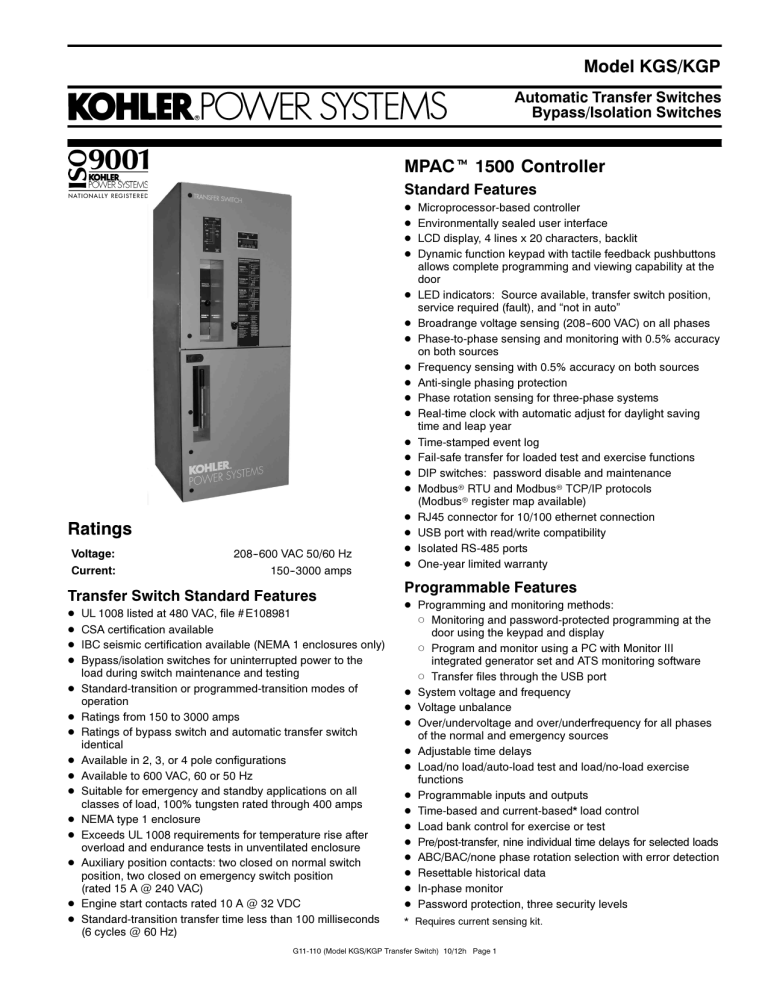

Model KGS/KGP Ratings MPACt 1500 Controller

Model KGS/KGP

Automatic Transfer Switches

Bypass/Isolation Switches

Ratings

MPAC

t

1500 Controller

Standard Features

D Microprocessor-based controller

D Environmentally sealed user interface

D LCD display, 4 lines x 20 characters, backlit

D Dynamic function keypad with tactile feedback pushbuttons allows complete programming and viewing capability at the door

D LED indicators: Source available, transfer switch position, service required (fault), and “not in auto”

D

Broadrange voltage sensing (208--600 VAC) on all phases

D Phase-to-phase sensing and monitoring with 0.5% accuracy on both sources

D Frequency sensing with 0.5% accuracy on both sources

D Anti-single phasing protection

D Phase rotation sensing for three-phase systems

D Real-time clock with automatic adjust for daylight saving time and leap year

D Time-stamped event log

D Fail-safe transfer for loaded test and exercise functions

D DIP switches: password disable and maintenance

D

Modbus r

RTU and Modbus r

TCP/IP protocols

(Modbus r register map available)

D RJ45 connector for 10/100 ethernet connection

D USB port with read/write compatibility

D Isolated RS-485 ports

D One-year limited warranty

Voltage:

Current:

208--600 VAC 50/60 Hz

150--3000 amps

Transfer Switch Standard Features

D UL 1008 listed at 480 VAC, file # E108981

D CSA certification available

D IBC seismic certification available (NEMA 1 enclosures only)

D Bypass/isolation switches for uninterrupted power to the load during switch maintenance and testing

D Standard-transition or programmed-transition modes of operation

D Ratings from 150 to 3000 amps

D Ratings of bypass switch and automatic transfer switch identical

D Available in 2, 3, or 4 pole configurations

D Available to 600 VAC, 60 or 50 Hz

D Suitable for emergency and standby applications on all classes of load, 100% tungsten rated through 400 amps

