LED Driver Basics - Jade Sky Technologies

advertisement

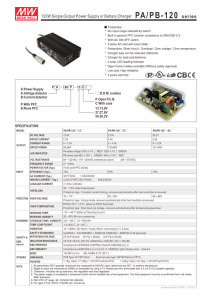

White Paper LED Driver Basics INTRODUCTION This brief provides basic information on the topics, and puts them in perspective in relation to JST drivers. EFFICIENCY Efficiency typically depends on choice of external components and switching frequency. The switching frequency multiplies losses associated with energy delivered to and then lost from capacitances and stray inductances. Snubbers used in flyback transformer designs also add to frequency dependent losses. RMS resistive losses arise based on steady state current flow through the components, most particularly the main switching FET, the freewheeling diode, and the inductor. EMI filter components add to the conductive steady state RMS loss. Each EMI filter inductor has a series resistance. Because the components strongly determine the efficiency, and because the input voltage source and output LED string are necessarily predefined, then IMPROVING efficiency is mostly a power electronics game. The game to play is to choose the right components and switching frequency. Saving cost arises from using smaller components, as feasible with higher switching frequencies. However, higher switching frequencies can cause additional difficulty in passing conducted EMI specifications, should EMI be a requirement. • JST controllers provide the flexibility to switch up to 500 kHz. As such, an engineer maintains freedom in power optimization. Less obvious is the distinction between buck and buck-boost converters. The JST drivers can seamlessly control buck and buck-boost converters. What is special about using buck converters in LED drive? With a buck converter, the LED output power can be reduced to 0. Thus 0 to 100 % dimming is possible. There is a misconception that buck regulators cannot work with dimmers, and pass EMI conducted emissions testing. This is false, inasmuch as JST drivers DO pass. Buck regulators are more efficient than buck-boost converters. For the same given input and output specifications, and for same size / cost, buck is more efficienct. Achieving same efficiency with buck-boost requires more size/cost. Also, buck converters provide much lower output current ripple, making it a better option for reliability of the output capacitor. A buck output capacitor current ripple, being much smaller, will heat up less, and therefore have longer life. Furthermore, the JST solution is one stage of power conversion. One stage is typically more efficient than two. Compatibility with dimmers is enabled at no cost to efficiency at full load. Summarizing • The JST solution is a one stage power converter. This has the advantage of using only one power switch in series between input and output at any given time. • JST controller can work with buck power conversion, with an EMI filter, pass conducted emissions testing, and interoperate with all dimmers. • Buck conversion features much smaller output current ripple, and so JST enables longer lifetime for less cost on the output capacitor. • Efficiency / cost / size is better with a buck, so long as the output voltage is reasonable (10 to 50 Volts). • Dimmer compatibility is ensured at no cost to efficiency at full load. • Simply, JST can equal or better competitive switching regulator offline LED drivers. • JST’s one stage switching regulator offline driver is typically better in efficiency than AC LED drivers (80 % at best). JADE SKY TECHNOLOGIES Confidential 1 White Paper LED Driver Basics HIGH VOLTAGE High voltage LED stacks require low current. If high voltage LED stacking is desired, it requires a buck-boost converter. Beyond 75 Volts, the buck may struggle to provide power to the output with sufficient power factor. High voltage output is not a problem for JST. Buck-boost operation works. • JST operates with high voltage LED stacks. Buck-boost conversion is available with the same chip. • JST can operate in boost converter mode as well if the LED stack voltage is greater than even the maximum AC line instantaneous voltage. BUCK OR BUCK-BOOST The following is a general guideline for non-isolated: • • 110 VAC 50 Volts or less buck > 50 Volts buck-boost > peak VAC boost 220 VAC 100 Volts or less buck > 100 Volts buck-boost > peak VAC boost So even at 80 or 90 Volts, if the input is 220 VAC, then a buck is still likely feasible. Buck is always preferable because • it has lower current ripple (better efficiency, smaller components) • it has a lower output current ripple (better reliability for electrolytic capacitor) Buck-boost is fine if needed for higher output voltage. 