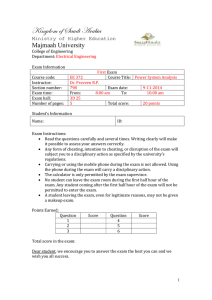

Feeder Separation and High-Voltage Distribution Systems

advertisement

Madhya Pradesh Energy Efficiency Improvement Investment Program (RRP IND 43467) FEEDER SEPARATION AND HIGH VOLTAGE DISTRIBUTION SYSTEMS A. Feeder Separation 1. A power supply line to a rural area begins at a 33 kV/11 kV substation (a primary substation), where incoming power at 33 kV is stepped down to 11 kV (Figure 1). A threephase, three-wire distribution line operating at 11 kV, known as a feeder, begins at the primary substation, and traverses the rural areas through villages and agricultural areas, serving a mixed customer base of agriculture, households and small businesses. The total length of this 11 kV feeder may exceed 10 km, and if feasible, would terminate when it meets another 11 kV feeder from another primary substation. Otherwise, the 11 kV feeder would terminate at a location beyond which there are no customers. Along each such 11 kV feeder, there are 11 kV/433 V distribution substations at suitable locations, to step down the voltage from 11 kV to the nominal 400 V, three-phase, four-wire supply required for agricultural water pumps and other industrial equipment, if any. Single-phase, two-wire supply from the same line provides the service for household customers and small businesses. Agricultural pumps are scattered in vast areas of farmland, while household and small businesses are located in the villages. Figure 1: Present arrangement of feeders in rural areas Primary Substation DS2 Mixed customers P, H, B 11 kV feeder 33 kV line from EHV substation MF1 X DL1 DL2 DL3 Mixed customers P, H, B HH MF2 DS3 HH HH HH P HH 11 kV feeder, to another group of villages and farms HH Mixed customers P, H, B HH P B HH P P HH P B P HH P Bare conductor distribution lines Normally open switch 11 kV feeder DS1 33 kV/11 kV transformer X 11 kV feeder P DS4 Another 11 kV feeder from a different primary substation Mixed customers P, H, B MF: Mixed 11 kVFeeder DS: Distribution Substatioin DL: Distribution line P Agricultural Water Pump P HH B Household customer Small business Note: The layout does not refer to any particular area or village. Distances are not to scale and they have been shrunk or exaggerated to elaborate the concept. Source: Project preparatory technical assistance consultants. 2. Electricity supply to agricultural water pumping for metered customers is provided on the basis of a charge per kilowatthour (KWh). In DISCOM-C (Table 1) in 2009-10, 58% of pumps were un-metered, and the estimated sales to such un-metered pumps (on the basis of approved consumption) was 25.4% of total sales of the DISCOM. In DISCOM-E, 69% of pumps were un-metered and estimated sales to such pumps were 16% of the total sales of teh DISCOM. Thus, a significant percentage services to water pumps is un-metered, and for such connections, the amount of electrical energy allowed to be used per month in each season is determined on the basis of the approved capacity of pump(s) for each customer. Such approved use from un-metered connections is stated in the tariff schedule approved by the Madhya Pradesh Electricity Regulatory Commission (MPERC). However, there is no effective mechanism to monitor excessive use of electricity for water pumping, off unmetered service connections. For example, the approved consumption of an un-metered 2 three-phase 10 hp water pump for agriculture in the month of March 2011 is 1500 kWh. The electricity input to a 10 hp pump is about 9 kW. If the pump is used for 8 hours per day, its consumption is 9 x 8 x 30 = 2160 kWh per month. The approved 1500 kWh per month is therefore adequate to operate the pump only for about 5.5 hours per day. Any use above the approved use is counted as commercial losses. Hence, DISCOMs are compelled to ration the electricity supply to rural areas. Table 1: Metered and un-metered pumps in DISCOM-C, and estimated sales 2009-10 Agricultural pumps Metered general Metered temporary Metered free Un-metered general Un-metered temporary Un-metered free Total Customers 100,352 596 196 178,803 34,989 4,581 319,517 Total DISCOM-C 2,209,964 Source: DISCOM-C estimates. % of pumps 31.4% 0.2% 0.1% 56.0% 11.0% 1.4% 100.0% 25.0 8.9 0.2 1,390.5 349.0 30.7 1,804.4 As a share of Sales to agri. Total sales of pumps DISCOM 1.4% 0.4% 0.5% 0.1% 0.0% 0.0% 77.1% 20.0% 19.3% 5.0% 1.7% 0.4% 100.0% 26.0% 6,942.4 100.0% Sales (GWh) in 2009-10 3. Presently, the 11 kV feeder is switched-off from the primary substation end for several hours each day, when DISCOMs require to ration electricity