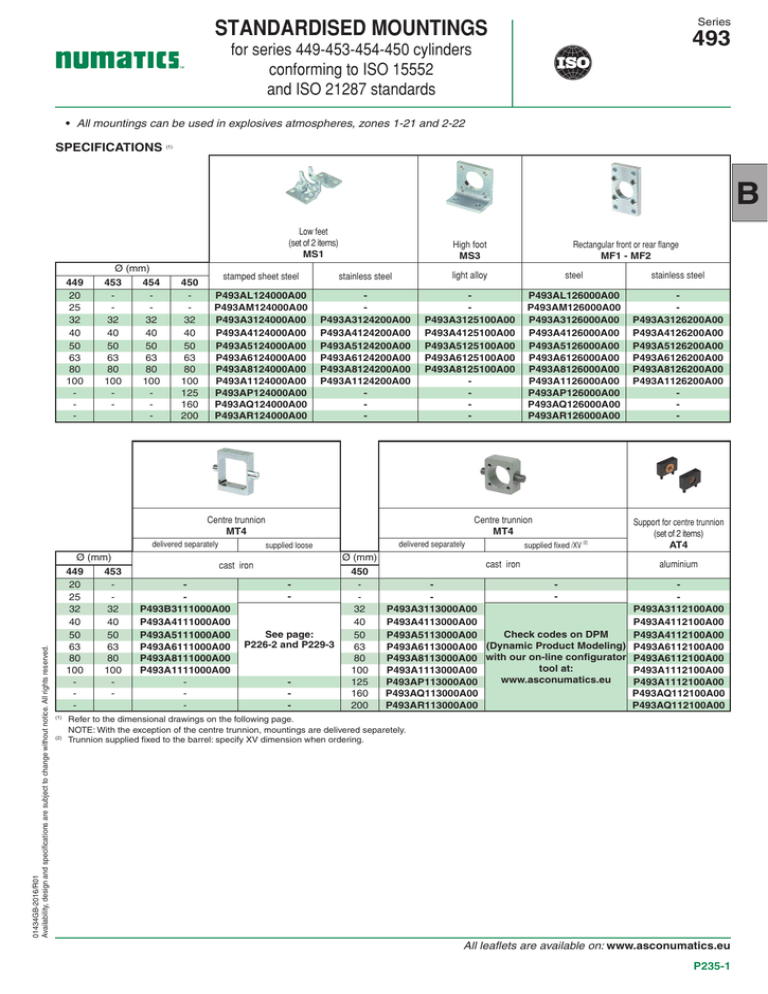

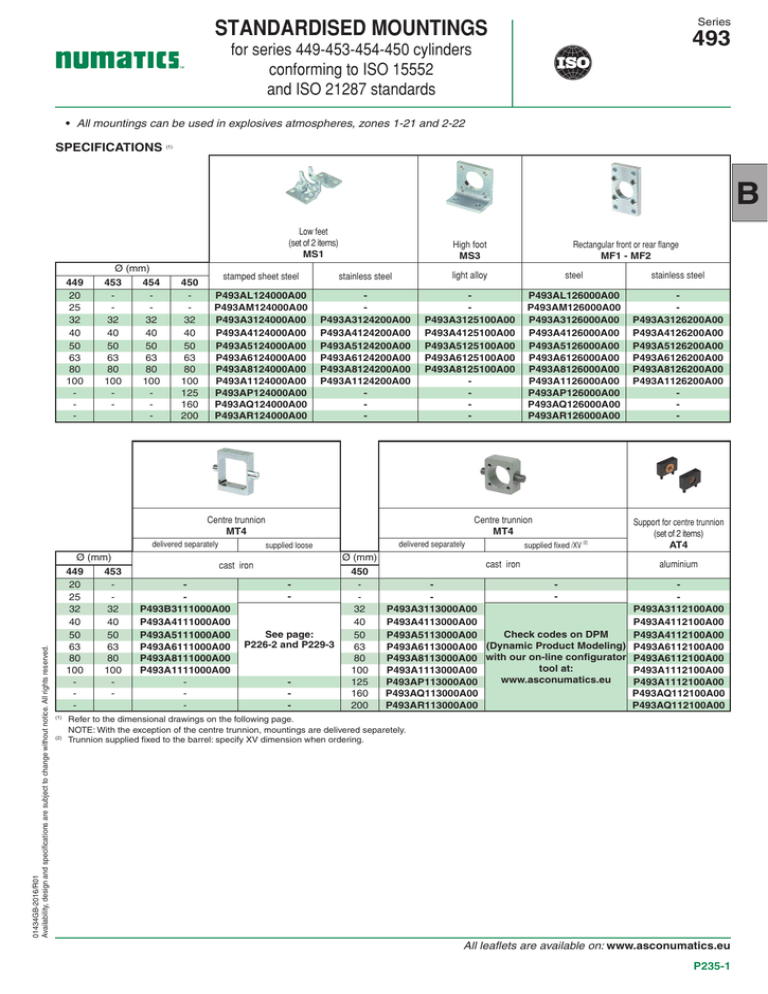

STANDARDISED MOUNTINGS

Series

493

for series 449-453-454-450 cylinders

conforming to ISO 15552

and ISO 21287 standards

• All mountings can be used in explosives atmospheres, zones 1-21 and 2-22

SPECIFICATIONS (1)

B

Low feet

(set of 2 items)

MS1

449

20

25

32

40

50

63

80

100

-

Ø (mm)

453

454

32

32

40

40

50

50

63

63

80

80

100

100

-

450

32

40

50

63

80

100

125

160

200

High foot

MS3

stamped sheet steel

stainless steel

light alloy

steel

stainless steel

P493AL124000A00

P493AM124000A00

P493A3124000A00

P493A4124000A00

P493A5124000A00

P493A6124000A00

P493A8124000A00

P493A1124000A00

P493AP124000A00

P493AQ124000A00

P493AR124000A00

P493A3124200A00

P493A4124200A00

P493A5124200A00

P493A6124200A00

P493A8124200A00

P493A1124200A00

-

P493A3125100A00

P493A4125100A00

P493A5125100A00

P493A6125100A00

P493A8125100A00

-

P493AL126000A00

P493AM126000A00

P493A3126000A00

P493A4126000A00

P493A5126000A00

P493A6126000A00

P493A8126000A00

P493A1126000A00

P493AP126000A00

P493AQ126000A00

P493AR126000A00

P493A3126200A00

P493A4126200A00

P493A5126200A00

P493A6126200A00

P493A8126200A00

P493A1126200A00

-

Centre trunnion

MT4

01434GB-2016/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

delivered separately

Ø (mm)

449

453

20

25

32

32

40

40

50

50

63

63

80

80

100

100

-

Rectangular front or rear flange

MF1 - MF2

Centre trunnion

MT4

supplied loose

cast

P493B3111000A00

P493A4111000A00

P493A5111000A00

P493A6111000A00

P493A8111000A00

P493A1111000A00

-

Ø (mm)

iron

