Liquid Filled Gauges - Marsh Bellofram Europe Ltd

advertisement

Liquid Filled Gauges

• 40 mm 50 mm Filled Gauges

40 / 50 mm Liquid Filled Gauges

Marsh Instruments liquid filled gauges are designed to perform

in rugged and harsh environmental conditions where pulsation

and vibration is a problem. Liquid filled gauges offer a significant cushioning and dampening effect, reducing pointer flutter

and internal gauge damage. Liquid-filled gauges feature a vent

/ filling plug in the top and can be mounted on a horizontal or

vertical plain. The hermetically sealed construction reduces the

chance of leaks and makes field filling an easy option.

Specifications

Generally to EN-837 –1

Standards

40 or 50 mm Diameter

Case Size

ST/ST with either Brass bronze internals or All ST/ST

Construction

Bottom, centre back or panel mount U Clamp

Entry

Various, as required

Connection

Various, as required

Range

Dual range, PSI / BAR with batch no and class

Dial Standard

Cl 2.5 FSD at ambient temperature

Accuracy

Acrylic

Window

Glycerine standard or Silicone

Fill medium

- 40 to + 85 Deg C

Temp specs

Filler / pressure relief plug

Vent

We can offer various ranges

Non std dial

Glycerine Filling Plug

Glycerine Filling Plug

• Robust and IP65

• Glycerine filled for dampening

40 / 50 mm Liquid Filled Gauges

Construction

304SS case

316SS internals

304SS case

Brass/bronze internals

33

93

Mounting

1

6

8

Bottom

Back

U Clamp

Connection Size

K

W

Z

A

D

L

1/8" BSPT

1/8" BSP

1/8" NPT

1/4" BSP

1/4" NPT

1/4" BSPT

Range PSI / BAR

00

01

18

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Special Range

Vacuum

15 PSI / 1 BAR

30 PSI / 2 BAR

60 PSI / 4 BAR

100 PSI / 7 BAR

160 PSI / 11 BAR

200 PSI / 14 BAR

300 PSI / 20 BAR

400 PSI / 27 BAR

600 PSI / 40 BAR

800 PSI / 55 BAR

1000 PSI / 70 BAR

1500 PSI / 100 BAR

2000 PSI / 140 BAR

3000 PSI / 200 BAR

4000 PSI / 275 BAR

5000 PSI / 344 BAR

6000 PSI / 413 BAR

10,000 PSI / 690 BAR

Case Diameter

C

D

40 mm

50 mm

Special Requirements

P

S

G

PC

001

16

316

Glycerine

Silicone Filled

Glass Window

Plated Connection

Non Standard Dial

Cl 1.6 Enhanced Accuracy

316 SS Case

Some configurations may not be possible, please consult factory.

9 Castle Park Queens Drive , Nottingham NG2 1AH England

Tel: (44) 115 993 3300

e-mail: bellofram@aol.com

Fax: (44) 115 993 3301

www.marshbellofram.com

LTUK09001

Liquid Filled Gauges

• Brass or Stainless Steel Internals

63 mm Liquid Filled Gauges

Marsh Instruments Liquid Filled Gauges are designed to perform

in rugged applications and harsh environmental conditions

- especially where pulsation and vibration are a problem. Liquid

Filled Gauges offer a significant cushioning and dampening effect, reducing pointer flutter and internal gauge damage; also

lubricating the internals, and reducing corrosion. All stainless

steel Liquid Filled Gauges feature a ventable top fill plug for

pressure relief and ease of venting after installation. The hermetically sealed construction reduces the chance of leaks, and

makes field filling an easy option.

Typical applications include refineries, chemical plants, offshore

platforms, oil rigs, marine applications, general industrial application and OEM processes.

Specifications

Standards

EN837-1

Case Size

63MM

Construction

304 ST/ST Case with Brass or ST/ST Internals

Entry

Bottom or Back or U Clamp

Connection

NPT-BSPP-BSPT-1/8-1/4-3/8-1/2

Range

from Vac to 15000 Psi

Dial Standard

PSI / BAR

Accuracy

Cl 1.6

Window

Acrylic - Safety Glass as an option

Fill medium

Glycerine , Silicone as an option

Temp specs

0 TO 60 deg C Standard

Vent

Filler plug / blow out vent

PRESSURE RELIEF PLUG

1.06

[26.9]

• Glycerine filled for dampening

63 mm Liquid Filled Gauges

Case

J

ST/ST

Mounting

76

64

72

78

66

74

Brass Bottom

Brass Back

Brass Panel Mount

All ST/ST Bottom

All ST/ST Back

All ST/ST Panel

Ranges

05

40

42

46

48

52

54

58

60

64

72

74

76

78

80

82

84

90

30 " Vacuum

15 PSI / 1 BAR

30 PSI / 2 BAR

60 PSI / 4 BAR

100 PSI / 7 BAR

160 PSI / 11 BAR

200 PSI / 14 BAR

300 PSI / 20 BAR

400 PSI / 27 BAR

600 PSI / 40 BAR

1000 PSI / 70 BAR

1500 PSI / 100 BAR

2000 PSI / 140 BAR

3000 PSI / 200 BAR

4000 PSI / 275 BAR

5000 PSI / 344 BAR

6000 PSI / 413 BAR

10,000 PSI / 690 BAR

Connection & Options

PM/999

P/NPT

P/BSP

SG

RP

RC

001

Brass, any connection

All ST/ST in NPT Filled

All ST/ST in BSP Filled

Safety Glass

Red Pointer

Rubber Cover

Speical dial / range

Some configurations may not be possible, please consult factory.

PRESSURE RELIEF PLUG

1.03

[26.2]

• Ranges to 10,000 PSI

.95

[24.1]

.25

[6.4]

2.66

[67.6]

2.66

[67.6]

2.4

[61.0]

2.2

[55.6]

9/16 HEX

[14.0 HEX]

1/4 NPT

9/16 HEX

1/4 NPT

.37

[9.4]

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300

e-mail: bellofram@aol.com

Fax: (44) 115 993 3301

www.marshbellofram.com

LTUK09002

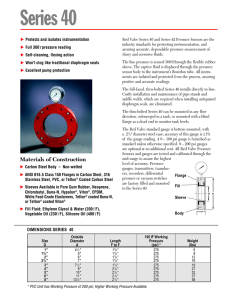

Pneumatic Gauges

• 40mm / 50mm / 63mm Available

• Dual Scale

Pneumatic Gauges

• BSP-BSPT-NPT Connection

Pneumatic Gauges

Marsh Instruments Pneumatic gauges are designed for industrial use and are suitable for gaseous and liquid media that will not

obstruct the pressure system or attack the brass/ bronze internals they are ideal for use in hydraulic and pneumatic systems

where there is no vibration evident.

Typical applications include FRL’s . Regulators , Compressors ,

Pumps and Water Systems

Specifications

Standards

Case Size

Construction

Entry

Connection

Range

Dial Standard

Non Standard Dial

Window

Temp specs

Accuracy

Construction

33

93

99

All ST/ST

ST / ST

Steel

Mounting

1

6

8

Bottom

Back

U Clamp

Connection Size

A

D

K

W

Z

L

Generally to En 837-1

40mm / 50mm and 63mm

Brass internals see Table for case options

Bottom , Center Back

See Table

See Table

PSI / BAR Dual Scale options are available

Options are available

Push in Clear Acrylic

- 40 + 60 ˚C

2.50 %

1/4" BSP

1/4" NPT

1/8" BSPT

1/8" BSP

1/8" NPT

1/4" BSPT

Range PSI / BAR

Special Range

(High Pressure Available)

Vacuum

15 PSI / 1 BAR

30 PSI / 2 BAR

60 PSI / 4 BAR

100 PSI / 7 BAR

160 PSI / 11 BAR

200 PSI / 14 BAR

300 PSI / 20 BAR

00

01

18

20

21

22

23

24

25

Case Diameter

C

D

E

40 mm / 1.5 "

50 mm / 2"

63 mm / 2.5"

Special Requirements

G

R

RP

1

BCL

Glass Window

Restrictor Fitted

Red Pointers

Special dial and logo

Bright Bezel

Some configurations may not be possible, please consult factory.

