

63

63

54

54

47

47

315

*

276

*

246

209

221

144

201

112

185

89

171

71

145

58

120

48

100

40

84

33

71

28

363

394

318

346

283

307

255

277

232

252

212

231

196

213

171

186

149

160

131

133

112

112

95

95

82

82

70

70

61

61

338

*

296

*

263

258

237

179

216

140

198

111

183

89

165

73

144

60

126

50

106

42

90

36

77

31

389

423

341

370

303

329

273

297

248

270

228

248

210

229

190

207

166

180

146

158

129

140

115

120

103

103

89

89

77

77

360

*

315

*

281

*

253

217

230

170

211

135

195

109

181

89

158

74

139

62

123

52

110

44

95

38

82

33

72

28

414

450

363

394

323

351

291

316

264

287

242

264

224

243

208

226

182

198

160

174

142

154

127

138

114

124

103

110

93

96

360

*

315

*

281

*

253

*

230

203

211

162

195

131

181

108

169

89

152

75

135

63

120

54

108

46

97

40

87

34

414

450

363

394

323

351

291

316

264

287

242

264

224

243

208

226

194

211

175

190

155

168

138

150

124

135

112

122

101

110

378

*

331

*

295

*

265

*

241

239

221

191

204

155

190

127

177

106

164

89

146

75

130

64

117

55

105

47

95

41

435

473

381

414

339

369

305

332

278

302

255

277

235

256

218

237

204

222

189

206

167

182

149

162

134

146

121

132

110

119

387

*

339

*

302

*

272

*

247

*

227

222

210

181

195

149

182

124

170

104

157

88

140

75

125

65

113

56

103

49

446

484

390

424

347

378

313

340

285

309

261

284

241

262

224

243

209

227

196

213

180

196

161

175

144

157

130

142

118

128

387

*

339

*

302

*

272

*

247

*

227

*

210

208

195

172

182

143

170

120

160

102

149

87

134

75

121

65

110

57

446

484

390

424

347

378

313

340

285

309

261

284

241

262

224

243

209

227

196

213

184

201

172

187

154

168

139

151

126

137

Red-I90H™ Allowable Uniform Load (PLF)

117⁄ 8"

Span

14'

16'

18'

20'

22'

24'

26'

28'

30'

32'

34'

36'

38'

40'

42'

14"

16"

8

20"

Depth

22"

24"

26"

28"

30"

100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL

100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL

271

208

237

146

211

95

162

65

125

50

98

39

78

31

312

339

273

297

243

264

217

217

167

167

131

131

104

104

84

84

69

69

57

57

48

48

41

41

35

35

30

30

293

290

257

206

229

135

206

93

180

72

142

56

113

45

92

36

76

30

337

367

296

321

263

286

237

257

215

234

189

189

151

151

123

123

101

101

84

84

70

70

60

60

51

51

44

44

38

38

315

*

276

270

246

179

221

123

201

96

185

76

152

61

124

49

102

41

85

34

71

28

363

394

318

346

283

307

255

277

232

252

212

231

196

203

165

165

136

136

114

114

95

95

81

81

69

69

60

60

52

52

* Indicates total load (TL) value controls.

Red numbers refer to 115% total load (TL).

■

18"

