Compact Fluorescent Lamp CFL)

advertisement

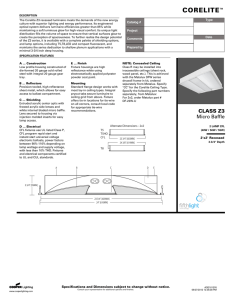

MAZAGON DOCK LIMIED DESIGN Mumbai 400010. - ELECTRICAL TECH.SPEC. NO. 5182 REV. 00 PROJECT / YARDS: P15A/12701, 12702 & 12703 DATE 16/06/2014 TECHNICAL SPECIFICATION FOR PROCUREMENT FOR Compact Fluorescent Lamp CFL) PART 0 PREAMBLE APPLICABLE PART I TECHNICAL SPECIFICATION AND SOTR APPLICABLE PART 2 GENERAL REQUIREMENTS OF ELECTRICAL EQUIPMENT APPLICABLE PART 3 PR NO. 1110013886 APPLICABLE ---- ---- -- ---- -- ------ ------ - - -------------------------------------------------------------------------------------------------------- --------- ----------------- -------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------- ------ -- ---------------- -------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------- ------ - -------------- ---------------------------------------------- ----------------------------- ----------------------------------------------------------------------------------------- ------ ------ -------------------- ---------------------------------------------- ----------------------------- ----------------------------------------------------------------------------------------- ------ ---- -- -- ---------------- -------------------------------------------------------------------------- ----------------------------------------------------------------------------------------- ------- --------------------------- ---------------------------------------------- 0 Reference - Planning memo No. 16/6/2014 ---------------------------------------------- PMT/P15A/PLG/SBT/CFL, Amdt-1 dated- 24/5/2014 for procurement of additional CFLs. REV.ND . ^jj DESCRIPTION DATE AUTHORISED BY PREPARED BY CHECKED BY SECTION HEAD 1 K aJPUT D. K. AJPUT R. K. SHRIVATVA Manager(D-L) Manager(D-L) AGM(D-L&WN) (Part-0) Sheet 1 of 1 YARD NO.12701 , 12702 & 12703 TECHNICAL SPECIFICATION NO.5182 Rev-0 PART O: PREAMBLE 01 INTRODUCTION This specification is written in two (2) parts: 010 Part 0 - Preamble 011 Part 1 - Technical Specification and SOTR 012 Part 2 - General Requirements of Electrical Equipments 02 DEVIATION 021 The supplier should clearly indicate the clauses in the specification not being complied with. In the absence of a clear statement to the contrary, it will be assumed that the equipment supplied will meet the requirement s in full. In case there is conflict between clause in technical specification and in General Requirements of Electrical Equipments, clause in Technical Specification shall take precedence. 022 The supplier should not alter the binding drawings or the scope of supply or any other aspect governed by this procurement requisition as finally agreed, without specific concurrence from MDL, even if any other authority (Inspection authority or their resident inspectors, subcontractors to the main equipment and machinery etc.) seek such alterations. 03 CLAUSES NOT APPLICABLE TO THIS EQUIPMENT (SEE ALSO CLAUSE 02): Clause Applicable Meets the requirement Yes / No. Yes / No I Remarks (Part-1) Sheet 1 of 3 YARD 12702 & 12703 TECHNICAL SPECIFICATION NO. 5182 Rev-0 PART - 1 TECHNICAL SPECIFICATIONS 1. BRIEF DESCRIPTION: 1.1 Equipment Compact Fluorescent Lamps (CFL) 1.2 Use For Lighting onboard Naval Ships 2. PERFORMANCE REQUIREMENT 2.1 As per Naval Specifications/Joint Service Specifications and DPIN Drawings as applicable. 2.2 Available power Supply is 230V, 50Hz, 1-Phase with insulated neutral(both phases). 