2 Confidential JADE SKY TECHNOLOGIES White Paper LED Driver Basics BUCK, BUCK-BOOST, BOOST, AND FLYBACK Isolation may be desirable within an LED driver for safety. In the case of isolation, the flyback converter is the standard low cost single stage conversion topology. The flyback transformer operation matches that of the buck-boost, except the storage element is the magnetizing inductance of a transformer. The following table compares the different single stage LED converters. TABLE 1. CONVERTER TOPOLOGIES, PRIMARY AND SECONDARY All converters are asynchronous (one diode and one switch). The boost converter is italicized because it does not apply in this application note. Converter Primary Circuit Device Secondary Circuit Device Input Capacitor Current Ripple Buck NMOS, low side Diode, picks up the High control and gate current when drive, current in NMOS turns off. inductor increases. Output Capacitor Current Ripple Highest Reverse Voltage Across NMOS Highest Reverse Voltage Across Diode Efficiency Cost, Relative Relative to to Buck Buck When To Use Low Input Input 0% VAC=110, Vout < 50 0% VAC=220, Vout < 100 Primary inductor current flows through the load. Buck-Boost NMOS, low side Diode, picks up the High control and gate current when drive, current in NMOS turns off. inductor increases. High Input + LED Input + LED 2-3 % penalty Load not connected to inductor. Boost 0 % possible, or 2-3 % if resize for better efficiency VAC=110, Vout > 50 VAC=220, Vout > 100 And Vout < VACmax NMOS, low side Diode, picks up the Low control and gate current when drive, current in NMOS turns off. inductor increases. High Input Input 0% possible 0 % possible Vout > VACmax High Input + N*LED Input/N + LED 3-5 % penalty 5-10 % increase likely Isolation Required Load not connected to inductor. Flyback NMOS, low side control and gate drive, current in transformer primary increases. Load not connected to inductor. JADE SKY TECHNOLOGIES Diode, picks up secondary transformer current when primary side NMOS turns off High Confidential 3 White Paper LED Driver Basics POWER FACTOR Power factor = 1 if the load is a resistor. Power factor control seeks to emulate a resistor but ensuring the input current follows the shape of the input voltage. JST’s controllers to this power factor correction. The PFC is elegant, simple, effective. The PFC is NOT unnecessarily complicated. As a result, the power factor is typically 0.975 at full load. It is not 0.95, 0.9, or other lower values. It is high. The load is very much like a resistor. The JST controller is one stage. In this way, power factor control is combined with current delivery to the LED. The capacitor at the LED provides the necessary filtering to avoid 120 Hz or 60 Hz strobe light appearance. Even more significant, high power factor is maintained even as the dimming angle changes. JST’s proprietary control algorithms enable this significant performance advantage. Other solutions lose power factor quickly as the power decreases from full load. JST’s power factor remains over 0.9. Essentially, JST’s LED driver emulates an incandescent light bulb, which is a resistor. The power factor remains high for an incandescent bulb as power decreases. JST provides the same loading response to the dimmer. FIGURE 1. POWER FACTOR VERSUS DIMMING • JST power factor correction yields 0.975 or greater power factor at full load. • Consistent verification of this power factor at customers. • High power factor maintained over the entire range of dimming. • JST’s LED controller emulates an incandescent light bulb. 4 Confidential JADE SKY TECHNOLOGIES White Paper LED Driver Basics TOTAL HARMONIC DISTORTION JST’s buck controller THD sits around 20-25 % typically. Depending on how the solution is tweaked, it can be lowered a bit. The THD for buck-boost conversion is less than 10 %, maybe even 5 %. THD is the measure of how much the input current does NOT look like a sine wave. If it is a sine wave, THD = 0. If not, then THD goes up. The THD of a buck suffers some because the input voltage is less than the LED voltage for some of the line cycle. When Vin < Vled, then no power conversion occurs. So there are parts of the line cycle with 0 input current. These dead zones do not affect the power factor significantly, but they increase THD. Buck-boost converters, on the other hand, can deliver power even with very low input voltage. As a result, the input current can follow the voltage sine wave shape for virtually the entire line cycle. THD can be very low. • JST operates with a buck • JST’s buck conversion can achieve 20-25 % THD, matching or exceeding competition • JST’s buck-boost conversion can achieve 5-10 % THD, matching or exceeding competition If the output voltage is high (80 Volts, 220 VAC input), and the buck works, but THD is too high, then of course one can change to buck-boost at that point. FLICKER AND SHIMMER AND MORE! Flicker is nasty flashing at high but visible frequency. This can occur at any power level. Flicker is ugly and obvious. When flicker occurs, one suspects that the circuitry is having great difficulty arriving at some kind of stable operating condition. Flicker is quite strong (i.e. more like flashing on/off). It is very much noticeable to everyone and is typically viewed as unacceptable. The instability in current (and triac mis-firing) is very obvious on the oscilloscope measurements of input current, output current, and input voltage. The JST301 solution is designed to avoid this type of flicker on all dimmers, analog and digital. Shimmer appears as subtle fluctuations of light, often at very low light levels. The lamp appears to “shimmer,” suggesting some kind of instability or noisy operation. Shimmer is a very weak variation in light output. It is more like very faint candlelight. Even on the oscilloscope, it is hard to detect. Shimmer typically is detectable only at the very dimmest settings. Whether shimmer is acceptable is very subjective and depends on the observer. The JST301 solution is designed also to minimize shimmer. However, sometimes there are tradeoffs, and it is possible to see a little