315

*

276

*

246

227

221

158

201

123

185

97

171

78

158

64

132

53

111

44

93

37

79

31

363

394

318

346

283

307

255

277

232

252

212

231

196

213

182

198

170

177

148

148

124

124

106

106

90

90

78

78

68

68

338

*

296

*

263

*

237

196

216

153

198

122

183

98

170

80

158

66

139

55

118

47

100

40

86

34

74

29

389

423

341

370

303

329

273

297

248

270

228

248

210

229

195

212

182

198

168

183

149

157

133

133

114

114

99

99

86

86

360

*

315

*

281

*

253

237

230

186

211

149

195

120

181

98

169

82

158

68

142

58

123

49

106

42

92

36

80

32

414

450

363

394

323

351

291

316

264

287

242

264

224

243

208

226

194

211

182

198

164

178

146

159

131

141

118

122

106

106

360

*

315

*

281

*

253

*

230

222

211

178

195

144

181

118

169

98

158

82

149

70

139

59

124

51

111

44

97

38

414

450

363

394

323

351

291

316

264

287

242

264

224

243

208

226

194

211

182

198

171

186

160

173

143

156

129

141

117

127

378

*

331

*

295

*

265

*

241

*

221

209

204

170

190

140

177

116

166

98

156

83

148

71

135

61

122

53

110

46

435

473

381

414

339

369

305

332

278

302

255

277

235

256

218

237

204

222

191

208

180

196

170

185

155

169

140

152

127

138

387

*

339

*

302

*

272

*

247

*

227

*

210

198

195

163

182

136

170

114

160

97

151

83

143

71

131

62

119

54

446

484

390

424

347

378

313

340

285

309

261

284

241

262

224

243

209

227

196

213

184

201

174

189

165

179

151

164

137

149

See Load Table Instructions and General Notes on page 6

387

*

339

*

302

*

272

*

247

*

227

*

210

*

195

188

182

157

170

132

160

112

151

96

143

83

136

72

127

63

446

484

390

424

347

378

313

340

285

309

261

284

241

262

224

243

209

227

196

213

184

201

174

189

165

179

157

171

146

159

Load Tables

Red-I90HS™ Allowable Uniform Load (PLF)

117⁄ 8"

Span

14'

16'

18'

20'

22'

24'

26'

28'

30'

32'

34'

36'

38'

40'

42'

44'

14"

16"

18"

20"

Depth

22"

24"

26"

28"

30"

32"

100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL

100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL

327

263

287

186

255

121

209

83

161

64

127

50

101

40

82

32

376

409

330

358

293

319

264

278

215

215

169

169

135

135

109

109

90

90

75

75

63

63

53

53

45

45

39

39

34

34

29

29

362

*

317

265

282

175

254

121

231

94

185

74

149

59

121

48

100

40

83

33

70

28

46'

48'

50'