supply to agricultural pumps. With a mixed customer base on the feeder, villages served by this 11 kV feeder, their households and businesses too suffer with no electricity supply during this period. In general, the feeder is switched-on for a maximum of eight hours each day, depending on the assessed pumping requirements, based on the season and weather. Thus, power supply is not available to any customer in rural areas for about 16 hours of the day. 4. In some areas, to implement rationing, DISCOMs have adopted the practice of switching off one line of the three-wire 11 kV feeder at the point of its origin (the primary substation), which technically prevents three-phase water pumps being operated by agricultural customers served by the feeder. Single-phase, two-wire services will remain live, to serve households and small businesses. However, this practice causes the 11 kV feeder and the distribution substations along the feeder to be operated in an unbalanced mode, resulting in poor voltage of supply to households and frequent damages to distribution transformers. The GOMP has made it a requirement to supply three-wire supply both type od customers since 2009. 5. Therefore, GOMP is in the process of implementing a “Feeder Separation Program”. Please see Figure 2. Once the program is implemented, to serve the areas presently served by a single 11 kV feeder, with mixed village and agricultural customers, there will be two such feeders. (i) The existing 11 kV mixed feeder (MF1), in most cases1, will be rehabilitated and designated as the agricultural feeder (AF1), and it will serve only the distribution substations serving water pumps. The AF1 will be switched on and off direct from the primary substation, based on the approved duration allowed for water pumping each day, on the basis of seasonal water requirements and daily weather. (ii) a new 11 kV feeder, designated as the village feeder (VF1), will commence from the primary substation and traverse the rural areas, serving only the villages. VF1 will remain live throughout the day. Distribution substations located along the present 11 kV mixed feeder will be rehabilitated and re-located if required, to be closer to their intended customers, ie either the village or the 1 In some cases, depending on the layout of the existing 11 kV feeder and the farmlands/villages, the existing feeder may be designated as the village feeder and a new feeder would be built to serve agriculture. 3 agricultural water pumps. Presently, a distribution substation serves both the village and the agricultural customers, but after feeder separation, the substation will also be designated to serve either village or agricultural customers. The distribution substation DS1 which was previously on the mixed feeder MF1, serving mixed agricultural pumps, households and businesses (Figure 1) will be designated as an agricultural distribution substation ADS1 (Figure 2). In this example, two of the three low voltage lines commencing from ADS1 have been removed, while the remaining low voltage line has been extended to serve some pumps located closer to the village. Figure 2: Feeders separated to serve agricultural and village areas Primary Substation ADS2 11 kV feeder 33 kV line from EHV substation AF1 X 33 kV/11 kV transformer 11 kV feeder ADS1 VF1 (new) X ADL3 P customers only P customers only HH AF2 X New 11 kV bay Normally open switch 11 kV feeder P customers only ADS3 HH ADS4 HH HH X P HH HH VF2 (new) To other villages P customers only Anothe r 11 kV feeder 11 kV agricultural feeder P B HH HH P P HH P B P HH P P P AF: Agricultural Feeder VF: Village Feeder ADL: Distribution line for agriculture ADL: Distribution line for agric. (extended) New Village Feeder 11 kV (see details of HVDS in Figure 3) Note: The layout does not refer to any particular area or village. Distances are not to scale and they have been shrunk or exaggerated to elaborate the concept. ADS: Distribution Substatioin for Agriculture P Agricultural Water Pump HH Household customer B Small business Source: Project preparatory technical assistance consultants. 6. Substation DS1, now designated as ADS1 has a smaller number of customers (pumps only), and is now too far from most of the pumps. Therefore, depending on the distances and existing substation transformer capacities, ADS1 may be relocated to a position closer to the main area where pumps are located, and its transformer may replaced with a new, smaller capacity transformer. As the total power requirement for agricultural water pumping is substantially higher than the power requirements for the village, in most situations, the existing transformer in DS1 would be rehabilitated and used in ADS1. If the substation is relocated, AF1 would be extended to such new location, requiring a certain length of new 11 kV line to be built. 