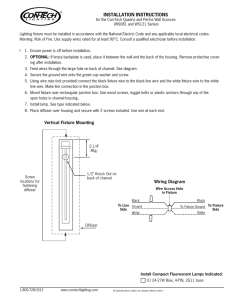

installation instructions

advertisement

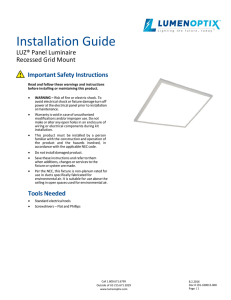

INSTALLATION INSTRUCTIONS Lightplane 3.5 Recessed Page 1 of 5 IMPORTANT SAFETY INSTRUCTIONS When installing or using this recessed fixture basic safety precautions should be followed Read ALL INSTRUCTIONS before installing fixture. •This fixture is intended for installation in accordance with the National Electric Code and Local and State Codes and must be installed by a licensed electrical contractor. •DO NOT INSTALL THIS FIXTURE IN DAMP LOCATIONS. •DO NOT INSTALL FIXTURE WITHOUT A MINIMUM 1/2 INCH CLEARANCE ALL AROUND THE FIXTURE. ENSURE CLEARANCE AT TOP OF CHANNEL IS 3 INCHES. • THIS FIXTURE IS FOR INSTALLATION IN NON INSULATED CEILINGS ONLY. •To prevent electrical shock, turn off electricity at fuse box before installing the fixture. •Turn off power and allow fixture to cool down before adjusting position of lamp gimbals. •Use AWG#12 wire only for supply to the fixture. © 2015 Architectural Lighting Works. Specifications subject to change without notice. Limited warranty. Complete terms available on website. A 30984 Santana Street n Hayward, CA 94544 P 510 489 2530 n n E TalkToUs@alwusa com n W alwusa com n INSTALLATION INSTRUCTIONS Lightplane 3.5 Recessed Page 2 of 5 TYPICAL INSTALLATION ALWAYS FOLLOW APPLICABLE BUILDING CODES WHEN INSTALLING ANY LIGHT FIXTURE. DUE TO PRODUCT VARIATIONS AND CONFIGURATIONS, THESE INSTRUCTIONS SERVE ONLY AS A GENERAL GUIDE. REFER TO FACTORY PROVIDED SUBMITTALS FOR DETAILS GRID/WALLBOARD Flex conduit or cable INSTRUCTION: 1. TURN OFF POWER at fuse box before installing fixture. 2. Remove LENS and REFLECTOR ASSEMBLY on the fixture that connects to the building wire . Set parts aside. 3. SUPPORT UNIT TO STRUCTURE VIA ALLTHREAD, HANGING WIRE OR BLOCKING (BY OTHERS) 4. If Joining multiple fixtures together remove endcaps where fixtures are joined together and loosen set screws on JOINING BAR hardware. Extend JOINING BARS from end of fixture & secure. Connect wires between fixtures. Attach the white, black green wire connectors using connectors provided. Push Excess wire into fixtures. DO NOT PINCH WIRES BETWEEN THE PARTS. Join segments together and secure joined fixtures with the JOINING BAR Set Screw hardware. 5. While protecting finished parts and supporting the fixture pull building wires through KNOCKOUT and attach conduit hardware to fixture. Secure fixture to ceiling with brackets (Provided) or using fasteners to secure fixture to blocking or building structure (By Others). 6. While Supporting the Reflector assembly, Attach Building wire to fixture using disconnect (Provided) or using U.L. approved wire connectors: connect the luminary neutral (white) to the supply neutral, connect the luminary line wire (black) to the supply line wire. Fasten ground wire(s) (Green) to ground wire. 7. Push wires into wirebody and secure REFLECTOR ASSEMBLY with SCREWS (DO NOT PINCH THE WIRES BETWEEN THE PARTS) . 8. Install Lamps and LENS(S) 9. Turn On Power Threaded rod or Hanger Wire SUPPORT TO STRUCTURE MUST BE PROVIDED VIA BLOCKING, HANGING WIRE OR THREADED ROD (ALL BY OTHERS) GRID/WALLBOARD INSTALLATION: ALWAYS PROVIDE ADDITIONAL SUPPORT TO STRUCTURE IN ANY GRID MOUNTING. UNITS ARE NOT SUPPORTED BY GRID Optional Twist Install Bracket . Suction Cup © 2015 Architectural Lighting Works. Specifications subject to change without notice. Limited warranty. Complete terms available on website. A 30984 Santana Street n Hayward, CA 94544 P 510 489 2530 n n E TalkToUs@alwusa com n W alwusa com n INSTALLATION INSTRUCTIONS Lightplane 3.5 Recessed Page 3 of 5 TYPICAL INSTALLATION ALWAYS FOLLOW APPLICABLE BUILDING CODES WHEN INSTALLING ANY LIGHT FIXTURE. DUE TO PRODUCT VARIATIONS AND CONFIGURATIONS, THESE INSTRUCTIONS SERVE ONLY AS A GENERAL GUIDE. REFER TO FACTORY PROVIDED SUBMITTALS FOR DETAILS TRIMLESS INSTRUCTION: 1. TURN OFF POWER at fuse box before installing fixture. 2. Remove LENS and REFLECTOR ASSEMBLY on the fixture that connects to the building wire . Set parts aside. 3. SUPPORT UNIT TO STRUCTURE VIA ALLTHREAD, HANGING WIRE OR BLOCKING (BY OTHERS) 4. If Joining multiple fixtures together remove endcaps where fixtures are joined together and loosen set screws on JOINING BAR hardware. Extend JOINING BARS from end of fixture & secure. Connect wires between fixtures. Attach the white, black green wire connectors using connectors provided. Push Excess wire into fixtures. DO NOT PINCH WIRES BETWEEN THE PARTS. Join segments together and secure joined fixtures with the JOINING BAR Set Screw hardware. 