View PDF File

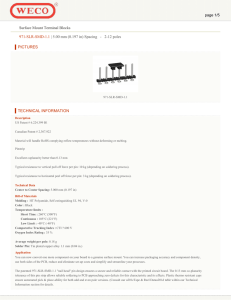

advertisement