D NEMA type 1 enclosure

D

Exceeds UL 1008 requirements for temperature rise after overload and endurance tests in unventilated enclosure

D Auxiliary position contacts: two closed on normal switch position, two closed on emergency switch position

(rated 15 A @ 240 VAC)

D Engine start contacts rated 10 A @ 32 VDC

D

Standard-transition transfer time less than 100 milliseconds

(6 cycles @ 60 Hz)

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 1

Programmable Features

D Programming and monitoring methods: d Monitoring and password-protected programming at the door using the keypad and display d

Program and monitor using a PC with Monitor III integrated generator set and ATS monitoring software d Transfer files through the USB port

D System voltage and frequency

D Voltage unbalance

D Over/undervoltage and over/underfrequency for all phases of the normal and emergency sources

D Adjustable time delays

D Load/no load/auto-load test and load/no-load exercise functions

D Programmable inputs and outputs

D Time-based and current-based* load control

D Load bank control for exercise or test

D Pre/post-transfer, nine individual time delays for selected loads

D

ABC/BAC/none phase rotation selection with error detection

D Resettable historical data

D In-phase monitor

D Password protection, three security levels

* Requires current sensing kit.

User Interface LED Indicators

D Contactor position: source N and source E

D Source available: source N and source E

D Service required (fault indication)

D Not in automatic mode

LCD Display

D System status

D Line-to-line voltage

D Line-to-neutral voltage

D Active time delays

D Source frequency

D Preferred source selection

D

System settings

D

Common alarms

D

Load current, each phase [

D

Inputs and outputs

D Faults

D Time/date

D Address

D Event history

D Maintenance records

D Exerciser schedule

D Exerciser mode

D Time remaining on active exercise

Dynamic Function Tactile Keypad Operations

D Scroll up/down/forward/back

D Increase/decrease/save settings

D End time delay

D Start/end test or exercise

D Reset fault

D Lamp test

DIP Switches

D Maintenance mode

D Password disable

MPAC

t

1500 Controller Features

Communications

D USB port with read/write capability

D Isolated RS-485 ports

D RJ-45 connector for 10/100 ethernet connection

D Modbus r RTU and Modbus r TCP/IP protocols

(Modbus r register map available)

D USB Port. Upload or download files from a PC or a memory device through the USB port.

d Application software d Event history files d

Language files d Parameter settings d Usage reports d Feature configuration

USB Data Logger

D Time-stamped voltage and frequency readings

D Minimum and maximum current and voltage readings for a selected time period

Event History

D View up to 99 time and date-stamped events on the display or on a personal computer equipped with optional Monitor III software.

D Download up to 2000 events with Monitor III software or download complete event history file to a PC or a memory device connected to the USB port.

Main Logic Board Inputs and Outputs

D Two (2) programmable inputs

D Two (2) programmable outputs, isolated form C (SPDT) contacts rated 1 amp @ 30 VDC, 500 mA @120 VAC

Programmable Features

D System voltage, 208--600 VAC *

D System frequency, 50/60 Hz *

D

Single/three-phase operation *

D Standard/programmed-transition operation *

D Preferred source selection

D Phase rotation: ABC/BAC/none selection with error detection

D Voltage and frequency pickup and dropout settings

D Voltage unbalance, enable/disable

D In-phase monitor: enable/disable and phase angle

D Transfer commit/no commit

D

Source/source mode: utility/gen, gen/gen, utility/utility, or utility/gen/gen for 3-source systems

D Passwords, system and test

D Time, date, automatic daylight saving time enable/disable

D Time delays (see table)

D Exerciser: calendar mode, loaded/unloaded up to 21 events

D Test: loaded/unloaded/auto load (1--60 minutes)

D Remote test: loaded/unloaded

D Automatic override on generator failure (loaded test and exercise)

D Peak shave delay enable/disable

D Current monitoring [

D Pre/post-transfer, 9 individual time delays for selected loads

D Current-based load control settings: high/low current levels and load add/remove priority for 9 separate loads [

D Prime power sequence alternates between two generator sets

D

Resettable historical data

Main Board I/O Specifications

Output contact type Isolated form C (SPDT)

Output contact rating 1 amp @ 30 VDC, 500 mA @120 VAC

I/O terminals wire size range #12--24 AWG

* System parameters factory-set per order

[

Requires optional current sensing kit.

