dynamic behaviour of dfig-based wind turbines during symmetrical

advertisement

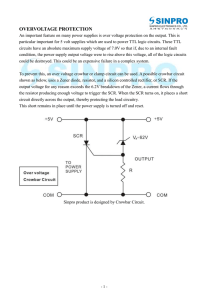

Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 DYNAMIC BEHAVIOUR OF DFIG-BASED WIND TURBINES DURING SYMMETRICAL VOLTAGE DIPS Almoataz Y. Abdelaziz, Amr M. Ibrahim, Ahmed M. Asim, Ahmed H. Abdel Razek Electrical Power and Machines Department, Faculty of Engineering, Ain Shams University, Cairo, Egypt almoatazabdelaziz@hotmail.com, amrmohamedhassan@yahoo.com, asd.200n@gmail.com, ahheizen@gmail.com ABSTRACT Recently, wind power generation has reached a significant penetration levels in some countries. This is the case for instance in Denmark, Spain and Germany. This imposes new challenges to the transmission system operators (TSOs). New grid requirements for wind generation are needed. These requirements stipulate that wind farms should contribute to power system control, much as the conventional power stations and focus on wind farm behaviour in case of grid disturbances. Isolation of wind turbines in case of voltage dips is not allowed anymore as low voltage ride through (LVRT) capability is required. This paper will discuss the dynamic behaviour of DFIG based wind turbine under severe three phase voltage dips without and with the usage of crowbar protection system including simulation results to verify the discussion. KEYWORDS Wind Turbine, Low Voltage Ride Through, Crowbar &DFIG 1. INTRODUCTION Doubly fed induction generators (DFIG) are the most commonly used wind turbine technology [1-4]. It uses a wound rotor induction generator with slip rings to transmit electrical power between the converter system and rotor windings. Variable speed operation is obtained by injecting a controllable voltage into the rotor at desired slip frequency. The DFIG based wind turbine can transmit electrical power to the grid through both the generator stator and the converters. When the generator operates in super-synchronous (slip < 0) mode, power will be delivered from the rotor through the converters to the grid, and when the generator operates in sub-synchronous (slip > 0), the rotor will absorb power from the grid through the converters. The generator slip ranges from -0.3 to 0.3, this means that maximum power transferred through the converters is nearly 30% of the nominal power of the generator, therefore smaller and cheaper converters can be used compared with full size converters used with other wind turbine technologies [5]. In normal grid conditions, power electronic converters enable DFIG to operate at optimal rotor speed. It maximizes electrical power generated by controlling the active and reactive power flow into the grid [6]. 47 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 In case of severe voltage dips [7-10], large transient currents are induced in the stator circuit. Due to magnetic coupling between stator and rotor windings, large transient currents are induced in the rotor circuit. Such high currents could damage the converters and increase the voltage of the DC-link, therefore a protection is required. The protection of the converter is achieved by short circuiting the rotor circuit through a crowbar, thus protecting the converters from high rotor currents. Once the rotor currents are blocked from the converters, control on the DFIG is lost, thus losing the active and reactive power control on the stator of the DFIG and the machine operates as a typical induction generator [11-12]. The aim of this paper is to provide insight and understanding about the dynamic behaviour of DFIG based wind turbines, its protection against overcurrent and overvoltage and its LVRT capability. This paper is organized as follows. Section 2 presents configuration of DFIG variable speed wind turbine. Section 3 presents the dynamic model of DFIG. Section 4 describes effects of severe voltage dips on DFIG. Section 5 presents simulation and results. Section 6 presents conclusions. 