Dial Size

40mm

50mm

63mm

A

40

50

63

B

26

29

30

C

18

21

25

D

11

14

14

E

38

50

55

F

7

9

9

J

26

30

32

K

5.5

5.5

5.5

L

16

22

22

M

47

57

70

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300

e-mail: bellofram@aol.com

Fax: (44) 115 993 3301

www.marshbellofram.com

LTUK09003

Process Gauges

Process Gauges

Marsh instruments process gauges are manufactured for

industrial use and are suitable for gaseous and liquid media that

will not obstruct the pressure system. They are manufactured

using a heavy duty 304 stainless cases and a bayonet lock bezel.

The instruments can be filled to dampen the effect of vibration

and are suitable for use in various applications such as Petrochemical, Chemical, Food and Beverages.

Specifications

Standards

Generally to EN 837-1

Case Size

100mm / 160mm and 250mm

Construction

Brass and Stainless internals

Entry

See Table

Connection

Bottom or Bottom Back

Range

See Table

Dial Standard

PSIG / BAR

Window

Glass Std -- Acrylic available

Temp specs

- 40 + 60 degrees C

Accuracy

1 % Std 0.60% available

Process Gauges

Construction

33

93

99

38

All ST/ST

Brass

Steel

All ST/ST F. S. P.

Mounting

1

4

6

8

Bottom

Surface

Back

3 Hole Pane Mtg.

Connection Size

E

G

J

P

DM/V, SM/V

63

100

160

250

• 100/160/250mm Available

• Heavy duty with Bayonet

Lock Bezel

• Dry or Filled

• Ranges Vacuum to 1000 BAR

Available

D

D1

D2

D3

L1

L3

L4

F1

F2

S1

SW

99

159

250

101

161

253

132

192

289

118

178

276

52

52

55

58

58

58

5.5

5.5

3.0

15

15

16

90

119

164

5.5

6

6.5

22

22

22

3/8" BSP

1/2" BSP

1/2" NPT

3/8" NPT

Range PSI / BAR

00

01

18

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Special Range

Vacuum

15 PSI / 1 BAR

30 PSI / 2 BAR

60 PSI / 4 BAR

100 PSI / 7 BAR

160 PSI / 11 BAR

200 PSI / 14 BAR

300 PSI / 20 BAR

400 PSI / 27 BAR

600 PSI / 40 BAR

800 PSI / 55 BAR

1000 PSI / 70 BAR

1500 PSI / 100 BAR

2000 PSI / 140 BAR

3000 PSI / 200 BAR

4000 PSI / 275 BAR

5000 PSI / 344 BAR

6000 PSI / 413 BAR

10,000 PSI / 690 BAR

Case Diameter

H

J

K

80 mm / 3"

100 mm / 4"

160 mm / 6"

Special Requirements

P

Glycerine Filled

Some configurations may not be possible, please consult factory.

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300

e-mail: bellofram@aol.com

Fax: (44) 115 993 3301

www.marshbellofram.com

LTUK09004

63mm FSP Gauges

•

•

•

•

63mm FSP Gauges

Marsh full safety pattern gauges are manufactured generally

to BS -EN837-1 (S3). Manufactured with 316 wetted parts these

instruments can be supplied dry or filled with either glycerine or

silicone.

All options can be supplied with dials printed to customer

requirements. Typically used in applications where increased

safety is required and on gaseous and liquid media that are not

viscous or crystallizing .

63mm FSP Gauges

Construction

38

All ST / ST

Mounting

1

Bottom

Connection Size

A

1/4 BSPP

D

1/4 NPT

Range PSI / BAR

Specifications

Standards

Generally to EN837-1

Case Size

63 mm

Construction

304 ST/ST Case - 316 Wetted Parts

Entry

Bottom

Connection

See Table

Range

See Table

Dial Standard

PSI / BAR Dual Scale

Accuracy

1 - 60 %

Window

Safety

Fill medium

See Option

Temp specs

-40 +60˚C Dry

-20 +60˚C Filled

Vent

Blow Out Back

D

63

Solid Baffle Wall

Laminated Safety Glass Window

All Stainless Steel Construction

BSP and NPT Connections

D1

F2

L1 SW

63 63.5 59 40 14

20

30

21

60

22

100

23

160

24

200

25

300

26

400

27

600

29

1000

30

1500

31

2000

32

3000

33

4000

34

5000

35

6000

36

10,000

Case Diameter

E

63 mm

Special Requirements

P

Filling

I

Special Dial

Some configurations may not be possible, please consult factory.

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300

e-mail: bellofram@aol.com

Fax: (44) 115 993 3301

www.marshbellofram.com

LTUK09005

Medical Gauges

Marsh produces a wide range of specialist

pressure and temperature gauges for the

medical equipment industry. These range

from simple standard gauges fitted with

custom dial faces to complete specials

designed for specific applications.

The applications are varied and there are

always new challenges to solve presented

to us but the current and past applications include the following:

• Compound Gauges (pressure and

vacuum) for respirator and critical

care devices

• Supply pressure gauges for the above

and anesthesia machines

• Contents gauges for portable

medical gases

• Gauges for medical gas regulators

and distribution systems

• Pressure gauges for angioplasty pumps

• Ambulance applications

• Suction pumps and controllers

• MRI scanners

• Insulflators

• Autoclave temperature gauges

The Marsh range includes capsule gauges

for high accuracy low pressure and vacuum applications, bourdon tube gauges for

general and high pressure applications,

cleaned gauges and isolated gauges for

speciality/hazardous gases and liquids, bimetallic and vapour pressure gauges with

pockets or capilliaries for temperature

measurement.

Our gauges are available in sizes ranging from 25mm dia to

160mm dia in various accuracies and configurations.

We manufacture them in a wide range of materials including

stainless steel, brass, steel and plastic and can supply dial faces

with special scales and company logo’s

Marsh Bellofram Group also make specialist electronic and

manual gas/air pressure regulators for the medical equipment

market for use in many of the above and other fields as well

as rolling diaphragm seals for medical applications.

9 Castle Park Queens drive , Nottingham NG2 1AH England

Tel: (44) 115 993 3300

e-mail: bellofram@aol.com

Fax: (44) 115 993 3301

www.marshbellofram.com

LTUK09007

Brass Gauges

Series 904 Solid Brass Gauges

•

•

•

•

•

Solid Brass Case

Dry

Ranges Vacuum to 600 psi

Three Hole Surface Mount

Removable Back Plate

Standard Ranges and Part Numbers

Marsh Instruments Solid Brass Gauges were primarily built for

the standard commercial market. They are also ideal for use in

applications where appearance is important such as steam or

boat enthusiasts who are looking for something that is aesthetically suited to their requirements. Built with a full size bourdon

tube and a removable back plate the Marsh Solid Brass Gauge is

a robust instrument that can be recalibrated easily if required.

0 - 30 VAC/Hg

904E01J

0 - 15 psi/BAR

904E18J

0 - 30 psi/BAR

904E20J

0 - 60 psi/BAR

904E21J

0 - 100 psi/BAR

904E22J

0 - 160 psi/BAR

904E23J

0 - 200 psi/BAR

904E24J

0 - 300 psi/BAR

904E25J

0 - 400 psi/BAR

904E26J

0 - 600 psi/BAR

904E27J

Specifications

Accuracy

+/- 1% with reference to EN 837

Case Size

100 mm (4")

Case Material

Solid back - Laquered

Bezel

Polished & laquered brass

Case Style

3 hole surface mount

Removable back plate

Back Plate

Movement

Black alloy, removable

Full 4" bourdon tube

& brass Block

Brass

Connection

3/8" bsp parallel

Ranges

Vacuum to 600 psi/Bar

Dial Standard

Dual scale psi/bar or to

Customer specifications

Dial Color

Black markings on white

Pointer

Black aluminium

Window

Acrylic

Note

Not suitable for temperatures

above 80˚C

Tube & Block

Some configurations may not be possible, please consult factory.

9 Castle Park Queens drive , Nottingham NG2 1AH England

Tel: (44) 115 993 3300

e-mail: bellofram@aol.com

Fax: (44) 115 993 3301

www.marshbellofram.com

LTUK09008

Train Industry Full Range

Marsh Bellofram supply the Train Industry with a range products that

include air operated horns, horn operating valves and pressure gauges.

To compliment these we also offer an extensive repair, refurbishment

and certification programme of either Marsh Bellofram products or

those that are manufactured by other companies.