Modbus r is a registered trademark of Schneider Electric.

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 2

MPAC

t

1500 Controller Features, continued

Programmable Inputs

D External time delay input

D External battery fault

D External common fault

D Inhibit transfer

D Peak shave/area protection input

D External test

D Three-source system disable

D Bypass disable

Programmable Outputs

D Chicago alarm control

D Common alarm events

D Contactor position

D Exercise active

D Failure to acquire standby source

D Failure to transfer

D

Generator engine start, source N and E

D

I/O module faults

D Load bank control

D Load control active (pre/post transfer delay, up to 9 outputs)

D Loss of phase fault, source N and E

D External battery fault

D Non-emergency transfer

D Not in automatic mode

D Over/underfrequency faults, source N and E (generator)

D Over/undervoltage faults, source N and E

D Peak shave/area protection active

D Phase rotation error, source N and E

D Preferred source supplying load

D Software-controlled relay outputs (four maximum)

D Source available, preferred and standby

D Standby source supplying load

D Synchronizing output

D Test active

D Transfer switch auxiliary contact fault

D Transfer switch auxiliary contact open

D Voltage unbalance

Parameter

Voltage and Frequency Sensing

Undervoltage dropout

Undervoltage pickup

Overvoltage dropout *

Overvoltage pickup

Unbalance enable

Unbalance dropout

Unbalance pickup

Voltage dropout time

Underfrequency dropout

Underfrequency pickup

Overfrequency dropout

Overfrequency pickup

Frequency dropout time

Adjustable Time Delays

Time Delay Default Adjustment Range

Engine start, Source S2 3 sec.

0--6 sec.

[

Engine start, Source S1 (gen/gen) 3 sec.

Engine cooldown, Source S2

Engine cooldown, S1 (gen/gen)

Fail to acquire standby source

Fail to acquire preferred source

Transfer, preferred to standby

Transfer, standby to preferred

Transfer, off to standby

Transfer, off to preferred

Fail to synchronize

Auto load test duration

Default

90% of pickup

90% of nominal

115% of nominal*

95% of dropout

Disable

20%

10%

0.5 sec.

99% of pickup

90% of nominal

101% of pickup

110% of nominal

3 sec.

5 sec.

2 sec.

1 min.

1 min.

3 sec.

15 min.

1 sec.

1 sec.

60 sec.

30 min.

Adjustment

Range

75%--98%

85%--100%

106%--135%

95%--100%

Enable/Disable

5%--20%

3%--18%

0.1--9.9 sec.

95%--99%

80%--95%

101%--115%

105%--120%

0.1--15 sec.

* 690 volts, maximum. Default = 110% for 600 volt applications.

0--60 min.

1 sec. -- 60 min.

10 sec -- 15 min.

1--60 min.

(1 min. increments)

Prime power run duration 6 min.

6 min. -- 100 days

(6 min. increments)

Load Control Time Delays:

Pretransfer to preferred

Post-transfer to preferred

Pretransfer to standby

0 sec.

0 sec.

0 sec.

0 sec.

0--60 min.

Post-transfer to standby

Load add Source1/Source2

Load remove Source1/Source2

0 sec.

0 sec.

Note: Time delays are adjustable in 1 second increments, except as noted.

[

Engine start time delay can be extended to 60 minutes with an

External Battery Supply Module Kit.

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 3

Standard Features

Transfer Switch Standard Features:

D Switches are factory-wired, interconnected, and tested prior to shipment.

D All current-carrying components provide withstand current ratings in excess of those specified in UL-1008 standards.

D The contactor is electrically operated and mechanically held by a simple, over-center mechanism.

D The transfer switch has a double-throw, interlocked operation. Mechanical and electrical interlocks ensure proper sequence of operation.

D The transfer switch has segmented silver tungsten alloy contacts with separate arcing contacts on all sizes of switches. Transfer switches have arc quenching grids, enclosed arc chambers, and wide contact air gap to ensure superior source-to-source isolation on all units.

D The transfer switch components are accessible for inspection and maintenance without removal of the switch or the power conductors.

D A mechanical indicator and transparent chamber cover aid inspection, improve safety, and ease position designation.

