Finger Lakes Community College Climate Action Plan

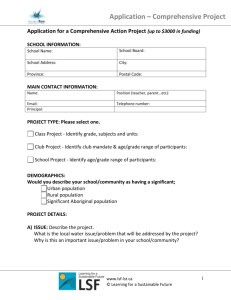

advertisement