450

32

40

See page:

50

P226-2 and P229-3

63

80

100

125

160

200

delivered separately

supplied fixed /XV (2)

Support for centre trunnion

(set of 2 items)

AT4

cast iron

aluminium

P493A3113000A00

P493A4113000A00

Check codes on DPM

P493A5113000A00

P493A6113000A00 (Dynamic Product Modeling)

P493A8113000A00 with our on-line configurator

tool at:

P493A1113000A00

www.asconumatics.eu

P493AP113000A00

P493AQ113000A00

P493AR113000A00

P493A3112100A00

P493A4112100A00

P493A4112100A00

P493A6112100A00

P493A6112100A00

P493A1112100A00

P493A1112100A00

P493AQ112100A00

P493AQ112100A00

Refer to the dimensional drawings on the following page.

NOTE: With the exception of the centre trunnion, mountings are delivered separetely.

(2)

Trunnion supplied fixed to the barrel: specify XV dimension when ordering.

(1)

All leaflets are available on: www.asconumatics.eu

P235-1

ISO 15552-ISO 21287 STANDARDISED MOUNTINGS - SERIES 449-453-454-450

REAR MOUNTINGS (1)

Cap, detachable clevis

MP2

light alloy

anticorrosion

(NPC treatment)

P493A3121100NPC

P493A4121100NPC

P493A5121100NPC

P493A6121100NPC

P493A8121100NPC

P493A1121100NPC

-

Ø (mm)

449

20

25

32

40

50

63

80

100

-

453

32

40

50

63

80

100

-

454

32

40

50

63

80

100

-

450

32

40

50

63

80

100

125

160

200

light alloy

P493A3121110A00

P493A4121110A00

P493A5121110A00

P493A6121110A00

P493A8121110A00

P493A1121110A00

-

cast iron

P493AP121010A00

P493AQ121010A00

P493AR121010A00

stainless steel

P493A3121200A00

P493A4121200A00

P493A5121200A00

P493A6121200A00

P493A8121200A00

P493A1121200A00

-

Cap, detachable eye (trunnion)

