DryLin - Drive Engineering

advertisement

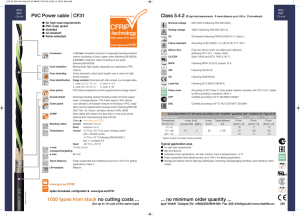

DryLin® - Drive Engineering DryLin® HTSC-Linear slide table DryLin® ZLW-belt drive ideal for: • High loads and low speed • Format adjustments and easy positioning ideal for: • Small loads and high speed • Fast positioning for lower speed quick handling also for high loads for lighter loads low-priced, robust and compact cost-effective self-braking by friction corrosion resistant DryLin® SLW DryLin® HTS / HTSC/HTSS HTS-PL/HTS DryLin® Slide Table Selection Guide Based on our innovative DryLin® W double rail system, the SLW offers a fully supported rail with resistance to twisting and deflection. SLW also offers a lower profile than most other standard lead-screw tables, and runs absolutely maintenance-free. Tough and adaptable, HTS is the most flexible system, and is available with several shaft and screw combinations, including hard-anodized aluminum and stainless steel. All HTS tables are designed to be simple bolt-on solutions. HTSC offers a compact carriage. *Handwheel is optional *Handwheel is optional • • • • • • • • Features Threaded nuts are available as separate parts. Please see page xx.xx for more information Simple, bolt-on solution Resists twisting Maintenance-free No messy lubrication Ideal for positioning Saves assembly time and cost 316 stainless version available • • • • • Flexible system offering several shaft/material combinations Completely maintenance-free Clean, oil-free operation Compact version available for design constraints Saves assembly time and cost XY and preloaded versions available Properties Maximum Static Radial Load 1400 lbs 2200 lbs 350 lbs 550 lbs 5.25 fpm 3.9 fpm 3.28 ft (1000 mm) 4.10 ft (1250 mm) Spindle type M8 / TR 10x2 / TR 14x4 / TR 18x4 TR 10x2 / TR 18x4 / TR24x5 Rail Material Hard Anodized Aluminum 316 Stainless Available Hard Anodized Aluminum, Hardened Steel, Stainless Steel, Carbon Fiber Anodized Aluminum and Chromated Zinc 316 Stainless available Anodized Aluminum -40°F to +194°F -40°F to +194°F -58°F to +356°F option Available Available Maximum Static Axial Load Maximum Continuous Speed* Maximum Stroke Length Carriage Material Temperature Handwheel *Figure given reflects continuous motion with no cool-down period. Higher speed / loads are possible for non-continuous movement. DryLin® HTSP DryLin® Easy Tube HTSP is the most cost-effective and lightweight unit available. Recommended for handling low weight applications by hand or low-speed motor. HTSP works especially well in corrosive environments. Simple, but and effective and solid design: that’s the new DryLin® SET EasyTube. A complete system from few components for simple linear adjustments. *Handwheel is optional • • • • • • • Lightweight Cost-effective Corrosion resistant Can use several shaft materials Compact Saves assembly time and cost Also available in miniature size DryLin® ZLW For higher speed applications the ZLW BeltDrive system offers clean and quiet high performance. The system uses iglide® J glide pad technology, tough plastic end blocks, hard anodized aluminum rails, and requires no maintenance or lubrication. *Handwheel is optional • • • • • Totally lubrication-free Corrosion-resistant when specified with a stainless leadscrew Lightweight (aluminum and polymer) Can be driven from both sides by hand or motor drive Temperature resistant up to 176°F • • • • High speed linear movement up to 19 fps possible Clean, oil-free operation Corrosion resistant Low friction iglide® J glide pads 315 lbs 90 lbs 65 lbs 77 lbs 45 lbs — 3 fpm — 16.4 fps 2.46 ft (750 mm) NA 6.56 ft (2000 mm) M8 / TR 10x2 M4 / TR 10x2 / TR 12x3 Belt Drive Hard Anodized Aluminum, Hardened Steel, Stainless Steel, Carbon Fiber Hard Anodized Aluminum, Hardened Steel, Stainless Steel, Carbon Fiber Hard Anodized Aluminum Plastic iglide® Anodized Aluminum and Chromated Zinc -40°F to +194°F -40°F to +194°F +32°F to +122°F Available Available Available DryLin® Linear Slide Table Based on our innovative DryLin® W double rail system, the SLW table offers a fully supported rail with resistance to twisting and deflection. Available in two cost-effective sizes offering lubrication-free operation and a lower profile than most standard lead-screw table assemblies. Telephone Fax SLW-1040-ES: All 316 stainless components XY version available HTS – Flexible 1-888-803-1895 1-401-438-7680 DryLin® Slide Tables SLW – Compact* The most flexible system for your application. HTS tables are available in 3 sizes. Choose from several shafting types and screw materials. The rugged blocks and our durable DryLin® R liners enable maintenance-free duty in extreme environments. HTS-PL: Pre-loaded nut and adjustable clearance