Loss Prevention Safety Resources

Commercial Cooking: Fixed Suppression Systems

All commercial cooking operations should have an automatic

fire suppression system installed within the hood. This system

provides protection to the cooking appliances, hood and

plenum spaces, including the exhaust duct; in accordance with

NFPA 96 - Standard for Ventilation Control and Fire Protection

of Commercial Cooking Operations. NFPA 96 requires that

automatic fire-extinguishing systems comply with UL 300 or

another equivalent testing standard.

At the bottom of this document, under “Related Links” is a

list of the current manufacturers of UL listed “pre-engineered

systems.

Defining UL 300

UL 300 is the Standard for the Testing of Fire Extinguishing

Systems for Protection of Restaurant Cooking Areas. UL 300

addresses the method of fire testing for self-contained chemical

extinguishing systems commonly referred to as pre-engineered

systems. UL 300 has been identified as a baseline for testing

pre-engineered fire-extinguishing systems intended for the

protection of commercial cooking-related hazards. Additional

equivalent testing standards have been written for other types

of fire-extinguishing systems not considered pre-engineered

that demonstrate equivalent fire testing severity to the UL 300

test standard. Current examples include, but are not limited to,

UL 199, UL Subject 199B, UL Subject 199E, and UL 710B.

Since UL 300 is limited in scope to a performance standard,

refer to NFPA 17A - Standard for Wet Chemical Extinguishing

Systems and the manufacturers’ guidelines for installation and

servicing.

UL released a revised version of UL 300 on November 21,

1994. The primary revisions in this document addressed

changes to the cooking equipment, a change from lard to

vegetable oils, plus substantial enhanced performance aspects

of the suppression systems. In addition to pre-engineered

systems, NFPA 96 does permit the installation of “engineered”

suppression systems as well. These engineered systems are

outside of the scope of UL 300, but it should be noted that

the typical cost to design and install an engineered system is

substantially more than a pre-engineered system.

Determining if your system is compliant

How can you determine if your installed pre-engineered

suppression system is acceptable? First, the pre-engineered

system should not have been manufactured by either of the two

following brands: Safety First or FSI / Casco, both of which

stopped manufacturing wet chemical systems when the revised

UL 300 was released in 1994.

