α-MAX Electric Actuators types ER 20-45-60-100

Installation and operating instructions

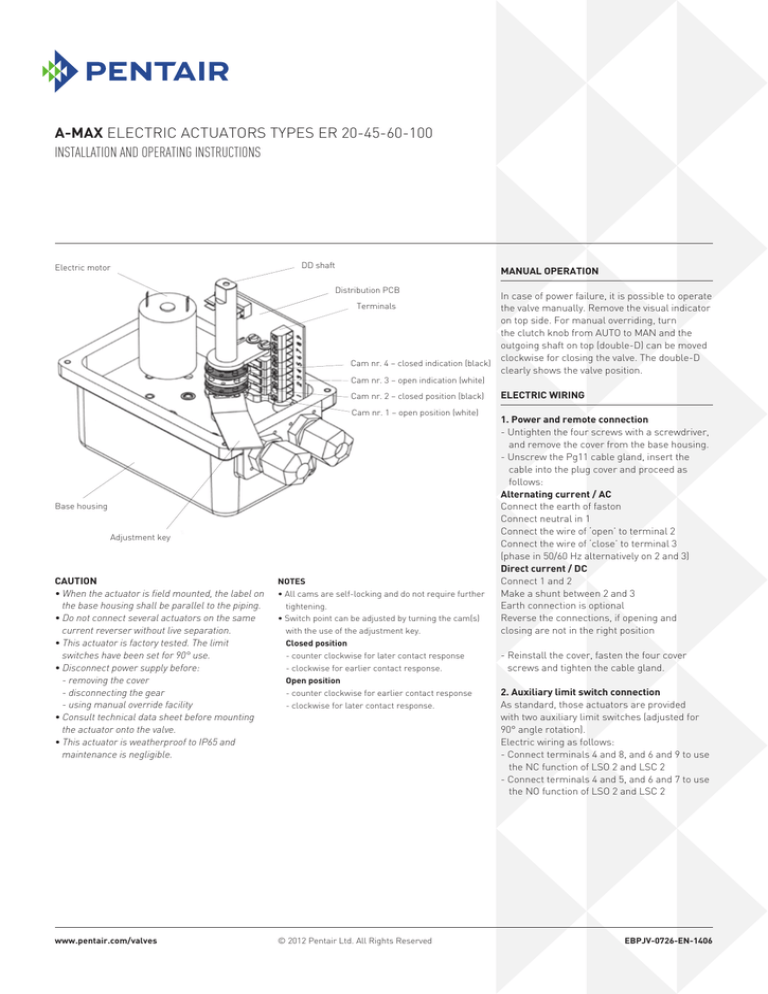

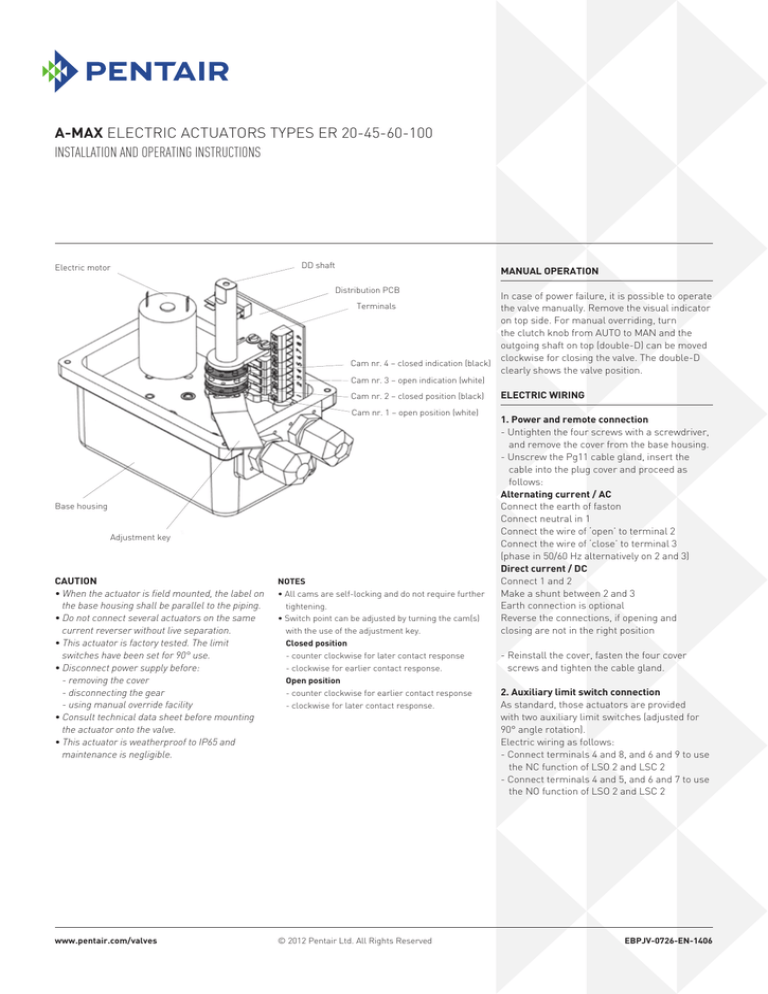

Electric motor

DD shaft

Manual operation

Distribution PCB

In case of power failure, it is possible to operate

the valve manually. Remove the visual indicator

on top side. For manual overriding, turn

the clutch knob from AUTO to MAN and the

outgoing shaft on top (double-D) can be moved

clockwise for closing the valve. The double-D

Cam nr. 4 – closed indication (black)

clearly shows the valve position.