MP4

449

20

25

32

40

50

63

80

100

-

453

32

40

50

63

80

100

-

454

32

40

50

63

80

100

-

450

32

40

50

63

80

100

125

160

200

light alloy

P493AL122110A00

P493AM122110A00

P493A3122100A00

P493A4122100A00

P493A5122100A00

P493A6122100A00

P493A8122100A00

P493A1122100A00

-

cast iron

P493AP122010A00

P493AQ122010A00

P493AR122010A00

AB7

449453 454 450

20 - - 25 - - 32 32 32 32

40 40 40 40

50 50 50 50

63 63 63 63

80 80 80 80

100100 100 100

- - - 125

- - - 160

- - - 200

light alloy

P493A3123110A00

P493A4123110A00

P493A5123110A00

P493A6123110A00

P493A8123110A00

P493A1123110A00

-

light alloy

anticorrosion

cast iron

(NPC treatment)

P493A3123100NPC

P493A4123100NPC

P493A5123100NPC

P493A6123100NPC

P493A8123100NPC

P493A1123100NPC

P493AP123010A00

P493AQ123010A00

P493AR123010A00

stainless steel

P493A3123200A00

P493A4123200A00

P493A5123200A00

P493A6123200A00

P493A8123200A00

P493A1123200A00

-

Refer to the dimensional drawings on the following page.

These accessories allows accurate angular compensation adjustment spherical of 4°.

(1)

(2)

All leaflets are available on: www.asconumatics.eu

P235-2

stainless steel

P493A3122200A00

P493A4122200A00

P493A5122200A00

P493A6122200A00

P493A8122200A00

P493A1122200A00

-

Cap clevis for spherical Cap eye with spherical

eye or clevis bracket

eye (2)

AB6

MP6

Angular clevis bracket

Ø (mm)

light alloy

anticorrosion

(NPC treatment)

P493A3122100NPC

P493A4122100NPC

P493A5122100NPC

P493A6122100NPC

P493A8122100NPC

P493A1122100NPC

-

Angular clevis bracket

spherical bearing (2)

AB5

steel

steel

steel

P493A3129000A00

P493A4129000A00

P493A5129000A00

P493A6129000A00

P493A8129000A00

P493A1129000A00

P493AP129000A00

-

P493A3128000A00

P493A4128000A00

P493A5128000A00

P493A6128000A00

P493A8128000A00

P493A1128000A00

P493AP128000A00

-

P493A3127000A00

P493A4127000A00

P493A5127000A00

P493A6127000A00

P493A8127000A00

P493A1127000A00

P493AP127000A00

-

01434GB-2016/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

Ø (mm)

ISO 15552-ISO 21287 STANDARDISED MOUNTINGS - SERIES 449-453-454-450

ROD MOUNTINGS (1)

Femelle rod clevis (2)

AP2

449

20-25

32-40

50-63

80-100

-

Ø (mm)

453

454

450

32

32

32

40

40

40

50-63 50-63 50-63

80-100 80-100 80-100

125

160-200

Spherical rod end

AP6

Alignement compensator

(3)

steel

stainless steel

steel

stainless steel

steel

P493AL431000A00

P493A3131000A00

P493A4131000A00

P493A5131000A00

P493A8131000A00

P493AP131000A00

P493AQ131000A00

P493A3131200A00

P493A4131200A00

P493A5131200A00

P493A8131200A00

-

P493AL432000A00

P493A3132000A00

P493A4132000A00

P493A5132000A00

P493A8132000A00

P493AP132000A00

P493AQ132000A00

P493A3132200A00

P493A4132200A00

P493A5132200A00

P493A8132200A00

-

P493A3134000A00

P493A4134000A00

P493A5134000A00

P493A8134000A00

P493AP134000A00

-

Refer to the dimensional drawings on the following page.

Ø125 to 200 mm: Clevis with axis locking pin

This accessory allows accurate angular compensation adjustment spherical of 4° and radial of 0,7 mm.

(1)

(2)

01434GB-2013/R04

Availability, design and specifications are subject to change without notice. All rights reserved.

(3)

All leaflets are available on: www.asconumatics.eu

P235-3

B

ISO 15552-ISO 21287 STANDARDISED MOUNTINGS - SERIES 449-453-454-450

DIMENSIONS (mm), WEIGHT (kg)

MOUNTING

Low feet

MS1

XA + 1

ATG

AT

=

XA + 1

TG

=

=

AT

=

2øAB

TR =AU

=

E max.=

AU

AO max.

L8 + 1

TR

= AU=

E max.

AU

AO max.