HTSC: Compact carriage HTSS: High-pitch leadscrew for faster positioning HTS-XY: 2-axis movement Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp HTSP – Low-Cost Solution Our most cost-effective unit for basic duties. Choose from 3 different sizes ranging from miniature to medium. All sizes offer lightweight and corrosion-free plastic blocks and carriages. SET - EasyTube Simple, but and effective and solid design: that’s the new DryLin® SET EasyTube. A complete system from few components for simple linear adjustments. ZLW – Belt Driven Developed for quickly positioning low loads [16 fps (5 m/s)]. Corrosion resistant, lightweight, and completely maintenance-free. Accessories Nearly all linear slide table can be combined with hand wheels, clamps or position indicators. 25.4 Key features of DryLin® linear slide table include: • • • • • • • maintenance-free performance lubrication-free plastic inserts dry running operation excellent vibration dampening high static-load capacity low-profile lightweight • • • • • • • compact corrosion resistant chemical resistant heavy duty flexible self-locking screws quiet operation Structure of the part number: HTS - 12 - AW M - 150 - H R - E S Leadscrew material Leave blank = Steel (standard) ES = Stainless steel AL = Hard anodized aluminum High dirt resistance Additional options Leave blank = Standard HR = Hand wheel PA = Position indicator HK = Leadscrew clamping HK-PA-HR = Different combinations Z = No machining (TR10x2) PL = preload HTX = High temp. version PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp Unlike ball bearings, contaminants cannot build up in DryLin®. This prevents performance degradation or shaft damage. DryLin® slide tables have a low coefficient of friction, are corrosion-resistant and wear-resistant. Because they are dry running, DryLin® tables are an ideal alternative to using bronze, especially when oil and grease will contaminate a cleanroom or wash-down application. DryLin® developed based on 40 years of testing and designing maintenance-free plastic bearing materials. All DryLin® slide tables use iglide® selflubricating plastic liners that need no oil. More than 2,000 tests are performed on 200 materials each year. This time-tested, proven technology enables DryLin® slides to last in applications where expensive ball screws and slides fail. Slide Tables DryLin® Linear Slide Table Tables are ... Length of stroke Cost-effective and reliable at the same time Shaft material AWM = Hard anodized aluminum SWM = Case-hardened steel EWM = Stainless steel mm Dimensions 1040 = shaft Ø 10 mm, TR10x2 (SLW) 12 = shaft Ø 12 mm, TR10x2 1660 = shaft Ø 16 mm, TR14x4 (SLW) 20 = shaft Ø 20 mm, TR18x4 2080 = shaft Ø 20 mm, TR18x4 (SLW) 25 = shaft Ø 25 mm, TR10x2 (SET) 30 = shaft Ø 30 mm, TR24x5 Modular design, al lows easy installation Type HTS HTSP SLW HTSC HTSS SET = Basic = Cost-effective = Compact = Flexible = Fast = EasyTube 25.5 DryLin® Linear Slide Table - SLW DryLin® linear leadscrew units have been developed for position settings of all types. The linear setting is achieved by means of leadscrew that can be operated manually or by low speed motor. The maximum linear continuous speed is 5.25 ft/min (1.6 m/min.) Use the graphs below to check suitability. Slide Tables SLW The following trapezoidal leadscrew drive sizes are used in HTSC linear tables: TR 10x2: HTSC-12, HTSC-12, HTSP-12, SLW-1040, TR 14x4: SLW-1660 TR 18x4: HTSC-20, HTSC-20, SLW-2080 TR 24x5: HTSC-30, HTSC-30 SLW-1040-ES, SET-25 For horizontal (radial load) applications with centric loads, use the following formula to determine the axial load Please note that the loads given are axial loads. Radial loads are not given for trapezoidal leadscrews. Faxial = Fradial x 0.25 5.91 5.25 4.59 3.94 3.28 2.63 1.97 1.31 Feed (fpm) Telephone Fax 1-888-803-1895 1-401-438-7680 Maximum Feed (fpm) 0.66 0.00 0 45 90 135 Axial load (lbf) 180 225 TR10 x 2 270 315 360 TR14x 4 405 450 TR18 x 4 495 540 585 630 585 630 TR24 x 5 25.6 Rotation speed leadscrew (rpm) 600 500 400 300 200 100 0 0 45 90 135 Axial load (lbf) 180 225 TR10 x 2 270 315 360 TR14x 4 405 TR18 x 4 450 495 540 TR24 x 5 Drive Torque (lbf · ft) 10.33 8.85 7.37 5.90 Drive torque (lbf · ft) Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp Maximum permissible rotation speed leadscrew (rpm) 4.42 2.95 1.48 0 0 45 Axial load (lbf) 90 135 TR10 x 2 180 TR14x 4 225 270 TR18 x 4 315 TR24 x 5 360 405 Low-profile and compact Zinc diecast or anodized aluminum High torsional stiffness end blocks (SLW-0630 = polymer Fully supported Stainless steel version SLW-1040- Hard anodized rail ES available +194°F (+90°C) -58°F (-50°C) HTS Special properties Slide Tables DryLin® Linear Slide Table - SLW