5. Pull building wires through KNOCKOUT and attach conduit hardware to fixture. Secure fixture to ceiling with SCREWS(By Others) or using fasteners to secure fixture to blocking or building structure (By Others)as needed. 6. Insert fixture into opening and align the opening to be flush with the surface. D not force fixture into opening or bend the WIREBODY. Expand opening in SURFACE as needed to fit fixture through. BENDING THE WIREBODY WILL CAUSE THE LENS TO NOT FIT SECURELY IN THE WIREBODY. Secure the extrusion with screws by attaching the FINS to the drywall and / or BLOCKING. PUTTY in the gap between the OPENING and the WIREBODY and finish the area smooth. 7. While Supporting the Reflector assembly,. Attach Building wire to fixture using disconnect (Provided) or using U.L. approved wire connectors: connect the luminary neutral (white) to the supply neutral, connect the luminary line wire (black) to the supply line wire. Fasten ground wire(s) (Green) to ground wire. 8. Push wires into wirebody and secure REFLECTOR ASSEMBLY with SCREWS (DO NOT PINCH THE WIRES BETWEEN THE PARTS) 9. Install Lamps and LENS(S) 10. Turn On Power Flex conduit or cable Threaded rod or Hanger Wire SUPPORT TO STRUCTURE MUST BE PROVIDED VIA BLOCKING, HANGING WIRE OR THREADED ROD (ALL BY OTHERS) TRIMLESS INSTALLATION: DRYWALL IS IN FRONT OF "MUD WINGS", TAPE AND PUTTY TO EDGES. NO METAL SHOULD BE EXPOSED ON DRYWALL. 3 68" 4" Blocking 7 38" Ceiling/Gypsum Board 3 34" (Lens) 4” (Rough Opening) Feathering Compound/Tape . © 2015 Architectural Lighting Works. Specifications subject to change without notice. Limited warranty. Complete terms available on website. A 30984 Santana Street n Hayward, CA 94544 P 510 489 2530 n n E TalkToUs@alwusa com n W alwusa com n INSTALLATION INSTRUCTIONS Lightplane 3.5 Recessed Page 4 of 5 TYPICAL INSTALLATION ALWAYS FOLLOW APPLICABLE BUILDING CODES WHEN INSTALLING ANY LIGHT FIXTURE. DUE TO PRODUCT VARIATIONS AND CONFIGURATIONS, THESE INSTRUCTIONS SERVE ONLY AS A GENERAL GUIDE. REFER TO FACTORY PROVIDED SUBMITTALS FOR DETAILS SUPPORT TO STRUCTURE MUST BE PROVIDED VIA BLOCKING, HANGING WIRE OR THREADED ROD (ALL BY OTHERS) Perimeter Detail By others: 1/2" Electrical fitting to rear hole 1 7 2 " Min Block Height 5 48" Hanger threaded rod by others For hard ceilings, blocking installed before fixture installation 1 3 16 " Distance: Lens to blocking 1 44" Blocking Width installation Housing affixed to blocking Gypsum Ceilings Ceiling/Surface installed after fixture By others: 1/2" Electrical fitting to rear hole Hanger Wire by others blocking installed before fixture installation. Fixture flange fastened to blocking. 3 4 16 " Grid Ceilings Ceiling Tiles installed after fixture Perimeter Detail 2. Housing is fastened to blocking 3. Electrical is brought to rear knockouts and connected. 4. Ceiling surfaces are installed. For gypsum, they are then patched and painted. © 2015 Architectural Lighting Works. Specifications subject to change without notice. Limited warranty. Complete terms available on website. A 30984 Santana Street n Hayward, CA 94544 P 510 489 2530 n n E TalkToUs@alwusa com n W alwusa com n INSTALLATION INSTRUCTIONS Lightplane 3.5 Recessed Page 5 of 5 TYPICAL INSTALLATION ALWAYS FOLLOW APPLICABLE BUILDING CODES WHEN INSTALLING ANY LIGHT FIXTURE. DUE TO PRODUCT VARIATIONS AND CONFIGURATIONS, THESE INSTRUCTIONS SERVE ONLY AS A GENERAL GUIDE. REFER TO FACTORY PROVIDED SUBMITTALS FOR DETAILS LENSES MUST FULLY SEAT INTO CLIPS FOR PROPER INSTALLATION. FAILURE TO DO SO IS CONSIDERED AN IMPROPER INSTALLATION. Lens Security Clip Installation Guide Warning: Turn Off All Power At Circuit Breaker Do Not Install Clips On An Energized Fixture. Lens 2x Self Drilling/ Self Tapping Sheet Metal Screws (Provided) Are Used To Secure The Clip Lamps 2x Lens Security Clip Installs 1/3 Of The Length Of The Aluminum Extrusion. Avoid Installing Lens Clips in the Center of the Lens. Prevent Damage To Electrical Components Second Slot Lens Security Clip Should Apply Pressure To Lens At This Location. The Clip Can Be Adjusted To Contact The Lens As Needed. © 2015 Architectural Lighting Works. Specifications subject to change without notice. Limited warranty. Complete terms available on website. A 30984 Santana Street n Hayward, CA 94544 P 510 489 2530 n n E TalkToUs@alwusa com n W alwusa com n