SA + 1

=

Series 449

=

AT

Series 450

AH

AT

AH

L8 + 1

SA + 1

TG

2ØAB

2ØAB

Series 454

AU

=

AT

AH

Series 453

XA + 1

=

AT

A

ZA + 1

SA + 1

=

AU

TR

= =

E= max.

=

AO max.

1 Stroke

MOUNTING

High foot

MS3

US max.A

=

AT1

=

US max.

=

AT1

=

US max.

=

TG =

XA + 1

AT1

=

2øAB

AO

AT1

L8 + 1

SA + 1

AU

TR =

=

AU

Series 449

TR

=

AO

=

ZA + 1

SA + 1

AU

=

=

=

TR=

AT1

UF

AH

AU

Series 450

UF

2øAB

AT1

AH

TG

=

2øAB

L8 + 1

SA + 1

AU

XA + 1

=

=

AH

Series 453

TG

UF

XA + 1

A

AU

AO

1 Stroke

Ø (mm)

449

20

25

32

40

50

63

80

100

-

453

32

40

50

63

80

100

-

454

32

40

50

63

80

100

-

450

32

40

50

63

80

100

125

160

200

ØAB A

AO AH AT AT1 AU

7

7

7

9

9

9

12

14,5

16,5

18,5

24

7 27 4

7 29 4

11 32 4

13 36 4

13 45 5

13 50 5

20 63 6

25 71 6

25 90 8

25 115 10

35 135 12

22

24

32

32

40

40

54

72

72

8

8

10

10

12

12

16

-

16

16

24

28

32

32

41

41

45

60

70

E

L8

38

41

50

58

70

85

105

130

157

195

238

94

105

106

121

128

138

160

180

180

SA

XA

TR TG UF US

ZA

449 453/454/450

449 453/454/450

69

22 22 59

37

71

26 26 61

39

92

142

32 32,5 54 50 79

144

44

101

161

36 38 62 58 83

163

45

109

170

45 46,5 77 70 88

175

45

113

185

50 56,5 87 85 91,5

190

49

146

210

63 72 110 105 107,5

215

54

149

220

75 89 130 130 128,5

230

67

250

90 110 161 157 270

300

115 140 320

320

135 175 345

-

weight

2 x MS1 1 x MS3

0,064

0,076

0,150

0,180

0,190

0,250

0,395

0,470

0,445

0,595

0,790

1,265

1,400

2,330

4,860

7,900

-

Front or rear flange

MF1 - MF2

Rectangular

Series 454

Series 450

E max.

=

=

R

Series 449

=

=

2Ø FB

=

4Ø FB

=

ØDH11

UF max.

TF

UF max.

Series 453

ØD

E max.

4Ø FB

TF

ØDH11

Ø 32 - 200

UF max.

MF

Ø 20 - 25

TF

W

H11

ZF + 1

+ 1

EZB

max.

=

=

MF R

=

=

W

UF max.

ZJ + 1

max.

ZF + 1

AE

=

=

R

ZJ + 1

=

=

W

MF 4Ø FB

TF

ZF + 1

A

ØDH11

1 Stroke

Ø (mm)

449 453 454 450

20

25

32

40

50

63

80

100

-

32

40

50

63

80

100

-

32

40

50

63

80

100

-

32

40

50

63

80

100

125

160

200

A

ØD

22

24

32

32

40

40

54

72

72

16

16

30

35

40

45

45

55

60

65

75

E

ØFB

MF

R

TF

UF

38 6,6

41 6,6

50

7

58

9

70

9

85

9

105 12

130 14

157 16

195 18

238 22

8

8

10

10

12

12

16

16

20

20

25

32

36

45

50

63

75

90

115

135

55

60

64

72

90

100

126

150

180

230

270

70

76

86

96

115

130

165

187

224

280

320

All leaflets are available on: www.asconumatics.eu

P235-4

449

W

453/454/450

ZB

2

2

3

3

4

4

6

6

-

16

20

25

25

30

35

45

60

70

43

45

55

55

56

59,5

66,5

77,5

-

ZJ

449

51

53

120 65

135 65

143 67

158 71,5

174 82,5

189 93,5

225

260

275

-

ZF

453/454/450

weight

130

145

155

170

190

205

245

280

300

0,016

0,020

0,190

0,245

0,500

0,580

1,390

1,630

4,270

6,880

12,330

01434GB-2014/R02

Availability, design and specifications are subject to change without notice. All rights reserved.

