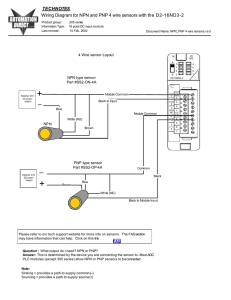

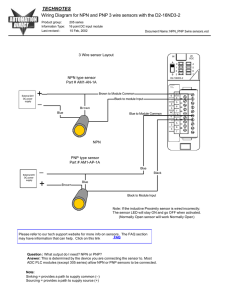

Pressure Sensors

advertisement