416

452

364

396

324

352

292

317

266

289

244

247

199

199

162

162

133

133

111

111

93

93

79

79

68

68

58

58

51

51

44

44

39

39

34

34

30

30

393

*

345

*

307

232

276

161

251

126

230

100

201

80

164

65

136

54

113

45

95

38

81

32

452

492

396

431

353

383

318

345

289

314

265

288

245

266

219

219

181

181

151

151

127

127

108

108

93

93

80

80

70

70

61

61

53

53

47

47

42

42

426

*

373

*

332

295

299

207

272

162

249

129

230

104

214

85

177

70

148

59

125

50

106

42

91

36

79

31

490

532

429

467

382

415

344

374

313

340

287

312

265

288

246

268

230

236

197

197

167

167

142

142

122

122

105

105

91

91

80

80

70

70

62

62

55

55

458

*

402

*

357

*

322

256

293

202

268

161

248

131

230

107

215

89

187

75

158

63

135

54

116

46

100

40

87

35

76

30

527

573

462

502

411

447

370

402

337

366

309

336

285

310

265

288

247

269

232

250

211

211

180

180

155

155

134

134

116

116

102

102

90

90

79

79

70

70

490

*

429

*

382

*

344

310

313

245

287

197

265

160

246

132

230

109

216

92

195

78

167

66

143

57

124

49

108

43

95

38

83

33

74

29

564

613

494

537

439

478

396

430

360

391

330

359

305

332

283

308

264

287

248

270

233

254

220

222

191

191

166

166

144

144

126

126

111

111

99

99

88

88

494

*

432

*

385

*

347

*

315

292

289

235

267

192

248

158

232

132

217

111

204

94

193

80

174

69

151

60

131

52

115

46

101

40

90

36

80

32

568

617

497

541

443

481

399

433

363

394

333

362

307

334

285

310

266

290

250

272

235

256

222

241

210

229

198

201

175

175

154

154

135

135

120

120

107

107

494

*

432

*

385

*

347

*

315

*

289

276

267

226

248

187

232

156

217

131

204

112

193

96

183

82

174

71

157

62

138

55

121

48

108

43

96

38

568

617

497

541

443

481

399

433

363

394

333

362

307

334

285

310

266

290

250

272

235

256

222

241

210

229

200

217

190

207

177

184

162

162

144

144

128

128

494

*

432

*

385

*

347

*

315

*

289

*

267

262

248

217

232

182

217

154

204

131

193

112

183

97

174

84

166

73

158

64

143

57

127

50

113

45

568

617

497

541

443

481

399

433

363

394

333

362

307

334

285

310

266

290

250

272

235

256

222

241

210

229

200

217

190

207

182

198

174

189

161

169

148

151

494

*

432

*

385

*

347

*

315

*

289

*

267

*

248

*

232

210

217

177

204

151

193

130

183

112

174

98

166

85

158

75

151

66

145

59

132

52

568

617

497

541

443

481

399

433

363

394

333

362

307

334

285

310

266

290

250

272

235

256

222

241

210

229

200

217

190

207

182

198

174

189

167

181

159

173

494

*

432

*

385

*

347

*

315

*

289

*

267

*

248

*

232

*

217

203

204

173

193

149

183

129

174

112

166

98

158

86

151

76

145

68

139

60

568

617

497

541

443

481

399

433

363

394

333

362

307

334

285

310

266

290

250

272

235

256

222

241

210

229

200

217

190

207

182

198

174

189

167

181

160

174

* Indicates that total load (TL) value controls.

■

Red numbers refer to 115% total load (TL).

See Load Table Instructions and

General Notes on page 6

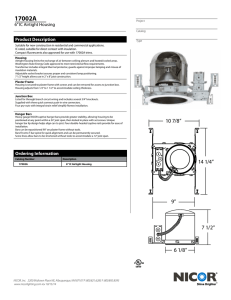

8' On-center Roof Span Table

Red-I90HS™ Joist 8' On-Center Roof Span

Joist

Depth

16"

18"

20"

22"

24"

26"

28"

30"

32"

12 PSF

Dead Load

27'- 0''

29'- 9''

32'- 7''

35'- 3''

38'- 0''

40'- 2''

41'- 11''

43'- 7''

45'- 3''

14 PSF

Dead Load

26'- 0''

28'- 5''

31'- 0''

33'- 7''

36'- 3''

38'- 9''

40'- 4''

42'- 0''

42'- 2''

Simpson HWU or WPU hanger

16 PSF

Dead Load

24'- 5''

26'- 7''

28'- 11''

31'- 4''

33'- 9''

36'- 3''

37'- 10''

39'- 0''

39'- 0''

Web stiffener

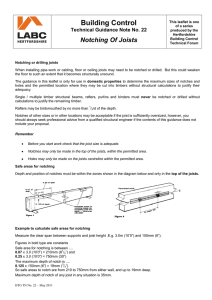

General Notes

Table assumes uniformly loaded, simple-span joists.

■

Roof live load is 20 psf with live load reductions applied per 2009 IBC

Section 1607.11.2.

■

■

Red-I™joists are spaced at 8' on-center.

■

■

Spans are limited by total load deflection of L/180.

■

■

■

■

Span is defined as horizontal clear distance between inside face of beam/wall

supports. Spans reflect 125% duration of load adjustment.

Roof is assumed to be sloped 1⁄4" per foot.

Reaction based on 3" minimum bearing length and web stiffeners. See web

stiffener information on page 16.

Bold italic numbers indicate span may be increased by 1 foot when HWU

hanger is used.

Fill all nail holes in hanger. Use 10d (3") common nails into joists and 16d

(31⁄2") common nails into header.

9

Floor Details

Typical Floor System

See Red-I™ Joist Installation Guide

(Available online at www.RedBuilt.com)

for additional installation guidelines

Header and Red-I™ Joist

Refer to detail 8 on page 12

A 250 lb maximum load can be

­supported on each side of

the bottom flange of the

Red-I™ joist at 5' o.c.

Backer blocks

Field installed backer

blocks at header location

Rim Board

WARNING

Safety bracing required to

ensure adequate bracing

during construction

Hanger on Beam

Refer to detail 4 on page 11

Red-I™ joist overhang

must be protected

from the weather

Cantilever

Red-I™ Blocking Panel

Refer to page 15

Sheathing provides

sway bracing

Outriggers

Refer to page 12

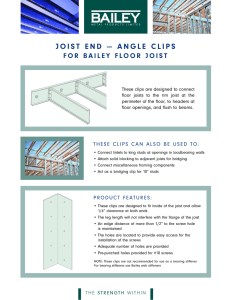

1Nailing Red-I™ Joist to Bearing Plate

11⁄2" rim board

Web stiffener. See page 16.

General Notes

■

■

Details shown on pages 10–14 are conceptual. Attachments and connections

shall be made to the supporting structure in accordance with the specific

design requirements.

