Install and Maintain HV Overhead Equipment and

advertisement

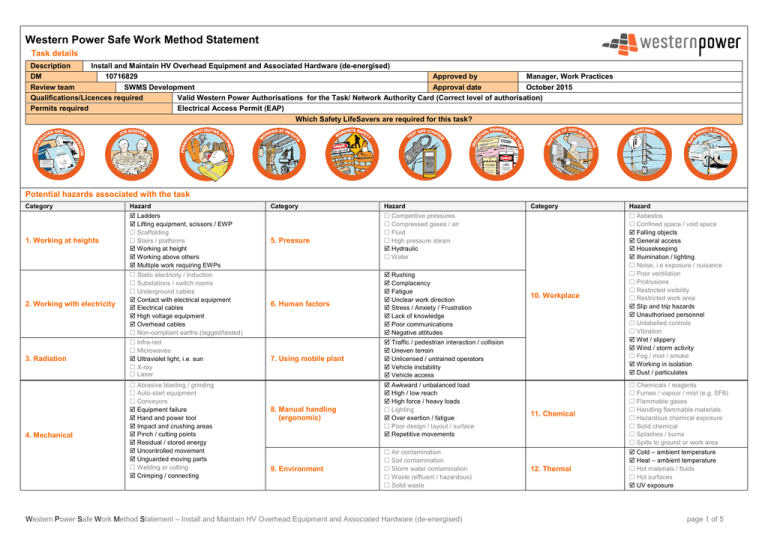

Western Power Safe Work Method Statement Task details Description Install and Maintain HV Overhead Equipment and Associated Hardware (de-energised) DM 10716829 Approved by Manager, Work Practices Review team SWMS Development Approval date October 2015 Qualifications/Licences required Valid Western Power Authorisations for the Task/ Network Authority Card (Correct level of authorisation) Permits required Electrical Access Permit (EAP) Which Safety LifeSavers are required for this task? Potential hazards associated with the task Category Hazard 1. Working at heights Ladders Lifting equipment, scissors / EWP Scaffolding Stairs / platforms Working at height Working above others Multiple work requiring EWPs 2. Working with electricity Static electricity / induction Substations / switch rooms Underground cables Contact with electrical equipment Electrical cables High voltage equipment Overhead cables Non-compliant earths (tagged/tested) 3. Radiation Infra-red Microwaves Ultraviolet light, i.e. sun X-ray Laser 4. Mechanical Abrasive blasting / grinding Auto-start equipment Conveyors Equipment failure Hand and power tool Impact and crushing areas Pinch / cutting points Residual / stored energy Uncontrolled movement Unguarded moving parts Welding or cutting Crimping / connecting Category 5. Pressure Hazard 6. Human factors Rushing Complacency Fatigue Unclear work direction Stress / Anxiety / Frustration Lack of knowledge Poor communications Negative attitudes 7. Using mobile plant Traffic / pedestrian interaction / collision Uneven terrain Unlicensed / untrained operators Vehicle instability Vehicle access 8. Manual handling (ergonomic) 9. Environment Category Hazard 10. Workplace Asbestos Confined space / void space Falling objects General access Housekeeping Illumination / lighting Noise, i.e exposure / nuisance Poor ventilation Protrusions Restricted visibility Restricted work area Slip and trip hazards Unauthorised personnel Unlabelled controls Vibration Wet / slippery Wind / storm activity Fog / mist / smoke Working in isolation Dust / particulates 11. Chemical Chemicals / reagents Fumes / vapour / mist (e.g. SF6) Flammable gases Handling flammable materials Hazardous chemical exposure Solid chemical Splashes / burns Spills to ground or work area 12. Thermal Cold – ambient temperature Heat – ambient temperature Hot materials / fluids Hot surfaces UV exposure Competitive pressures Compressed gases / air Fluid High pressure steam Hydraulic Water Awkward / unbalanced load High / low reach High force / heavy loads Lighting Over exertion / fatigue Poor design / layout / surface Repetitive movements Air contamination Soil contamination Storm water contamination Waste (effluent / hazardous) Solid waste Western Power Safe Work Method Statement – Install and Maintain HV Overhead Equipment and Associated Hardware (de-energised) page 1 of 5 Steps required to perform the task, in the correct sequence Hazards for each task step Initial Risk Rating Control required to eliminate or minimise the risk of injury Controlled Risk Rating References Plan and prepare Pre-plan • Plan trip • Accreditation, training and competency • Pre-start checks on vehicles, plant and equipment • Valid test certificates for EWP • Valid inspection certificates and tags for plant and equipment • Consumer / land owner notification (if required) • Contact Dial Before You Dig (if required) • Notify Network Operations Control Centre (NOCC) / issuing officer for DNAR / permit • Advise Main Roads and local Council (if required) • Engage GPA Accredited Traffic Management Company (if required) Control pedestrian and vehicle interface • Keep pedestrians and vehicles apart, Control vehicle movements on site and when vehicles enter and exit the workplace • Minimise vehicle movements • Manage the risks of reversing vehicles • Lack of skills, knowledge, competency: shock, burns, injury • Travelling to site – fatigue, injury • Vehicular traffic / pedestrian / animals: injury • Adverse weather conditions: injury, harm • Vehicle accident / breakdown or stranded at a remote location: heat stress, harm • Working / driving in high fire risk areas – fires: burns, injury • Faulty equipment: shock, burns, injury • Unsecured material / equipment: injury • Failure to notify affected consumers: public risk – reliance on supply