MOUNTING

ISO 15552-ISO 21287 STANDARDISED MOUNTINGS - SERIES 449-453-454-450

DIMENSIONS (mm), WEIGHT (kg)

MOUNTING

MOUNTING

Centre trunnion

MT4

(Series 450)

XV Dimension must be specified when ordering.

Centre trunnion

MT4

(Series 449-453)

XV Dimension must be specified when ordering.

Series 450

e9

Ø TDe9

TK1

TL

ØTD

h14

TM

3

3

XV 2

XV 2

ZB + 1

ZJ + 1

A

Ø (mm)

449

32

40

50

63

80

100

-

453

32

40

50

63

80

100

-

450

32

40

50

63

80

100

125

160

200

E1

A

E

22

24

32

32

40

40

54

72

72

46,5

52

64

74

92

109

145

180

220

(1)

48

54

66

78

96

115

-

TG=

E =

UWA

=

=

=

XV min.

12

16

16

20

20

25

25

32

32

120

135

143

158

174

189

225

260

275

22

28

28

35

35

40

40

50

50

12

16

16

20

20

25

25

32

32

50 (2)

63

75

90

110

132

160

200

250

55

58

68

84

102

145

175

220

260

64,5

74,5

91

94

130

125

175

220

260

55

55

56

59,5

66,5

87,5

-

Applies to 450 series with options AT1, AT2, HTP, FPM, FFP and NPC.

449

31

32

33

35

40

45

-

453

70

79

86

89

102

109

-

XV max. (+ stroke)

450

72

83

90

94

107

114

135

160

174

449

27

27

28

30

35

42

-

453

77

86

95

107

119

132

-

Series 450

STATIC ROD-LOCKING DEVICE

XV min.

453

450

130

132

149

153

176

180

179

184

212

217

224

219

weight

449

449/453

0,185

0,33

0,475

0,57

1,12

1,52

-

5

5

5

5

5

5

-

450

0,2

0,4

0,5

0,9

1,1

1,86

2,55

4,7

4,2

Series 453

Series 450

Series 450

XV

DYNAMIC ROD-LOCKING DEVICE

XV max. (+ stroke)

453

450

137

135

156

152

185

181

197

192

229

224

242

237

min. stroke

Series 453

XV

XV

450

75

82

91

102

114

127

156

181

197

=

(2)

Series 453

XV min.

453

174

198

209

242

259

XV max. (+ stroke)

453

450

181

177

207

203

227

222

259

254

282

277

450

178

202

214

247

264

1 Stroke

2 Except when XV dimension is specified

when ordering, the position of the trunnion may be adjusted along the unit.

Consequently, the centre trunnion is not

screwed on and must be adjusted after

delivery.

3 8 locking screws.

MOUNTING

Support for centre trunnion (set of 2 items)

AT4

(Series 449-453-450)

UL

TH

=

=

=

=

= =

UL

TH

Ød4

=

= =

Ø CRH9

=

=

UL

TH

Series 449

Series 450

FK

FN

HB

H3

15

18

18

20

20

25

25

30

30

30

36

36

40

40

50

50

60

60

6,6 6,8

9

9

9

9

11

11

11

11

13,5 13

13,5 13

17,5 17,5

17,5 17,5

=

C

Series 453

=

=

NH

=

Ø (mm)

C ØCR Ød4

449 453 450

11

32 32 32 10,5 12

16

15

40 40 40 12

16

15

50 50 50 12

20

18

63 63 63 13

20

18

80 80 80 13

25

20

100 100 100 16

- 125 16

25

20

- 160 22,5 32

26

- 200 22,5 32

26

-

FN

Ø HB

L6

L5

=

TMh14

=

=

=

FK

=

= =

UL

TH

H3

=

=

01434GB-2016/R03

Availability, design and specifications are subject to change without notice. All rights reserved.

=

TG

E/E1=

=

UW

TM dimension is 53 for series 449 and 453, in Ø32.

(1)

Ø (mm)

453 450

32 32

40 40

50 50

63 63

80 80

100 100

=

=

ZJ

18

20

20

25

25

30

40

50

50

=

XV

ZJ + 1

A

TD TG TK TK1 TL TM UW UWA ZB

32,5

38

46,5

56,6

72

89

110

140

175

B

TL

TK

TMh14

Series 449

TK

h14

Series 453

L5

L6

NH

TH

TM

UL

weight

71

87

99

116

136

164

192

245

295

86

105

117

136

156

189

219

280

330

18

21

21

23

23

28,5

28,5

40

40

32

36

36

40

40

50

50

60

60

50 (2)

63

75

90

110

132

160

200

250

46

55

55

65

65

75

75

92

92

0,12

0,23

0,23

0,33

0,33

0,58

0,58

1,03

1,03

TM dimension is 53 for series 449

and 453, in Ø32.

