Nitrogen Injection Explosion Prevention System for Oil Transformers

NITROGEN INJECTION

T YPE PNT

Explosion

Prevention

System for Oil

Filled Transformers

Licence : ELIN ENERGIEVERSORGUNG , AUSTRIA

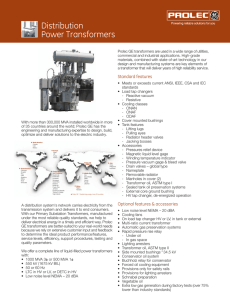

TRANSFORMER CONSERVATOR ISOLATION VALVE ( TCIV)

BUCHHOLZ RELAY

FIRE DETECTOR

PRESSURE RELIEF VALVE

OIL DRAIN

CONTROL

BOX

OPERATING

SIGNALS

FROM

CONTROL

ROOM/

RELAY

PANEL

TRANSFORMER

FIRE

EXTINGUISHING

CUBICLE

1

NITROGEN

INJECTION

CIVIL WORK

COVERED

OIL PIT

N

2 2

1 QUICK

OIL DRAIN VALVE

ASSEMBLY

2 N2 RELEASE

DEVICE

GENERAL

Dedicated system. Proven technology. Over 6000 systems operating worldwide in transformers upto

2500 MVA. Approved by major Electricity boards, Industrial customers, Project consultants, Tariff advisory committee, Fire Brigade, Oil Industrial Safety Directorate and others. Type PNT is suitable for transformer rating 2.5 to 315 MVA, three phase. Also single phase 3 X 200 = 600 MVA.

DESCRIPTION

Consists of a fire extinguishing cubicle near the transformer, a control box in the control room, several fire detectors on the top cover of the transformer, specially designed Transformer Conservator Isolation

Valve between buchholz relay and conservator, signal box placed on transformer. The fire extinguishing cubicle is connected to the transformer tank by pipes for oil drain and nitrogen injection. Cable connections are provided from signal box to control box and from control box to fire extinguishing cubicle.

Prevents rupture of the transformer tank and fire due to internal failures. Extinguishes external fire caused due to transformer tank rupture, fire in bushings, fire in tapchanger or fire from surrounding. Apart from automatic operation, also operates on remote electrical and local manual controls.

SYSTEM ACTIVATION SIGNALS

For Prevention : Differential relay trip+Rapid pressure rise relay or Buchholz relay or Pressure relief valve trip+Transformer Isolation

For Extinction : Fire detector operation+Rapid pressure rise relay or Buchholz relay or Pressure relief valve trip+Transformer Isolation

POWER SUPPLY

For System Operation : 110 / 220 V DC. For lighting and heater for F.E. Cubicle : 230 V AC.

FIRE SYSTEMS DIVISION PHONE : (020) 26633402/05 PM FS 1002

CTR MANUFACTURING INDUSTRIES LTD. FAX : 91 (020) 26633425

NAGAR ROAD, POONA - 411 014, INDIA E-MAIL : firesystems@ctr.in OCT 2008

OPERATION

On receipt of required activating signals, a pre-determined quantity of oil drain commences. Simultaneously Nitrogen is injected under pressure at a pre-determined flow rate to create a stirring action thereby bringing the temperature of top oil surface below ignition point. Fire is extinguished within 30 seconds maximum. Nitrogen gas occupies the space created by oil drain and acts as an insulating layer between the oil in the transformer tank and fire above top cover. Transformer Conservator Isolation Valve blocks the passage of oil and isolates conservator oil thereby preventing escalation of fire.

Fire extinguishing cubicle , Control Box, etc.

ADVANTAGES

Low investment compared to conventional systems.

Very low maintenance and running cost compared to conventional systems.

Minimal post-fire and no secondary damage.

Space required is less than conventional systems.

System can be tested on energised transformers, not possible with conventional systems.

Suitable for indoor / outdoor installation.

Multi activation signals, eliminates possibility of maloperation.

Unaffected by climatic changes.

System can be installed on existing/installed transformers at site with minimal outage typically 8 hours

Indication available for N low pressure.

2

Alarm and visual indication for DC supply fail.

Inside view of fire extinguishing cubicle

The system has prevented transformer explosion and subsequent fire in various transformers more than 1600

MVA for which certificates are available.

INSTALLATION AND SERVICING

Service engineers available for system installation and servicing.

ORDER INFORMATION

For transformers rating below 2.5 MVA, refer to product catalogue PMFS1003 for ENT system.

Please provide information as required in our Marketing Enquiry Questionaire Form PTFS1005 to enable correct equipment to be offered. Our communication will use nomenclature shown below.

NOMENCLATURE

P N T M 50 B 10

1

2

3

4

1. Prevention & extinguishing System 5. MVA rating of Transformer

2. Nitrogen injection 6. Drain Pipe Size

3. Transformer application A : Din 50

4. Monitoring circuit B : Din 80

M : With monitoring control box C : Din 125

W : Without monitoring control box 7. N2 cylinder capacity in cub. Mtrs.

5

7

6

Rights reserved to amend design data without prior notification