3. SCOPE OF SUPPLY 3.1 FIRST FITTING ITEM Compact Fluorescent Lamps ( CFL) requirement per ship as listed below :- CFL Description 15 watts Twister 20 watts Twister Yd. 12701 Q Nos 300 150 Yd.12702 Qty (Nos) 2000 300 Yd.12703 Q ty (Nos) 2000 300 4. Technical specification :The design, shape and size of the CFLs should be compatible to existing GLS luminaries (with B22) fitted onboard ships and catered for trouble free operation under the most adverse environmental and marine conditions. The CFLs should conform to IS-15111 (Part I&II)-2002 for safety and performance requiremnts. b) The CFLs should be designed for 230V, 50Hz, 1-Ph supply.The voltage or voltage ranges, wattage should be marked on the lamp clearly. Please refer Para-4 of SOTR for Input AC Supply Characteristics. c) The CFL casing shall be made of cast aluminium alloy (A6M) with suitable glass covering. The enclosure of CFL should be of splash proof (IP 55) construction providing adequate protection against Ingress of moisture and dust. All electronic compon ents, lamp holder and reflector etc. sholud be of standard manufacturer and be mounted on single PCB. However the transformer should be secured inside the casing. The panel cover should be secured with captive secews with lock-in-nuts. Please refer Para-5 of SOTR for manufacturer's technical specification and compatibility of CFL vis-a-vis lamp fittings. d) The CFL's are to be manufactured strictly as per State of Technical Requirement NO. DEE/01/04 issue dated Oct'04 (enclosed). Any deviation/modification with respect to SOTR is not acceptable. The power factor should be above 0.9. Part-1) Sheet 1 of 3 YARD 12702 & 12703 TECHNICAL SPECIFICATION NO. 5182 Rev-0 e) The approx dimension of CFLs lisetd below, which are not to be exceeded :Wattage 15 Watts 20 Watts Lenght of CFL(mm) 115 mm 115 mm Diameter(mm) 50 mm 50 mm f) The sample CFLs of each rating has to be submitted during TNC to check the dimensions indicated above and to check the luminuous output: 5. TESTS 5.1 Type Test: The type tests to be carried out on selected samples of self-ballasted lamps would be as per IS 15111 Part I and II. For details, refer Para-6 of SOTR. 5.2 EMI/EMC Test: a. The CFLs should meet EMI/EMC requirements onboard ships as per IEC-1547. OEM will provide EMI/EMC test report. b. The CFL should comply EMI/EMC requirement as MIL-STD-461E. 6. GOVERNING SPECIFICATIONS The CFLs offered should be manufactured and conform to following specifications. - Self-ballasted lamps for general lighting services L IS 15111 (Part 1&2)-2002 Part-I Safety Requirements Part-2 Performance Requirements H. IS 1258 ( 1987) - Bayonet lamp holders - Methods of measurement of lamp cap temp. rise iii.IS 8913 ) Dimentions of caps for tungsten filament iv.IS 9206 (1979 GLS lamps v. IS 11000 (Part2/Secl)( 1988) - Fire hazard testing. Part-2 - Test methods Section-I - Glow wire test and Guidance vi.IS 6873 (Part -5)(1999) - Methods of measurement of EMI Part-5 - Fluorescent lamps and luminaries vii.IS 2592 (1980) - Vibration tests - Requirements for lighting system viii . NES 587 ix. EED -Q-261 - Specifications for light fittings - Catalogue of Naval Stores (Class Group 0581) - Environmental Test Methods for Electrical and Electronics. xii. MIL-STD-461E - Control of EMI/EMC of equipment. xiii. IEC-1547 - EMI/EMC requirements. x. BR 320D xi. JSS 55555 7. EQUIPMENT PERFORMANCE RESPONSIBILITY Supplier to ensure for satisfactory performance of the equipment on board ship. 8. GUARANTEE The manufacturer should give guarantee against poor performance/bad workman ship for the period of 48 months from the date of delivery or 12 months from the date of commissioning of the ship. Part-1) Sheet 2 of 3 YARD 12702 & 12703 TECHNICAL SPECIFICATION NO. 5182 Rev-0 9. PRODUCT SUPPORT The supplier should confirm product support for 10 years. 