D The disconnect switch inhibits transfer when activated.

D The automatic transfer switch is located on a drawout mechanism to facilitate maintenance.

D

Emergency power systems can be electrically tested without disturbing the load.

D Power cables do not have to be disconnected to remove the automatic transfer switch.

D The engine start circuit is maintained during bypass operation. Normal power failure causes the engine start contact to close even with the automatic transfer switch removed.

D The electrical controls are mounted on the enclosure door and connected by a wire harness and multipin disconnect plugs. The automatic transfer switch and/or the control panel may be tested, isolated, or removed for maintenance without load interruption.

D

Diagnostic lights and detailed instructions allow simple step-by-step operation.

D Bypass switch contacts are closed only during the bypass isolation operation.

D A silver-plated, copper bus interconnection for the automatic transfer switch and bypass switch is standard for all sizes of switches.

Programmed-Transition Model Additional Features:

D The programmed transition function allows the load’s magnetic field to collapse before transferring to either source.

D Switching is accomplished by a dual DC solenoid drive for rapid operation and long life.

D

The time delay after the opening of the closed contacts and before the closing of the open contacts is adjustable.

D The transfer switch is suited for applications where the load consists of large motors and/or transformers.

Bypass Isolation Switch Description and Operation

The bypass-isolation transfer switch consists of two major components: an automatic transfer switch and a bypass-isolation switch.

The automatic transfer switch power switching components are available in standard and programmed-transition configurations and constructed for rugged, reliable operation.

The bypass section is a manually operated transfer switch that includes a manual load transfer handle and a control and interlock system. The switches are mounted in a compact enclosure and completely interconnected, requiring only the source and load connections. Once installed, no cables need to be removed to isolate the transfer switch module for maintenance or inspection.

Additional load-break contacts that cause load interruption during bypass-isolation functions are not required. The bypass- isolation switch contacts are out of the system’s current path except during actual bypass operation. Therefore, they are not constantly exposed to the destructive effects of potential fault currents. The normal source, emergency source, and load are connected between the automatic transfer switch and the bypass-isolation switch through solid-braced isolating contacts that open when the transfer switch is isolated.

The transfer switch has three positions:

D Automatic: The automatic transfer switch is supplying power to the load, and the bypass switch is in the open position. This position is the normal operating position.

D Test: The bypass switch is closed and supplying power to the load. The automatic transfer switch’s electrical controls are powered and the test switch on the enclosure door can be used to test the automatic transfer switch.

D Isolate: The bypass switch is closed and supplying power to the load. The automatic transfer switch is withdrawn from all power and is ready for maintenance.

The bypass-isolation switch has the same design as the transfer switch and thus has the same electrical ratings.

Manually operated, it features high-speed, quick-make, quick-break contact action. The bypass-isolation switch has three positions:

D Automatic: Normal bypass contacts open and emergency bypass contacts open

D Bypass Normal: Normal bypass contacts closed and emergency bypass contacts open

D Bypass Emergency: Normal bypass contacts open and emergency bypass contacts closed

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 4

Application Data

Environmental Specifications

Operating Temperature --20

°

C to 70

°

C (--4

°

F to 158

°

F)

Storage Temperature --40

°

C to 85

°

C (--40

°

F to 185

°

F)

Humidity 5% to 95% noncondensing

Input and Output Connection Specifications

Component Wire Size Range

Main board I/O terminals

I/O module terminals

#12--24 AWG

#14--24 AWG

Al/Cu UL-Listed Solderless Screw-Type Terminals for

External Power Connections

Switch Rating, amps

150--400

600

Normal, Emergency, and Load Terminals

Cables per Pole Range of Wire Sizes*

2

1

2

1/0 to 250 MCM

#4 AWG to 600 MCM

#2 AWG to 600 MCM

800--1200

1600--2000

4

8

#2 AWG to 600 MCM

1/0 to 750 MCM

2600--3000 12 1/0 to 750 MCM

* Use 60

°

C minimum wire for #14 to #1 AWG. Use 75

°

C minimum wire for 1/0 AWG and larger.