Rim board or Red-I™ blocking panels (or an equivalent alternative) must

always be used to prevent rollover and to provide structural attachment of the

deck sheathing to the supporting structure in accordance with the specific

design requirements.

10

Nails may need to be

driven at an angle to

minimize splitting of

bearing plate

For 11⁄2" thick flanges, attach

with one 10d (3") box nail,

minimum, each side of Red-I™

joist at bearing. Use 12d (31⁄4")

box nails with 13⁄4" thick flanges.

Maintain 11⁄2" minimum end

distance to minimize splitting.

Floor Details

3Hanger on Ledger

2 Hanger on Stud Wall

If seismic tension ties are

required, see page 17

Web stiffener

each side of joist

(if required)

Web stiffener

each side of

joist (if required)

Joist hanger

Joist hanger

Ledger

The potential for top plate rotation may reduce hanger capacities.

Contact RedBuilt™ for assistance.

4 Hanger on Beam

5 Hanger on Steel Beam

Nailer thickness must accommodate

hanger nail length and may affect

capacity. Refer to hanger manufacturer’s

literature for details.

Web stiffener

each side of joist

(if required)

Web stiffener

each side of joist

(if required)

Joist hanger. Hanger height

must be a minimum of 60%

of the joist depth.

Web stiffeners are required if the sides of the hanger do not laterally ­

support at least 3⁄ 8 " of the Red-I™ joist top flange

Joist hanger

6 Hanger on Masonry Wall

If seismic tension ties are

required, see page 17

Blocking as required

Fasteners to bond

beam as required

Web stiffener

each side of joist

(if required)

Masonry or

concrete wall

Masonry hanger

Traditional masonry hangers will not support construction loads ­without

a minimum amount of cured masonry construction above ­hanger level.

Refer to hanger manufacturer’s literature for information on the correct

installation and use of masonry hangers.

11

Floor Details

7 Side-Loaded Double Joist

8 Side-Loaded Double Joist

(Ladder Framing)

(Header Location)

Field-installed backer

block at header locations

1,050 plf ­maximum

load (or 2,100 lbs

at 2' on-center

m

­ inimum)

Double Red-I™ joists

sized for side load

Hanger

Double Red-I™ joists

sized for header load

2x ladder framing

Continuous filler

blocks (nail to

joist web)

Header

Field-installed backer block

at reactions over 250 lbs.

9 Support Detail

Header hanger

10Top-Loaded Double Joist

Filler block

each side;

nail to web

Field- or shop-installed

full-length filler blocks. (Not

required on joists 20" or less in

depth if sheathing is nailed to

both joist flanges.)

Face mount hanger

Support member

Red-I™ joists

Load

A 250 lb ­maximum load can be supported on each side of the Red-I™ joist

bottom flange at 5' on-center, provided the load is included in normal design

loads. Use this detail for loads exceeding these limits.

For additional information on supporting hanging loads and

sprinkler systems, see the Sprinkler System Installation Guide

(Available online at www.RedBuilt.com).

CANTILEVERS AND Outriggers

11Red-I™ Joist Cantilever

Red-I™ blocking

panel

Web stiffener

each side of joist

(if required)

2x_ block as

required

12

Red-I™ joists are intended

for dry-use applications

CantileverS AND OUTRIGGERS

12a Cantilevers

12b Outriggers

(Field Assembled Only)

(Available as Plant Asembled)

Red-I™ blocking panel

Wood backer:

Use 3⁄4" net thickness

with 11⁄2" wide joist

flanges; use 2x_ with

31⁄2" wide joist flanges

L

2x_ cantilever nailed to the

side of the Red-I™ joist

with wood backer. Use with

two rows 10d (3") nails,

minimum, at 6" o.c.

ver

tile L

n

a

C gth

len iform )

­(un s only

d

loa

ver

tile

Can gth L

len

Red-I™

blocking panel

L

Red-I™ joists and

cantilevers/outriggers

are intended for

dry-use applications

Two rows 10d (3")

nails minimum at

6" o.c.

2x_ outrigger

Squash block

(tight fit)

Double application shown in details 12 & 13. Single application is similar.

See general notes regarding allowable loads.