SR 022 OC

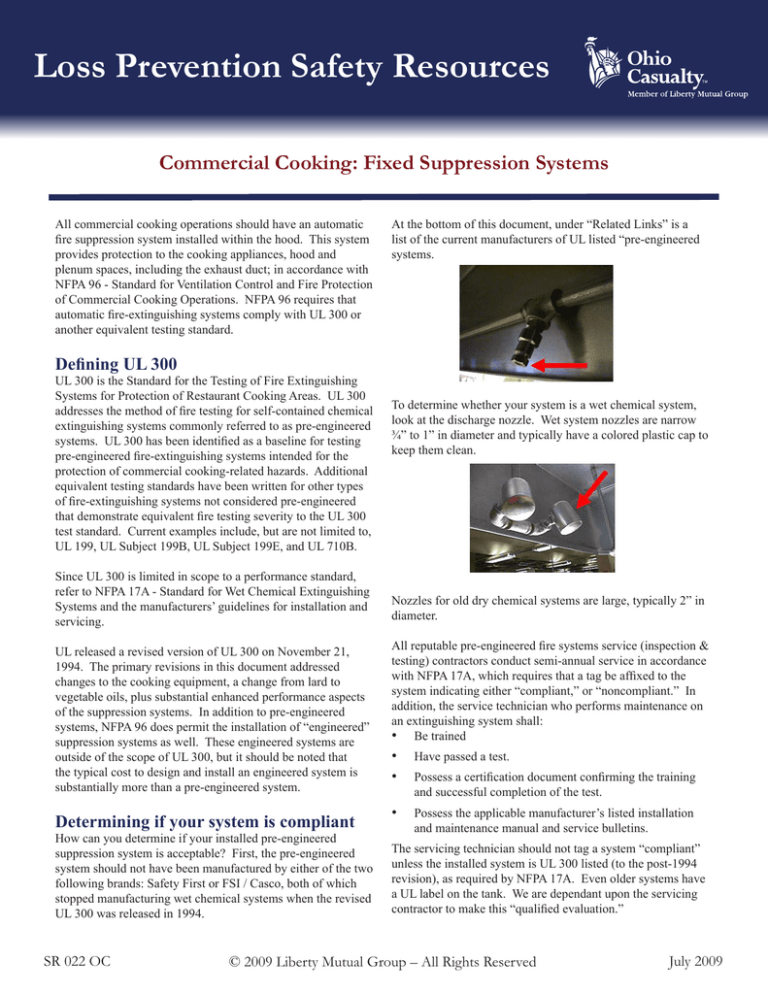

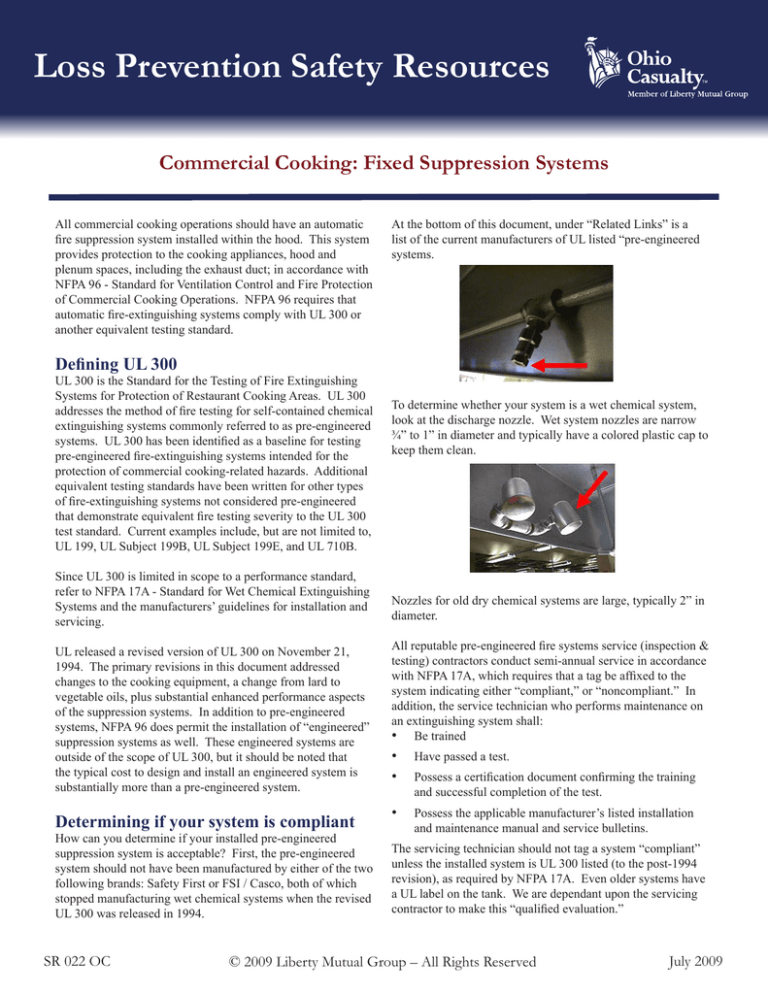

To determine whether your system is a wet chemical system,

look at the discharge nozzle. Wet system nozzles are narrow

¾” to 1” in diameter and typically have a colored plastic cap to

keep them clean.

Nozzles for old dry chemical systems are large, typically 2” in

diameter.

All reputable pre-engineered fire systems service (inspection &

testing) contractors conduct semi-annual service in accordance

with NFPA 17A, which requires that a tag be affixed to the

system indicating either “compliant,” or “noncompliant.” In

addition, the service technician who performs maintenance on

an extinguishing system shall:

• Be trained

• Have passed a test.

• Possess a certification document confirming the training

and successful completion of the test.

• Possess the applicable manufacturer’s listed installation

and maintenance manual and service bulletins.

The servicing technician should not tag a system “compliant”

unless the installed system is UL 300 listed (to the post-1994

revision), as required by NFPA 17A. Even older systems have

a UL label on the tank. We are dependant upon the servicing

contractor to make this “qualified evaluation.”

© 2009 Liberty Mutual Group – All Rights Reserved

July 2009

Identifying the service provider

A service record tag is attached to the system, either at the

manual pull box or at the cylinder. Again, systems that are

noncompliant are also tagged. It is important to read the tag

and note which tag was installed and whether any notes were

written on the back of the tag. The tag will list the name and

phone number of the service provider. You can contact this

provider directly for confirmation of compliance.

If you have any further questions or concerns, please contact

your Loss Prevention Consultant, who will gladly assist you.

Related Links:

• National Fire Protection Association - www.nfpa.org/

• Underwriter’s Laboratories, Inc. www.ul.com

• Amerex - KP Restaurant System www.amerex-fire.com/

products/product/8

Obvious indicators a fixed suppression does not meet the

current version of UL 300:

• Ansul® - R-102™ Restaurant Fire Suppression Systems

• Installed prior to 11/21/1994

• Noncompliant tag, or a tag

• Ansul® - Piranha® Fire Suppression Systems www.ansul.

www.ansul.com/en/Products/kitchen_sys/kitchen_list.asp

com/en/Products/kitchen_sys/kitchen_piranha.asp

with notes written on the back

indicating items to be corrected

• Dry chemical nozzles and

• Badger Fire Protection - Range Guard www.badgerfire.

com/utcfs/Templates/Pages/Template-53/0,8062,pageId%3

D5938%26siteId%3D603,00.html

• Buckeye Fire Equipment – Kitchen Mister www.buckeyef.

extinguishing media

com/Restaurant_Main.asp

• System uses a single nozzle to

• Kidde - WHDR™ Wet Chemical Fire Suppression System

protect multiple appliances or

multiple cooking surface

What if your system is not UL 300

compliant?

www.kiddefiresystems.com/utcfs/Templates/Pages/

Template-53/0,8062,pageId%3D890%26siteId%3D383,0

0.html

• Pyrochem – Kitchen Knight® II Restaurant System www.

pyrochem.com/html/prodkitchen.html

If your system is not compliant, you should immediately

contact a qualified servicing licensed contractor to replace the

existing fire suppression system.

The illustrations, instructions and principles contained in the material are general in scope and, to the best of our knowledge, current at the time of publication. No

attempt has been made to interpret any referenced codes, standards or regulations. Please refer to the appropriate code-, standard-, or regulation-making authority for interpretation or clarification. Provided that you always reproduce our copyright notice and any other notice of rights, disclaimers, and limitations, and provided

that no copy in whole or in part is transferred, sold, lent, or leased to any third party, you may make and distribute copies of this publication for your internal use.

SR 022 OC

© 2009 Liberty Mutual Group – All Rights Reserved

2