10. Information to be supplied by the vendor with technical offer :- a. A brief specification/description of the equipment being offered including a statement showing anyway in which the equipment is deviated from this TSP. b. Operating supply voltage and frequency c. Wattage of lamp and lux d. Power factor e. Part number f. Dimentional details of CFL and weight g. Type of CFL ie. electronic or magnetic ballast h. Colour ie. Daylight i. TSP/SOTR/GREEPara wise comments/confirmation /deviations/notes to be furnished without fail. 11. INSPECTION:Inspection Authority - Third Party Inspection as nominated by MDL. - MDL/WOT (MB). Receipt Inspection 12. BINDING DRAWING AND DOCUMENTS FOR APPROVAL:Three sets of the following drawings/ documents along with quality assurance plan in detail are to be submitted for approval to MDL within two weeks of placement of order. a) General arrangement drawing indicating, overall dimensions, maintenance envelope, fixing details, weight, CGs of the item, tallies, etc. b) Circuit diagram and terminal connection details. c) Bill of Materials indicating part no., Qty, maker's name, material, conforming specifications etc. 13. The vendor should be IHQ approved vendor or should have successfully type tested (Environmental- JSS 55555 & EMI/EMC-MIL-STD-461E) the offered CFL only shall be considered for this tender. 14. Any clarification required regarding Technical Specification / Requisition should be sought before submission of the offer. 15. The para wise confirmation (compliance matrix) to TSP has to be submitted alongwith the technical offer. The non-compliance to any para of TSP shall be liable to reject the Technical Offer. 16. PACKING: Each of the item is to be individually PIP packed, suitable identification label giving details such as Sr. No. of the item, Order No. etc., are to be marked legibly on outside the packing., which should be prominently visible. The lists are to be attached to the cases. ----------------------------------------------- End Of Part - 1 ------------------------------------------------- (Part-2) Page 1 of 2 PART - 2 GENERAL REQUIREMENTS ❑ F ELECTRICAL EQUIPMENTS (G R E E) The equipment / Item is generally required to withstand following marine conditions: Ambient temperature 0 to 50 °C for Machinery Space and 45 °C at other places. Humidity 100 % at 35 °C, Seawater temperature 35 °C, Roll +/- 30 ° P & S, pitch 0 +/- 15 °, list 20 °. 5. All items must strictly conform to relevant drawings / specifications mentioned in the requisition. 6. General arrangement drawing giving overall dimensions and approximate weight of the unit and center of Gravity is to be supplied along with the offer, for non-patternised item. 4. Wherever applicable, the production drawings are to be approved by DQA / Statutory & regulatory agency. The manufacture of the items is to be started only on approval of the drawings. A set of approved production drawings is to be made available to MDL for dimensions, fixing details etc. 5. Wherever a pilot sample is required to be manufactured, the bulk production is to start only after approval of the sample by inspecting Agency / MDL. 6. No Component will be supplied by MDL. 7. The items are to be of robust construction so as to withstand adverse marine conditions. Similar parts are to be interchangeable. The castings are to be free from blowholes, sharp edges to be rounded off, the threads are to be even and sharp. The switches, lamps, fuses, internal wires etc. used in the equipment are to be either patternised or type approved by DQA / classification societies, as applicable. The details regarding this can be obtained from respective agencies. The indicating lamps should be easily accessible by unscrewing the bull's eye from the front. Fuses are to be clearly marked. a) The holes for mounting the equipment should be on lugs outside the casing of the equipment. b) The equipment is to be suitable for bulkhead / deck mounting. If equipment contains movable parts such as relays, contactors or electronics assemblies etc. the equipment is to be suitable for mounting on shock / vibration mounts. The mounts are to be supplied along with the equipment. c) Suitable earthing arrangement is to be provided on the equipment. d) Lifting arrangement is to be provided for heavy items. 