Double 2x_ Capacities

Allowable Uniform Loads (plf)

Cantilever/

Outrigger

Length

L

24"

30"

36"

42"

48"

54"

60"

66"

72"

78"

84"

90"

96"

Cantilever/

Outrigger

Length

L

24"

30"

36"

42"

48"

54"

60"

66"

72"

78"

84"

90"

96"

Solid Sawn Lumber

Two 2x4

Floor

Snow

Roof

342

219

152

111

77

54

393

251

174

128

97

77

62

Two 2x6

NonSnow

Roof

427

273

189

139

106

83

63

47

Floor

Snow

Roof

393

384

323

237

181

143

115

95

79

68

56

451

441

371

272

208

163

132

109

91

77

66

57

50

■

Floor

Snow

Roof

393

384

378

374

289

227

183

151

126

107

92

80

70

451

441

435

430

330

260

209

172

144

122

105

91

79

Two 2x10

NonSnow

Roof

491

480

473

467

358

281

227

186

156

132

113

97

85

Floor

Snow

Roof

393

384

378

374

371

337

271

222

186

157

135

116

102

451

441

435

430

426

384

308

252

210

178

152

131

114

Two 2x12

NonSnow

Roof

491

480

473

467

463

414

332

271

226

190

162

139

121

Floor

Snow

Roof

393

384

378

374

371

368

362

296

246

207

177

153

133

451

441

435

430

426

424

410

335

277

232

197

169

146

NonSnow

Roof

491

480

473

467

463

460

441

359

295

246

208

178

153

RedLam™ LVL

Two 2x4

Floor

Snow

Roof

393

292

173

110

74

53

451

441

277

177

119

84

62

46

36

Two 2x6

NonSnow

Roof

491

467

277

177

119

84

62

46

36

Floor

Snow

Roof

393

384

378

374

277

198

146

110

85

67

54

451

441

435

430

417

317

233

177

137

108

87

71

58

General Notes

■

Two 2x8

NonSnow

Roof

491

480

403

295

225

177

143

118

99

84

72

62

54

Bold Italic cells indicate a single 2x can be used; use

half of the allowable load shown for double 2x members.

For all other cells single 2x members are not permitted.

Members have been evaluated for 300 lb. point load.

Two 2x8

NonSnow

Roof

491

480

473

467

444

317

233

177

137

108

87

71

58

Floor

Snow

Roof

393

384

378

374

371

368

322

246

191

152

122

100

83

451

441

435

430

426

424

421

348

288

242

196

160

132

Two 2x10

NonSnow

Roof

491

480

473

467

463

460

456

371

306

243

196

160

132

Floor

Snow

Roof

393

384

378

374

371

368

366

365

363

306

247

203

168

451

441

435

430

426

424

421

419

410

339

283

238

202

Two 2x12

NonSnow

Roof

491

480

473

467

463

460

458

456

425

350

291

244

206

Floor

Snow

Roof

393

384

378

374

371

368

366

365

363

362

334

281

238

451

441

435

430

426

424

421

419

418

417

346

289

245

NonSnow

Roof

491

480

473

467

463

460

458

456

454

425

351

293

247

Table is based on:

Solid Sawn

RedLam™ LVL

Cantilever/Outrigger Deflection

• 2L/480 at floor live load

Fv = 175 psi

Fv = 285 psi

(live load = 0.80 x total load)

Fb = 900 psi(1)Fb = 2140 psi(2)

• 2L/240 at roof total load

E = 1.6 x 106 psi

E = 1.6 x 106 psi

(1) Size Factor, CF, per NDS Table 4a may be applied.

(2) For 12" depth. For other depths, multiply by (12/d)0.136

13

Roof DETAILS

14Slope Detail at High End

13Slope Detail

Web stiffener

each side of joist

(if required)

Red-I™ joist blocking

Web stiffener

each side of joist

(if required)

Beveled plate

Hanger with sloped seat

per manufacturer recommendations

15Beveled Plate Requirements

16Ridge Detail

Web stiffener

each side of joist

(if required)

Red-I™ joist blocking

Beveled plate

Required

Bearing Length

13⁄4"

31⁄2"

51⁄2"

Maximum Slope Without

Beveled Plate

1⁄2" in 12"

1⁄4" in 12"

1 ⁄ 8" in 12"

17Cantilever with Mansard Framing

A strap and alternating blocking panels, or two rows

of blocking panels, are required for lateral stability.