bit of shimmer at the dimmest settings (below which our competition typically operates). Typically a 9W or greater driver solution can be implemented to have negligible shimmer. For less than 9W, it is more challenging, and shimmer can be observed in some cases, but again at very low light levels. Line Cycle Ripple current will flow into the output of the JST single stage converter. In one extreme, the output capacitor is so large that the LED carries only DC current. In the other extreme, the output capacitor only carries switching ripple current, but not the line cycle current, and so the LED carries the entire 120 Hz ripple current. Typically the ripple is 120 Hz, but there may be 60 Hz content if the dimmer is asymmetrical. If the output capacitor is not large enough, then the LED will accept ripple current rather than the capacitor. This is fine, as long as the LED ripple current does not result in visible LED fluctuation. It appears like a strobe light. The strobe light is not obvious, like flicker. Yet the effect can be real. The ripple current in the LED, relative to the average, determines how much of an effect this fast-action ripple has on the light. This 60/120 Hz ripple is a natural consequence of a one-stage power factor corrected LED driver. It is not a fault. It is normal. In most cases, it is small enough that the visual effect is negligible. Increasing the output capacitor redces LED line cycle ripple current, and thereby the strobe effect. Error Behavior is gross enough that one basically things “it does not work.” For example, as light increases with a dimmer, suddenly the light turns off and then cycles back up. The light cycles up, then off, then up, then off over and over. The cycle may be seconds long. As another example, one plugs in a light bulb, moves the dimmer up, and then suddenly the light has a blinding strobe effect. These error behaviors are crazy enough that one cannot possibly claim interoperation with the relevant dimmer. These effects are especially problematic when interoperation is with digital dimmers. Causes of Flicker JADE SKY TECHNOLOGIES Confidential 5 White Paper LED Driver Basics 1. Insufficient power drawn from the LED controller is often the problem. A dimmer requires some minimum power after the TRIAC fires. 2. Poor power electronics design, or poor power electronics control. 3. Controller problems handling the entire dynamic range of the dimmer. 4. Controllers having trouble figuring out what kind of dimmer is present. 5. Controllers not providing enough loading, particularly for digital dimmers. Causes of Shimmer 1. Shimmer occurs when there is small-scale variability. One example of variability is in the switching behavior at the edges of the line cycle, where the input voltage is close to the LED voltage, and where the input voltage is very low. JST’s parts have been carefully and thoroughly designed to interoperate with dimmers. The staff are experienced, and have used their engineering know-how to go very deep in studying the interaction with dimmers. The result is a solution that operates with any type of dimmer. The solution is different from other competitive chipsets that struggle to find out exactly what kind of dimmer is present. The JST solution operates with any of the dimmers, and as a result does not have the flicker and shimmer issues. Also, the JST solution provides enough flexibility to handle different power levels and input voltage amplitudes. In cases in the lab, when a JST board did in fact have flicker or shimmer, JST engineers were able to eliminate the effects by appropriate external component value change. • JST solutions interoperate with any type of dimmer. • Flicker and shimmer associated with controllers operating with a wrong dimmer type do not happen. There is no wrong dimmer type. • JST’s solution provides flexibility to adjust component values to eliminate shimmer and flicker for a given application requirement. • JST method to match incandescent bulb characteristics eases the compatibility burden. Incandescent bulbs do not flicker. PATENT INFORMATION The products and circuits illustrated herein may be covered by one or more U.S. and foreign patents, or potentially by U.S. and foreign patent applications assigned to Jade Sky Technologies, Inc. LIFE SUPPORT POLICY Jade Sky Technologies products are not authorized for use as critical components in life support devices or systems without the express written approval of the CEO of Jade Sky Technologies. As used herein: 1. A life support device or system is one which, (i) is intended for surgical implant into the body, or (ii) supports or sustains life, and (iii) whose sfailure to perform, when properly used in accordance with instructions for use, can be reasonably expected to result in significant injury or death to the user. 6 Confidential JADE SKY TECHNOLOGIES White Paper LED Driver Basics 2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to cause the failure of the life support device or system, or to affect its safety or effectiveness. ©2013, Jade Sky Technologies, Inc. REVISION HISTORY TABLE 2. REVISION HISTORY Revision 1.0 1.1 Description Initial Release Added information about buck or buck-boost based on Vin and Vout, including implication on THD. Added buck, buck-boost, boost, flyback table JADE SKY TECHNOLOGIES Confidential Date June 2013 July 2013 7