8. For Ship's cables, the entries are to be through glands, unless otherwise stated. The glands are to be as per specification DGS/EED/VI/1535/R6, (For Naval Ships) / Standard Siemen's gland for Merchant Ships. The gland nut and washers are to be left un drilled, unless specified. 9. For connection of the ship's cables the terminals are to be easily accessible, For cables of sizes of 7/0.044 and higher, crimped sockets and clamp type terminals are to be provided for incoming & outgoing cable connection. An adequate space should be maintained between terminals, terminal block, the casing of the equipment and the cable entry glands. a. Internal wiring in the panels to be of Low Fire Hazard cables. b. The installation material, viz. free end connectors, cable crimps, special tools if any, mounts etc. to complete installation is to be supplied by you along with the equipment. 10. The Part No. / The Patt. No. of each item is to be prominently and indelibly cast / embossed / tallied. (Part-2) Page 2 of 2 PART - 2 GENERAL REQUIREMENTS ❑ F ELECTRICAL EQUIPMENTS (G RE E) 11. The following engraved tallies of brass / anodized aluminum are to be screwed on each equipment: a. Manufacture 's tally indicating name, description of the item, part/patt. No., rating, Sr. No., Year of manufacture, weight etc. b. Functional tallies for switches, lamps, pushes etc. c. Danger tallies for equipment operating on 220 V and above, the tally should have white letter on red background. d. Where applicable `MODIFICTION STATE' of the equipment tally. e. Special tallies to be provided as applicable viz. Circuit diagram tallies, operating instructions motor direction of rotation etc. 12. The item is to be painted with admiralty ship ' s gray paint as per approved painting specification/ procedure. 13. Minor modifications required by Owner /Inspecting Agencies / MDL are to be incorporated. 14. For any deviations , however minor, prior approval is to be obtained from DQA (Navy) / MDL Deviations once granted will not be necessarily applicable for repeat manufacture. 15. Net weight of each item is to be recorded in the presence of the inspector and a certificate to that effect is to be submitted along with supplies. 16. The equipment supplied by you will be installed on board the ship by MDL. The services of your engineers, if required during installation, setting to work, harbour trials, sea trials, etc. to prove your equipment to NAVY, be provided. Your service engineers are to bring their own test equipments/tools and spares for this purpose. ----------------------------------------------- End Of Part - 2 ------------------------------------------------- DIRECTORATE OF ELECTRICAL ENGINEERING STA TEMENT OF TECHNICAL REQUIREMENTS (SOTR) FOR -il COMPA CT FL UORESCENT LAMPS (CFLs) SUITABLE FOR 230VSUPPL Y FOR P-17AND LST(L) SOTR NO. DEE/01/04 DA TE OF ISSUE; OCT 04 IR*2 G^ i ^a G ctl v e .Tot-e- Dgcr C,g -Yi N ^6 ° 36 l ,7 1^ a.SJ a os . 5. Technical Requirements. 5.1 Construction . The CFL casing shall be/made of cast,,aluminum alloy (A6M) with suitable glass covering . The enclosur of CFL should be of splash proof (IP 55) construction providing adequate Prot ction agains ingress of moisture and dust. All electronic components , lamp hol er and reflector etc. should be of standard manufacturer and be mounted on ingle PCB. 'However the transformer should be secured inside the casing. Th panel co ver should be secured with captive screws with lock -in-nuts. The details are as follows:5.2 Compatibility of CFL vis-a-vis Lamp Fittings . CFLs (EL Type) CFL Length in mm Min Max 20 W 140 155 Compatible Lamp Fittings which are already Patternised Patt No. 0581 /923-7422 Patt No. 0581 /923-5751 Patt No. 0581 /923-5752 Remarks To be used with large type lamp fittings as per BR 320D 15 W 106 125 Patt No. 0581 /923-5758 To be used with small type lamp fittings as per BR 320 D 11 W 120 142 Patt No. 0581 /923-7421 To be used only - for lighting bathroom/cabin mirrors. 