Air Horns

Marsh Bellofram supply a range of air

operated horns designed for installing into

locomotives. They can be used to warn of

potential hazards in areas such as mines,

large buildings and process plants.

Robustly constructed in aluminium or brass

they require a supply of compressed air and

operate Using a low consumption of air.

The Horns that Marsh Bellofram supply can

be operated in all weather conditions and

give years of trouble free service.

Air Horn Valve

Marsh Bellofram supply an Air Horn Control

Valve that can be used to control any two

way pneumatic alarm of a railway vehicle

and is operated by the driver using a Lever

that returns to the a central position when

released and mounted on the control desk in

the cabin

Locomotive Gauges

Marsh Bellofram are a leading manufacturer

of pressure and temperature instruments

some of which are specifically designed for

use in the manufacturing of locomotives.

Repairs

Marsh Bellofram instruments are used

throughout the world where accuracy and

dependability are a priority

Repair and Refurbishment

To compliment our products we also offer an

extensive repair, refurbishment and certification programme of either Marsh Bellofram

products or those that are manufactured by

other companies.

2 Way Valve

4" Gauge

6" Gauge

KS1

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300

e-mail: bellofram@aol.com

Fax: (44) 115 993 3301

www.marshbellofram.com

KS2

LTUK09009

Diaphragm Seal Gauges

Description

A diaphragm seal is a separator connected to

either directly or via a capillary tube, to the

pressure gauge to isolate it from the process

fluid. They are also known as chemical seals,

barrier seal or fluid separators.

These are used when; The process fluid can

solidify or crystallize; When the process contains solid matter, or has a high viscosity;

When the process fluid could corrode the measuring element.

Operation

The diaphragm seal consists of an elastic element, [diaphragm] that isolates the process

material from the pressure gauge element,

transmitting the pressure through the compression of the filling medium to the gauge.

Connection

Direct mounting, or remote reading via a capillary tube. [Maximum length 15 metres.]

Fitting

Specifications: Stainless Threaded Diaphragm Seals

Seal

Diaphragm

Working

Temperatures

Connection

Transmission Fluid

Accuracy

316 Stainless Steel

316 Stainless Steel

(deg.C): Max: 150 Min: -20

Flanged: BS, DIN, ANSI

White Food Oil

1% direct reading, 1.5% remote reading (20 deg C)

Diaphragm seals must be connected to the

process by tightening using the spanner flats

on the seal, and not by the gauge. On remote

reading gauges, if the gauge is to be fitted

higher than the seal, a feet head allowance

should be made.

Specifications: Stainless Bolted Diaphragm Seals

Upper Chamber

Lower Chamber/

Flange

Diaphragm

Bolts

Seals

Working

Temperatures

Connection

Transmission Fluid

Accuracy

316 Stainless Steel

6 off m6 bolts

316 Stainless Steel

316 Stainless Steel

304 Stainless Steel

Viton Rubber

(deg. C ):- Max: 150 Min: -20

Flanged: BS, DIN, ANSI

White Food Oil

1% direct reading, 1.5% remote reading (20 deg C)

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09010

Hygienic Diaphragm Seals

Description

These Hygienic seals are manufactured with a 316

stainless steel body and diaphragm which is flush

welded to meet the needs of the food, dairy, brewing and other industries, that requires no unnecessary contamination from bacteria traps.

The design is free of dead space, making the gauges

easy to clean and hygienic.

Transmission of pressure to the gauge, from the

seal, is from a nontoxic liquid, (approved food oil is

our standard) or silicon fluid. The gauges can be fitted directly or remotely, via a capillary tubing, maximum length 10 metres.

Transmission Fluid

Glycerine

White Food Oil

Silicon Fluid

-10 to + 70˚C

-20 to + 140˚C F.D.A. approved

DC 200/10; -30 to +180˚C

Fittings

IDF RJT SMS DIN11851

Above fittings are available in either a fixed, 316

stainless steel male seal, or a 316 stainless steel seal

with a 304 stainless steel running nut. Nominal sizes

1.5" &2.0", others on request.

HY/RJT/F

Size

1.5

2

A

1/2G

1/2G

B

10

10

C

16

16

D

22

25

A/F

65

76

B

10

10

C

16

16

D

30

30

A/F

60

70

HOMOGENIZERS

Available with or with out clamping block, with

either a button diaphragm or a fish tale tube.

THREADED SEAL

BSP or NPT, male, or female thread Sizes -3/4", to 2".

TRI-CLAMP

A quick-release seal. Available with or without the

clamp and/or bottom ferrel. Sizes, -1 - 1.5" & 2".

FISH TAIL SEAL

316 stainless steel tube seal, fittings available; 1/2",

3/4", BSP male fixed or swivelling, 1" BSP female

swivelling nut.

PAPER SEAL

Standard with loose flange fitting, or specials, also

fixed flange machined from solid.

Size

1.5

2

A

1/2G

1/2G

HY/SMF/F

Size A

B

1.5

1/2G 10

2

1/2G 10

Accuracy

±1% @ 20˚C for direct reading

±1.5% @ 20˚C for remote reading

Working

Fitting

Temperature

Direct Fitting

+ 15 to +25˚C

Remote Fitting

Direct Fitting

+ 5 to +15˚C

+25 to +50˚C

Remote Fitting

Direct Fitting

-30 to +15˚C

+25 to +50˚C

Remote Fitting

Direct Fitting

+100 to +250˚C

Remote Fitting

HY/IDF/F

Final

Accuracy

1.0%

1.5%

1.5%

2.0%

2.5%

3.0%

3.0%

3.5%

C

16

16

D D2 SLOTS

25 74 5 x 8mm

26 84 5 x 8mm

HY/SMF/F

Size A

B

1.5 1/2G 10

2

1/2G 10

C

16

16

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

D D2 SLOTS

25 72 4 x 10mm

26 92 4 x 10mm

LTUK09011

Bimetal Thermometer

Description

Stainless steel bi-metal industrial dial thermometer

Model SBT/V SBT/B

According to BS EN 13190 Nominal sizes, 63, 100,

160 and 250 mm Accuracy: Class 1

Features

Rugged stainless steel case construction

Specifications:

Bayonet locking case and bezel

Dial Size

Construction

Measuring Element

Ranges {deg C}

Over-range limit

Material Construction

Stem / Bulb

Protection to IP65

Usable over 90% of l scale

Bimetal coiled element

Over-range protection 130%

(max 500 deg C)

Ranges

Stem / Bulb dia (mm)

From -60 to + 500 deg C.

Case / Bezel ring

Window

Applications

Dial

Heating and ventilation industry

Machine and apparatus construction

Pointer

Movement

D

D1

B

C

D

E

F

G

H

100

40

4

47

6

47 30

15

90

40

160

40

4

47

6

47 30

15

119

40

250

40

7

49

6

49

16

164

40

63

31

Accuracy

Permissible

Ambient Temperature

Protection

Filling Liquid

Mountings

Weight dry / filled {kg}

Accessories

SBT/V

SBT/B

63

100

160

250

Flush fitting bayonet locking case and bezel.

Bimetallic Coil

See table SBT

130% full scale....short periods. (Max 500 deg C)

316 Stainless Steel

6, 8, 10, 12 mm. 1/4, 3/8, 1/2 in....max length.

800mm

Stainless steel AISI 316L

Glass and Acrylic

Aluminium, black figures on white...optional...

steel...other colours

Aluminium, black,...optional...micro adjustment,...

steel

Direct drive on back entry. Copper flat wire spring

on bottom entry

Class 1 (1% F.S.D.)

+10, +30 Degree C

Max. 0,3% / 10 Deg C

EN 60 529 IP65

Silicone (SI)

Direct bottom, direct centre back

0.8 / 1.0

1.4 / 2.3

1.9 / 2.6

Index pointers, Fitting, Thermowell

2.3 / 4.2

All specifications are subject to change without notice

Minimum Stem Lengths

Stem

Range C˚

60

80 100 120 160 200 250 300 400 500

6mm

65 100 100 65 65

65

65

65

65

65

8mm

65 100 100 65 65

65

65

65

65

65

10mm

100 100 100 65 65

65

65

65

65

65

12mm

100 n/a n/a 65 65

65

65

n/a

65

n/a

1/4 in.

65 100 100 65 65

65

65

65

65

65

3/8 in.