7. New distribution substations will be required to be installed owing to feeder separation. The typical existing arrangement in a village is to place the distribution substation in a central location (see DS1 in Figure 1), and to draw low voltage distribution lines, typically using bare conductors, along public roads and pathways. Village customers are then provided with a service drop from the closest pole. Long distribution lines drawn in the villages using bare conductors presently, (i) cause poor service voltage to customers at the far end of distribution lines, (ii) cause frequent interruptions and damages to transformers owing to vegetation touching the lines, and (iii) make un-authorized use of electricity 4 convenient. Therefore, the feeder separation program also plans to restructure the distribution network in each village, as a high voltage distribution system (HVDS). B. High Voltage Distribution Systems 8. The new 11 kV village feeder (VF1) built under the feeder separation program, depending on the extent of the village, will not serve only one location of a village, but will traverse the village. In contrast with the present practice of placing a distribution transformer in one location and drawing long distribution lines throughout the village, the village feeder at 11 kV will serve several new distribution substations in the village. Please see Figure 3. The village customers are new served off two new distribution substations VDS1 and VDS2. This will require some low voltage lines along village roadways to be converted to 11 kV lines. Each new substation in the village will have a smaller (25 kVA) transformer serving a section of the village, and new distribution lines to serve households and businesses in the village. Thereby, the length of the distribution lines from the distribution substation to reach the customers, will be shorter than at present. Shorter low voltage lines would reduce energy losses in distribution system. Furthermore, these new distribution lines along roads and pathways will use aerial bundled cables (ABC), which are insulated. Therefore, short distribution lines and the use of ABC would provide (i) an improved service voltage to village customers, (ii) completely eliminate impacts of vegetation on the lines (and vice versa, because vegetation needs not be cleared to draw ABC lines), (iii) reduce technical losses, and (iv) minimize unauthorized use of electricity2. Figure 3: High voltage distribution system to serve village areas Primary Substation 33 kV line from EHV substation X 33 kV/11 kV transformer X AF1 11 kV agri. feeder VF1 (new) HH VDS1 (new) New 11 kV bay HH HH HH VDL1 VDL2 To other villages HH VDS2 (new) HH B HH VDL1 VDL2 HH HH B New service drop to customers HH New Aerial bundled cable distribution lines AF: Agricultural Feeder VF: Village Feeder (new) VDS: Village Distribution Substatioin To other villages New Village Feeder 11 kV VDL: Distribution line for village (new) HH Note: The layout does not refer to any particular area or village. Distances are not to scale and they have been shrunk or exaggerated to elaborate the concept. B Household customer Small business Service drop (new) Source: Project preparatory technical assistance consultants. 2 11 kV lines traversing the village would continue to use un-insulated bare conductors, from which no unauthorized connections are possible, owing to the higher operating voltage. Unauthorized connection from the new distribution lines using ABC too, are not possible by simply placing a wire above the line, as it is done presently off bare conductor lines. 5 9. Alternatives to feeder separation, considering that the Government policy is to continue providing electricity at concessionary prices for water pumping, are (i) metering electricity use by all agricultural customers and charging on the basis of actual consumption, (ii) single-phasing (already practiced by some DISCOMs in certain areas), and (iii) feeder separation at low voltage level. Each alternative is discussed below. 