Hydraulic Accessories Index | Stauff

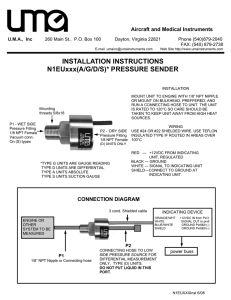

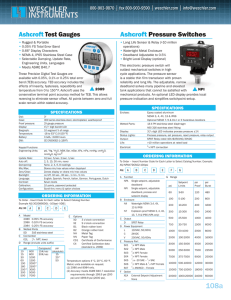

advertisement