The ATS meets or exceeds the requirements of the following specifications:

D Underwriters Laboratories UL 508, Standard for Industrial

Control Equipment

D Underwriters Laboratories UL 1008, Standard for Automatic

Transfer Switches for Use in Emergency Standby Systems, file # E108981

D CSA C22.2 No. 178 certification at 600 VAC available, file # LR58301

D

NFPA 70, National Electrical Code

D NFPA 99, Essential Electrical Systems for Health Care

Facilities

D NFPA 110, Emergency and Standby Power Systems

D IEEE Standard 446, IEEE Recommended Practice for

Emergency and Standby Power Systems for Commercial and Industrial Applications

D NEMA Standard ICS 10--2005, Electromechanical AC

Transfer Switch Equipment

Codes and Standards

D EN61000-4-4 Fast Transient Immunity Severity Level 4

D IEC 60947-6-1, Low Voltage Switchgear and Control Gear;

Multifunction Equipment; Automatic Transfer Switching

Equipment

D EN61000-4-5 Surge Immunity Class 4

(voltage sensing and programmable inputs only)

D IEC Specifications for EMI/EMC Immunity: d CISPR 11, Radiated Emissions d IEC 1000-4-2, Electrostatic Discharge d IEC 1000-4-3, Radiated Electromagnetic Fields d IEC 1000-4-4, Electrical Fast Transients (Bursts) d IEC 1000-4-5, Surge Voltage d IEC 1000-4-6, Conducted RF Disturbances d IEC 1000-4-8, Magnetic Fields d IEC 1000-4-11, Voltage Dips and Interruptions

D IEEE 472 (ANSI C37.90A) Ring Wave Test

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 5

Weights and Dimensions

Weights and dimensions are shown for transfer switches in NEMA type 1 enclosures. Consult the factory for other available enclosures.

Note: Weights and dimensions are provided for reference only and should not be used for planning installation. See your local distributor for submittal drawings.

Bypass/Isolation Switches in NEMA 1 Enclosures

Number of

Poles

2

3

Amps

150, 225, 260, 400

150, 225, 260, 400

600

800, 1000, 1200

1600, 2000

Height

2184 (86.00) *

2184 (86.00) *

2362 (93.00) *

2362 (93.00) *

2286 (90.00)

Dimensions, mm (in.)

Width

762 (30.00)

762 (30.00)

914 (36.00)

1016 (40.00)

1016 (40.00)

Depth

787 (31.00)

787 (31.00)

718 (28.25)

[

718 (28.25)

[

1552 (61.12)

4

2600, 3000

150, 225, 260, 400

600

800, 1000, 1200

2286 (90.00)

2184 (86.00) *

2362 (93.00) *

2362 (93.00) *

2286 (90.00)

2286 (90.00)

1016 (40.00)

762 (30.00)

1016 (40.00)

1168 (46.00)

1270 (50.00)

1270 (50.00)

1857 (73.12)

787 (31.00)

718 (28.25)

[

718 (28.25)

[

1552 (61.12) 1600, 2000

2600, 3000 1857 (73.12)

* Height includes removeable 76 mm (3 in.) lifting eyes on 150--1200 amp models.

[

Depth with optional adapter bay for bottom cable entry is 1074 mm (42.3 in.). (600--1200 amp models only.)

Weight, kg (lb.)

340 (750)

340 (750)

553 (1220)

615 (1355)

1406 (3100)

1769 (3900)

386 (850)

619 (1365)

712 (1570)

1815 (4000)

2268 (5000)

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 6

Withstand and Close-On Ratings (WCR)

Switch

Rating, amps

150

225

260

400

600

Withstand Current Ratings, Maximum Current in RMS Symmetrical Amperes When Coordinated with:

Current-Limiting Fuses Molded-Case Circuit Breakers

Specific Manufacturer’s

(see separate tables)

Maximum

Fuse Size, amps

@ 480 VAC

Maximum

Rating, amps Class

@ 600 VAC

Maximum

Rating, amps Class

Any Manufacturer’s (3 cycles)

Maximum

Amps @

480 VAC

Maximum

Amps @

600 VAC

Maximum

Size, amps

Maximum

Amps @

480 VAC

Maximum

Amps @

600 VAC

200

300

350

600

200,000

100,000

J

RK5,

RK1

200,000 J 35,000 30,000 800 50,000 42,000

750 200,000

J, L,

RK1,

RK5

150,000

J, L,

RK1,

RK5

800 65,000 50,000

800

1000

1200

1600

1000

1200

1500

2000

200,000 L 200,000

2000

2600

2500

200,000 L 150,000

4000

3000

* UL 1008 listed at 480 VAC and CSA listed at 600 VAC.