10. A tariff for metered agricultural customers is already included in the tariff order of MPERC. However, metering of electricity used for agricultural water pumping has met with limited success owing to difficulties in locating the meter, safety of the meter which has to be located in the middle of the field at locations where the owner does not reside, and difficulties in reading the meters. Some groups of agricultural pumps are metered at the distribution transformer, enabling a group bill to be issued. The large majority of agricultural pumps remain un-metered, for which there are guidelines provided by MPERC to assess the monthly energy use. Given the policy context and the current practices, it is unlikely that metering of electricity served to water pumps can be implemented in the near future. 11. Single phase service during the period outside the approved hours of water pumping, is already experimented by DISCOMs. Deviating from prudent utility practice, one of the three conductors in the existing 11 kV mixed feeder is intentionally switched off at the primary substation. Power continues to be available on two phases of the 11 kV feeder. Therefore, in each distribution transformer along the 11 kV feeder, one phase out of the three phases on the low voltage side, has the correct phase voltage of 230 V, while the other two phases has about half the voltage. Switching off arrangement at the primary substation is usually for the same conductor all the time. Therefore, single phase customers in the villages are generally served by the only phase on the low voltage side that has the correct delivery voltage. Providing supply to a majority of village customers through one phase, causes the relevant phase winding of each distribution transformer to be overloaded. Correspondingly, the two live phases of the 11 kV feeder are also overloaded. When overloaded, the transformer and the two lines of the 11 kV feeder carry currents in excess of their rated current, causing excessive energy losses and cause poor service voltage to customers. As the village customers are aware of the phase that has the correct voltage, both authorized and unauthorized connections are mostly served by this healthy phase on the low voltage side. Thus, the village customer load that should be distributed among three phases of the low voltage network too, is effectively provided only by one phase. This causes excessive losses in the corresponding low voltage winding of the transformer, the phase conductor of the healthy phase and in the neutral conductor. Compared with the customer load evenly distributed between the three phases, the loss in the phase conductors of the healthy phase on the low voltage side can be 9 times the normal loss, and the loss on the neutral conductor too can be 9 times3. Furthermore, with three times the current in phase and neutral conductors, the voltage drop would be six times the normal voltage drop if the customer loads are distributed evenly between the three phases. 12. During periods of single-phase supply, farmers too presently use their three-phase water pumps. This is done by using the healthy supply available in one phase of the low voltage network to produce a three-phase supply required to run the pumps, with the assistance of an inverter, also known as a “phase splitter”. As the pump load is much higher than the village customer load, the overloading on the healthy phase of the transformer and distribution lines will be severe, and the current on the transformer winding of the healthy phase would be severely stressed, causing frequent winding failures. As the transformer is 3 Under normal conditions, if the line current on each phase is I and the phase conductor resistance is R, the 2 2 power loss would be 3 x I x R = 3I R. Ideally, there will be no loss in the neutral conductor. When all customers are connected to one phase, the current will be 3 x I and hence the loss in the phase conductor 2 2 2 would be (3xI) x R = 9I R. The loss in the neutral conductor will also be 9I R. Therefore, the total loss will be 2 2 2 9I R + 9I R = 18I R. Thus, single-phasing causes a loss of six times the loss during normal operation. 6 frequently overloaded, the protection equipment generally fixed to prevent damage, are all disabled. Moreover, inverters causes harmonic currents, causing the water pump motors to overheat, thus shortening the life of such motors. Thus, single-phasing causes poor voltage to all customers and excessive losses all over the network, making this option unacceptable, and cannot be considered as a long-term solution to the objective to ration the subsidized electricity supply to water pumps. 