2. CONFIGURATION OF DFIG VARIABLE SPEED WIND TURBINE. A schematic diagram of DFIG wind turbine is shown in Figure 1. The AC/DC/AC converter is divided into two converters rotor side converter (RSC) and grid side converter (GSC) [13]. Both converters are voltage source converters. They use forced commutated power electronic devices (IGBTs) to convert from AC to DC and vice versa. A capacitor connected to the DC side of the converter acts as a DC voltage source. A coupling inductor is used to connect the GSC to the grid. The rotor winding is connected to the RSC by slip rings and brushes. Both the stator and the GSC are connected to the grid through a transformer to convert low voltage into medium voltage. The mechanical power captured by the wind turbine is converted into electrical power by the generator and transmitted to the grid through the stator and the converters. The control system of the DFIG based wind turbine consists of three parts [14]. • Speed control which controls the electrical power reference of converter as well as of the pitch angle. • RSC control which controls active and reactive power on the stator side. • GSC control that regulates the DC-link voltage to keep it constant and can be used to inject additional reactive power to the grid. 3. DYNAMIC MODELLING OF DFIG To demonstrate effects of severe voltage dips on the DFIG based wind turbine system, a detailed time model is used [15-16]. This model preserves stator transients. It is called the fifth order model. 48 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 Figure 1 A schematic diagram of DFIG based wind turbine Figure 2 Equivalent circuit of an induction generator dynamic model The equivalent circuit of the dynamic model is represented as in Figure 2. Stator and rotor voltage equations can be written as follows (1) (2) Where and represents the voltage, current and flux respectively, is the synchronous speed and is the rotor speed. The subscripts and refer to stator and rotor respectively. The relation between flux and currents is given by, (3) 49 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 (4) Where represents the magnetizing reactance. Symbols inductances respectively, where and represent the stator and rotor (5) (6) Where and are the stator and rotor leakage inductances respectively. The electromagnetic torque of the generator can be calculated as follows (7) The apparent power of the stator is given by (8) The mechanical equation is as follows (9) Where represents the generator inertia and represents the mechanical torque. 4. EFFECTS OF SEVERE VOLTAGE DIPS ON DFIG At normal operating conditions, there is a stator flux rotating in the air gap of DFIG. This flux is directly proportional to the stator voltage, if a voltage dip takes place, from equation (1), the flux can't change instantaneously with voltage change. A transient flux component is induced in the stator. This transient flux is a DC decaying component which depends on the time constant of the stator circuit and the value of the rotor current. Due to mutual coupling between rotor and stator of the DFIG, a transient emf is induced on the rotor circuit. This transient emf component is very large as it depends on the rotor speed [17-18]. This large transient emf in the rotor winding saturates the RSC which leads to • Loss of current control RSC controls the rotor circuit current by changing output voltage of the converter. If the rotor emf is very high so that maximum output voltage of the converter is reached, saturation takes place and current control is lost. RSC can't compensate for large rotor emf. Current levels in the rotor 50 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 circuit increase to high values especially at the beginning of voltage dip. Unless a very oversized converter is used large currents will damage the semiconductor of the converter. • Increase of DC-link voltage Due to large amount of power that the RSC absorbs, while being saturated, DC-link voltage increases. During severe voltage dips this power can't be evacuated to the grid, because the power transfer capability of the GSC has dropped due to low voltage of the grid, as a result the power accumulates in the capacitor of the DC-link and its voltage increases. Crowbar is to be used to protect the system from loss of current control and increase in DC-link voltage, a schematic diagram of DFIG