5.3 Manufacturerer's Technical Specification. The manufacturer's technical specification of the above CFLs is shown in Appendix 'A' Classification of Tests Type Test. The type tests to be carried out on selected samples of self ballasted lamps would be as per IS 15111 Part I and II. The details are given in succeeding paragraphs:As per IS 15111 Part I 6.2.1 Marking. The lamps shall be clearly and durably marked with the following mandatory markings:(a) Mark of origin (this may take the form of a trade-mark, the manufacturers name or the name of the responsible vendor); (b) Rated voltage or the voltage range (marked 'V' or'Volts); (c) Rated wattage (marked 'W' or `Watts'); (d) Rated Frequency (marked in 'Hz'); (e) Rated luminous flux; (f) Rated colour temperature; and (g) Country of manufacture. 6.2.1.1 The durability of the marking is checked by trying to remove it by rubbing lightly for 15 seconds with a piece of cloth soaked with water and, after drying, for a further 15 seconds with a piece of cloth soaked with hexane. The marking shall be legible after the test. 6.2.2 Interchan eeability. Compliance of combination of cap and bulb is checked by the use of gauges for checking the dimensions controlling interchangeability in accordance with IS 9206. 6.2.3 Protection against Electric Shock. Test finger shall not touch live parts in normal use when applied in all directions with force of 10 N. 6.2.4 Insulation Resistance and Electric Strength after Humidity Treatment. The lamps shall be conditioned for 48 hours in a cabinet containing air with a relative humidity between 91 % and 95%. The temperature of the air is maintained within 1°C of any convenient value between 20°C and 30°C. 6.2.4.1 Insulation resistance shall be measured in the humidity cabinet with a dc voltage of approximately 500V. One minute after application of the voltage, the insulation resistance between current-carrying metal parts of the cap and accessible parts of the lamp (assessable parts of the insulating material are covered with metal foil) shall be not less than 4 M. 6.2.4.2 The insulation resistance of B 22 caps between shell and contact shall be not less than 5 Mo. 6.2.5 Mechanical Strength. The cap shall be subjected to the torque by means of the torsion test holder. The torque shall not apply suddenly, but shall be increased continuously from 0 to the specified value. The Lamp should withstand minimum 3.0 Nm of mechanical strength. 6.2.6 Cap Temperature Rise. The cap temperature rise tests of the complete lamp during run-up, stabilization period and after stabilization shall not exceed the value mentioned below:For B 22d ........................125 K 6.2.7 Resistance to Heat. External part of insulating material of self ballasted lamp shall be sufficiently resistant to heat. The test is made in a heating cabinet for a sufficient time to ensure that they have attained the stabilized testing temperature before the test commences. The surface of the part to be tested is placed in the horizontal position and a steel ball of 5 mm diameter pressed against this surface with a force of 20 N. After ball pressure test the diameter of impression shall not exceed 2 mm. 6.2.8 Resistance to Flame Ignition. _ External parts of the insulating material retaining live parts in position and external parts of insulating material providing protection against electric shock are subjected to the glow wire test at 650°C. 6.2.9 Fault Condition. Lamps shall not impair safety when operating under following fault conditions:(a) Short circuit in starter. (b) Short circuit across capacitors. (c) Broken cathode. (d) De-activated lamp. (e) Open