Antenna Matching within an Enclosure Part 2

advertisement

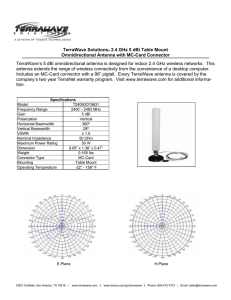

Antenna Matching within an Enclosure Part 2: Techniques & Guidelines By: John Lienau Antenna Matching Within an Enclosure Part II: Techniques & Guidelines John Lienau, RF Design Engineer Antenna selection and placement can be a difficult task, and the challenges of implementing the antenna are not over once it’s placed on the board. As previously discussed in Antenna Matching Within an Enclosure Part I: Theory and Principle, the enclosure affects the antenna match. The process of matching an antenna can be a very complicated process. Not only is an in-depth knowledge of RF principles and components needed, but proper technique and understanding of the antenna properties is required. Any error introduced into the measurement while matching the antenna will ultimately reduce the effectiveness of the antenna and its performance. For this reason, as much care should be taken in the setup of your measurements as the actual matching process itself. The most important factors in antenna tuning are proper connection to the PCB, calibration and port extension of the network analyzer, and knowledge of the antenna to ground plane relationship. These three factors must be taken into account when attempting to tune an antenna for an enclosure, and will be covered in this paper. Tuning an antenna is not as easy as simply connecting it to a network analyzer and chasing the impedance around the smith chart. Without doing the little steps right, it is easy to introduce error into the measurement and improperly match the antenna. Before matching can begin, a proper connection must be established to the PCB. There are usually two methods for connecting to the PCB to match an antenna. The first is using a U.FL connector. This involves finding an area big enough to place the connector down and an area that allows for good grounding. It is often difficult to find enough room near the antenna trace for this method; additionally care must be taken to make sure you don’t introduce additional parasitic effects. The U.FL is typically only effective for tuning if the PCB was designed with specific component pads for placement of the U.FL. The second, more common method is to strip a thin coaxial cable and solder it directly to the trace line. This requires less space on the PCB and is more flexible than placing a U.FL on the board. When soldering a coaxial cable to the PCB, the inner conductor must be soldered to the beginning of the trace and the outer shield well soldered to ground. Occasionally, it is not possible to solder to the beginning of a trace (see Figure 1). This will give an inaccurate measurement of the antenna’s impedance. The RF signal propagates down both ends of the trace at the same time. The signal will reach the end of the stub, reflect back, and interfere at the solder point to give false impedance readings. To eliminate this problem, the trace behind the solder point has been cut. The RF signal will now propagate down the cable and only to the antenna. Similarly, as shown in the third picture of Figure 1, make sure there are no extra lengths of trace line after solder point as well. This will result in the same reflections problem. 1 Cable soldered to feed trace. Trace must be cut to prevent reflections. Trace is cut. RF signal will now flow down cable and straight to the antenna. Figure 1: Soldering a Cable to an Antenna Feed Trace 2 Small PCBs can be particularly difficult for tuning because of their ground plane size. This is a common a problem with chip antennas because they are placed on very small boards. With a small ground plane, the outer conductor of the coaxial cable can act as the antenna ground. This causes currents to flow on the outer conductor of the cable. As a result, the cable actually becomes part of the antenna and radiates. An easy way to test for this is by touching the coaxial cable, if the S11 measurement on the network analyzer shifts significantly, this indicates a problem. This can be rectified by making sure the cable is well connected to ground. If this still does not solve the issue, other methods including adding a ferrite or routing the coaxial cable different may help. Figure 2: Trace F Antenna After the cable has been properly attached to the antenna feed trace, the network analyzer needs to be calibrated. The antenna in Figures 1 and 2 is a trace F. This type is designed to be tuned without matching components. The F has been intentionally created too long, and hence tunes too low in frequency. The advantage to doing this is that the engineer can slowly trim the end of the antenna and increase the resonant frequency. This technique can be used to tune a trace antenna in its final enclosure. Table 1 below documents the trimming and tuning of the F antenna above. The desired frequency band is 2.4 GHz. This represents the most basic form of tuning an antenna. The dimensions are being physically altered, which is changing the impedance of the antenna, and consequently the load seen by the transmission line delivering the RF signal. This trace F antenna example was designed at LS Research. The overall dimensions for the feed width, trace width, height, and feed location were determined through simulation. The final step of tuning by trimming the overall length can be done on a bench, but optimization of the antenna dimensions for bandwidth and Return Loss should be done by an experienced antenna designer. 