Modeling and Comparison of Power Converters for Doubly Fed

advertisement

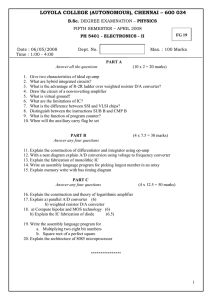

Modeling and Comparison of Power Converters for Doubly Fed Induction Generators in Wind Turbines Ph.D. thesis by Lars Helle 1 Agenda 1. 2. 3. 4. 5. 6. 7. Introduction Wind turbine comparison issues Models of surrounding components Converter modeling Design and maturing efforts System comparison – an example Conclusion and perspectives 2 Introduction 140 120 ¾ Dramatic increase in the use of windpower ¾ Requirements for active and reactive power control. ¾ Increasing turbine size ¾ Need for active load reduction control ¾ Demand for reduced energy price ¾ Optimized technical solution ªThese requirements seems to call for a variable speed wind turbine Accumulated worldwide installed wind power [GW] 100 80 60 40 20 1980 2000 1990 2010 Year 1500 Average turbin e p ow er of new installations[kW] 1000 500 0 1980 1985 1990 1995 2000 2005 Year Wind energy price [DK K/kWh] 1 0.8 0.6 0.4 0.2 0 1980 1985 1990 1995 2000 2005 Year 3 Introduction 1. Several variable speed topologies are potential candidates: 1. 2. 3. 4. Converter fed IG DFIG SG with external magnetization SG with PM magnetization 2. All these topologies need a frequency converter 3. Good models are required to select the most appropriate solution. Converter IG Converter DFIG Converter Converter Converter SG PMSG 4 Wind turbine comparison 1. 2. 3. 4. 5. 6. Cost Efficiency Reliability Serviceability Weight Volume η Two-level Matrix ? ? ? ? Multi-level 5 Wind turbine comparison 1. Cost (Qualitative meas.) ¾ Cooling needs (loss) ¾ Component count ¾ Component util. η Two-level Matrix 2. Efficiency (Quantitative meas.) ¾ Converter losses ¾ Annual energy production ? ? ? ? Multi-level 3. Reliability (Qualitative meas.) ¾ Component count ¾ Maturity 6 Wind turbine comparison ¾ Four converters are evaluated for a DFIG system: ¾ ¾ ¾ ¾ Back-to-back two-level converter Matrix converter Diode clamped three-level converter Transistor clamped three-level converter ¾ Common basis for evaluation ¾ Harmonic distortion (HDF) ¾ Equal turbine power capability (in terms of operating temperature) ¾ Maturity of the converters 7 Wind turbine comparison ¾ All modeling and design guidelines are based on analytical approaches in order to obtain: ¾ Very fast evaluation for the entire operating area ¾ Easy comparison and design evaluation based on information from standard datasheets. ¾ Easy access to the modeling approaches. ¾ “Transparent” documentation for the obtained results 8 Models of surrounding components ¾ Establish analytical models of the wind turbine components in order to: ¾ Calculate the correct loading of the converter in arbitrary working conditions ¾ Determine the effect of changing surrounding component properties. Wind power Aerodyn. loss Gear loss Turbine blades Cp Gear Fric. loss Elec. Switch Cond. loss loss loss Gener ator Converter Elec. loss Produced power Transformer Grid Stator power 9 Converter modeling ¾ Model of the four converters: Net filter Grid filter Generator filter Rotor filter A 1 sw 2 sw 3 sw Net filter Net filter B Generator filter Generator filter C Matrix Converter 10 Converter modeling - Model of converter losses ¾ Model of the converter conducting losses: iC it id ir ¾ Model of the converter switching losses: 11 Converter modeling - Model of converter temperature ¾ Calculation of peak semiconductor temperatures for the different converter topologies and modulation method: k·Tda k·Ttb Zthjc,d Zthjc,d k·T ta k·Tdb Zthjc,t Zthjc,t Z thx T tb Td b Ptb Pdb Zthch Zthh a Tam b Tta C th x1 Rthx1 Cth x2 Rthx 2 Cth xy Rthxy Tda Pta Pda 