for health, safety and medical reasons • Vehicle and equipment movement: impact, injury , property damage • Unauthorised access: injury • M M • Confirm all staff have the skills, training and competency to do their task • Ensure that drivers have a current MVDL for the vehicle they are driving. • Complete pre-start checks on vehicles, plant and equipment • Plan the trip to avoid long periods of driving without a break, where possible, share the driving • Adjust driving to suit weather conditions and terrain • Notify formal leader / office of daily plan • Carry emergency beacon or satellite phone if travelling out of mobile phone / radio range • Confirm work teams have all the required PPE • Confirm the location of all utilities in the vicinity of the proposed work • Secure all equipment, tools and materials in the vehicles • Confirm switching program with NOCC • Ensure tools and equipment are approved and suitable for the task • Confirm that an accredited traffic management company has been engaged (if required) • Ensure suitable traffic and pedestrian management arrangements are in place. This will involve the development and implementation of a traffic and pedestrian management plan by a competent authorised Western Power representative. • Provide separate clearly marked pedestrian walkways that take a direct route where possible. If the walkway crosses a roadway, provide a clearly signed and crossing point where drivers and pedestrians can see each other clearly. • Before exiting the work zone ensure both vehicle and pedestrian traffic can be clearly seen in both directions. • Keep walkways clear to avoid pedestrians having to step onto the vehicle route. • Designate parking areas for workers’ and visitors’ vehicles outside the work zone. • Appoint a vehicle spotter when: a. vehicles or plant are operating in close proximity to each other Western Power Safe Work Method Statement – Install and Maintain HV Overhead Equipment and Associated Hardware (de-energised) Electrical System Safety Procedures (ESSP) sections: 1.6; 3.2; 4.7; 5.3; 6.1 Work Practice Manual (WPM) sections: 2.16; 2.21; 3; 5.9; 5.10; 6; 11.2; 11.10; 11.13 L Main Roads Traffic Management for Works on Roads Code of Practice L page 2 of 5 Steps required to perform the task, in the correct sequence Hazards for each task step Initial Risk Rating Control required to eliminate or minimise the risk of injury Controlled Risk Rating References b. reversing vehicles c. persons are on the ground and in proximity to moving vehicles and d. in other situations as indicated by a risk assessment. • Ensure visual (flashing lights) warning devices, reversing alarms and high-visibility markings for powered mobile plant are operational prior to commencing work. Workplace set up • Correct location / apparatus • Conduct a Workplace Risk Assessment Plan (WRAP) – include all staff • Vehicles and equipment checks • Set up plant and equipment • Earth vehicles (if required) • Site conditions / fire alerts • Emergency procedures • Staff fit for duty • Accreditation and training • Communicate with NOCC or issuing officer for EAP • Communicate with land owner (if required) • Clean and inspect equipment • Use approved and tested tools and equipment • • • • • • • • • • • • • • • Failure to wear correct PPE: shock, burns, injury Unfit for work: injury Lack of skills or knowledge: injury Slip, trip, fall, obstacles; injury Manual handling / using tools: strain, injury Failure to maintain MAD to live apparatus: shock, burns, injury Induced / capacitive voltage: shock, burns Electrical apparatus failure: injury Damaged or faulty plant, tools or equipment Fires: injury No clear access / egress plan: injury Insects, vermin, reptiles, animals: injury, harm Weather conditions: rain, sun, wind, lightning: Failure to notify affected consumers: public risk – reliance on supply for health, safety and medical reasons Tools or equipment failure: shock, burns, injury • • • • • H • • • • • • • • • • • • • • • • Isolation and permits • Communicate with Network Operations Control Centre • Failure to wear correct PPE: shock, burns, injury • Failure of work party to clearly understand the conditions of the EAP and the work boundaries: Ensure correct PPE is worn at the workplace Comply with the fatigue management plan Comply with the drug and alcohol policy Apply body fit principles Confirm staff are trained and have appropriate competencies and