L

L

50,000

100,000

42,000

85,000

1600

2500

4000

85,000

100,000

65,000

85,000

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 7

Withstand and Close-On Ratings with Coordinated Circuit Breakers,

480 V Maximum, UL Listed and CSA Certified

The following chart lists contactor withstand and close-on ratings (WCR) with specific manufacturer’s circuit breakers.

Molded-Case Circuit Breakers

Switch

Rating

WCR, RMS

Symmetrical

Amperes

150,

225,

260,

400

600

800,

1000,

1200

50,000

65,000

85,000

Manufacturer

General Electric

Merlin Gerin

ITE

Square D

Cutler-Hammer

ITE

General Electric

Square D

Cutler-Hammer

General Electric

Merlin Gerin

ITE

Square D

Cutler-Hammer

Type or Class

SFL, SFP, TFL, THLC2

SGL4, SGP4, TB4, THLC4, TLB4

SGL6, SGP6, SGPA, TB6, TJL4V, TKL4V, TJL1S--6S

SKL8, SKP8, TB8, SKH8

CF250L, CF250H

CJ400L, CK400H, CJ400H, CK400N

CJ600H

CK800H, CK800N

CFD6, HFD6

CJD6, SCJD6, HHJD6, HHJXD6 SHJD6, HJD6

CLD6, SCLD6, HHLD6, HHLXD6, SHLD6, HLD6

CMD6, SCMD6, HMD6, SHMD6, HMXD6, MD6, MXD6, SMD6

KI, KC

LI, LXI, LX, LE, LC

MX, MH, ME

HJD, JDC

HKD, CHKD, KDC, LCL, LA TRI-PAC

HLD, CHLD, LDC, CLDC

NB TRI-PAC

CLD6, HLD6, SCLD6, SHLD6

CMD6, SCMD6, HMD6, SHMD6

TB6, TJL, SGL6, SGP6

TB8, TP, THP, TC, THC, SKL8, SKP8

LC, LE, LI, LX, LXI

ME, MH, MX, NC, NE, NX

CHDC, CLDC, HLD, LDC

CHMDL, HMDL, NB TRI-PAC, DSL206

SKP8, TB8, THC, THP

SKP12

THP, THC, TRP

CK1000L

CM1600

CMD6, SCMD6

CND6, SCND6

CPD6

NC, NE, NX

PCF, PEF, PHF, PXF

NB TRIPAC

CNDC, NDC

CRDC, PB TRIPAC, PC, PCC, RDC

Maximum

Size, amps

800

250

400

600

800

250

600

250

400

600

800

250

400

600

800

600

800

600

800

800

250

400

600

800

600

800

1200

1600

1200

1600

800

1200

1600

600

800

800

1200

1600

1200

1600

1600,

2000,

2600,

3000

100,000 Any, 4000 Ampere Maximum 4000

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 8

Withstand and Close-On Ratings with Coordinated Circuit Breakers,

600 V Maximum, CSA Certified

The following chart lists contactor withstand and close-on ratings (WCR) with specific manufacturer’s circuit breakers.