(2)

All leaflets are available on: www.asconumatics.eu

P235-5

ISO 15552-ISO 21287 STANDARDISED MOUNTINGS - SERIES 449-453-454-450

DIMENSIONS (mm), WEIGHT (kg)

REAR MOUNTING

MP2 + MP4

Cap, detachable clevis

+

Cap, detachable eye (trunnion)

Cap, detachable clevis

MP2

=

=

E

=

TG

=

=

FL

CBH14

=

E

TG

FL

=

=

FL

4Ø D

FL

=

4Ø HB

UL

TE

EM

4Ø HB

RA

UR

XD + 1

449

20

25

32

40

50

63

80

100

-

453

32

40

50

63

80

100

-

454

32

40

50

63

80

100

-

450

32

40

50

63

80

100

125

160

200

450

32

40

50

63

80

100

125

160

200

A

CB CD

BT EM

CK

22

24

32

32

40

40

54

72

72

8

10

12

12

14

15

20

25

30

26

28

32

40

50

60

70

90

90

D

E

EW FL

max.

8

38 16

8

41 16

10 6,6 50 26

12 6,6 58 28

12 9

70 32

16 9

85 40

16 11 105 50

20 11 130 60

25 14 157 70

30 18 195 90

30 18 238 90

GL HB

20

20

22 21

25 24

27 33

32 37

36 47

41 55

50 70

55 97

60 105

AB7

0,16

0,23

0,39

0,57

0,95

0,5

-

6,6

6,6

9

9

11

11

14

18

18

weight

cast iron

MP4 AB7

3,1

6,61

5,22 12,47

7,78 16,76

MP2

3,57

6,66

9,89

=

=

E

=

stainless steel

MP2 MP4 AB7

0,41 0,41 0,16

0,67 0,67 0,24

0,97 0,97 0,42

1,585 1,585 0,525

3,46 3,46 1,055

5,35 5,35 1,36

XE + 1

XD + 1

A

Series 454

All leaflets are available on: www.asconumatics.eu

P235-6

454

32

40

50

63

80

100

-

XD + 1

A

Series 453

Ø

(mm)

453

32

40

50

63

80

100

-

light alloy

MP2 MP4

0,085

0,092

0,105 0,085

0,15 0,092

0,24 0,17

0,37 0,25

0,635 0,445

0,99 0,755

-

Series 449

Series 450

L4

L5

MR PH RA

TE

TG UB UR UL

5,5

5,5

6,5

6,5

10

10

10

10

11

1,6

1,6

1,6

1,6

2,5

2,5

3,2

4

4

9

22

9

26

11 32 18 38 32,5

13 36 22 41 38

13 45 30 50 46,5

17 50 35 52 56,5

17 63 40 66 72

21 71 50 76 89

26 90 60 94 110

31 115 88 118 140

31 135 90 122 175

45

52

60

70

90

110

130

170

170

31

35

45

50

60

70

90

126

130

51

54

65

67

86

96

124

156

162

XD

XE

Y

α

142

160

170

190

210

230

275

315

335

63

65

73

77

80

89

100

118

-

56

63

71

81

101

128

149

183

183

45°

50°

40°

55°

45°

35*

30°

30°

30°

01434GB-2016/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

PH Js15

L5

449

20

25

32

40

50

63

80

100

-

BT

Ø CK H9e8

RA

UR

1 Stroke

Ø

(mm)

UL

EM

Angular clevis bracket

AB7

GLJs14

PH Js15

L5

Ø CKH9e8

BT

TG

=

=

E

=

=

Ø CDH9

TE

TG

=

=

MR

=

E

=

=

MR

FL

REAR MOUNTING

A

GLJs14

TG

=

=

=

E

=

=

TG

Cap, detachable clevis

+

Angular clevis bracket

=

TG

EW

=

=

=

E

=

=

MP2 + AB7

Cap, detachable eye (trunnion)

MP4

=

L4

Ø CDH9/e8

Y

REAR MOUNTING

E

α

Ø CDH9/e8

UBh14

=

=

Y

=

α

TG

=

TG

=

E

=

=

MR

ISO 15552-ISO 21287 STANDARDISED MOUNTINGS - SERIES 449-453-454-450

DIMENSIONS (mm), WEIGHT (kg)