with crowbar system is shown as in Figure 3. The crowbar shorts the rotor winding at severe voltage dip. It is connected at the first stage of the dip when the rotor emf is at its highest level. Once the transient flux has decayed and rotor emf is no longer dangerous, the crowbar can be disconnected, so that the machine can resume its normal operation. When the crowbar is connected, it causes the rotor current to increase but this doesn't affect the RSC, as it's disconnected and its current is zero. This means that DFIG is not controlled anymore and it acts as typical squirrel cage induction machine. Once the crowbar is disconnected the RSC can resume its operation and controls the stator power [19-23]. Figure 3 DFIG with crowbar system 5. SIMULATION AND RESULTS To verify discussion in the previous section a simulation is conducted to study the electrical dynamics of DFIG based wind turbine without and with the addition of crowbar to the system. The simulation is carried out in MATLAB®/ SIMULINK/ SimPowerSystem software [24]. In this simulation the DFIG is subjected to a severe voltage dip of about 90% for 0.15 sec. An EMT of DFIG is used to preserve the stator dynamics as discussed previously. Vector control is used for controlling both RSC and GSC. It's assumed that the DFIG produces its nominal active power and zero reactive power at normal conditions, also wind speed is assumed to be constant during the simulation period. Turbine rated voltage and power are taken as base values. GSC is rated at 30% of the turbine rated current. GSC controller limits the GSC current to 0.5 p.u. 51 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 5.1. Dynamic Behaviour of DFIG without Crowbar A voltage dip of 90% takes place from 0.1 sec. to 0.25 sec. as shown in Figure 4. This leads to transient overcurrents in stator and rotor circuits as shown in Figure 5 and Figure 6 respectively. Currents reach values of 6-7 p.u in both stator and rotor circuits, then decay exponentially subjecting the RSC to very large stresses which are not acceptable because they may destroy the RSC as shown in Figure 7. Figure 4 Stator voltage under 90% voltage dip Figure 5 Stator current without crowbar protection 52 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 Figure 6 Rotor current without crowbar protection Figure 7 RSC current without crowbar protection Figure 8 shows an increase in the DC-link voltage to reach a value 2-3 p.u that exceeds the capacitor rating which is not acceptable. Figure 8 DC-link voltage without crowbar protection 53 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 GSC tries to regulate the DC-link voltage at 1 p.u, its current increases to 50% of the wind turbine rated current as shown in Figure 9, this causes a significant overload on the GSC. However, the GSC is not able to regulate the DC-link voltage due to low grid voltage. Figure 9 GSC current without crowbar protection Figure 10 shows active and reactive power generated by wind turbine during severe voltage dip. Active power drops nearly to zero due to low grid voltage. At the start of the dip DFIG inject a burst of reactive power into the grid and at the end of the dip (voltage recovery) it absorbs a burst of reactive power from the grid. Figure 10 Active and reactive power without crowbar protection Finally from the simulation results it is concluded that without crowbar severe voltage dips may result in destruction of the converter system as fast separation of DFIG is not allowed as LVRT capability is required. 5.2. Dynamic Behaviour of DFIG with Crowbar To provide LVRT capability, a crowbar is used to prevent the DFIG from being disconnected from the grid during severe voltage dips. The system is subjected to voltage dip of 90% as in the previous case. Figure 11 shows the stator voltage. 