Molded-Case Circuit Breakers

Switch

Rating, amps

WCR, RMS

Symmetrical

Amperes

150,

225,

260,

400

600

800,

1000,

1200

42,000

50,000

65,000

Manufacturer

General Electric

Merlin Gerin

ITE

Cutler-Hammer

Square D

General Electric

ITE

Square D

Cutler-Hammer

General Electric

Merlin Gerin

ITE

Square D

Cutler-Hammer

Type or Class

THLC2

SGL4, SGP4, TB4, THLC4

SGL6, SGP6, TB6

SKL8, SKP8, TB8

CF250L

CJ400L, CK400H

CK800H

CFD6

CJD6, SCJD6, HHJD6, HHJXD6

CLD6, SCLD6, HHLD6, HHLDX6

CMD6, SCMD6, HMD6, SHMD6, HMXD6

KDC, LCL, LA TRI-PAC

LDC, CLDC

NB TRI-PAC

KI

LI, LXI

TB6, SGL6, SGP6

TB8, THP, THC, SKP8

CLD6, SCLD6

CMD6, HMD6, SCMD6, SHMD6

LI, LXI

NC, NE, NX

CLDC, LDC

NB TRI-PAC, DSL206

SKP8, TB8, THC, THP

SKP12

THC, THP, TRP

MP16H1, MP16H2, MC16H1

CMD6, SCMD6

CND6, SCND6

CPD6, HPD6, HRD6

NC, NE, NX

PCF, PEF, PHF, PXF

NB TRIPAC

PC, PCC, PB TRI-PAC, RDC, CRDC

1600

800

1200

1600

1200

600

800

800

1200

1600

800

600

800

600

800

600

800

250

600

600

1600

800

1600

Maximum

Size, amps

250

400

250

400

600

800

400

600

800

250

400

800

1600,

2000,

2600,

3000

85,000 Any, 4000 Ampere Maximum 4000

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 9

Accessory Modules

The mounting kit holds up to five optional modules. The maximum total current draw is 300 mA. If an External Battery

Module is installed, there is no current restriction.

Module Current Draw Specifications, mA

Alarm Module 75

Accessories

Accessories are available either factory-installed or as loose kits, unless otherwise noted.

-

Alarm Module

D 90 dB Audible alarm

D Any alarm function can be programmed to trigger the audible alarm

D Chicago alarm function

D Preferred source selection

D Supervised transfer control (supervised transfer control switch required)

D Connection for external alarm

Standard I/O Module

High Power I/O Module

-

Standard Input/Output Module

75

100

External Alarm Connection Specifications

Wire Size

Contact Voltage Rating

#12--22 AWG Cu

500 mA @ 120 VAC

250 mA @ 240 VAC

Inputs

Available Inputs

Input Definition

Current

Connection Type

Wire Size

Max Distance

Outputs

Outputs Available

Contact Type

Contact Voltage Rating

Connection Type

Wire Size

2

Contact closure

5 mA Max

Terminal Strip

#14--24 AWG

700 feet

6

Form C (SPDT)

2 A @ 30 VDC

500 mA @ 125 VAC

Terminal Strip

#14--24 AWG

-

External Battery Supply Module

D Energizes the ATS controls using an external battery when no source power is available

D Allows extended engine start time delays

D Allows the use of any combination of accessory modules

(no current draw restriction, maximum of five modules total)

D Connects to one or two batteries, 12 VDC or 24 VDC system

D Current draw, 140 mA @ 12 VDC, 86 mA @ 24 VDC

D Provides low external battery voltage indication to the transfer switch controller

D Reverse-polarity protected

Other Accessories

-

Adapter Bays

D Available for 600--1200 amp models

-

High-Power Input/Output Module

Inputs

Available Inputs

Input Definition

Current

Connection Type

Wire Size

Max Distance

2

Contact closure

5 mA Max

Terminal Strip

#14--24 AWG

700 feet

Outputs

Outputs Available

Contact Type

Contact Voltage Rating

Connection Type

Wire Size

3

Form C (SPDT)

12 A @ 24 VDC

12 A @ 250 VAC

10 A @ 277 VAC

2 A @ 480 VAC

Terminal Strip

#14--24 AWG

Environmental Specifications

Temperature --40

°

C to 85

°

C (--40

°

F to 185

°

F)

Humidity 35% to 85% noncondensing

-

CSA Certification

-

Current Sensing Kit

D Monitor current on all phases with 1% accuracy

-

Digital Meter

D

Measure and display for both sources: d Voltage d Current d Frequency d Power

D Programmable visual alarms: d High voltage d

Low voltage d

High current

D Serial port for optional network connections

D Password-protected programming menus

D Available factory-installed

D See TT-1506, Digital Power Meters

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 10

-

Extended Warranties

D 2-year basic

D 5-year basic

D 5-year comprehensive

D 10-year major components

-

Export Packaging

Accessories, continued

-

Neutral Assembly

D Available as loose kit for open units

-

Remote Annunciator for ATS

D Allows remote monitoring and limited control of up to four transfer switches connected in an RS-485 network

D Includes surface and flush mounting provisions

-

Seismic Certification

D Certification depends on application and geographic location. Contact your distributor for details.