18Bevel Cut or Fire Cut

Do not bevel cut joist beyond

inside face of wall

Web stiffener

each side of joist

(if required)

14

Rim Board

Rim board (up to 24" in depth) is available

from RedBuilt™ and may be used for:

■

Shear transfer (nailing must be ­established by design).

■

Vertical load transfer.

■

General closure.

■

Helping to prevent rollover during joist installation.

Attach rim board to

b­ earing plate. Nail with

­connections ­equivalent to

­decking nail schedule.

Minimum spacing per

Nailing Information

on page 16

11⁄2" rim board

Red-I™ Blocking Panels

Minimum Red-I ™ blocking panel attachment:

Use 10d (3") box nails (16d [31⁄2"] with I90HS joists) at

6" on-center. When used for shear transfer, nail to bearing

plate with connections equivalent to decking nail schedule.

Nail per Web Stiffener

Attachment table on page 16

Red-I™ blocking panel

Red-I™ blocking panels are available from

RedBuilt™ and may be used for:

■

Shear transfer. Shear ­transfer capacity is 1,745 lbs per linear foot for Red-I45™

,

2,255 lbs for Red-I65™and Red-I90™, 2,300 lbs for Red-I90H™

, and 2,320 lbs

for Red-I90HS™joists. Nailing must be established by design.

■

Vertical load transfer.

■

General closure.

■

Helping to prevent rollover during joist installation.

Red-I™ Joist Series

Red-I™ Blocking Panel Depth

91 ⁄ 2 "

117⁄ 8"–14"

2,100

91 ⁄ 2 "

–

2,100

117⁄ 8"–14"

3,050

16"

2,100

16"–20"

2,450

■

Loads are for Red-I™ blocking panels or Red-I™ joists as rim board.

Loads shown may not be increased for duration of load.

Lc + 2ts + 2tf

12

]

–

–

22"–24"

1,850

–

–

26"–30"

1,200

Pallow = Allowable concentrated vertical load (lbs)

Wallow = Allowable uniform vertical load for blocking panel (plf)

Lc

= Bearing length of column on blocking panel (in.)

ts

= Sheathing thickness (in.)

tf

=Effective flange thickness: 7⁄8" for Red-I45™

, Red-I65™ and Red-I90™;

11⁄8" for Red-I90H™; and 11⁄4" for Red-I90HS™

Example:

4x4 post applied to 20" Red-I65™ joist through 23⁄32" sheathing.

Pallow = 2,700

■

[

Where:

Allowable Uniform Vertical Load Transfer (PLF)

I65, I90,

I90H and I90HS

The allowable concentrated vertical loads on Red-I™ blocking panels or rim

joist can be determined by using the equation provided below. Loads exceeding

the calculated value should be supported by squash blocks.

Pallow = Wallow

When Red-I™ blocking panels are used for vertical load transfer, the following values

may be used:

I45

Concentrated vertical loads

[

]

3.5 + 2(23⁄32) + 2(7⁄8)

12

= 1,505 lbs

15

Web Stiffeners

To Ensure System Performance

The Importance of Web Stiffeners

Web stiffeners are available from RedBuilt™ in pre-cut sizes and can be installed at

the plant on one or both ends upon request. Web stiffeners are an important part

of almost all Red-I™ joist installations because they will:

■

Stiffen the Red-I™ joist web material and prevent buckling.

■

Minimize the bearing length required for the Red-I™ joist.

■

Help transfer reaction loads into the Red-I™ joist web.

■

Provide stabilization in hangers.

■

■

■

■

Web stiffeners must be installed at bearing points as shown in the details below

and at points of concentrated loads exceeding 1,500 lbs.

Web stiffeners are required on joists 20" and greater in depth.

Web stiffeners are available from RedBuilt™ and typically have the maximum

gap shown below. Verify that hanger nails adequately engage the web stiffener.

Gap must be at top for all bearing conditions. For concentrated loads, the gap

must be at the bottom (see details below).

