Electronic Monitoring System

advertisement

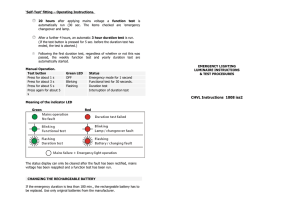

Electronic Te s t P e r f o r m a n c e The state-of-the-art microprocessor technology used by the WatchGuard EMS (Electronic Monitoring System) Self-Diagnostics Option enables it to offer a variety of unique and useful features, plus unsurpassed programming flexibility to suit any application. The use of surface mounted components minimizes PC board size allowing the option to be added within the standard housing of Sure-Lites units and exits; this makes specification easier and avoids attracting unwanted attention to the fixtures from mischievous persons. Voltage and load sensing resolution of ±0.1% insures maximum accuracy and reliability. The tricolor LED diagnostic indicator (see chart on back) pinpoints detected failures to the component level and continuously displays the status of the charger (float or high charge modes) during normal operation. In addition, fixtures with the WatchGuard EMS Option have all of the standard electronic features which are found on all Sure-Lites selfpowered fixtures such as dual voltage input, AC Line-latching, solid-state charging, solid-state switching (no mechanical transfer relays), brownout detection, and short circuit/overload protection. A programmable Time Delay feature is standard with all WatchGuard EMS Options; designed for use especially in HID environments, the Time Delay feature causes the emergency lighting heads (lamps) to remain on for 15 minutes (programmable to 0, 20 or 30 minutes) after resumption of AC power following a power outage or brownout condition. The WatchGuard EMS is a continuous monitoring system. Input transformer status, battery charger function, and battery voltage are monitored at all times. The WatchGuard EMS is also an automatic test system. Once per day, the emergency and exit lamps are briefly tested (less than 1 second) to insure that they will be operational in the event of an emergency. The emergency and exit lamps are also continuously monitored in the emergency operating mode. Every 30 days, the entire system is subjected to a 1minute confidence test. This monthly confidence check verifies lamp operation, battery integrity, battery connections, battery charging function, and transfer circuitry per the requirements of the NFPA 101 Life Safety Code. Every 6 months, a semi-annual full battery capacity test is conducted to verify all of the above plus test the capacity of the battery to operate the connected lamp load for the required emergency mode time frame (90 or 120 minutes). This battery capacity test, which is also required by the NFPA 101 Life Safety Code, can be field programmed for durations of 30 minutes, 90 minutes (default), or 120 minutes (default for Chicago Approved fixtures); a battery capacity test will only be initiated if the system detects that the battery is fully charged, thus, avoiding false failure indications. The monthly and semi-annual tests can also be field disabled, if desired. In addition to continuous monitoring and automatic testing, various manual tests are also available. Pressing the test switch for one beep will initiate a 5minute confidence test; pressing the test switch for two beeps will initiate a full battery capacity test. All automatic tests can be conveniently delayed for 36 hours and manual tests can be aborted simply by pressing the test switch for one beep after the test has begun. The STAR (System Test Abuse Restriction) feature is an essential component to the WatchGuard EMS Option. STAR limits the maximum number of manual tests which can be performed in a 24hour period. This protects the diagnostic system (especially batteries and lamps) from excessive testing by mischievous persons and insures that the exit/unit will be ready to respond in the event of a real emergency. The STAR feature limits the 5-minute confidence test to 4 per day and the full battery capacity test to 1 per day. Te s t S w i t c h / D i a g n o s t i c Indicator The test switch provides the field programming interface for the WatchGuard EMS Option. Programmable parameters such as test durations, Time Delay feature durations, and audible diagnostic indicator operation can be changed by simply pressing the test switch in the proper sequence as outlined in the installation instructions (and pocket reference card). The test switch can also be used to initiate a “read back” of the factory programmed settings for battery voltage, battery type, Flasher Option status, and Buzzer Option status making it easy to confirm the electronic configuration of a fixture with the WatchGuard EMS Option at any time. Temporarily silencing the audible diagnostic indicator (for 7 days) is also accomplished by pressing the test switch following detection of a failure. The diagnostic indicator provides the visual diagnostic interface for the WatchGuard EMS Option. A red/yellow/green tricolor LED diagnostic indicator visually annunciates all of the diagnostic conditions by adjusting its color and flash sequence per the failure detected (see chart on back). It also indicates float charge mode (steady green) and high charge mode (pulsing green) at all times during standby mode operation. Being a single indicator, without any external module or other unusual construction, the tricolor LED minimizes unwanted attention and inherently protects the system from mischief. In addition to the tricolor LED diagnostic indicator, an audible indicator provides further indication of a detected failure condition. It has been designed to output a noticeable (but not obnoxious) “beep” in the event of a failure; this “beep” can be programmed to sound continuously or pulse (default). If desired, the audible indicator can be permanently disabled in the field. Installation Fixtures with the WatchGuard EMS Option are very simple to install because they do not require any special actions or provisions when compared to standard Sure-Lites fixtures. Most importantly and unlike competitive self-diagnostic systems, the WatchGuard EMS Option automatically selfcalibrates the emergency and/or exit lamp loads. There are no time consuming adjustments to potentiometers and no difficult-to-move PC board jumpers like on most competitive products. Each lamp circuit measures its respective lamp load at start-up and stores that data in the microprocessor memory. Any time a change in lamp load is detected, a failure diagnostic will appear. The change could be caused by a failed lamp, removed lamp, or even an incorrectly replaced (wrong wattage) lamp. If lamp loads need to change later, simply disconnect AC power and the battery to reinitiate a system calibration routine. Installation is also made simple by the unique design of the PC board and test switch/diagnostic indicator which does not add any additional wires that require field connection. Any programming required at installation is quickly and easily performed via the test switch. Of course, any optional settings can also be preprogrammed during factory assembly when specified at the time of order.