13. Feeder separation at low voltage level is another option to exercise control over power supply to water pumps. In this approach, there will be no new 11 kV feeders built, except for any rehabilitation and upgrades to the existing feeder. Each distribution substation has several low voltage distribution lines. In low voltage feeder separation, these distribution lines are rearranged such that agricultural customers will be served by one or two threephase distributors originating at the distribution substation. All other village customers will be served by the remaining low voltage lines served by the same distribution substation. The existing 11 kV feeder remains live throughout the day. When the service to water pumps has to be provided, the relevant low voltage lines are switched on at the distribution substation. These distribution substations are located in the field, by the side of roadways or other public property, and they are unmanned. As there are tens of thousands of such distribution substations, it is not possible or economical to station operators at each such location to switch the agricultural services on and off. Therefore, the option available is to provide switches on each low voltage line and then operate such switches through a wireless signal issued from a central control centre. A pilot scheme has been implemented by DISCOM-C, and the results indicate good energy savings. However, the constraint is the requirement to use a control system located at isolated distribution substations, which are exposed to possible damage and vandalism. Attempts to damage the control equipment at the distribution substation is likely to be from persons who seek longer hours of supply for agricultural water pumps. The pilot project has introduced monitoring of the control system to indicate any vandalism. However, in spite of the encouraging results of savings in commercial losses, the DISCOMs do not consider low-voltage feeder separation as a long term solution to the need to ration electricity supply to water pumps. The reasons are (i) the need to maintain contactors (switches) and associated control systems located at tens of thousands of distribution substations scattered over vast areas, and the (ii) possibility of vandalism of such control equipment because the distribution substations are unmanned and with no access control. C. Previous Experience in Feeder Separation and HVDS 14. Feeder separation and HVDS in rural areas have been implemented on a pilot basis by DISCOM-C in Bhopal and in other states on India. Implementation of phase 1 of the feeder separation program (funded by the Rural Energy Corporation and GOMP) 4 is presently in progress, but post-implementation results are not available yet. In addition, HVDS have been installed in urban areas in MP. For a pilot project implemented by DISCOM-C in the Gharelu feeder serving a rural area, Table 2 shows the conditions before and after the implementation of the project. The Gharelu feeder was previously a mixed feeder, serving both agriculture and villages. The feeder had the facility to switch off one phase at the primary substation located in Lambakheda. Therefore, village customers were able to use electricity during the period of single-phase operation of the mixed feeder. The old feeder was designated as the agricultural feeder and a new 11 kV feeder was built. This new feeder commenced from the Lambakheda primary substation and serves nine villages. The project included addition of new transformers in the villages, conversion of certain low voltage lines to high voltage feeders, and replacement of bare-conductor low voltage lines 4 Phase 2 of the feeder separation program is proposed to be financed by ADB, GOMP and the DISCOMs. 7 with aerial bundled cables or armored cables5. Previously in the village, there were 339 metered customers, 76 un-metered customers 6 and an estimated 43 unauthorized connections. All the existing village households and other customers were provided with a new service connection and a new meter. The meter was fixed at a visible location in each premise. Table 2: Results of the HVDS installed at Islamnagar in DISCOM-C Primary substation: Lambakheda Feeder name: Gharelu Village: Islamnagar Distribution circle: Entkhedi DC HVDS Month Input energy at distribution transformer MWh/month Energy Sold at customer end MWh/month Total energy Loss (technical and commercial) MWh/month % Before project Dec 2009 161.0 48.0 implementation After project Oct 2010 52.2 38.0 implementation Note: The information is for one village and shows the benefits of HVDS only. Source: DISCOM-C estimates. 