54 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 Figure 11 Stator voltage with crowbar protection The crowbar will not be connected to the rotor circuit till the voltage of DC-link reaches a value of 1.1-1.2 p.u. When the DC voltage reaches 1.1 p.u the crowbar is connected and lasts connected for 100ms. At the end of the voltage dip the crowbar is connected again when the DC-link voltage reaches 1.1 p.u and it lasts connected for 40 ms. Having the crowbar connected the converter is separated from the rotor circuit. Figure 12 and Figure 13 show the rotor and stator currents with crowbar protection. They are quite similar to the previous cases. Figure 12 Rotor current with crowbar protection 55 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 Figure 13 Stator current with crowbar protection Figure 14 shows the RSC current with crowbar protection. A sharp spike takes place till crowbar is connected then the RSC currents drop to zero during the connection of the crowbar which protects the RSC from over currents. After the disconnection of crowbar, rotor current returns to its nominal values and it is controlled by RSC. Crowbar current is shown in Figure 15. Figure 14 RSC current with crowbar protection Figure 15 Crowbar current 56 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 Figure 16 DC-link voltage with crowbar protection The effect of crowbar on DC-link voltage is shown in Figure 16, DC voltage is kept almost constant at 1 p.u. Figure 17 shows the grid side converter current. The GSC current will not saturate at 50% of rated current of the turbine which means that GSC is protected from large stresses. Figure 17 GSC current with crowbar protection Active and reactive powers are nearly similar to what happen in the previous case as shown in Figure 18. Figure 18 Active and reactive power with crowbar protection 57 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 6. CONCLUSION DFIG based wind turbines are subjected to heavy stresses during severe grid voltage dips, which may cause the deterioration of the converter system. Therefore, the whole system is to be disconnected from the grid during severe voltage dips but this is not acceptable by the new grid requirements, which require wind turbines to have LVRT capability. A crowbar protection system is used to make wind turbines being able to stay connected to the grid during voltage dips while limiting currents and voltages levels within acceptable values. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] F. Blaabjerg, M. Liserre, K. Ma, "Power Electronics Converters for Wind Turbine Systems," in Proc. of ECCE, Sept. 2011. Z. Chen, J.M. Guerrero, F. Blaabjerg, "A Review of the State of the Art of Power Electronics for Wind Turbines," IEEE Transactions on Power Electronics, vol. 24, no. 8, pp.1859-1875, Aug. 2009. T. Abedinzadeh, M. Ehsan, and D. Talebi,"Dynamic Modeling and Control of Induction Generators in Wind Turbines", International Journal of Computer and Electrical Engineering, Vol. 4, No. 2, April 2012. A. D. Hansen, F. Iov, F. Blaabjerg and L. H. Hansen, “Review of Contemporary Wind Turbine Concepts and their Market Penetration”, Journal of Wind Engineering, Vol. 28, No. 3, 2004, pp. 247-263. O. Anaya-Lara, N. Jenkins, J. Ekanayake, P. Cartwright and M. Hughes, Wind Energy Generation: Modelling and Control, Chichester, West Sussex, United Kingdom, 2009. C. Feltes , S. Engelhardt , J. Kretschmann, J. Fortmann and I. Erlich, “Comparison of the Grid Support Capability of DFIG-based Wind Farms and Conventional Power Plants with Synchronous Generators,” in IEEE PES '09 GM, 2009, pp. 1–7. Lluís Trilla, Oriol Gomis-Bellmunt, Adrià Junyent-Ferre, Montserrat Mata, Javier Sanchez Navarro, Antoni Sudria-Andreu “Modeling and Validation of DFIG 3MW Wind Turbine Using Field Test Data of Balanced and Unbalanced Voltage Sags”, IEEE Transactions on Sustainable Energy , vol. 2, no. 4, pp. 509-519, 2011. C. Wessels and F. W. Fuchs, “LVRT of DFIG wind turbines - crowbar vs stator current feedback solution,” in EPE Wind Energy Chapter 2010, Symposium on, April 2010. J. Lopez, P. Sanchis, X. Roboam and L. Marroyo, "Dynamic behavior of the doubly fed induction generator during three phase voltage dip," IEEE Transactions on energy conversion, vol. 22, no. 3, pp. 709–717, Sept. 2007. M. P. Comech, J. Sallán and A. Lombart, “Modelling wind farms for grid disturbance studies,” Renewable Energy, vol. 33, no. 9, pp. 2109–2121, Sept, 2008. C. Rahmann, H. J. Haubrich, L. Vargas and M. B. C. Salles, “Investigation