Web Stiffener Attachment - Nail Quantities

Joist

Depth

91 ⁄ 2 "

117⁄ 8"

14"

16"

18"

20"

22"

24"

26"

28"

30"

32"

Red-I45™

Red-I65™

8d (21⁄2") Nails

End or

Intermediate

3

3

3

3

–

–

–

–

–

–

–

–

8d (21⁄2") Nails

End or

Intermediate

–

3

5

6

7

8

9

10

11

12

13

–

1⁄8"

Red-I90™ and

Red-I90H™

16d (31⁄2") Nails

End

Intermediate

–

3

3

4

4

5

6

6

7

8

8

–

–

3

3

4

4

5

11

13

14

15

17

–

Red-I90HS™

16d (31⁄2") Nails

End or

Intermediate

–

4

6

6

8

10

10

12

14

14

16

18

Web Stiffener Size

13/4"

5 ⁄8"

21⁄2"

1" x 2 5 ⁄16"

31⁄2"

2x4

Web Stiffener Material

Gap

Space nails

equally(2)

Snug fit

1" typical(1)

(1) 11/ 2 " (typical) with 2x4 solid sawn lumber web stiffeners.

(2) Nails may be driven from one side only.

If concentrated loads from above exceed

1,500 lbs, install web s­ tiffeners tight to

Red-I™ joist top flange. See tables at left

for ­nailing and material requirements.

Sheathing (with face grain ­vertical) that

meets the ­requirements of PS1 or PS2

Sheathing (with face grain ­vertical) that

meets the ­requirements of PS1 or PS2

Construction grade or better

x 2 5 ⁄16"

1" typical(1)

Concentrated Load (No Bearing Wall Below)

Web Stiffener Size and Material

Flange

Width

minimum

23⁄4" maximum

Nailing Information

Minimum Nail Spacing

Nail Type

8d(1)

10d

12d

16d

Box

Common

Box

Common

Box

Common

Box

Sinker

Common

Nail Size

0.113" x 21⁄2"

0.131" x 21⁄2"

0.128" x 3"

0.148" x 3"

0.128" x 31⁄4"

0.148" x 31⁄4"

0.135" x 31⁄2"

0.148" x 31⁄4"

0.162" x 31⁄2"

Face

Face

2"

2"

2"

3"

2"

3"

3"

3"

4"

RedLam™ LVL

Edge

Joist

Rim Board,

Flange Header, Beam

4"

3"

6"

3"

6"

3"

6"

4"

6"

3"

6"

4"

6"

4"

6"

4"

8"

8"

Sawn Lumber

Face

Edge

4"

6"

6"

6"

6"

6"

6"

6"

8"

2"

2"

2"

21⁄2"

2"

21⁄2"

21⁄2"

21⁄2"

4"

(1)14 gauge staples may be a direct ­substitute for 8d nails if a ­minimum penetration of 1" into

the flange is maintained.

If more than one row of nails is used, offset rows at least 1⁄2" and stagger. Use 10d (3")

common nails, maximum, and maintain 3⁄8" minimum edge distance. Exception: Wind/Seismic

Connections (page 17).

Nailing pattern to be per plans and specifications, and nail ­spacing should comply with criteria

listed on this page.

For member stability, nail sheathing to the full length of the member (24" on-center, ­maximum).

■

■

Edge

Flatwise orientation

(typical with Red-I™ joists and

plywood edge blocking)

Edge

Face

Edgewise orientation

(typical with rim board, beams,

and headers)

Red-I™

joist flange

Sheathing

■

1⁄2"

16

Closest

spacing

wind or seismic connections

19Wall Tension Tie—With Straps

For

2 1⁄2"

Strap Tension Tie Nailing and Capacities

or wider Red-I™ joists.

Simpson

Strap

Model

Strap

Length

PAI18

PAI23

PAI28

PAI35

MPAI32(3)

MPAI44 (3)

LTT20B

18"

23"

29"

35"

32"

44"

20"

PAI18

PAI23

PAI28

PAI35

MPAI32 (3)

MPAI44 (3)

LTT20B

18"

23"

29"

35"

32"

44"

20"

Wind or ­seismic tie

Masonry or

concrete wall

Ledger

Allowable Loads (2) (lbs)

10d (11⁄2")

Common Nails (1)

Masonry

Concrete

Masonry

Concrete

133%

160%

133%

160%

13⁄4" RedLam™ LVL or 3x_ Ledger

8 nails

10 nails

1,000

1,205

1,255

1,505

13 nails

15 nails

1,630

1,955

1,880

2,255

19 nails

21 nails

2,380

2,815

2,630

3,160

24 nails

27 nails

2,815

2,815

3,385

3,685

16 nails