101 Basic Series

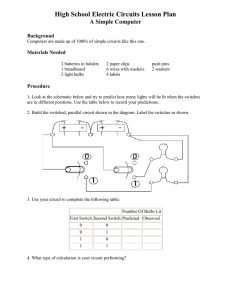

advertisement