REAR MOUNTING

AB6 + MP6

Cap clevis for spherical eye or clevis bracket

AB6

FM

E

=

=

L65/1

Ø CXH7

Ø CFH7/h9

4°

+0

EN - 0,1

EP

4°

REAR MOUNTING

Angular clevis bracket spherical bearing

AB5

K1

=

TG

=

=

E

=

=

L65/2

=

4°

4°

10°

CHJs15

=

=

E

=

MS

G1Js14

180°

TG

DL

=

=

Ø CFH7/h9

FM

TG

E

=

=

TG

=

=

EX +-0,1

= =

=

TG

Cap clevis for spherical eye or clevis bracket

+ Angular clevis bracket spherical bearing

Cap eye with spherical eye

MP6

E

B

AB6 + AB5

REAR MOUNTING

=

DL

=

E

=

Ø CF F7/h9

CP

FM

4Ø D

=

=

=

SR

=

TG

=

E

=

=

=

4Ø S5

K2

CG D10

=

=

E

=

=

TG

=

=

E

TG

TG

=

Cap clevis for spherical eye or clevis bracket

+ Cap eye with spherical eye

G2

G3

Js14

G1

4°

01434GB-2013/R02

Availability, design and specifications are subject to change without notice. All rights reserved.

K1

0

EN -+0,1

4°

4Ø S5

G2

G3

XD + 1

A

K2

H7/h9

Ø CF

449

20

25

32

40

50

63

80

100

-

453 454 450

32 - 32

40 - 40

50 - 50

63 - 63

80 - 80

100 - 100

- 125

- 160

- 200

A

22

24

32

32

40

40

54

72

72

Series 449

Series 450

DL E EN

CG CH CP CX

CF FM max. EX

14

16

21

21

25

25

37

-

XE + 1

XD + 1

A

Series 453

Ø

(mm)

449

20

25

32

40

50

63

80

100

-

CH

L65/2

Js15

Ø

(mm)

32

36

45

50

63

71

90

-

34

40

45

51

65

75

97

-

10

12

16

16

20

20

30

-

22

25

27

32

36

41

50

-

50

58

70

85

105

130

157

-

EP

G1

G2

14 10,5 21

16 12 24

21 15 33

21 15 37

25 18 47

25 18 55

37 25 70

-

18

22

30

35

40

50

60

-

453 454 450 AB6

32 - 32 0,190

40 - 40 0,300

50 - 50 0,460

63 - 63 0,680

80 - 80 1,460

100 - 100 2,130

- 125 4,240

- 160

200

-

38

41

50

52

66

76

94

-

51

54

65

67

86

96

124

-

MP6

0,180

0,290

0,420

0,650

1,210

1,870

3,640

-

1 Stroke

G3

K2

MS

SR S5

K1

L65/1 L65/2

TG

max.

max.

max.

max. D

31

35

45

50

60

70

90

-

weight

steel

AB5

0,180

0,230

0,450

0,520

0,940

1,070

2,470

-

5,5

5,5

6,5

6,5

10

10

10

-

8,5

8,5

10

10

11,5

12,5

16,5

-

15 32,5 11

18 38 13

20 46,5 18

23 56,5 18

27 72 22

30 89 22

40 110 30

-

6,6

6,6

9

9

11

11

14

-

XD

XE

α

142 73 40°

160 77 45°

170 80 35°

190 89 50°

210 100 40°

230 118 30°

275

25°

315

335

-

All leaflets are available on: www.asconumatics.eu

P235-7

ISO 15552-ISO 21287 STANDARDISED MOUNTINGS - SERIES 449-453-454-450

DIMENSIONS (mm), WEIGHT (kg)

ROD MOUNTING

ROD MOUNTING

Female rod clevis

AP2

Spherical rod end

AP6

Series 453

AV

K max.

ØCK H9/d10

Series 454

Series 454

ØCN H9

AX

CM

LE

CE

CH

ER max.

Series 450

ER max.

Series 450

CL

ØKK

Series 449

Series 449

Ø

(mm)

449

20

25

32

40

50

63

80

100

-

Series 453

ØKK

α α

EN h12

E max.

453

32

40

50

63

80

100

-

AV

AX

454

32

40

50

63

80

100

-

450

32

40

50

63

80

100

125

160

200

15

15

20

20

22

22

28

22

28

28

33

28

33

51

56

56

CE CH ØCK CL

32

32

40

40

48

48

64

48

64

64

80

64

80

110

144

144

36

36

43

43

50

50

64

50

64

64

77

64

77

110

125

125

8

8

10

10

12

12

16

12

16

16

20

16

20

30

35

35

CM

16

16

20

20

24

24

32

24

32

32

40

32

40

55

70

70

8

8

10

10

12

12

16

12

16

16

20

16

20

30

35

35

E

EN

max.