12 Converter modeling - Model of converter temperature 13 Converter modeling - Model of converter temperature 14 Design and maturing efforts ¾ Design for equal harmonic performance ¾ New modulation methods for three-level converters ¾ New modulation methods for matrix converters ¾ Filter design guide lines 15 Design and maturing efforts 50 0 200 0 -200 1.1 1.2 1.3 -400 Resistor current [A] -50 DC-link voltage [V] Output voltage [V] Load current [A] -Modulation strategy for three-level inverters 1.1 1.2 1.3 1.4 1.2 1.3 Time [s] 1.4 20 350 300 10 250 200 1.1 1.2 1.3 Time [s] 0 1.1 16 Design and maturing efforts -Modulation strategy for three-level inverters Load current [A] After imbalance is applied 50 0 -50 Output voltage [V] 1.06 1.08 0 1.1 200 0 -200 -400 50 -50 Output voltage [V] Load current [A] Before imbalance is applied 1.36 1.38 1.4 1.36 1.38 Time [s] 1.4 200 0 -200 1.06 1.08 Time [s] 1.1 -400 17 Design and maturing efforts -Modulation strategy for three-level inverters 18 System comparison – an example 1. All the developed models have been implemented in a simulation tool “D’rives” 2. D’rives calculates all component loadings, component temperatures, losses etc. in a few seconds for the entire operating area. -> initial design validation 3. D’rives calculates the power capability determined by the individual components – also within a few seconds. 19 System comparison – an example 20 System comparison – an example 21 System comparison – an example 22 System comparison – an example 23 System comparison – an example 24 System comparison – an example 25 System comparison – an example ¾ 2MW turbine ¾ Diameter of 80 m ¾ Gear ratio of 1:100 ¾ Max tip speed of 72 m/s (steady state) ¾ Max tip speed of 80 m/s (transient) 26 System comparison – an example ¾ 2MW turbine ¾ Diameter of 80 m ¾ Gear ratio of 1:100 ¾ Max tip speed of 72 m/s (steady state) ¾ Max tip speed of 80 m/s (transient) ¾ DFIG generator ¾ Nom. speed 1719 RPM ¾ Winding ratio 1.5 (Y-Y connection) ¾ Nom. stator voltage 690V (p-p) 27 System comparison – an example ¾ Two-level converter design (as an example): Gen. inverter Grid inverter diodes IGBT diodes IGBT 28 System comparison – an example ¾ Power losses of the two-level converter designs Grid inverter losses Rotor inverter losses 29 System comparison – an example ¾ Power losses of the two-level converter designs 30 System comparison – an example ¾ The power capability of the designed converters is determined by operating each design until it reached maximum temperature. (TC) ¾ The switch utilization factor: 31 System comparison – an example ¾ The power losses of the considered converter designs become: ¾ The normalized annual energy production: (TC) ¾ The component counts of the considered converter designs 32 Conclusion Tools and methods could ¾ Comparison of different converter wind turbine based on a DFIG. be used for any drive train configuration topologies for use in a ¾ Analytical expressions for individual component currents and losses. ¾ Methods for calculating peak temperatures in the semiconductors. ¾ A comprehensive tool D’rives for evaluating a certain turbine layout under various loading conditions. ¾ Maturing efforts. ¾ Design guidelines for the different converter topologies in order to obtain a fair comparison. ¾ New modulation methods for the matrix converter. ¾ New modulation methods for the three-level converters. ¾ An example of a design and comparison of 4 different converter topologies. 33 Perspectives ¾ Semiconductor lifetime estimation ¾ Converter design margins due to speed variations ¾ Including an estimation of current harmonics 34 Thank You For Your Attention 35