Compact Length and weight (mm) Part No. Maximum Stroke length Weight Shaft Additional weight Max. static load-bearing capacity axial radial (mm) (kg) (per 100 mm) (kg) (N) SLW-0630 300 0.2 0.08 50 200 SLW-1040 750 0.7 0.1 700 2800 SLW-1040-ES 750 1.4 0.2 700 2800 SLW-1080 750 0.9 0.2 700 2800 SLW-1660 1000 1.5 0.3 1200 4600 SLW-2080 1000 3.0 0.4 1600 6400 (1N = .225 lbs) PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp 5 sizes (N) mm Dimensions (mm) Part No. A AI** –0.3 –0.3 SLW-0630 54 60 SLW-1040 74 69 SLW-1040-ES 74 SLW-1660 SLW-2080 Part No. E1 E2 E3 ±0.15 ±0.15 ±0.15 20 40 45 51 100 17.5 1.2 20 11 6.2 – 29 60 60 56 113 24 1.5 22 11 6.8 M8 100 29 60 60 87 113 17 1.5 22 11 6.8 M8 104 100 37 84 86 82 150 35 1.5 25 15 9.0 M10 134 150 46 116 116 132 206 44 1.5 28 15 8.6 M10 kt H s sk sg I hw f lt tk ts tg –0.1 kq d T l2 ±0.1 d2 ha Standard SLW-0630 8.0 4.5 7.0 M4 2.0 6 M8 15 M8 9.5 SLW-1040 6.4 6.6 9.5 M6 4.4 10 TR10x2 17 TR10x2* 14.5 SLW-1040-ES 6.4 6.6 9.5 M6 4.4 10 TR10X2 17 TR10X2* 14.5 SLW-1660 8.6 9.0 11 M8 5.5 16 TR14x4 20 TR14x4* 18.5 SLW-2080 8.6 9.0 14.0 M8 5.5 20 TR18x4 26 12 h9 23.0 * end of leadscrew not machined/journaled ** Carriages also available in 100, 150, 200 and 250 mm lengths 25.7 DryLin® Linear Slide Table - SLW XY Table DryLin® Slide Tables 1-888-803-1895 1-401-438-7680 XY Table Special properties Low cost Lubricant- and corrosion-free Drive with trapezoidal thread TR10 x 2 Accessories available (rotary knob, position indicator …) L R Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp Telephone Fax x y I + Stroke I + Stroke Lengths [mm) and Weight Part No. A H –0.3 SLW-XY-1040 E1 E2 ±0.15 Basic length Basic length f ±0.15 lt tk ts tg kt ±0.1 (mm) (mm) (mm) (mm) lx (mm) ly (mm) (mm) (mm) (mm) (mm) 74 48 60 60 117 117 1.5 22 11 6.6 ha1 (mm) M8 6.4 Dimensions [mm) Part No. sg d T I1 d1 Standard (mm) SLW-XY-1040 M6 10 d1 I2 alternative (mm) TR10x2 17 d2 d2 Standard alternative TR10x2 6h9 (mm) TR10x2 6h9 17 ha2 W ha2 – ha1 (mm) (mm) (mm) 18 38 20 Order example: The rotary knob on the y-axis can be ordered installed on the left or on the right side. Order example for left SLW-XY-1040-L-200-300 for 200 mm stroke length on the x-axis and 300 mm on the y-axis. Order example for left SLW-XY-1040-R-200-300 for 200 mm 25.8 Lifetime calculation, CAD files online: www.igus.com stroke length on the x-axis and 300 mm on the y-axis. DryLin® Linear Slide Table - HTS Basic Solid design version 3 different sizes Different shaft and leadscrew materials offering highest flexibility +356°F (+180ºC) Maintenance-free and corrosion resistant Preload version available -59°F (-50º C) HTS - Basic High temperature Slide Tables Special properties NEW! High temperature (+180 °C) possible. Shafts and leadscrews made from stainless steel. l + Stroke +194°F (+90°C) d2 E2 T Standard E1 l2 d -58°F (-50°C) E3 ha kq f R A lt Al sg kt H lt tk ts tg s sk PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp High temperature version available. Temperatures up to +356°F Lengths (mm) and Weight Part No. Maximum Stroke length Aluminium Shaft Weight Additional weight Weight Steel Shaft Additional weight Max. static load-bearing capacity axial radial (N) (1N = .225 lbs) (N) (mm) (kg) (per 100 mm) (kg) (kg) (per 100 mm) (kg) HTS-12-AWM 750 1.1 0.1 1.3 0.2 700 2800 HTS-12-EWM-HTX** 750 1.1 0.1 1.3 0.2 700 2800 HTS-20-AWM 1000 3.2 0.3 3.9 0.6 1600 6400 HTS-30-AWM 1250 8.6 0.6 10.9 1.4 2500 10000 mm Dimensions (mm) Part No. HTS-12-AWM A AI –0.3 –0.3 85 85 H 34 E1 E2 E3 ±0.15 ±0.15 ±0.15 I 70 73 73 R f lt tk ts 11 6.6 ±0.1 145 42 2 30 HTS-12-EWM-HTX** 85 85 34 70 73 73 145 42 2 30 11 6.6 HTS-20-AWM 130 130 48 108 115 115 202 72 2 36 15 9.0 HTS-30-AWM 180 180 68 150 158 158 280 96 4 50 20 13.5 Part No. tg kt s sk sg kq d T l2 ±0.1 d2 ha Standard HTS-12-AWM M8 6.4 6.3 10 M6 6.0 12 TR10 x 2 17 TR10 x 2* 18 HTS-12-EWM-HTX** M8 6.4 6.3 10 M6 6.0 12 TR10 x 2 17 TR10 x 2* 18 HTS-20-AWM M10 8.6 6.4 11 M8 7.0 20 TR18 x 4 26 12 h9 23 HTS-30-AWM M16 12.6 11.0 18 M12 10.6 30 TR24 x 5 38 14 h9 36 * TR10x2 leadscrew end unmachined (10 mm OD x 2 mm pitch) ** High temperature version with shafts and leadscrew made from stainless steel. More dimensions in preparation. Bearing material: iglidur® T500 Order example: More details on part no. options: Page 25.5 25.9 DryLin® Linear Slide Table - HTS-PL Adjustable Clearance Properties Lubricant-free Slide Tables HTS-PL Preloaded trapezoidal lead screw nut, Pretension force 11.2 lbf (50 N) Radial clearance is adjustable Low weight Preloaded trapezoidal lead screw nut 1-888-803-1895 1-401-438-7680 Radial clearance adjustable from both sides Telephone Fax I + Stroke Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp Length (mm) and Weight 