ØCN

+ 0,5

+ 0,15

+ 0,5

+ 0,15

+ 0,5

+ 0,15

+ 0,5

+ 0,15

+ 0,5

+ 0,15

+ 0,5

+ 0,15

+ 0,5

+ 0,15

+ 0,5

+ 0,15

+ 0,5

+ 0,15

+ 0,5

+ 0,15

+ 0,6

+ 0,15

+ 0,5

+ 0,15

+ 0,6

+ 0,15

+ 0,6

+ 0,15

+ 0,6

+ 0,15

+ 0,6

+ 0,15

8

8

10

10

12

12

16

12

16

16

20

16

20

30

35

35

42

42

56

56

67

67

89

67

89

89

112

89

112

155

201

201

12

12

14

14

16

16

21

16

21

21

25

21

25

37

43

43

ER

max.

12

12

14

14

16

16

21

16

21

21

25

21

25

35

40

40

weight

K

ØKK

22

22

26

26

32

32

41

32

41

41

48

41

48

65

84

84

LE

M8x1,25

M8x1,25

M10x1,25

M10x1,25

M12x1,25

M12x1,25

M16x1,5

M12x1,25

M16x1,5

M16x1,5

M20x1,5

M16x1,5

M20x1,5

M27x2

M36x2

M36x2

ROD MOUNTING

A

16

16

20

20

24

24

32

24

32

32

40

32

40

54

72

72

α

4°

4°

4°

4°

4°

4°

4°

4°

4°

4°

4°

4°

4°

4°

4°

4°

steel

AP2

0,08

0,08

0,1

0,1

0,15

0,15

0,33

0,15

0,33

0,33

0,67

0,33

0,67

1,81

3,85

3,85

stainless steel

AP6

0,04

0,04

0,07

0,07

0,12

0,12

0,22

0,12

0,22

0,22

0,39

0,22

0,39

1,6

1,6

1,6

AP2

0,09

0,16

0,31

0,31

0,67

0,67

-

AP6

0,08

0,12

0,23

0,23

0,42

0,42

-

spherical angular

compensation

(°)

weight

ZJ + 1

X

Alignement compensator

Series 453

R

A1

A

Series 450

øKK

4°

A

4°

øKK

1 Stroke

2 Width across flats

Ø

(mm)

A

449 - - ●

- 453 450 20 - - 16

25 - - 16

32 32 32 20

40 40 40 22

50 50 50 24

63 63 63 24

80 80 80 32

100 100 100 32

125 -

A1

- ●

● - 18

- 18

20 22

24 26

32 26

32 26

40 34

40 34

54 -

ZJ + 1

X

T

P

W1

W2

2

2

2

2

P

- ●

● - 7

- 7

22 12

23 12

32 12

32 12

39 19

39 19

40 -

ØKK

R

T

-

●

-

●

●

M8x1,25

M8x1,25

M10x1,25

M10x1,25

M12x1,25

M12x1,25

M16x1,5

M16x1,5

-

●

- ●

4 - 55 - 13

4 - 55 - 13

5 5 71,5 71,5 16

6 7 73 75 17

7 8 77 103 19

7 8 77 103 19

8 10 106 119 24

8 10 106 119 24

- 13,5 - 147 -

12

12

20

20

20

20

24

M10x1,25

M12x1,25

M16x1,5

M16x1,5

M20x1,5

M20x1,5

M27x2

ZK + 1

Series 449

KW

-

X

●

W1

W2

-

● - ● - ● ● - ● - ● - ●

16

19

24

24

30

30

41

17 17 30 30

30 30

30 41

30 41

42 41

42 41

- Ø62

10

10

19

19

19

19

30

30

-

19

19

27

27

27

27

54

radial

ZJ ZK compensation

(mm)

● - - ● ●

- ● ● ●

45 - - 43 0,5

45 - - 45 0,5

57 57 120 51 0,7

0,7

58 57 135 52 0,7

0,7

59 79 143 53 0,7

1

59 79 158 57 0,7

1

82 89 174 64 1

1

82 89 189 77 1

1

- 107 225 1

X

min.

●

●

4

4

4

4

4

4

4

4

4

0,06

0,06

0,22

023

0,66

0,66

0,7

0,7

1,7

NOTE: The compensator is preset with an axial clearance of 0,05 to 0,1 - Do not reset.

All leaflets are available on: www.asconumatics.eu

P235-8

01434GB-2014/R03

Availability, design and specifications are subject to change without notice. All rights reserved.

A

KW