100 100 100 65 65

65

65

65

65

65

1/2 in.

100 n/a n/a 65 65

65

65

n/a

65

n/a

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09012

Any Angle Thermometers

Specifications:

Description

SBT/AA

According to BS EN 13190

Dial Size

Nominal sizes, 100 and 160 mm

Construction

Flush fitting bayonet locking case and

bezel.

Measuring Element

Ranges {deg C}

Bimetallic Coil

See table SBT1

Over-range limit

130% full scale....short periods. (Max 500

deg C)

Accuracy: Class 1

Features

Rugged stainless steel case construction

Bayonet locking case and bezel

Usable over 90% of l scale

Bimetal coiled element

From -60 to + 500 deg C.

Stem / Bulb dia (mm)

6, 8, 10, 12 mm. 1/4, 3/8, 1/2 in. max

length. 800mm

Dial

Applications

Heating and ventilation industry

Machine and apparatus construction

B

316 Stainless Steel

Window

(max 500 deg C) Ranges

A

Stem / Bulb

Case / Bezel ring

Over-range protection 130%

D1

C

160

Material Construction

Protection to IP65

D

100

E

F

G

63

100

99

101

80

28

50

20

45

100

160

158 158

80

28

50

20

45

100

Stainless steel AISI 316L

Instrument glass standard, lamited safety

glass or acrylic optional

Aluminium, black figures on white...

optional, steel, other colours

Pointer

Aluminium, black, optional micro adjustment, steel

Movement

Stainless flat wire spring in a 304 stainless

flexible.

Accuracy

Permissible

Ambient Temp.

Temperature Effect

Protection

Filling Liquid

Class 1 (1% F.S.D.)

Degree C

+10 +30

Max. 0,3% / 10 Deg C

EN 60 529 IP65

Silicone (SI)

Mountings

Fully adjustable and rotatable thru 90

degrees.

Weight dry / filled {kg}

Accessories

1.1 / 1.4

1.3 / 1.9

Index pointers, Fitting, Thermowell

All specifications are subject to change without notice

Minimum Stem Lengths

Stem

Range C˚

60 80 100 120 160 200 250 300 400 500

6mm

100 100 100 65 65

65

65

65

65

65

8mm

100 100 100 65 65

65

65

65

65

65

10mm

100 100 100 65 65

65

65

65

65

65

12mm

100 n/a n/a 65 65

65

65

n/a

65

n/a

1/4 in.

100 100 100 65 65

65

65

65

65

65

3/8 in.

100 100 100 65 65

65

65

65

65

65

1/2 in.

100 n/a n/a 65 65

65

65

n/a

65

n/a

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09013

Capsule Gauges

Description

Stainless steel case low range capsule gauge

Models: SSC / CAP

ST/CAP

According to DIN EN 837-3

Nominal sizes: 63, 100, 160 and 250 mm

Accuracy: Class 1,6

Construction

These heavy duty industrial gauges, are manufactured with either a mild steel or aluminum case and

bezel, [black epoxy coated], or with a stainless steel

case and bezel.

General construction is with a brass, bar type movement, fully adjustable, beryllium copper capsule

with brass connection block. Alternatively, for the

more aggressive environment, a stainless steel connection and capsule is available

Operation

Atmospheric is used as the reference pressure.

Changes in the measuring pressure causes the capsule to expand, this expansion is in proportion to the

applied pressure, this is then transmitted to the instrument pointer by means of a fine precision movement. This is then indicated as a deflection on the

gauge dial.

Features

Rugged stainless steel case construction

Bayonet locking case and bezel

Protection to IP54

Usable at full scale

Beryllium or stainless steel capsule

Over-range protection 130% Ranges

0 - 25 mbar. Up to 0....600 mbar 0 - 10 IN.WG.

Up to 0...250 IN..WG.

Application

For use in the measurement of low pressure and

vacuum gases, which are compatible with the gauge

materials.

Specifications:

Dial Size

Construction

Measuring Element

Ranges {mbar}

Over-range limit

Process Connection

Material Construction

Process Connection

Capsule Beryllium

Window

Dial

Pointer

Movement

Accuracy

Permissible

Ambient Temperature

Process Temperature

Storage Temperature

Temperature Effect

Protection

Filling Liquid

Mountings

Weight dry {kg}

Accessories

SSC/CAP

ST/CAP

63

100

160

250

Flush fitting bayonet locking case and bezel.

Capsule

Pressure, vacuum or compound ranges. 0 -25. 40 .

60. 100.

130% full scale, short periods

1/4 npt, 1/2 npt, according to ANSI/ASME B1.20.1

1/4 bsp, 3/8 bsp, 1/2bsp according to EN837

Brass or Stainless steel AISI 316L

Copper or Stainless steel AISI 316L Case / Bezel

ring Stainless steel AISI 304L.

Instrument glass standard , lamited safety glass or

acrylic optional

Aluminium, black figures on white, optional other

colours

Aluminium, black, balanced

Brass Optional. Stainless steel 304

Class 1.6 (1.6% F.S.D.) Optional class 1 (1%)

Degree C

-15 +50

Min. -20 Max +65

-20 +60

Max. 0,3% / 10 Deg C

EN 60 529 IP54

N/A

Direct bottom, direct back, surface, flush panel,

panel fixing

0.3

1.0

1.4

2.6

Snubber screw, special dial, red setting pointer,

special connection

All specifications are subject to change without notice

Petrochemical and chemical Food and Beverage Gas

Industry Machine and apparatus construction

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09014

Brass Case Absolute Gauges

Description

Brass case absolute capsule gauge

Models BRC / ABS

Specifications:

According to DIN EN 837-3

Dial Size

Nominal sizes, 100, mm Accuracy: Class 2

Construction

Features

Brass case construction, from bar stock.

Barometrically Compensated

Screw locking case and bezel,

6 bar gauge overange protection.

Protection to IP65

Usable at full scale

Inconel capsule

Measuring Element

Ranges {mbar}

Over-range limit

Process Connection

Material Construction

Process Connection

Capsule

Case / Bezel ring

Window

Dial

Ranges

0 - 25, 0 -50, 0 -125, 0 -160, 0-1000 mbar

Applications

Petrochemical and chemical

Food and beverage

Gas industry

Machine and apparatus construction

Pointer

Movement

Accuracy

Permissible

Ambient Temperature

Process Temperature

Storage Temperature

Temperature Effect

Protection

Filling Liquid

Mountings

Weight dry {kg}

Accessories

BRC/ABS

100

Screw fitting case and bezel machined from brass

bar stock

Evacuated Capsule

0 - 25, 0 -50, 0 -125, 0 -160, 0-1000

130% full scale. short periods

1/4 npt, 1/2 npt, according to ANSI/ASME B1.20.1

1/4 bsp, 3/8 bsp, 1/2 bsp according to EN837.

KN16. KN20.

Brass

Inconel

Brass

Toughened Instrument glass

Aluminium, black figures on white, optional, other

colours

Aluminium, black, balanced

Brass

Class 2 (2% F.S.D.)

-15 +50 Degree C

Min. -20. Max. +65

-20 +60

Max. 0,5% / 10 Deg C

EN 60 529 IP65

N/A

Direct bottom, direct back, flush panel, all in one

design

2.2

Snubber screw, special dial, special connection

All specifications are subject to change without notice

BRC

304 BRASS

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09015

Capsule Differentials Gauges

Description

Stainless steel case low range capsule gauge Models SSC / CAP/DIF ST / CAP/DIF

According to DIN EN 837-3 Nominal sizes, , 100 and

160 mm Accuracy: Class 1,6

Specifications:

Rugged stainless steel case construction

Dial Size

Construction

Measuring Element

Bayonet locking case and bezel

Ranges (m bar)

Protection to IP65

Over-range limit

Features

Usable at full scale

Beryllium or stainless steel capsule

Over-range protection 130%

Ranges

0 - 10 mbar. up to 0....600mbar 0 - 4 N.WG. up to

0...250 IN..WG.

Applications

Petrochemical and chemical Pressure drops across

filters Gas industry Machine and apparatus construction

SSC/ CAP / DIF

Process Connection

Material Construction

Process Connection

ST / CAP / DIF

63

100

160

Flush fitting bayonet locking case and bezel.

Capsule

0 -10. 16. 25. 40. 60. 100. 160. 250. 400. 600. In

either pressure or vacuum.