25.10 Part No. Maximum Stroke length Aluminum Shaft Weight Additional weight Weight Steel Shaft Additional weight Max. static load-bearing capacity axial radial (N) (1N = .225 lbs) (N) (mm) (kg) (per 100 mm) (kg) (kg) (per 100 mm) (kg) HTS-12-AWM-PL 750 1.1 0.1 1.3 0.2 700 HTS-20-AWM-PL 1000 3.2 0.3 3.9 0.6 1600 6400 HTS-30-AWM-PL 1250 8.6 0.6 10.9 1.4 2500 10000 2800 Dimensions (mm) Part No. A AI –0.3 –0.3 H E1 E2 E3 ±0.15 ±0.15 ±0.15 I R f lt tk ts ±0.1 HTS-12-AWM-PL 85 85 34 70 73 73 145 42 2 30 11 6.6 HTS-20-AWM-PL 130 130 48 108 115 115 202 72 2 36 15 9.0 HTS-30-AWM-PL 180 180 68 150 158 158 280 96 4 50 20 13.5 Part No. tg kt s sk sg kq d T l2 ±0.1 d2 ha Standard HTS-12-AWM-PL M8 6.4 6.3 10 M6 6.0 12 TR10x2 17 TR10x2* 18 HTS-20-AWM-PL M10 8.6 6.4 11 M8 7.0 20 TR18x4 26 12 h9 23 HTS-30-AWM-PL M16 12.6 11.0 18 M12 10.6 30 TR24x5 38 14 h9 36 * TR10x2 leadscrew end unmachined Lifetime calculation, CAD files online: www.igus.com Order example: More details on part no. options: Page 25.5 Slide Tables Special properties Solid flexible design Ideal for 2 carriages Dry running and maintenance-free 3 sizes HTSC DryLin® Linear Slide Table - HTSC Flexible T E1 d2 I + Stroke E2 d l2 lt lt Al H R A PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp Adjustable radial clearance Length (mm) and Weight Part No. Maximum Stroke length (mm) Aluminum Shaft Weight Additional weight (kg) Weight (per 100 mm) (kg) Steel Shaft Additional weight (kg) Max. static load-bearing capacity axial radial (N) (1N = .225 lbs) (N) (per 100 mm) (kg) HTSC-12-AWM 750 0.7 0.1 0.8 0.2 700 HTSC-20-AWM 1000 1.9 0.3 2.3 0.6 1600 2800 6400 HTSC-30-AWM 1250 4.6 0.6 5.8 1.4 2500 10000 mm Dimensions (mm) Part No. A AI H –0.3 –0.3 E1 E2 I ±0.15 ±0.15 R f lt tk ts tg ±0.1 HTSC-12-AWM 85 30 34 70 73 90 42 2 30 11 6.6 M8 HTSC-20-AWM 130 36 48 108 115 108 72 2 36 15 9.0 M10 HTSC-30-AWM 180 50 68 150 158 150 96 4 50 20 13.5 M16 Part No. kt sk sg kq d T l2 ±0.1 HTSC-12-AWM d2 ha Standard 6.4 10 HTSC-20-AWM 8.6 11 HTSC-30-AWM 12.6 18 M6 6.0 12 TR10x2 17 TR10x2* 18 M8 7.0 20 TR18x4 26 12 h9 23 M12 10.6 30 TR24x5 38 14 h9 36 * TR10x2 supplied with leadscrew end unmachined Order example: Lifetime calculation, CAD files online: www.igus.com More details on part no. options: Page 25.5 25.11 DryLin® Linear Slide Table - HTSS Fast Special properties High helix pitch leadscrew High-speed solution Slide Tables Dry running I + Stroke d2 E2 T 1-888-803-1895 1-401-438-7680 E1 l2 d HTSS Maintenance-free E3 lt tk ts lt Al ha kq Telephone Fax kt sg tg H s sk f R A Length (mm) and Weight Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp Part No. 25.12 Maximum. Stroke length Weight Aluminum Shaft Additional weight Max. static load-bearing capacity axial radial (mm) (kg) (per 100 mm) (kg) HTSS-12-AWM 750 0.7 0.1 700 2800 HTSS-20-AWM 1000 1.9 0.3 1600 6400 (N) (1N = .225 lbs) (N) Dimensions (mm) Part No. A AI –0.3 –0.3 HTSS-12-AWM 85 85 HTSS-20-AWM 130 130 Part No. kt H s E1 E2 E3 ±0.15 ±0.15 ±0.15 34 70 73 73 145 42 2 48 108 115 115 202 72 2 sk sg I R f lt tk ts tg 30 11 6.6 M8 36 15 9.0 M10 ±0.1 kq d T l2 ±0.1 d2 ha Standard HTSS-12-AWM 6.4 6.3 10 M6 6.0 12 TR10x50 17 TR10x50* 18 HTSS-20-AWM 8.6 6.4 11 M8 7.0 20 TR18x100 26 12 h9 23 * TR10x50 supplied with leadscrew end unmachined Available lead screws: 10 mm OD w/ 50 mm pitch 18 mm OD w/100 mm pitch Lifetime calculation, CAD files online: www.igus.com Order example: More details on part no. options: Page 25.5 XY Table Special properties High precision, extreme stiffness and exact alignment, single piece carriage Available as standard and preloaded Totally lubricant- and corrosion-free Driven with trapezoidal thread: TR10x2 or TR18x4 HTS/HTS-PL DryLin® Linear Slide Table - HTS/HTS-PL XY Table Also available with stainless shafting and lead screw DryLin® HTS Ix + Stroke l1 tk f c DryLin® HTS-PL ha1 kt d1 ts R lt tg E2 sg L R Iy + Stroke d2 ha2 H d T E1 f l2 T d lt PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp Accessories available (rotary knob, position indicator …) 90 ° lt A x y Length (mm) and Weight Part No. A H –0.3 E1 E2 ±0.15 Basic length Basic length R ±0.15 f lt tk ts tg mm kt ±0.1 (mm) (mm) (mm) (mm) lx (mm) ly (mm) (mm) (mm) (mm) (mm) (mm) HTS-XY-12 85 56 70 73 145 145 42 2 30 11 6.6 M8 (mm) HTS-XY-12-PL 85 56 70 73 145 145 42 2 30 11 6.6 M8 6.4 HTS-XY-20-EWM-PL 130 86 108 115 202 202 72 2 36 15 9.0 M10 8.6 I2 6.4 Dimensions (mm) Part No. sg d (mm) HTS-XY-12 M6 HTS-XY-12-PL M6 T I1 d1 d1 Standard alternative TR 10x2 TR 10x2 6h9 6h9 (mm) 12 TR10x2 17 12 TR10x2 17 d2 d2 ha1 Standard alternative (mm) 17 17 TR10x2 TR10x2 6h9 6h9 ha2 W ha2 – ha1 (mm) (mm) (mm) 18 18 38 38 20 20 PL = HTS-Preload-version Order example: The rotary knob on the y-axis