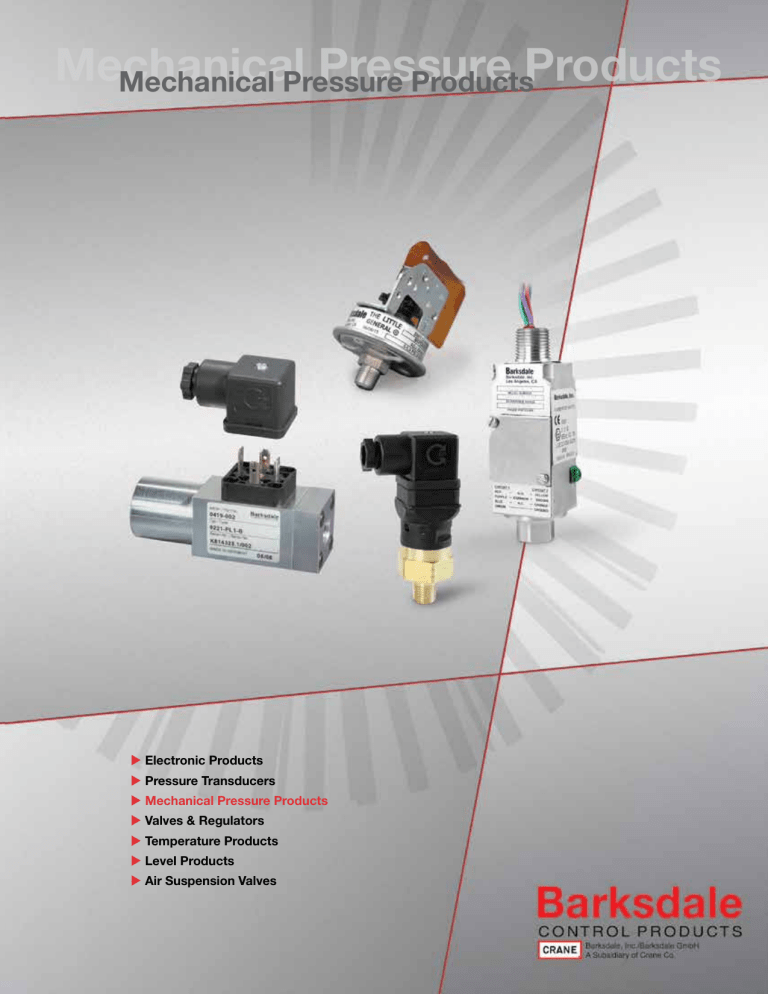

Mechanical Pressure Products

advertisement