Beryllium copper, 130% short period

316 stainless steel 115% short period

1/4bsp, 3/8bsp, 1/2 bsp according to EN 837 1/4npt,

1/2 npt according to ANSI/ASME B1.20.1

Brass

316 SS

Capsule

6, 8, 10, 12 mm. 1/4, 3/8, 1/2 in max length. 800mm

Case / Bezel Ring

Stainless steel AISI 316L

Instrument glass, optional,laminated safety glass,

acrylic glass

Aluminium, black figures on white, optional, steel,

other colours

Aluminium, black, optional, micro adjustment,

steel

Direct drive on back entry. Copper flat wire spring

on bottom entry

Class 1 (1% F.S.D.)

Degree C

+10, +30

Max... 0,3% / 10 Deg C

EN 60 529 IP65

Silicone (SI)

Direct bottom, direct centre back

0.8 / 1.0

1.4 / 2.3

1.9 / 2.6

Index pointers, Fitting, Thermowell

Window

Dial

Pointer

Movement

Accuracy

Permissible

Ambient Temperature

Temperature Effect

Protection

Filling Liquid

Mountings

Weight dry / filled {kg}

Accessories

All specifications are subject to change without notice

D1 D2 D3

63

100 101 132 118

160 161 192 178

250 251 289 276

L7 L8

63

100 40 4

160 40 4

250 40 7

D4 D5 D6 L1 L2 L3 L4 L5 L6

107 118 132 52 52 58 5.5 85 49

167 178 192 52 52 58 5.5 82 49

265 276 285 55 55 58 3 84 51

L9 L10 L11 L12 F1 F2 F3 F4 S1 S2 SW

47

47

49

6

6

6

47 30 15 90 40 32 6

47 30 15 119 40 32 6

49 31 16 164 40 32 7

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

6

6

7

22

22

22

LTUK09016

Contact Gauges

Description

Stainless steel case electrical contact units

Model EC (magnetic snap action)

Available for bourdon tube & diaphragm gauges,

& gas filled thermometers.

Nominal sizes, 100 & 160 mm

Accuracy: Class 1 (bourdon tube)

Class 1.6 (diaphragm)

Magnetically assisted snap-action, interference

contacts, which open or close a circuit when

actioned by the instrument pointer. By means of

a removable setting key, it is possible to alter the

contact points to any position over the instrument

scale. With a single contact the instrument pointer

meets with the set limit contact, the touching pins

giving the contact. With a double contact, this occurs at two set points. The magnetic attraction of

the contacts can be altered by adjusting the magnet, by means of suitable driver, closer or further

away from the contact pins.

The magnetic attraction and / or release always

involves an interference in comparison with the

set limit values, this is between 1 and 6% of the

full scale value, depending on the intensity of the

magnetic attraction.

Features

Fully adjustable contacts

Built in behind the dial contacts

Specifications:

MEC

Dial Size

Case & Bezel Construction

Cable box Construction

-40 to +85˚C

Material Construction

Contact:

Plate

Contact Material

Solder Terminal

100

160

Flush fitting bayonet locking case and bezel.

304 stainless steel. IP65 (filled) IP54 (dry)

Polyamide 6. 6 pole plus earth. Screw terminals, up to 2.5mm wire.

Cable gland. PG 13.5 exterior cable 7 - 13 mm

diameter.

Plastic

Silver nickel, optional, gold plated,

gold silver, platinum iridium.

Nickel plated brass

Spacer / window

Polycarbonate, optional toughened glass

window

Suitable for bourdon tube or diaphragm gauge

Dial

Aluminium, black figures on white, optional,

other colours

Protection up to IP65

Pointer

Over-range limit

Technical Data

Rated operational voltage

Making or breaking current

Permanent current

Switching capacity

Standards

Permissible

Ambient Temperature

Aluminium, black, balanced

105% full scale

Filling Liquid

FDA approved food oil. Silicone. Flurolube

Mountings

Direct bottom, direct back, surface, flush

panel, panel fixing

Deep stainless steel bayonet locking case and bezel

Usable at full scale

Sealed cable box

Ranges

0 - 40 mbar (diaphragm)

0-1000 bar (bourdon tube)

Applications

Petrochemical and chemical Food and beverage Gas

industry Machine and apparatus construction

250 V max

1.0 A max

0.6 A max

DC 30 W max

AC 50 VA

EN 60947-1 EN 60947-1A11 EN 60947-5-1

-20 to +70 Degree C

All specifications are subject to change without notice

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09017

Differential Gauges

Description

Bourdon tube differential gauge Models BB/DUP

BS/DUP

According to DIN EN 837-1 Nominal sizes, 100 and

160 mm Accuracy: Class 1

Features

Rugged stainless steel case construction

Bayonet locking case and bezel

Protection to IP65

Usable at full scale

Liquid fillable case

Over-range protection 130% Ranges

Ranges

0 - 600 mbar... up to 0- 1000bar

0 - 10psi... Up to 0 -15,0000 psi

Applications

Petrochemical and chemical Pressure drops across

filters Fire industry apparatus Machine and apparatus construction

Specifications:

BB / DUP

Dial Size

Construction

Measuring Element

100

160

Flush fitting bayonet locking case and bezel.

C shaped bourdon tube

0,6. 1. 1,6. 2,5. 4. 6. 10. 16. 25. 40 . 60 . 100 . 160 .

250 . 400 . 600 . 1000

-1/0. -1/0,6. -1/1,5. -1/3. -1/5. -1/9. 0,6.

130% full scale, short periods

Ranges {bar}

Over-range limit

Process Connection

Material Construction

Process Connection

Bourdon Tube

Case / Bezel Ring

Window

Dial

Pointer

Movement

Accuracy

Permissible

Ambient Temp.

Process Temperature

Storage Temperature

Temperature Effect

Protection

Filling Liquid

Mountings

D1 D2 D3 D4 D5 L1 L2 L3 L4 L5 L6

100 101 132 118 132 118 52 52 79 5.5 20 75

160 161 192 178 192 178 52 52 79 5.5 20 75

100

160

Weight dry / filled {kg}

Accessories

L7 L8 L9 L10 L11 L12 F1 F2 F3 F4 S1 S2 SW

40 4 47 6 47 30 15 85 40 32 6 6 17

40 4 47 6 47 30 15 114 40 32 6 6 17

BS / DUP

1/4bsp, 3/8bsp, 1/2bsp according to EN837

1/4npt, 1/2npt, according to ANSI/ASME B1.20.1

Brass, Stainless steel AISI 316L

Phosphor bronze, Stainless steel AISI 316L

Stainless steel AISI 304L

Instrument glass, optional, laminated safety

glass, acrylic glass.

Aluminium, black figures on white, optional,

steel, other colours

Aluminium, 1 black, 1 RED, optional, other colours

Brass

Class 1 (1% F.S.D.)...optional class 0.6 (0.6%)

Degree C

-25,+60

-30, max,+100

-40,+60

max, 0,3% / 10 Deg C

EN 60 529 IP54 (dry) IP65 (fillable and filled)

Glycerine (GL) Silicone (SI)

Direct bottom, direct back, surface, flush panel,

panel fixing

1.2 / 2.0

2.3 / 4.2

Diaphragm seals, special connections, other

designs to customer specs

All specifications are subject to change without notice

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09018

Full Safety Pattern Gauges

Description

Stainless steel case process gauge, full safety

pattern Model SSC/SAF ST/SAF

According to DIN EN 837-1

S3 Nominal sizes, 100 and 160 mm Accuracy: Class 1

Features

Specifications:

SSC/SAF

Dial Size

100

160

Flush fitting bayonet locking case and bezel,

solid front bulkhead with full blow out back.

DIN-EN 837 S3

C shaped bourdon tube to 60 bar, coiled 316ST.

ST to 1000 bar

0,6. 1. 1,6. 2,5. 4. 6. 10. 16. 25. 40. 60. 100.. 160.

400. 600. 1000.

-1/0. -1/0,6. -1/1,5. -1/3. -1/5. -1/9.