can be ordered installed on the left or on the right side. Order example for left HTS-XY-12-L-200-300 for 200 mm stroke length on the x-axis and 300 mm on the y-axis. Order example for left HTS-XY-12-R-200-300 for 200 mm Lifetime calculation, CAD files online: www.igus.com stroke length on the x-axis and 300 mm on the y-axis. 25.13 DryLin® Linear Slide Table - HTSP Small and Low Cost Properties Small version Slide Tables HTSP Very low weight Low cost Corrosion resistant Accessories available (rotary knob, position indicator …) Carriage and end blocks made from high performance polymers E3 lt E2 lt 1-888-803-1895 1-401-438-7680 T d2 E1 d l2 ts s Al tk Ht H ha kt Telephone Fax A f R I + Stroke Lengths (mm) and Weight Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp Part No. Maximum Stroke length HTSP-01-06 Aluminium Shaft Weight Add. weight (kg) (mm) (kg) (per 100 mm) 300 0.11 0.06 Special Properties Square carriage with four symmetrical connection bores Dimensions (mm) Part No. HTSP-01-06 A 45 AI 45 H 19 E1 18 E2 38 E3 36.5 I 36.5 Part No. s sg d T l2 ha 5.1 – 6 M8 15 d2* Standard M8 HTSP-01-06 9 R 67 f 25 lt 1 tk 11 ts 8 4.2 Max. static load-bearing capacity (1N = .225 lbs) axial (N) radial (N) 50 200 * Standard versions supplied with leadscrew end unmachined Order example: 25.14 Lifetime calculation, CAD files online: www.igus.com More details on part no. options: Page 25.5 DryLin® Linear Slide Table - HTSP Cost-effective Solid plastic version Light weight Cost-effective Corrosion resistant lt T T d2 d2 E2 E2 Al Al ltlt ts E1 D-D d D Øs D D D d l2 l2 tk I + Stroke sg A R PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp Slide Tables Special properties H ha f Length (mm) and Weight mm Part No. Maximum Stroke length (mm) Aluminium Shaft Weight Add. weight (kg) (kg) (per 100 mm) Special Properties HTSP-01-12 750 0.35 0.11 Liners and TR nuts made from iglidur® J HTSP-02-12 750 0.35 0.11 Bearing and nut integrated into carriage Dimensions (mm) Part No. A AI H E1 E2 E3 I R f lt tk ts HTSP-01-12 85 30 36 70 73 – 90 42 2 30 10 6.6 HTSP-02-12 85 30 36 70 73 – 90 42 2 30 10 6.6 s sg d T Standard l2 d2* ha 6.3 6.3 M6 M6 12 12 TR10x2 TR10x2 17 17 TR10x2 TR10x2 16 16 Part No. HTSP-01-12 HTSP-02-12 Max. static load-bearing capacity axial radial (1N = .225 lbs) (N) (N) 350 1400 350 1400 * Standard versions supplied with leadscrew end unmachined Order example: Lifetime calculation, CAD files online: www.igus.com More details on part no. options: Page 25.5 25.15 DryLin® Slide Tables DryLin® Linear Slide Table - SET Easy Tube +176ºF (+80°C) 3 Dimensions 2 Styles -58ºF (-50°C) This new addition to the DryLin® slide table range has a simple but solid design; the complete system only consists of a few components. The anodized aluminum tube guides the slide carriage and at the same time protects the leadscrew. The carriage and the trapezoidal nut are manufactured from a high performance polymer bearing material. The system runs without any lubrication, and gives a low friction value combined with an excellent wear rate. Also, iglide® plain bearings are used in the axial fixing of the leadscrew. Advantages Totally lubrication-free Corrosion-resistant when specified with a stainless leadscew Lightweight (aluminum and polymer) Can be driven from both sides by hand or motor drive Temperature-resistant up to 176°F (80° C) 1-888-803-1895 1-401-438-7680 Ideal for washdown applications Telephone Fax EasyTube with Flange version optional accessory (rotary knob, position Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp indicator) 25.16 Flange version Trapezoidal threaded nut and carriage made from polymer bearing material Anodized aluminum guide tube Radial and axial bearings made from polymer bearing material Hand wheel Stainless steel clamp Polymer end block Steel trapezoidal leadscrew Slide Tables DryLin® Linear Slide Table - SET Easy Tube s ts I + Stroke l2 E2 E4 A2 E1 Al E3 A3 sb also available as flange version (for axial fitting) lt H h1 E5 A Stainless shaft/leadscrew available upon request PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp h d2 lt E1 Length (mm) and Weight Part No. Maximum Stroke length Aluminium Shaft Weight end blocks add. (per 100 mm) and carriage Max. static load-bearing capacity axial radial (1N = .225 lbs) (mm) (kg) (kg) (N) SET-12-AWM 200 0.05 0.03 10 20 (N) SET-25-AWM 850 0.15 0.12 150 300 SET-30-AWM 850 0.20 0.21 200 400 mm Dimensions (mm) Part No. A AI H SET-12-AWM SET-25-AWM SET-30-AWM 30 60 80 30 23.5 55 44 55 49 E1 E2 E3 E4 I h h1 lt ts s sb l2 d2 20 40 60 20 40 40 20 40 40 – 20 20 60 115 125 22 39 39 – 45 50 15 30 35 3.3 5.2 6.5 4.2 5.2 5.2 – M4 M4 10 17 20 M4* TR10x2* TR12x3* E1 40 60 E2 40 40 E3 40 40 s 5.2 5.2 l2 27 30 