D Available on 150--3000 Amp models with NEMA 1 enclosures

-

Heater, Anti-Condensation

D Humidistat-controlled 120 VAC strip heater

(customer-supplied voltage source required)

D 125 or 250 watts (sized for enclosure)

D

Protective 15 Amp circuit breaker

-

Literature Kits

D Production literature kit

(one kit is included with each transfer switch)

D Overhaul literature kit

-

Line-to-Neutral Voltage Monitoring

D Monitors all line-to-neutral voltages

-

Logic Disconnect Switch

D Disconnects power to controller without disconnecting load

D Mounts inside the enclosure

-

Monitor III Software

D Monitor and control the power system’s generator sets and transfer switches from a personal computer using a single software package

D Monitor and control systems through a Windows r -based graphical user interface

D Monitor and control systems over a local area network, remotely via a modem connection, or through an Ethernet connection

D Password-protected data access: Guest, User, and

Supervisor levels

D Ethernet capability

D Start or stop a test from a remote PC

D View and adjust trip points, time delays, and system parameters

D Assign inputs and outputs

D Available as loose kits: d Software kit with serial cable d Software kit with device modem and cables

-

Supervised Transfer Control Switch

D Auto, Manual, and Transfer positions

D Automatic and non-automatic modes

D Alarm module required

-

Surge Protective Device (SPD)

D SPD available for the normal source supply

D Surge protection reduces transient voltages to harmless levels

D Replaceable without disconnecting power

D High-performance EMI/RFI filtering:

--75dB maximum 100 kHz to 100 MHz

D Protection modes: L-L, L-N, L-G, N-G

D Thermal and short circuit fusing

D

LED status indicators

D Remote contacts for customer-supplied status indicators

Form C (NO, NC, C) 60 W DC, 120 VAC, 3A max.

D Audible alarm, 90 dB

D Listed to UL 1449, Edition 3

D See additional specifications below

SPD Specifications

Surge

Current

(I max ), kA

UL SVR,

VAC

Limiting Voltage,

VAC at

3kAmps at

10kAmp

Working

Voltage

120/240

120/208

120/240

277/480

220/380

240/415

3

3

3

Ph.

Split

3

3

100

100

100

400

400/800

800

470

470/890 780/1200

890

780

1200

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 11

KOHLER CO., Kohler, Wisconsin 53044 USA

Phone 920-457-4441, Fax 920-459-1646

For the nearest sales and service outlet in the

US and Canada, phone 1-800-544-2444

KohlerPower.com

Model Mechanism Transition

Model Designation

Controls Voltage Poles Enclosure

Kohler Power Systems

Asia Pacific Headquarters

7 Jurong Pier Road

Singapore 619159

Phone (65) 6264-6422, Fax (65) 6264-6455

Current Rating Miscellaneous

Record the transfer switch model designation in the boxes. The transfer switch model designation defines characteristics and ratings as explained below.

Sample Model Designation: KGS-DCTA-0400S

Model

K: Kohler Transfer Switch

Mechanism

G: Bypass/Isolation

Transition

S: Standard

P: Programmed

Controls

D: MPAC t 1500

Microprocessor Controls, Automatic

Enclosure

A: NEMA 1 [

B: NEMA 12 w

C: NEMA 3R w

[

Standard w

Contact the factory

Current Rating: Numbers indicate the current rating of the switch in amperes:

0150

0225

0260

0400

0600

0800

1000

1200

1600

2000

2600

3000

Voltage/Frequency

C: 208 Volts/60 Hz

D: 220 Volts/50 Hz

F: 240 Volts/60 Hz

G: 380 Volts/50 Hz

H: 400 Volts/50 Hz

J: 416 Volts/50 Hz

K: 440 Volts/60 Hz

M: 480 Volts/60 Hz

N: 600 Volts/60 Hz

P: 380 Volts/60 Hz

R: 220 Volts/60 Hz

Number of Poles/Wires

N: 2-pole, 3-wire, solid neutral *

T: 3-pole, 4-wire, solid neutral

V: 4-pole, 4-wire, switched neutral

* 800 A, 480 Volts maximum

Miscellaneous

S: Standard connections

DISTRIBUTED BY:

Availability is subject to change without notice. Kohler Co. reserves the right to change the design or specifications without notice and without any obligation or liability whatsoever. Contact your local Kohler r Power

Systems distributor for availability.

©

2005, 2006, 2007, 2008, 2009, 2010, 2011, 2012 by Kohler Co. All rights reserved.

G11-110 (Model KGS/KGP Transfer Switch) 10/12h Page 12