130% full scale....short periods

1/4bsp, 3/8bsp, 1/2bsp according to EN837

1/4npt, 1/2npt, according to ANSI/ASME B1.20.1

Construction

Rugged stainless steel case construction

Bayonet locking case and bezel

Protection to IP54 or IP65

Usable at full scale

Measuring Element

Ranges {bar}

Solid front bulk head with full blow out back

Over-range limit

Over-range protection 130%

Process Connection

Ranges

1...0bar. up to 0...1000 bar

-30 inHg...0. psi up to 0...15000 psi

Applications

Heating and ventilation industry

Paper and pulp industry

Food and beverage

Petrochemical and chemical

ST/SAF

Material Construction

Process Connection

Bourdon Tube

Case / Bezel Ring

Window

Dial

Pointer

Movement

Accuracy

Permissible

Ambient Temp.

Process Temperature

Storage Temperature

Temperature Effect

Protection

Filling Liquid

Mountings

Weight dry / filled {kg}

Accessories

Brass or Stainless steel AISI 316L

Phosphor bronze or 316 ST ST,

Stainless steel AISI 304L, optional 316L

Laminated safety glass, optional, acrylic

Aluminium, black figures on white, optional,

steel, other colours

Aluminium, black, optional, micro adjustment,

steel

Stainless steel 304

Class 1 (1% F.S.D.), optional class 0.6 (0.6%)

Degree C

-25, +60

-30, Max.,+100

-40,+60

Max. 0,3% / 10 Deg C

EN 60 529 IP54 (dry) IP65 (fillable and filled)

Glycerine (GL) Silicone (SI)

Direct bottom, direct back, surface, flush panel,

panel fixing

1.0 / 1.3

1.5 / 2.3

Diaphragm seals, electrical contacts, index pointers, damped movement.

All specifications are subject to change without notice

D D1 D2 D3 D4 D5 D6 L1 L2 L3 L4 L5 L6

63

100 99 101 132 118 107 132 118 60 60 58 4.0 62 58

160 159 161 192 178 167 192 178 60 60 58 4.0 62 58

250

L7 L8 L9 L10 L11 L12 F1 F2 F3 F4 S1 S2 SW

100 19

160 19

4

4

55

55

6

6

55 26 28 90 42 31 5.5 5.5 22

55 26 28 119 42 31 6 6 22

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09019

Schaffer Diaphragms Gauges

Description

Stainless steel Schaeffer diaphragm gauge Models

ST / SCH

According to BS EN 837-3 Nominal sizes, 100 and

160 mm Accuracy: Class 1,6

Construction

These heavy duty industrial gauges, are manufactured with either an steel case and bezel, [blackepoxy coated], or with a stainless steel case and

bezel.

General construction is with a heavy duty fully

adjustable rotary geared movement, in stainless

steel with an upper flange and block in 304 ST.ST

and a lower process chamber in 316 ST.ST. Mounting connection is either threaded or flanged.

Operation

A convoluted diaphragm is clamped between two

flanges. One side is pressurized by the process fluid,

which deflects the diaphragm in proportion to the

pressure. On the other side, a ball joint is fixed to

the diaphragm and connected to the movement via

a push rod, this transfers the diaphragm deflection

to a pointer on the dial.

Applications

For the measurement of either gas or liquid The

fluids can be corrosive, polluted, or highly viscous.

For the measurement of highly viscous, or crystallizing process fluids, a flange connection is used.

Applications include, Liquid level measurement,

fuel pumps, storage tanks, generators, concrete

filling systems, paint filter presses, irrigation and

sludge pumps, trucks, and sewage removal among

others.

Features

Rugged stainless steel case construction

Specifications:

Dial Size

Construction

Measuring Element

Ranges {mbar}

{bar}

Over-range limit

Process Connection

Material Construction

Process Connection

Bourdon Tube

Diaphragm

Case / Bezel Ring

Window

Dial

Bayonet locking case and bezel

Pointer

Protection to IP54 or IP65

Movement

Accuracy

Permissible

Ambient Temp.

Process Temperature

Storage Temperature

Temperature Effect

Protection

Filling Liquid

Mountings

Weight dry / filled {kg}

Usable at full scale

Solid front bulk head with full blow out back

Over-range protection 130% Ranges

Ranges

0 - 40 mbar. up to 0.... 25bar

0 - 40 IN.WG. up to 0... 350psi.

Accessories

ST / SCH

100

160

Flush fitting bayonet locking case and bezel,

Shaeffer Diaphragm

0 -. 40. 60. 100. 160. 250 . 400. 600.

0 - 1. 2.5. 4. 6. 10. 16. 25. Pressure, vacuum or

compound ranges.

100% full scale, optional, 400% (max 25 bar).

1/2bsp according to EN837 1/2npt, according to

ANSI/ASME B1.20.1

Optional , Flanged connections in,-BS, DIN,

ANSI.

Stainless steel AISI 316L

Phosphor bronze or 316 ST ST,

Stainless steel AISI 316L.>2.5 bar. Chrome molly,

316 ST. Protected

Stainless steel AISI 304L

Instrument glass, optional, laminated safety glass,

acrylic glass

Aluminium, black figures on white, optional,

other colours

Aluminium, black, optional, micro adjustment,

steel

Stainless steel 304

Class 1.6 (1.6% F.S.D.)

Degree C

-15,+50

Min.-20, Max.+65 others available on request

-20,+60

Max. 0,3% / 10 Deg C

EN 60 529 IP65

Glycerine, silicone, others available

Direct bottom, direct back, DIN holder

1.6 / 1.9 2.1 / 2.5

1.9 / 2.4 2.4 / 3.0

Electrical contacts, index pointers, glycerine filling, other connections

All specifications are subject to change without notice

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09020

Square Case Gauges

Description

According to BS EN 837-1 Nominal size 96 mm

Accuracy: Class 1

Shown with optional steel case

Features

Rugged steel case construction

Specifications:

Brass bezel

Dial Size

Protection to IP55

Construction

Usable at full scale

Measuring Element

Phosphor bronze or stainless steel bourdon tube

Ranges {bar}

Over-range protection 130% Ranges

Over-range limit

Process Connection

Ranges

Material Construction

Process Connection

-1...0bar. up to 0...1000 bar

-30 in Hg...0. psi up to 0...15000 psi

Bourdon Tube

Applications

Heating and ventilation industry Machine and

apparatus construction

Case / Bezel Ring

Window

Dial

Pointer

Movement

Accuracy

Permissible

Ambient Temp.

Process Temperature

Storage Temperature

Temperature Effect

Protection

Filling Liquid

Mountings

Weight dry / filled {kg}

Options

Special Dial Marking

Special Range

Special Connections

Throttle Screw

Micro-adjust Pointer

Red Setting Pointer

Acrylic Window

Calibration 0.6%

Silicone Damped Movement

Electrical Contact

Diaphragm Seals

Hygienic Sales

Centre Back Entry

Size

96x96

A

52

B

9

C

26

Accessories

FPM / SQ

100

96 mm square Flush fitting case and bezel, safety

blow out disc, DIN-EN 837 S1

C shaped bourdon tube to 60 bar, coiled to 1000 bar

0,6. 1. 1,6. 2,5. 4. 6. 10. 16. 25. 60. 100. 160. 250.

400. 600. 1000.-1/0. -1/0,6. -1/1,5. -1/3. -1/5. -1/9.

130% full scale, short periods

1/4bsp, 3/8bsp, 1/2bsp according to EN837

1/4npt, 1/2npt, according to ANSI/ASME B1.20.1

Brass

Phosphor bronze C shaped to 60 bar, ST.ST. AISI

316L coiled to 1000 bar

Black, glass fibre reinforced abs. Optional- steel,

black finish

Poly carbonate

Aluminium, black figures on white...optional...

steel, other colours

Aluminium, black, optional, micro adjustment,

steel

Brass

Class 1 (1% F.S.D.) optional class 0.6 (0.6%)

Degree C

-25,+60

Min.-30, Max.+100

-40,+60

Max. 0,3% / 10 Deg

EN 60 529 IP55

N /A

Flush panel, clamp fixing

0.65

Electrical contacts, index pointers, glycerine fill

Diaphragm seals, electrical contacts

All specifications are subject to change without notice

D

91

E

96

F

86

G

12

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09021

ST/ST Cased Absolute Gauges

Description

Stainless steel case absolute capsule gauge Models

SSC / ABS

According to DIN EN 837-3

Nominal sizes, 100, mm Accuracy: Class 2

Features

Stainless steel case construction

Barometrically Compensated

Specifications:

Stainless steel bayonet locking case and bezel,

Usable at full scale

Dial Size

Construction

Measuring Element

Ranges {bar}

Over-range limit

Inconel capsule

Process Connection

2 bar gauge overange protection.