d2 TR10x2* TR12x3* Dimensions (mm) – flange version Part No. SET-25-AWM-F SET-30-AWM-F A2 60 80 * leadscrew end unmachined A3 60 60 H 49 59 E5 40 40 I 117 125 h 39 39 lt 30 35 ts 5.2 6.5 25.17 DryLin® Linear Slide Table - HTS Accessories DryLin® Slide Tables Position indicator Plastic analogue indicator for adjustment and direct reading of slide position 4-digit counter (red digit indicates tenths) Counting takes place clockwise Color: Orange 1-888-803-1895 1-401-438-7680 Part No. Leadscrew size Dimensions (Bx H x T) in mm HTS HTSC HTS-PA-12 HTS-PA-16 HTS-PA-20 HTS-PA-30 TR10x2 TR14 x 4 TR18 x 4 TR24 x 5 M8 32 x 46 x 33 32 x 46 x 33 32 x 46 x 33 32 x 46 x 33 22 x 33 x 31 HTSP-01-06* HTS-12 HTS-20 HTS-30 HTSC-12 HTSC-20 HTSC-30 HTSP HTSP-12 SLW SLW-1040* SET SET-25 SLW-1660* HTS-PA-06 SLW-2080* Telephone Fax * Only possible with an adapter plate Leadscrew clamp Shaft clamping flange for attachment to the position indicator and subsequent mounting on the leadscrew Provides a mechanical brake to the leadscrew Material: Plastic housing with aluminium shaft clamp Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp Colour: Black 25.18 Part No. Leadscrew size Dimensions (Bx H x T) in mm HTS HTSC HTS-HK-12 HTS-HK-16 HTS-HK-20 TR10x2 TR14 x 4 TR18 x 4 TR24 x 5 32 x 46 x 15 32 x 46 x 15 32 x 46 x 15 32 x 46 x 15 HTS-12 HTS-20 HTS-30 HTSC-12 HTSC-20 HTSC-30 HTSP HTSP-12 SLW SLW-1040* SET SET-25 * Only possible with an adapter plate HTS-HK-30 SLW-1660* SLW-2080* Slide Tables DryLin® Linear Slide Table - HTS Accessories Rotary knob Rotary knob for attachment to the end of the leadscrew For positioning Material: Aluminum and Polymer Dimensions (mm) Part No. HTS-HR-06 HTS-HR-12 HTS-HR-16 HTS-HR-20 HTS-HR-30 D 27 27 34 42 42 L 17 17 20 23 23 d 8 10 14 12 14 HTS – HTS-12 – HTS-20 HTS-30 HTSC – HTSC-12 – HTSC-20 HTSC-30 HTSP HTSP-06 HTSP-12 – – – SLW – SLW-1040 SLW-1660 SLW-2080 – SET – SET-25 – – – PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp Color: Black inch Adapter plate (included) for position indicator and/or leadscrew clamp in the case of the HTSP-01-06, SLW-1040 and SLW-2080 mm series, the system is delivered with a fitted adapter plate Order no. adapter plate SWX-104002 SWX-166003 SWX-208002 For DryLin® SLW: SLW-1040 SLW-1660 SLW-2080 25.19 DryLin® Slide Tables DryLin® Linear Slide Table +122ºF (+50°C) DryLin ® toothed belt drives were developed for quickly positioning of small loads. They are corrosion resistant, light and compact, low mass inertia due to the low weight of guide and sliding carriage. 0º Special properties Technical Data Material, slider: iglide® J Radial bearing: Version 01: (optional) iglide® L250 Version 02: G Excellent for high accelerations G Simple assembly G Flat and sturdy construction G Light and corrosion resistant G Delivered off the shelf G Motor mounts available 1-888-803-1895 1-401-438-7680 grooved ball bearing Axial bearing: iglide® J ZLW is available in two sizes, and two series: Drive belt: 0630 Basic Standard Series (Version 02): The Standard series use a white polyurethane steel-reinforced belt, the pulley and the shafts are made of plated steel (stainless optional) and are fitted with 2 deep-groove ball bearings. This version is capable of speeds up to 16.4 ft/s (5 m/s) and loads up to 45lbf (200N). Neoprene with GF 1040 Basic: Neoprene with GF Telephone Fax 0630 Standard Neoprene with GF Basic Series (Version 02-B): The Basic series use a black neoprene glass-reinforced belt; the shafts and pulleys are stainless steel and are square (but with a plastic adapter can be made into 10 mm OD parts); the gear wheel is high performance plastic and is fitted also with 2 deepgroove ball bearings. This version is capable of speeds up to 9.94 ft/s (3 m/s) and loads up to 33.75 lbf (150N). 1040 Standard: PU toothed belt with steel cord up to 5 m/s Plain Bearing (Version 01): This version uses iglide plain bearings in the pulley system instead of the deep-grooved ball bearings, and is intended for lower speeds. Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp Assembly of the part number 25.20 ZLW -1040 -02 -B -100 L XX Stroke length in mm L = drive shaft on the left R = drive shaft on the right L/R = drive shafts left and right Slide length in mm (Standard: 100, on request: 50/200 mm) Size 1040: 100 (optional 150/200 mm) Size 0630: 60 B = Basic series S = Standard series Version 01 (optional) – Drive shaft with L250 plain bearings Version 02 (faster speed) – Drive shafts with ball bearings Size 1040 (Guide shaft diameter 10 / Shaft width 40 mm) Size 0630 (Guide shaft diameter 6 / Shaft width 30 mm) DryLin® W toothed belt linear drive Carriage plate made of anodized aluminum Bearing housing made of blue chromated zinc (aluminum optional) Linear bearing made of iglidur® J Slot nuts For limit switches PU toothed belt, steel-reinforced or Neoprene belt, glass-reinforced Hard-anodized aluminum profile Mounting element made of Aluminium and/or plastic clamp Grooved ball bearings (Version 02) or optional Radial bearing made of iglide® L250 (Version 01) Solid plastic housing Technical Data Weight without stroke (kg) Weight 100 mm stroke (kg) max. stroke length* (mm) Transmission (mm/U) Gearteeth Basic 02 0.9 0.14 2.000 66 RPP 3M Neoprene with GF 15 150 Standard 02 1.0 0.14 2.000 70 AT 5 PU + steel cord 16 200 Basic 02 0.43 0.08 1.000 54 AT 5 Neoprene with GF 9 Standard 02 0.43 0.08 1.000 54 MTD3 PU + steel cord 9 -material Toothed belt-width (mm) max. -tension radial stress (N) (N) Pulley max. speed at 60% operation (m/s) Linear Positioning Tolerance 200 ball bearing 3 ±0.35 300 ball bearing 5 ±0.2 70 100 ball bearing 2.5 ±0.2 100 100 ball bearing 2 ±0.2 PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp Slide Tables DryLin® Linear Slide Table - Assembly of the Belt Drive ZLW-1040 ZLW-0630 inch * Larger stroke lengths upon request. ** these values were measured with maximum load in horizontal orientation x 1 mm 2 Right or left positioning for drive shaft. Position determined by view towards x! 1 = Left drive shaft 2 = Right drive shaft x = Line of vision Drive shaft 25.21 DryLin® Slide Tables DryLin® Linear Slide Table - ZLW 0630 Belt Drive Special properties G Compact size G Speeds up to 6.5 ft/s G Maintenance-free G For strokes up to 1000 mm 1-888-803-1895 1-401-438-7680 G Available in both Basic (02-8) and Standard (02-5) versions I + Hub H f AI Telephone Fax A lt R E2 E3 I2 Iz hc E AP T1 nw dp 25.22 X nh d Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp T2 d2 n nb Lp Dimensions (mm) Part No. A AI H –0.3 ZLW-0630-02-... 54 E2 I hc ±0.15 60 31 45 144 E3 R ±0.15 ±0.15 51 30 13.5 f lt sg ha lz I2 d2 M4 14 22 20 8 ±0.3 3 42 nb nw Mounting Dimensions X Part No. ZLW-0630-02-... variable E AP ±0.2 –1 40 52 LP 15 dp 5.5 n 5.2 9.5 4.3 nh 7 T1 T2 ±0.25 ±0.25 20 21 d 3.2 Vertical orientation ZLW-0630-02-B (Basic Version) Required drive torque* ZLW-0630-02-B (Basic Version) Required drive torque* a = acceleration a = acceleration 2 T 0.4 (a = T (a 1 m/s ) 2 /s ) T (a = 0 m 0.2 0 2 /s 2 ) m 2 T (a = 4 6 T (a 2 /s ) m =3 = 0.6 ) m 2) 2 /s s) m/ = 1 m 3 2 ) a s) /s a = T ( m/ m T( 0 5 a= = T( (a 2 T 10 0.8 m Drive torque (Nm) 2 /s 0.6 =5 10 a T( 0.8 Drive torque (Nm) ) /s 0.4 0.2 0 8 1 Load capacity (kg) 2 3 4 Vertical orientation ZLW-0630-02-S (Standard Version) Required drive torque* ZLW-0630-02-S (Standard Version) Required drive torque* a = acceleration a = acceleration T (a T( T (a 0.6 ) ) m/s 2 =3 2 ) 1 m/s T (a = 2 ) /s m T (a = 0 0.4 0.8 10 s m/ = 2 5 a= T (a 0.8 = ) 2 s) 2 ) m/ 1 s / 2) 2 ) = /s 3 m T (a /s m a= 0m 5 = ( a T = T( (a T 2 /s m Drive torque (Nm) 1.0 m /s 2 ) 1.0 10 6 Load capacity (kg) Horizontal orientation 1.2 5 PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp Horizontal orientation 1.0 Drive torque (Nm) Slide Tables DryLin® Linear Slide Table - ZLW 0630 Belt Drive 0.6 0.4 0.2 0.2 1 5 2.5 7.5 0 10 Load capacity (kg) 2 4 6 Load capacity (kg) * Assumption: The moving mass is located in a circumscribed circle with a max. R = 100 mm to the middle of the guiding rail, max. permissible torque version 01: 1.3 Nm, a = 0 m/s2; version 02: 2.4 Nm, a = 0 m/s2; constant drive without nominal value acceleration For unsupported applications Rail deflection between supports versions Basic and Standard Maximum load ZLW-0630/1040 100% operating time 5.0 4.5 ZLW-1040-Standard 100 3.5 80 0.1 mm 1.0 mm 0.5 mm 0.3 mm ZLW-1040-Basic 60 2.5 2.0 ZLW-0630-Standard 40 Load (N) Carriage speed (m/s) mm 120 4.0 3.0 inch 1.5 1.0 0.5 ZLW-0630-Basic 50 100 150 200 250 300 Carriage loads (N) The diagram accounts for the sum of all forces active on the carriage. 20 0 500 600 700 800 900 1000 1100 Length between supports (mm) Sag permissible up to maximum 2 mm. 25.23 DryLin® Linear Slide Table - ZLW 1040 Belt Drive DryLin® Slide Tables Special properties G High speed, up to 16.4 ft/s (5 m/s) G Maintenance-free G Lightweight G Cost-effective versus other actuator systems 1-888-803-1895 1-401-438-7680 G Maximum stroke, 2000 mm I + Hub H f AI A lt I2 R E2 Telephone Fax E3 d2 Iz nh dp 25.24 nw nb n T1 AP d hc Lp E Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp T2 X Dimensions (mm) Part No. A AI H –0,3 ZLW-1040-02-... 