Terminals

Cam nr. 3 – open indication (white)

Cam nr. 2 – closed position (black)

Cam nr. 1 – open position (white)

Base housing

Adjustment key

CAUTION

• When the actuator is field mounted, the label on

the base housing shall be parallel to the piping.

• Do not connect several actuators on the same

current reverser without live separation.

• This actuator is factory tested. The limit

switches have been set for 90° use.

• Disconnect power supply before:

- removing the cover

- disconnecting the gear

- using manual override facility

• Consult technical data sheet before mounting

the actuator onto the valve.

• This actuator is weatherproof to IP65 and

maintenance is negligible.

Notes

• All cams are self-locking and do not require further

tightening.

• Switch point can be adjusted by turning the cam(s)

with the use of the adjustment key.

Closed position

- counter clockwise for later contact response

- clockwise for earlier contact response.

Open position

- counter clockwise for earlier contact response

- clockwise for later contact response.

www.pentair.com/valves

© 2012 Pentair Ltd. All Rights Reserved

Electric Wiring

1. Power and remote connection

- Untighten the four screws with a screwdriver,

and remove the cover from the base housing.

- Unscrew the Pg11 cable gland, insert the

cable into the plug cover and proceed as

follows:

Alternating current / AC

Connect the earth of faston

Connect neutral in 1

Connect the wire of ‘open’ to terminal 2

Connect the wire of ‘close’ to terminal 3

(phase in 50/60 Hz alternatively on 2 and 3)

Direct current / DC

Connect 1 and 2

Make a shunt between 2 and 3

Earth connection is optional

Reverse the connections, if opening and

closing are not in the right position

- Reinstall the cover, fasten the four cover

screws and tighten the cable gland.

2. Auxiliary limit switch connection

As standard, those actuators are provided

with two auxiliary limit switches (adjusted for

90° angle rotation).

Electric wiring as follows:

- Connect terminals 4 and 8, and 6 and 9 to use

the NC function of LSO 2 and LSC 2

- Connect terminals 4 and 5, and 6 and 7 to use

the NO function of LSO 2 and LSC 2

EBPJV-0726-EN-1406

α-MAX Electric Actuators types ER 20-45-60-100

Installation and operating instructions

Wiring diagrams

Notes

LSO 1

LSC 1

LSO 2

LSC 2

C

M

H

Th

P

RM

Model TVC-ER with 240 V AC

Open

Close

= Open travel

= Close travel

= Open indication

= Close indication

= Capacitor

= Electro motor

= Heating element

= Thermostat

= Potentiometer

= Motor control

Optional

Model TVC-ER with 100-240 V AC multi-voltage

N

T

Open

1

2

LSO 1

Close

3

LSC 1

4

5

LSO 2

6

7

17

18

20

-

19

+

21

LSC 2

P

RM

EBS 24

Optional

Model TVC-ER with 24 V DC motor

Open

Customer

Close

Shunt

Pentair

2

α-MAX Electric Actuators types ER 20-45-60-100

Installation and operating instructions

Security enclosure for fail-safe action

Ph

N

Switch 1

Supply: 230V 50/60 Hz

1

2

Relay 2

EBR

Relay 1

EBR

0

4

5

6

1

2

3

230V 50HZ

Electric

Actuator 1

*

7

3

Security Enclosure

EBT 1/230

Type ER 20-45-60-100

Switch 2

Notes

1. As standard, this enclosure comes with single

relay EBR. Second relay is optional.

2. Before charging, reconnect the red wire of the

battery. During charging, LED (yellow) lights up.

Total charging time is 48 hours.

3.If battery is not fully charged at first usage,

LED (red) will light up during ± 2 minutes.

4.In case of supply failure, LED (green) lights up.

5.The NiCd battery shall be handled in accordance

with the local regulations.

6. Battery life is shortened by 50% for every 10°C

above an ambient temperature of 25°C

0

8

9

10

1

2

3

230V 50HZ

Electric

Actuator 2

Parts list type ER 20-45-60-100

Item

Description

1

Visual position indicator (or handle)

2

ABS cover

3

SS screws (4)

4

Circuit board for power distribution

5

Card support

6

Gear box plate

7

Shaft output gear

8

Gland Pg11 – IP67

9

Housing nylon GF6.6

10

Gear train assembly

11

Bearing

12

Cams (4)

13

Motor

* Handle only available for ER-20

3