correct network authority levels Appoint a competent safety observer trained in EWP emergency procedures (if applicable) Inspect structures and apparatus on both side of the workplace for condition and hazards Confirm the location of all utilities in the workplace Conduct a team brief and ensure that all staff have signed on to the WRAP and understand instructions and limitations of the task Ensure an emergency plan is in place and understood Inspect / check tools and equipment to be used Confirm correct operation of EDD (if EWP used) Confirm safe workplace access and egress Ensure fire fighting equipment, and people competent to use it are at the workplace Drink sufficient fluids to stay hydrated Apply correct manual handling techniques Communicate with land owner to determine safe entry requirements (if required) Confirm that consumers have been notified of outage before carrying out work (if required) Continually review potential hazards and control methods Inspect PPE. Replace if damaged or out of test date Use approved and tested tools and equipment • Ensure correct PPE is worn at the workplace • Plan and implement a safe approach to switching and the location of portable earths Western Power Safe Work Method Statement – Install and Maintain HV Overhead Equipment and Associated Hardware (de-energised) ESSP sections: 3; 5; 6 WPM sections: 2; 3; 5.9; 5.10; 6.2; 6.8; 6.9; 11 L Distribution Construction Standards Handbook (DCSH) ESSP sections: 3; 4.7; 5; 6 page 3 of 5 Steps required to perform the task, in the correct sequence (NOCC) / issuing officer • Electrical apparatus isolated, tested, earthed and tagged • Electrical Access Permit (EAP) issued to Recipient in Charge (RIC) • All staff sign onto EAP Carry out the task Install or maintain HV overhead equipment – deenergised (as appropriate for the particular task) Remove old overhead equipment • Ensure all signed onto EAP and know what to do and how to do it • Apply covers (if required) • Unlash, spread and support conductors (if required) • Remove old equipment and hardware • Identify phasing (if required) Install new overhead equipment • Ensure overhead equipment is installed correctly • Ensure all hardware is correctly secured • Replace conductors and resecure (if required) Hazards for each task step shock, burns, injury • Failure to observe the minimum approach distance (MAD): shock, burns, injury • Operating / switching the wrong apparatus: shock, burns, injury • Incorrect / ineffective earthing: shock, burns • Failure to test: shock, burns • Contact with live apparatus: shock, burns • Induced / capacitive voltages: shock, burns • Uneven / slippery surfaces: strain, sprain, injury • Damaged or faulty plant and equipment: injury • • • • • • • • • • • • • • • Failure to wear correct PPE: shock, burns, injury Unfit for work: injury, harm Working at heights; injury from falls Vehicle / equipment movement; injury Failure to test before touching; shock, burns, injury Contact with live electrical apparatus; shock, burns, injury Induced / capacitive voltage: shock, burns Apparatus / equipment / tool failure: injury Incorrect use of tools and equipment: injury Manual handling: strain, sprain, fatigue, injury Slip, trip, fall, obstacles; injury Objects / equipment falling: injury Conductor failure: injury Damaged / faulty apparatus: injury Fires: injury, burns, harm Initial Risk Rating H H Control required to eliminate or minimise the risk of injury • Maintain contact with NOCC / issuing officer • Confirm switching program with NOCC • Confirm correct apparatus / switch number before switching commences • Inspect test equipment and apparatus before operation / use • Use a competent safety observer • Avoid distractions during switching • Confirm correct equipment has been isolated • Test the apparatus is de-energised before applying earths • Apply correct locks and tags at isolation points • Apply program earths to both sides of worksite and tag • Confirm that all staff have signed onto the EAP • All staff understand the conditions of the EAP and are aware of the boundaries of the work area • All staff understand their allocated tasks and roles • All staff are aware of the risk from induced voltages and to use additional working earths – if required • Ensure correct PPE is worn by all at the workplace • Confirm all staff have signed onto the EAP and are aware of conditions and any limitations • Ensure safety observer