74 100 X Part No. ZLW-1040-02-... E2 I hc ±0,15 ±0.2 variable 45 E 60 AP 204 E3 R ±0,15 ±0,15 87 40 22.5 LP dp n f 1 nb –1 60 lt 52 nw ±0.25 78 40 6,4 5.2 sg ha lz I2 d2 M6 22 27 20 10 ±0,3 9.5 4.3 nh T1 T2 d 36 26.5 5.0 ±0.25 15.5 Horizontal orientation Vertical orientation ZLW-1040-02-B (Basic Version) Required drive torque, Nm ZLW-1040-02-B (Basic Version) Required drive torque, Nm T (a =1 1.2 2 /s ) 0.8 T (a =0m 0.6 0.4 0.2 1 5 10 1.0 0.8 T 0.6 0.4 0.2 15 2 4 6 8 Horizontal orientation Vertical orientation ZLW-1040-02-S (Standard Version) Required drive torque, Nm ZLW-1040-02-S (Standard Version) Required drive torque, Nm = m a T( ) m/s 2 T (a T 2.0 =1 1.5 2 /s ) 0m T (a = 1.0 0.5 0 0 5 10 15 m 5 20 s) 2 2 ) m/ s) /s = 3 m/ 1 m (a 2 5 T s) a= = m/ T( 0 (a T a= T( 2 10 T = (a 1.5 (a a = acceleration = 10 m 2.0 =3 m/ 2 (a /s 2 ) /s s) ) T 2 /s 2 ) 2.5 a = acceleration Drive torque [Nm] 2.5 10 Load Vertical [kg] Load Horizontal [kg] Drive torque [Nm] /s 2 ) 1.4 ) m/s 2 T 1.0 m/ m =3 2 10 a T( ) 2 /s s) 3 m 1 m/ 2 = 2 ) = a s) /s T ( T (a m/ m 0 5 a= = T( (a = = m a = acceleration (a (a (a 5 Drive torque [Nm] m /s 2 ) T = 1.2 Drive torque [Nm] /s 10 1.4 ) 2 1.6 s) 2 1.0 0.5 0 25 5 10 Load Vertical [kg] Load Horizontal [kg] * Assumption: The moving mass is located in a circumscribed circle with a max. R = 100 mm to the middle of the guiding rail, max. permissible torque version 01: 1.3 Nm, a = 0 m/s2; version 02: 2.4 Nm, a = 0 m/s2; constant drive without nominal value acceleration Maximum load comparison ZLW-0630 and ZLW-1040 100% operating time For unsupported applications Rail deflection between supports versions Basic and Standard 5.0 4.5 300 ZLW-1040-Standard 0.1 mm 250 3.5 inch mm 0.2 mm 0.5 mm 200 1.0 mm 2.0 mm ZLW-1040-Basic 150 2.5 2.0 Belastung [N] Carriage speed [m/s] 4.0 3.0 PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp 1.8 a = acceleration 1.6 T 1.8 Slide Tables DryLin® Linear Slide Table - ZLW 1040 Belt Drive ZLW-0630-Standard 1.5 1.0 0.5 ZLW-0630-Basic 50 100 150 200 250 300 Load on carriage [N] The diagram accounts for the sum of all forces active on the carriage. 100 50 0.5 500 1000 1500 2000 Length between supports [mm] Sag permissible up to maximum 2 mm. 25.25 DryLin® Linear Slide Table - ZAW DryLin® Slide Tables Special properties G Low weight G Maintenance-free G High rigidity G Perfect for applications where the rail moves, but the carriage is stationary E2 B2 ltf fa Internet: http://www.igus.com E-Mail: sales@igus.com QuickSpec: www.igus.com/qs/DryLin.asp H E5 ha E6 LG = Hub + 242 A E3 B E7 B7 E2 Al l7 l d lz Moving end block ZTF 25.26 lta H2 htf B4 Telephone Fax 1-888-803-1895 1-401-438-7680 ff lta E4 Fixed end block ZTA Dimensions (mm) Part No. A –0.3 [mm] ZAW-1040-02-R/L-LG Part No. H LG Al ha d l ±0.3 [mm] ±0.1 [mm] h9 [mm] +1 [mm] [mm] 150 74 10 20 75 E4 [mm] Hub [mm] 74 91 242 B B2 –0.3 ZAW-1040-02-R/L-LG M6 M8 lz htf ltf ff fa lta Hub [mm] ±0.3 [mm] ±0.1 [mm] h9 [mm] +1 [mm] [mm] 44 52 2 5 40 25 E2 E3 ±0.15 ±0.15 [mm] 60 60 B4 E5 E6 ±0.15 ±0.15 [mm] [mm] 26 62 M6 1. Clamping offers an easy fastening option for the drive, among other things, on aluminum machine profiles. Part No. 75.40. 2. Slot nuts enable the installation of 3 sides (1040: left, right, below) or 2 sides (0630: left, right) as well as the fixing of sensors and proximity switches. 3. Screw connection: Threaded holes for individual screws are located at each end block face. Slot nuts Clamp Screw connection Ideal for limit switches Included in delivery Included in delivery Directions for installation: The end blocks should not be used as a mechanical stop under any circumstances. A minimum spacing of 10 mm should be provided on both sides. The safety distance provided at both sides of the guide carriage can be reduced provided that it is ensured that the housings of the drive and end blocks do 4 x M6/M4 (optional) not collide with the mechanical parts. The igus® staff would be glad to provide you with more information on the fastening and connecting of the belt drive. Call 888-803-1895, or write to sales@igus.com Motor flange The motor flange can be fastened onto the end block with four screws. Different types of motor flanges are available. Item no. SAX-104005 PDF: www.igus.com/pdf/DryLin.asp Specs/CAD/RFQ: www.igus.com/DryLinN.asp RoHS info: www.igus.com/RoHS.asp The DryLin® ZLW belt drive can be fastened in different ways (clamp and slot nuts included in delivery): The orientation of the drive is optional. Overhead installation is the best option against fouling. Slide Tables DryLin® Linear Slide Table - ZLW Belt Drive HG mm AG The DryLin® ZLW belt drive is also available with hand crank. DM DS HM DT DB TS LM LG Suitable for ZLW-1040 ZLW-0630 Part No. MF-1040-xx MF-0630-xx Base plate LG HG AG 138 44 17 110.5 28 12 ____*: Please request individual values for each motor type HM ____* ____* LM ____* ____* Motor mounting plate DT DM DS TS ____* ____* ____* ____* ____* ____* ____* ____* DB ____* ____* 25.27