113 70.2% 14 27.2% 15. In the pilot project in Islamnagar, energy sold after project implementation is lower than before, because previously, there were un-metered customers, whose consumption was estimated on the basis of the approved regulatory limit, and included as sales. With all customers provided with meters, and all customers receiving bills based on the actual consumption, the consumption has decreased. Based on the estimated number of connections (metered, un-metered and unauthorized) before installation of the HVDS, the average consumption per village customer decreased from 105 to 83 kWh/month, when HVDS was installed. The Ghasipur feeder served four more villages in addition to Islamnagar, and these villages have not been installed with HVDS or feeder separation. Therefore, the combined impacts of feeder separation and HVDS, considering the preproject energy served to the old mixed feeder against the data, cannot be compared at this stage. 16. HVDS has been installed in urban areas of MP. Information provided by DISCOM-C about several HVDS schemes implemented in year 2009 in urban areas, indicate that for each feeder converted to HVDS, reported post-implementation losses between 12.5% and 30.3% with an average of 19.14% (Table 3). Table 3: Results of HVDS implementation in urban areas in DISCOM-C Feeder Month/year of implementation No of legal consumers Billed sales (kWh/month) Supplied energy (kWh/month) Total technical and commercial loss Balaji Nagar Piriya Mohalla Harijan Mohalla Bhopal Urban Janta BDA Qrts. Colony Om Nagar JJ Nai Basti Jatkhedi JJ Gwalior urban Lala Ka Mal Bazar Road Padav Sep-09 Sep-09 Sep-09 Jun-10 Sep-09 Oct-09 Apr-10 Dec-09 Aug-10 Aug-10 Aug-10 Before after Before after Before after Before 70 100 8,700 11,100 17,700 13,000 50.8% Nil 49 Nil 4,900 15,000 6,100 na 14 31 1400 3,200 2,900 3,900 51.7% Nil 349 Nil 28,000 129,000 32,000 na Nil 496 Nil 52,000 140,000 62,000 na 190 209 15,000 31,000 105,000 39,000 85.7% 63 180 5000 23,000 90,000 33,000 94.4% 3 265 0 40,000 133,000 48,000 100.0% 2,533 2,540 300,650 635,000 891,000 827,000 66.3% 1,672 2,343 218,642 641,170 768,000 823,000 71.5% 2,266 2,236 410,159 853,454 758,000 1,028,000 45.9% after 14.6% 19.7% 17.9% 12.5% 16.1% 20.5% 30.3% 16.7% 23.2% 22.1% 17.0% Note: The information is for Bhopal urban and Gwalior urban areas of DISCOM-C, which were highly prone for unauthorized connections. On certain feeders, almost all connections were unauthorized. After HVDS, losses of all the urban feeders have declined to the range between 12.5% to 30.3%. Source: DISCOM-C estimates. 5 An armored cable is a fully insulated electricity conductor, with a protective armor consisting of a mesh of steel wire. Their typical application is as underground buried cables, with the steel armor providing protection against unintentional mechanical damage. 6 MPERC allows un-metered household customers. 8 D. Energy Efficiency and GHG Emission Reduction 17. Technical losses in distribution networks are reduced through feeder separation and HVDS. Commercial loss reduction may vary after feeder separation and HVDS, depending on how much of the commercial losses would be converted to sales. Reduced technical losses have clear benefits by way of reduced purchases from transmission, thereby reducing purchases from generation. Any savings in thermal power generation would result in savings of greenhouse gas (GHG) emissions from power plants. These power plants may either be within MP or outside the state. As commercial losses may be converted to sales, savings in commercial losses were not considered in the estimation of GHG emission reduction. 18. A comprehensive analysis of pre-project technical losses using meters at input and output points of a rural distribution network would not be possible owing to unmetered and unauthorized service connections that would prevent accurate measurement of output from the network. Input to the network, however, can be measured. Therefore, the assessment of technical loss savings from feeder separation and HVDS network was based on a model of a typical rural network. The physical model was defined as follows: Length of 11 kV feeder from the 33 kV/11 kV substation Type of conductor used for the 11 kV feeder Capacity of the distribution transformer Length of 400 V, 3-phase distribution lines from the transformer Type of conductor used for distribution lines Current carrying capacity of each distribution line Number of village household/small business customers Village customer load profile Customer distribution along LV feeders Number and rating of pumps served through the LV lines 5 km 7/4.10 mm (Racoon7) 250 kVA 3 feeders 1.8 km each All aluminum bare conductor 25 