circuit. As er IS 15111 Part Ii 6.2.10 Dimensions• The lamp dimension shall comply with the requirements as indicated by the procurement age ncy. e htiwithin 4.0 alig 6.2.11 Starting and Run-up. The lamp shall fully light up and remain th sec. to reach 80 /o seconds at 92% of rated voltage. characteristics shall not exceed 6.2.12 Lamp Wattage. The initial wattage dissipated by the lamp shall not differ by more than + 15% and -10%. l not be l ss than 6.2.13 Luminous Flux. Initial lumen flux after the the ageing of at ld wattageeand the 90% of the rated luminous flux (derived from efficacy corresponding to the colour temp as specified in the standard). 6.2.14 Colour. The colour coordinated of a lamp shall be within the tolerance area on the chromaticity chart. 6.2.15 Power Factor. The power factor of the combination of the ballast and the lamp shall not be less than 0.80. 6.2.16 Life. The average life of lamp shall not be less than 6000 hrs. 6.2.17 Lamp Efficacy. The efficacy of the lamp will be as given in the table 2 of IS 15111 (Part II). 6.2.18 Lumen Maintenance. After 2000 h of operation including the aging period, the lumen maintenance shall be not less than 90% of the initial luminous characteristics. sabove 6.3 Acceptance Test. The acceptance tests would include the and ubjected tests at par 6.2.1 to 6.2.6 and 6.2.10 to 6.2.15. In addition, CFLs will be s vibration test as per IS 2592 (1980). 7. EMI EMCThe : CFLs should meet EMI/EMC requirements onboard ships as di^r n in z ' A' tom artments i.e., livin s aces, ao ber IEC hall bathroom stora g e s ac eyways etc onboard ships. . DQA(N) would be the inspection authority. 8. Inspection Authority 9. Procurement . The following information be provided to the manufacturer/vendor at the time of the procurement of CFL: (a) Operating Supply (in terms of voltage and frequency) (b) Wattage of lamp (c) Power factor (d) Part No. (e) Dimensional details of CFL. (f) Type of CFL (with electronic or magnetic ballast) (g) Colour (Day light/Warm white/Blue/Red) 10. Related Documents and Acceptable Standards. Specifications Titles IS 15111 ( Part I &II) (2002) - Self ballasted lamps for general lighting services. Safety requirements. Part I Part II- Performance requirements. IS 1258 (1987) - Bayonet lamp holders. IS 8913 (1978) - Methods of measurement of lamp cap temperature rise. IS 9206 (1979) - Dimensions of caps for tungsten filament GLS lamps. IS 11000 (Part II/Sec 1)(1988) G Fire hazard testing. Part II - Test methods Section 1- Glow wire test and guidance IS 6873 (Part 5)(1999) - Methods of measurement of electromagnetic interference Part 5 - Florescent lamps and luminaries. IS 2592 (1980) - Vibration tests. NES 587 - Requirements for lighting system. EED-Q-261 - Specification for light fittings BR 320 D - Catalogue of Naval Stores (Class Group 0581) APPENDIX 'A' MANUFACTURER'S TECHNICAL SPECIFICATION Lam Related Data ELD-11W ELD-15W ELT-20W Voltage to be 230V Working Voltage (V) Working Frequency (HZ) Rated light output (Base up) (1m) specified 50 Hz 900 1200 2700 K 600 4000 K 6500 K 600 565 2700 K 55 55 60 4000 K 6500 K 54 51 54 51 B-22d 59 56 0.080 0.100 0.140 1200 900 1120 850 2700, 4000,6500 Colour Temperature (K) Efficacy (Im/W) Lamps caps Lamp current(A): (Input) < 4 Second Maximum starting time (mS) Starting Voltage (V) Nominal Power (W) Lamp Power (W) (Tolerance) Lumen Maintenance (100 + 2000h) Lumen Maintenance (2000 + 6000h) Fre uen (kHz) Life (with Hf operation) 165 min ON/15 Min off (Hrs) Burning Position Applicable Torque cap (B-22d/E-27) 170 11 15 20 + 15%.- 10% (As per BIS) 85 (As per BIS) 70 (As per OG) >20 6000 hrs (As per BIS) Universal 3.0 NM Warm-up time after switch ON -80% of light output (S) -100%of light output (S) Max cap 120 Max 300 125°C temperature rise °C Min Starting Voltage(V) Power Factor Remarks 140V > 0.80