3 Frequency Return Loss 2.4 GHz -3.5 dB 2.44 GHz -2.7 dB 2.48 GHz -2.1 dB Without Trimming Frequency Return Loss 2.4 GHz -10.0 dB 2.44 GHz -7.2 dB 2.48 GHz -5.4 dB After 1st Cut Frequency Return Loss 2.4 GHz -16.5 dB 2.44 GHz -39.0 dB 2.48 GHz -14.9 dB After Final Cut Figure 3: Trace Antenna Tuning 4 While the previous example relied on looking at an S11 measurement on a network analyzer, most commonly an engineer will have to match an antenna via a discrete network of inductors and capacitors. Antennas that are purchased ‘off the shelf’ will require matching, the antenna dimensions cannot be altered as with the F example above. In order to match an antenna with components, an in depth knowledge of the Smith chart is needed to properly determine the matching network. When employing the use of matching components, the coaxial cable for measurement should be soldered on before the matching network. In the F antenna example, since it was being tuned without components, the coaxial cable had to be a directly connected to the feed. As shown below in Figure 4 and Figure 5, the cable is now placed before the matching network. In addition to properly placing the cable, the port extension feature of the network analyzer is needed. Since the Smith Chart will be used to determine the impedance of the antenna, the reference plane for the measurement must be correctly set. Since the cable is soldered directly to the board, you cannot calibrate to the end of it. A port extension must be applied to account for the phase change of the additional length of cable not included in the calibration. This will essentially move the calibration plane past the cable and to the end of the trace. If this is not done, impedance measurements on the Smith Chart will not be correct. Inner conductor is soldered to start of antenna match Calibration plane is set to here via port extension Observe that the trace is cut to prevent reflections. Outer shield of cable is well soldered to the PCB ground Figure 4: View of Matching Pads and Cable Under a Microscope 5 With the port extension properly set, the antenna impedance must be measured so that a matching network can now be designed. An RF short should be used to bridge the gap in the trace lines. However, whatever component is used to bridge the gap will inherently add some of its own capacitance or inductance to the measurement. At frequencies under 1 GHz, a 0 Ohm jumper is may be used as a short. However, at higher frequencies, the 0 Ohm jumper becomes inductive and will introduce error into the measurement. This is especially true for anything above 1 GHz. The best thing to use to bridge the gap is a capacitor that is resonant near your frequency of operation. This will eliminate most of its inductive or capacitive qualities. For example, an 8.2pF Murata GRM 0402 capacitor is resonant at approximately 2.4 GHz. While it’s not a perfect RF short, it is much better than a 0 Ohm jumper or a glob of solder. Both of the later alternatives will be inductive at higher frequencies. Also, the resonant frequency of the capacitor will vary depending on the manufacturer. A 10pF Johanson 0402 LSeries capacitor is a good RF short at 2.4 GHz. Make sure to have a thorough understanding of the components being used. Without Matching With Matching Figure 5: Puck Antenna Board Another key component that significantly affects the tuning and also radiated performance of an antenna is the ground plane. Many antennas, particularly traces and chips, are dependent on the shape and size of the PC B ground plane. The chip (or trace) is only half of the antenna, the other half is the ground plane. Recalling the dipole diagram and current distribution from the previous paper (Antenna Matching Within an Enclosure – Part 1), there is positive and negative charge buildup on the antenna. This buildup of charge is ultimately what causes current flow. In a similar fashion, charge builds up on the trace antenna and on its corresponding ground plane. There is current flow on the antenna due to this charge, but since the ground plane is now partially responsible for the charge buildup it will also directly affects the current distribution and ultimately the impedance and radiation of the antenna. 6 Manufacturers for chip antennas commonly give recommended matching circuits, but these are only valid if the PCB is the same size as the one the manufacturer tested with. Additionally, testing at the manufacturer would have been done in free space, using the chip antenna within an enclosure forces it to be re-tuned. Essentially, the recommended matching circuit is not usable for most implementations and the antenna must be re-tuned. Additionally, the orientation of the chip antenna with respect to the ground plane will affect tuning and performance. The datasheet for the chip antenna will depict an orientation and keep out area. This is should followed as closely as possible! The key to successfully matching an antenna is maintaining accuracy in the measurement. Good grounding of the coaxial shield, proper solder location on the feed line, and knowledge of your component are all very important. Small inaccuracies can easily result in an engineer designing the wrong matching network for an antenna. This paper has covered some common mistakes, but overall a good understanding of RF principles is the best tool for matching an antenna. 7