Protection to IP65

Ranges

0 - 25, 0 -50, 0 -125, 0 -160, 0-1000 mbar

Applications

Petrochemical and chemical

Food and beverage

Gas industry

Machine and apparatus construction

Material Construction

Process Connection

Capsule

Case / Bezel Ring

Window

Dial

Pointer

Movement

Accuracy

Permissible

Ambient Temp.

Process Temperature

Storage Temperature

Temperature Effect

Protection

Filling Liquid

Mountings

Weight dry / filled {kg}

Accessories

SSC / ABS

100

160

Flush fitting bayonet locking case and bezel

Evacuated Capsule

0 - 25, 0 -50, 0 -125, 0 -160, 0-1000

130% full scale, short periods

1/4bsp, 3/8bsp, 1/2bsp according to EN837

1/4npt, 1/2npt, according to ANSI/ASME B1.20.1

Brass or Stainless steel AISI 316L

Inconel

Stainless steel AISI 304L

Toughened Instrument glass

Aluminium, black figures on white, optional, other

colours

Aluminium, black, balanced

Brass

Class 2 (2% F.S.D.)

Degree C

-15,+50

Min.-20, Max. +65

-20, +60

Max. 0,5% / 10 Deg C

EN 60 529 IP65

N /A

Direct bottom, direct back, surface, flush panel,

panel fixing

1.0

1.4

Snubber screw, special dial, special connection

All specifications are subject to change without notice

D D1 D2 D3 D4 D5 D6 L1 L2 L3 L4 L5 L6

63

100 99 101 132 118 107 132 118 52 52 50 5.5 56 49

160 159 161 192 178 167 192 178 52 52 50 5.5 56 49

250

L7 L8 L9 L10 L11 L12 F1 F2 F3 F4 S1 S2 SW

63

100 16 4 47 6 47 30 15 90 40 32 5.5 5.5 22

160 16 4 47 6 47 30 15 119 40 32 6 6 22

250

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09022

Test Gauges

Description

Precision Bourdon Tube Test gauge. Class 0.25%

Models. BSC/TG SSC/TG

According to DIN EN 837-1 Nominal sizes, 160 and

250 mm Accuracy: Class 0.25

Features

Rugged stainless steel

or black steel case construction

Specifications:

Dial Size

Construction

Measuring Element

Ranges {bar}

Bayonet locking case and bezel

Over-range limit

Protection to IP54

Process Connection

Usable at full scale

Material Construction

Process Connection

Beryllium copper bourdon tube

Over-range protection 130% Ranges

Ranges

-1...0bar. Up to 0...1000 bar

-30 in Hg...0. PSI up to 0...15000 psi

Applications

Inspection and testing

Bourdon Tube

Case / Bezel Ring

Window

Dial

Pointer

Movement

Accuracy

Permissible

Ambient Temp.

Process Temperature

Storage Temperature

Temperature Effect

Protection

Filling Liquid

Mountings

Weight dry / filled {kg}

Accessories

BSC/TG

SSC/TG

160

250

Flush fitting bayonet locking case and bezel, safety

blow out disc, DIN-EN 837 S1

Bourdon Tube

0,6. 1. 1,6. 2,5. 4. 6. 10. 16. 25. 40. 60. 100.. 160.

250. 400. 600. 1000.

-1/0. -1/0,6. -1/1,5. -1/3. -1/5. -1/9.

130% full scale....short periods

1/4bsp, 3/8bsp, 1/2bsp according to EN837

1/4npt, 1/2npt, according to ANSI/ASME B1.20.1

Brass

Beryllium Copper, C shape to 100 bar, coiled to

1000 bar.

Steel, black finish or Stainless steel AISI 304L.

Instrument glass, optional, laminated safety glass,

acrylic glass.

Aluminium, black figures on white, optional,

anti-parallex mirror band.

Aluminium, black, balanced.

Precision brass.

Class 0.25 (0.25% F.S..D.)...optional class 0.6

(0.6%)

Degree C

-17 - 23.

Min. -30, Max.+100

-40, +60

Max...0,2% / 10 Deg C

EN 60 529 IP54

N /A

Direct bottom, direct back, surface, flush panel,

panel fixing

1.2

2.3

160mm full safety pattern case, other pressure

units, mirror scale

All specifications are subject to change without notice

D D1 D2 D3 D4 D5 D6 L1 L2 L3 L4 L5 L6

63

100

160 159 161 192 178 167 192 178 52 52 50 5.5 56 49

250 250 253 289 276 265 289 276 55 55 55 3.0 58 51

L7 L8 L9 L10 L11 L12 F1 F2 F3 F4 S1 S2 SW

63

100

160 40 4 47 6 47 30 15 119 40 45 6 6 22

250 40 7 49 6 49 31 16 164 40 45 6.5 6.5 22

For Panel Cut - Out Size, Add 1 mm to D1

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09023

Rigid Stem Thermometers

Specifications:

Description

Stainless steel inert gas industrial dial thermometer

Model STN/R

According to BS EN 13190 Nominal sizes, 63, 100,

160 and 250 mm Accuracy: Class 1.6, (63mm) Class 1

Features

Rugged stainless steel case construction

Bayonet locking case and bezel

Protection to IP65

Usable at full scale

Chrome moly coiled element

Over-range protection 130% (max 800 deg C)

Ranges

Ranges

Construction

Measuring Element

Ranges {bar}

Over-range limit

Process Connection

Material Construction

Stem / Bulb

Stem / Bulb dia (mm)

Case / Bezel Ring

Window

Dial

From -200 to + 800 deg C

Pointer

Applications

Heating and Ventilation Industry

Movement

Machine and Apparatus Construction

Accuracy

Model

STN/-STN/--/GL

STN/--/SI

STN/R

Dial Size

Dry

Glycerine Filled

Silicone Filled

Permissible

Ambient Temp.

Temperature Effect

Protection

Filling Liquid

Mountings

Weight dry / filled {kg}

Accessories

63

100

160

250

Flush fitting bayonet locking case and

bezel

Chrome moly coil

See table STN 1

130% full scale, short periods.

(Max 800 deg C)

1/4bsp, 3/8bsp, 1/2bsp

according to EN837

1/4npt, 1/2npt, according

to ANSI/ASME B1.20.1

321 Stainless steel, optional 316

6, 6.35, 8, 9.5, 10, 12, 12.5, 16

Stainless steel AISI 304L

Instrument glass ...optional...laminated

safety glass....acrylic glass

Aluminium, black figures on white...

optional...steel...other colours

Aluminium, black, optional

micro adjustment, steel

Brass

Class 1.6 (63mm) Class 1 (1% F.S..D.)...

optional class 0.6 (0.6%)

Degree C

+10, +30

Max. 0,3% / 10 Deg C

EN 60 529 IP65

Glycerine (GL) Silicone (SI)

Direct bottom, direct centre back

Electrical Contacts, Index Pointers,

Fitting, Thermowell

All specifications are subject to change without notice

Options

Special Dial Marking

Special Range

Special Connections

Micro-adjust Pointer

Maximum Demand Pointer

Red Setting Pointer

Acrylic Window

Laminated Window

Calibration 0.6%

Electrical Contact

63

100

160

250

D1

D2

L1

L2

L3

L4

L5

99

159

250

101

161

253

132

192

289

118

178

276

107

167

265

132

192

289

118

178

276

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09024

Capillary Thermometers

Specifications:

Description

Stainless steel inert gas industrial dial thermometer

Model STN/C

According to BS EN 13190 Nominal sizes, 63, 100,

160 and 250 mm Accuracy: Class 1.6, (63mm) Class 1

Features

Rugged stainless steel case construction

Bayonet locking case and bezel

Protection to IP65

Usable at full scale

Chrome molly coiled element

Over-range protection 130% (max 800 deg C)

Ranges

From -200 to + 800 deg C.

Applications

Heating and ventilation industry Machine

and apparatus construction

Standard

Bulb Diameters

in mm

6.0, 6.35, 8.0,

10.0, 12.0, 12.5,

16.0

Connections:

1/2 BSP

3/4 BSP

1 BSP

Dial Size

Construction

Measuring Element

Ranges {bar}

Over-range limit

STN/C

63

100

160

Flush fitting bayonet

locking case and bezel

Chrome molly coil

See table STN 1

130% full scale....short periods.