mm2 (Gnat) 140 A 600 (approximately) typical profile of a village uniformly distributed 9 pumps, each 10 hp 19. Present operating pattern: 3-phase supply is provided for eight hours each day. Thereafter, one phase of the 11 kV feeder is switched-off at the primary substation, and for sixteen hours, this situation prevails. It was assumed that owing to this practice of “singlephasing” for several years, 80% of village household customers (both legal and illegal connections) have got their service lines shifted to be served from the healthy phase of the distribution lines. The balance 20% of village customers would receive a poor quality of supply during this sixteen-hour period of single-phase supply each day. 20. The calculated technical losses of this feeding arrangement are given in Table 4. The highest technical loss will be on LV distribution lines. The highest overall technical loss (25.2% of input to 11 kV feeder) occurs if the 3-phase service is provided during the daytime. If the 3-phase service period is varied from day to day, the average loss will be 24.8% of the input to the network at 11 kV. The average technical losses in the existing network were therefore considered to be 24% of the input to the distribution network at 11 kV. 7 Bare (ie un-insulated) electrical conductors used in power transmission and distribution are identified by the number of strands and the diameter of each strand. Additionally the cross-sectional area and a code name is also used. 9 Table 4: Daily energy input and technical losses in a typical distribution network with mixed village and agricultural customers Pump Operation interval (3-phase service available) Total Input at 11 kV LV Loss Transformer Loss 11 kV feeder Loss (kWh/day) (kWh/day) % (kWh/day) % (kWh/day) 00:00 -08:00 2,458.2 3.2 0.1% 29.7 1.2% 596.4 08:00-16:00 2,183.7 2.9 0.1% 28.6 1.3% 519.3 16:00- 24:00 2,602.7 3.3 0.1% 30.2 1.2% 583.9 Average 2,414.9 3.1 0.1% 29.5 1.2% 566.5 All % losses are calculated as a share of the input at 11 kV. Source: Estimates by project preparatory technical assistance consultants. % 24.3% 23.8% 22.4% 23.5% Total Loss (kWh/day) 629.4 550.8 617.4 599.2 % 25.6% 25.2% 23.7% 24.8% 21. Feeder separation would avoid the need for switching off the village feeders, and the village customers will be served throughout the day. The agricultural pumps will be separately served for eight hours each day. The project will also ensure that single-phase households and other customers in the village would be distributed between the three phases, thus minimizing losses in the LV phase conductors as well as the neutral conductor along each LV feeder. The analysis was extended to assess the losses owing to even distribution of village customers, in the first case, with feeder separation only. The results of the analysis are given in Table 5. The calculated technical losses would be 18.8% of input at 11 kV, a reduction of 6% from the existing loss level. For subsequent analysis, the technical loss reduction was considered to be 3%, a conservative assessment compared with the 6% saving calculated using the model. The assessment of energy savings at generation level is given in Table 6. Table 5: Daily energy input and technical losses in a typical distribution network with village customers only (after feeder separation) Pump Operation Interval (3phase service available) Total Input at 11kV LV Loss Transformer Loss 11kV Feeder Loss (kWh/day) (kWh/day) % (kWh/day) % (kWh/day) 00:00-08:00 2,458.2 3.2 0.1% 29.7 1.2% 596.4 08:00-16:00 2,183.7 2.9 0.1% 28.6 1.3% 519.3 16:00-24:00 2,602.7 3.3 0.1% 30.2 1.2% 583.9 Average 2,414.9 3.1 0.1% 29.5 1.2% 566.5 All % losses are calculated as a share of the input at 11 kV. Source: Estimates by project preparatory technical assistance consultants. % 24.3% 23.8% 22.4% 23.5% Total Loss (kWh/day) 629.4 550.8 617.4 599.2 % 25.6% 25.2% 23.7% 24.8% Table 6: Assessment of energy savings at generation level, owing to reduced technical losses Description Technical loss savings at 11 kV level, for all DISCOMs Equivalent power generating capacity avoided units Amount GWh/year 487.8 MW 65.5 Transmission loss rate approved by MPERC GWh/year 4.08% Therefore, savings at the generation (net) level GWh/year 508.6 Source: Estimates by project preparatory technical assistance consultants. Notes equivalent to only 3% reduction of technical losses, calculated using data on total input to the 11 kV network in MP Based on an annual capacity factor of 0.85 Published in Tariff Order 2010-11 Calculated 22. Agricultural water pumps are presently operated