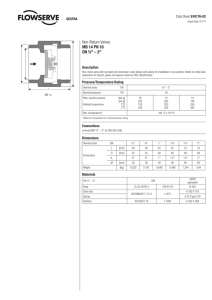

Hydraulic Accessories

advertisement