(Max 800 deg C)

250

Material Construction

Stem / Bulb

321 Stainless steel, optional 316

Stem / Bulb dia (mm) 6, 6.35, 8, 9.5, 10, 12, 12.5, 16

Case / Bezel Ring

Stainless steel AISI 304L

Instrument glass, optional, laminated safety glass,

Window

acrylic glass

Aluminium, black figures on white, optional, steel,

Dial

other colours

Pointer

Aluminium, black, optional, micro adjustment, steel

Movement

Brass

Class 1.6 (63mm) Class 1 (1% F.S..D.)...optional class

Accuracy

0.6 (0.6%)

Permissible

Degree C

Ambient Temp.

+10, +30

Temperature Effect

Max. 0,3% / 10 Deg C

Protection

EN 60 529 IP65

Filling Liquid

Glycerine (GL) Silicone (SI)

Mountings

Panel 3 hole, Panel clamp, Surface, or DIN Clamp

Weight dry / filled {kg}

0.8 / 1.0

1.4 / 2.3

1.9 / 2.6

2.3 / 4.2

Accessories

Electrical contacts, index pointers, Fitting, Thermowell

All specifications are subject to change without notice

1/2 BSPT

3/4 BSPT

1 BSPT

1/2 NPT

3/4 NPT

1 NPT

D D1 D2

63

100 99 101 132

160 159 161 192

250 250 253 289

D3 D4 D5 D6 L1 L2 L3 L4 L5 L6

118 107 132 118 52 52 58 5.5 82 49

178 167 192 178 52 52 58 5.5 82 49

276 265 289 276 55 55 58 3.0 84 51

For Panel Cut - Out Size, Add 3mm to Case Diameter (D1)

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09025

Dials and Specials

Description

Marsh Bellofram offers customers the option of

choosing their own gauge dial format.

This service compliments the comprehensive range of

professionally manufactured quality products that are

available.

Marsh Bellofram is able to design and print full colour

dials to their customers exact specifications.

These options may incur an extra cost or a minimum

quantity depending on the item chosen please contact

the office where a member of the sales team will discuss the options available.

Our wide variety of options insure that you will find

the perfect fit for your application.

Conversion Chart

Unit

1 BAR

1mBAR

1 kPa

1 psi

1 In.H2O

1 mmHg

1 In.Hg

1Kg/cm2

BAR

1

0.001

0.01

0.06895

0.00249

0.00133

0.03386

0.98067

Temperature Conversion

mBAR

1000

1

10

68.9476

2.49089

1.33322

33.8639

980.665

C X 1.8 + 32 = oF

kPa

100

0.1

1

6.89476

0.24909

0.13332

3.38639

98.0665

psi

14.5038

0.0145

0.14504

1

0.03613

0.01934

0.49115

14.2233

In.H2O

401.463

0.40146

4.01463

27.6799

1

0.53524

13.5951

393.701

Mmhg

750.064

0.75006

7.50064

51.7151

1.86833

1

25.4

735.561

In.Hg

29.53

0.02953

0.2953

2.03602

0.07356

0.03937

1

28.959

Kg/cm2

1.01972

0.00102

0.0102

0.07031

0.00254

0.00136

0.03453

1

(F – 32) : 1.8 = oC

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09026

Repairs and Calibration

Description

Marsh Bellofram Europe offer a comprehensive

repair and recalibraton service that compliments

their range of professionally manufactured quality

products. Our wide variety of options insures that

you will find the perfect fit for your application.

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09027

100mm XL SS Gauge

Description

Marsh Instruments all stainless steel gauges are

built for extended life, and designed for harsh and

corrosive environments. These stainless steel gauges feature top fill plugs and are field fillable. Marsh

Liquid Filled Gauges offer significant cushioning

and dampening which reduces pointer flutter and

internal gauge damage.

Typical applications include refineries, chemical

plants, offshore platforms, oil rigs, marine applications, general industrial application and OEM

processes.'

Features

Specifications:

• All Stainless Steel

Accuracy

ASME Grade 1A – ±1.0% of range across full scale

• Field Fillable

Case Size

100mm diameter (4")

• Ranges to 10,000 psi

Case Material

304 Stainless Steel

• Liquid Filled or Dry

• Solid Front Design — Safecase

Ranges

Case Style

Solid front & blow-out back

Safecase construction

LM – Lower Mount

Tube & Socket

316 Stainless Steel

30 to 10,000 psi

Movement

Stainless Steel

and 0 to 30" VAC Hg

Connection

1⁄2 NPT & 1/2 BSP available P.O.A.

30 to 10,000 psi

Standard Ranges & Part Numbers

Ranges

Case Size

Case Material

Mounting/Case Style

Connection

Scale Standard

0 to 30" Hg VAC

0 to 30 psi

0 to 60 psi

0 to 100 psi

0 to 200 psi

0 to 300 psi

0 to 600 psi

0 to 1,000 psi

0 to 1,500 psi

0 to 2,000 psi

0 to 3,000 psi

0 to 4,000 psi

0 to 5,000 psi

0 to 6,000 psi

0 to 10,000 psi

Dial Standard

Dual scale psi/kPa & psi/BAR

Dial Color

Black markings on white

Pointer

Aluminum, black painted

Window

Safety glass

Fill Medium

See Options

Vent

Internal compensating diaphragm

100mm diameter (4")

304 Stainless Steel

LM – Lower Mount

1⁄2 NPT

psi/kPa

W9605

W9642

W9646

W9648

W9654

W9658

W9664

W9672

W9674

W9676

W9678

W9680

W9682

W9684

W9690

0 to 30" VAC Hg

All specifications are subject to change without notice

Standard Ranges & Part Numbers

OPTION

Fill Medium

TYPE

SUFFIX

Available on Models

Dry (no fill)

Standard

All ranges

Glycerine (GL)

Add suffix P

All ranges

Silicone (SL)

Add suffix PI

All ranges

All specifications are subject to change without notice

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09028

Safety Valve

Description

Safety Relief Valves are available in 1/8, 1/4 and 3/8 BSP, and with Ring Pull

Test or Tamper Proof cap, and are CE Marked and certified.

Also available, on request - 1/2 and 1” BSP.

Many Factory Set SR Valves are held in stock at our Head Office in Nottingham, and are very economically priced.

Specifications

Seal

NBR

Body

Brass

Spring

Steel C98

Tamper proof cap

Available

Manual ring pull test

Standard

Certification

CE PED Cat. IV

Please contact 0115 9933300 for more details and technical

Typical Discharge Rates

1/4 BSP Model - Lt/Min - Real Discharge

BAR

1

Lt / min 123

2

3

4

5

6

185

333

507

875

1234

7

8

9

10

11

12

13

1602 2350 2690 3040 3464 3665 3741

14

15

16

3873 4000 4604

3/8 BSP Model - Lt/Min - Real Discharge

BAR

1

Lt / min 311

2

3

4

5

6

519

866

1229

1918

2645

7

8

9

10

11

12

13

14

15

16

3441 4200 4980 5804 6856 7812 9342 9682 10000 11056

1/2 BSP Model - Lt/Min - Real Discharge

BAR

1

Lt / min 531

2

3

4

5

6

1062

1593

2125

2655

3186

7

8

9

10

11

12

13

14

15

16

17

18

3717 4250 5955 8015 8949 10095 10601 11295 12050 12804 13604 14419

1 BSP Model - Lt/Min - Real Discharge

BAR

1

2

3

Lt / min 2120 3220 4320

4

5

6

5072

6172

7272

7

8

9

10

11

12

13

14

15

16

17

18

7944 8616 9288 9948 10584 11208 11820 12408 12996 13584 14172 14760

Repairs and Calibration

From our Works at Nottingham we are also able to offer repair and Certified

recalibration of all our Safety Relief Valves, at realistic prices.

We can also undertake recalibration of other makes of Safety relief Valves.

9 Castle Park Queens Drive, Nottingham NG2 1AH England

Tel: (44) 115 993 3300 • Fax: (44) 115 993 3301 • e-mail: bellofram@aol.com • www.marshbellofram.com

LTUK09030