for a period longer than the period stipulated. WIth the use of phase splitters, these pumps are operated during the period when one phase of the 11 kV feeder is switched off. This further increases the technical losses, owing to severe overloading of the healthy phase of the distribution network and the 10 resultant increase in the neutral current. After feeder separation, the pumps can be provided power for a fixed period of operation, adequate for agricultural purposes. The use of pumps will be limited to such period. Therefore, the energy used for the present over-use of pumps will be saved. The energy savings owing to restricting the use of pumps to eight-hours per day was estimated as given in Table 7. Table 7: Estimate of Savings Owing to Avoided Over-use of Agricultural Pumps Description units Amount Notes Energy allowed in the tariff order for agricultural customers reflects an average use of 6 hours/day estimated Estimated based on the allowed energy use of 7225 GWh/year for agriculture in MP Estimated hours of operation at which regulatory allowance will be exhausted hours/day 6.0 Additional period of use with splitters etc hours/day 2.5 Hence, estimated actual use for Agric. GWh/year 10,235.3 GWh/year 9,633.2 calculated GWh/year 602.1 calculated MW 80.9 GWh/year 4.08% calculated Published in Tariff Order 201011 calculated With 8-hour availability, estimated actual use for agriculture after feeder separation Therefore, estimated savings in actual use in agric. owing to feeder separation Equivalent power plant capacity Transmission losses approved by MPERC Therefore, savings at the generation (net) level GWh/year 627.7 Source: Estimates by project preparatory technical assistance consultants. 23. The total saving in technical losses and avoided wasteful use in agriculture is therefore estimated to be 508.6 + 627.7 = 1136.3 GWh. The savings in losses would cause a reduction in purchases from transmission, and therefore lead to reduced generation, either in MPGENCO or from central power plants. As India’s power generation is dominated by fossil fuels, the reduced generation would cause a reduction in CO2 emissions. A key parameter to calculate emission reductions, is the emission factor, measured in kg CO2 per kWh saved. UNFCC8 has standardized and published calculation methodologies to assess the emission factor of public electricity systems. Central Electricity Authority (CEA) of India calculates and publishes the emission factor for the Indian grid, using the UNFCCCapproved methodology ACM0002 version 6 9 . The calculated emission factor for India, published by CEA in March 2011 is 0.89 kg of CO2 per kWh for year 2009-10. In 2007-8, the emission factor has been 0.81, thus the Indian grid is showing an increasing trend of the emission factor. However, a conservative estimate of 0.81 was used, to calculate the emission reductions expected as a result of the feeder Separation and HVDS. The calculations are summarized in Table 8. Table 8: Estimation of annual savings of CO2 emissions owing to reduced technical losses Description units Amount Savings in technical losses and avoided GWh/year 1136.3 wasteful use in agriculture Emission factors published by Central Electricity Authority for India, after adjustment kgCO2/kWh 0.81 for imports from Bhutan Avoided GHG emissions owing to technical tonneCO2/ 920,369 loss reduction year Source: Estimates by project preparatory technical assistance consultants. 8 9 Notes calculated earlier, as at the point of generation Calculated Calculated United Nations Framework Convention on Climate Change. ACM002 is a methodology approved by UNFCCC for the calculation of emission factors to assess emission reduction from grid-connected renewable energy-based power plants. However, UNFCCC recommends that this assessment methodology may also be used to estimate the emission reductions owing energy efficiency as well. Please see page 15 of the CDM Methodology Booklet http://cdm.unfccc.int/methodologies/documentation/meth_booklet.pdf#ACM0002 11 24. The above is a conservative estimate of the annual savings, owing to the following reasons: (i) India’s grid emission factor indicates an increasing trend but the above analysis uses the lowest emission factor published over the past five years, (ii) reduction in technical losses has been conservatively assessed to be 3%, whereas, the reduction may exceed 6% in typical cases in MP, and (iii) the annual quantity of energy savings will increase as the seperated feeders and HVDS delivers more energy over its their economic life of 25 years.