of DFIG with Fault RideThrough Capability in Weak Power Systems,” in IPST '09 - Kyoto, Japan, 2009, paper 248, Session 7A. C. Feltes, S. Engelhardt, J. Kretschmann, J. Fortmann and I. Erlich, “Dynamic Performance Evaluation of DFIG based Wind Turbines regarding new German Grid Code Requirements,” in IEEE PES '10 GM, 2010, pp. 1–7. R. Gagnon, G. Sybille, S. Bernard, D. Paré, S. Casoria and C. Larose, “Modeling and Real-Time Simulation of a Doubly-Fed Induction Generator Driven by a Wind Turbine,” in IPST '05 Montréal, Canada, 2005, paper 162, section 26D. I. Erlich, H. Wrede, and C. Feltes, “Dynamic Behavior of DFIG-Based Wind Turbines during Grid Faults,” in PCC '07-Nagoya, 2007, pp 1195–1200. S. Panda and N. P. Padhy, “Stability Improvement of a Wind Energy Embedded Distribution System,” International Journal of Electrical and Computer Engineering, vol. 2, pp. 600–607, Nov. 2007. 58 Electrical and Electronics Engineering: An International Journal (ELELIJ) Vol 2, No 2, May 2013 [16] [17] [18] [19] [20] [21] [22] [23] [24] B. Babypriya and R. Anita “Modelling, Simulation and Analysis of Doubly Fed Induction Generator for Wind Turbines,” Journal of Electrical Engineering, vol. 60, no. 2, pp. 79–85, 2009. G. Abad, J. López, M. A. Rodríguez, L. Marroyo and G. Iwanski, Doubly Fed Induction Machine: Modeling and Control for Wind Energy Generation Applications, L. Hanzo, Ed. Hoboken, New Jersey: John Wiley & Sons, 2011. S. Y. Lei, A. Mullane, G. Lightbody, and R. Yacamini, "Modeling of the wind turbine with a doubly fed induction generator for grid integration studies," IEEE Trans. Energy Conversion, vol. 21, pp. 257-264, March, 2006. L. Peng, B. Francois, and Y. Li, “Improved crowbar control strategy of DFIG based wind turbines for grid fault ride-through,” Applied Power Electronics Conference and Exposition, APEC 2009. Twenty Fourth Annual IEEE, pp. 1932–1938, Feb. 2009. S. Sajedi, F. Khaliefah, T. Karimi and Z. Khaliefah, "Fault ride through protection of DFIG based wind generation system", Research Journal of Applied Sciences, Engineering and Technology, Vol. 4, No. 5, 2012, pp. 428-432 T. Sun, Z. Chen and F. Blaabjerg, “Voltage Recovery of Grid-Connected Wind Turbines with DFIG after a Short-circuit Fault”, 35th Annual IEEE Power Electronics Specialists Conference Aachen, Germany, 2004. J. Morren, and S. W. H. De Haan, "Ride through of Wind Turbines with Doubly-fed Induction Generator during a Voltage Dip", IEEE Trans. Energy Conversion, vol. 20, 2005, pp. 435–441. K. Lima, A. Luna, P. Rodriguez, E. Watanabe, R. Teodorescu, and F. Blaabjerg, “Doubly-fed induction generator control under voltage sags,” Energy 2030 Conference, 2008. ENERGY 2008. IEEE, pp. 1–6, November 2008. The MathWorks website. [Online]. Available: http://www.mathworks.com/. Authors Almoataz Y. Abdelaziz was born in Cairo, Egypt, on 1963. He received the B. Sc. and M. Sc. degrees in electrical engineering from Ain Shams University, Cairo, Egypt in 1985, 1990 respectively and the Ph. D. degree in electrical engineering from Brunel University, England in 1996. He is currently a professor of electrical power engineering in Ain Shams University.His research interests include the applications of artificial intelligence and new heuristic and evolutionary optimization techniques to power system protection, operation, planning and control. He has authored or coauthored more than 130 refereed journal and conference papers. Dr. Abdelaziz is a member of the editorial board and a reviewer of technical papers in several international journals. He is also a member in IEEE, IET and the Egyptian Sub-Committees of IEC and CIGRE`. Dr. Abdelaziz has been awarded Ain Shams University Prize for distinct researches in 2002 and for international publishing in 2011, 2012. Amr M. Ibrahim, was born in Egypt in 1975. He received the B.Sc., M.Sc. and Ph. D. degrees in electrical engineering from Ain Shams University, Cairo, Egypt in 1998, 2003 and 2008 respectively. He is currently an assistant professor in the department of electric power and machines, Ain Shams University. His research interests include power system protection and applications of AI in power systems. 59