is aware of safe working clearances and emergency descent procedures • Inspect and wear fall arrest harness • Check the condition of pole, cross arm and electrical apparatus • Support pole (if required) • Check conductor weight • Ensure safe crane / lifting techniques are used (if applicable) • Only trained staff are to operate tools and equipment • Use tools and equipment approved for the task • Maintain safe working clearances • Operate the EWP, tools and equipment within safe working limits • Use stabilisers, pads, wheel chocks (if applicable) • Earth EWP and crane (if required) • Use working earths to avoid induced voltages (if applicable) • Apply correct manual handling techniques, use mechanical means where possible Western Power Safe Work Method Statement – Install and Maintain HV Overhead Equipment and Associated Hardware (de-energised) Controlled Risk Rating References WPM sections: 2; 3 L ESSP, sections: 5; 6; WPM , sections: 2; 3; 6; 8; 11 Distribution Construction Standards Handbook (DCSH) L Network Standard 07 / 2011 Testing and Commissioning, (DM# 7892458) page 4 of 5 Steps required to perform the task, in the correct sequence Hazards for each task step Initial Risk Rating Control required to eliminate or minimise the risk of injury Controlled Risk Rating References • Keep area below workplace clear • Ensure fire fighting equipment, and people competent to use it are at the workplace while work is carried out • Continually review potential hazards and control methods Maintain HV overhead equipment • Check hardware and carry out maintenance as per instructions / manual • Carry out tests and record results (if required) Complete the task • Inspect work for completion and compliance to DCSH) • Complete tests and documentation (if required) • Remove ladder(s), EWP and crane / borer (if applicable) • All staff and equipment removed from electrical apparatus • Clean, inspect and stow tools and equipment • Reinstate site (if required) • Sign off EAP and communicate with NOCC / issuing officer • Remove all working and program earths • Re energise network according to switching program • Conduct debrief and sign off WRAP • Failure to wear correct PPE: shock, burns, injury • Contact with live electrical apparatus: shock, burns, injury • Vehicle and equipment movement: injury • Unstable ground rollover: injury • Uneven / slippery surfaces / obstacles: slip, trip, injury • Incorrect manual handling techniques: strain, sprain, injury • Plant / equipment failure: injury • Unsecured loads: injury • Failure to ensure all staff sign off the permit and understand the changed conditions • Restoring / working on incorrect apparatus: shock, burns, injury • Incorrect switching technique: strain, sprain, injury • Missed hazards and improvements • • • • • • • • H • • • • • • • • • • • Relinquish traffic management (if used) • Vehicle movement: injury • Unauthorised workplace access: injury M Ensure correct PPE is worn Inspect work for completion and compliance Maintain safe working clearances Remove all staff, tools and equipment from the electrical apparatus Inspect workplace. Remove all material / waste Apply correct manual handling techniques, use mechanical means where practicable Use correct load restraining devices (if applicable) Ensure the working party signs off the EAP and understand it is to be cancelled Sign off the WRAP and discuss any issues with the team All staff involved in debrief. Document suggestions Communicate with NOCC / Issuing Officer Plan and implement a safe approach to removal of earths and switching Confirm correct apparatus / switch number before restoration commences Inspect test equipment and apparatus before operation / use Avoid distractions during switching Ensure correct tags and locks are applied / removed Confirm network status at workplace Carry out and document required tests to prove compliance Continually review potential hazards and control methods • Maintain traffic management until all personnel and equipment have left site • Remove all signs and barriers to restore traffic flow Western Power Safe Work Method Statement – Install and Maintain HV Overhead Equipment and Associated Hardware (de-energised) ESSP sections: 3; 4.7; 5; 6 WPM sections: 2.2; 2.8; 2.9; 2.10; 2.15; 3, 8; 11 Distribution Construction Standards Handbook (DCSH) L Network Standard 07 / 2011 Testing and Commissioning, DM: 7892458 L WPM section: 2.21 page 5 of 5