Pressure Guage Catalogue

advertisement

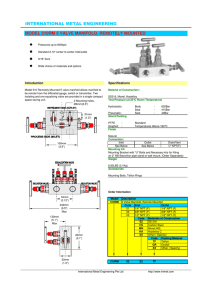

AN ISO 9001:2000 COMPANY isc w Blo el, t ne o ay P W/ to 47 47 9 :13 r IS e sp a Ø S 67 IP- o 2 11 ,B 4 30 e typ z be d ut PRESSURE GAUGES AND SU C DIFFERENTIAL PRESSURE GAUGES PG m rag h p Dia L 16 3 S ge n Fla AN ISO 9001:2000 COMPANY PRESSURE GAUGES 3 Bourdon Sensing Pressure Gauges Capsule Sensing Pressure Gauges 9 15 Receiver Gauges 21 Indicating Pressure Switches 27 Chemical / Diaphragm Seal Unit Liquid Filled Pressure Gauges 5 11 Diaphragm Sensing Pressure Gauges 17 Absolute Pressure Gauges 23 Hygiene Gauges Accessories 30 Safety Pattern Solid Front Pressure Gauges 7 13 Bourdon Sensing Pressure Gauges 250mm 19 Master Pressure Gauges 25 Bourdon Sensing Pressure Gauges 40 - 50-63 Bourdon Sensing Pressure Gauges MODEL : BSPG Features Compliance to latest EN-837 standard n Range : (-) 1 to 1600 kg/cm² n Bourdon in SS316 Ti as standard providing n better mechanical properties guaranteeing repeatability and accuracy Accuracy ± 1% FSD (Standard), ± 0.5% FSD on request n Unit of measurement - kg/cm², bar, n PSI, KPa, mbar n Pressure Gauges intended for Process Industries such as Chemicals, Petro-chemicals, Energy or Gas industry, Food processing, Nuclear etc. n These pressure gauges have been designed to satisfy requirements to operate in aggressive environment. Specifications Table 1 Ref. Standard Dial Gauge System Bar, kg/cm2 Least count Vacuum PB, SS (-)1 to 0 0.02 Compound PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS (-)1 to 0.6 (-)1 to 1.5 (-)1 to 3 (-) 1 to 5 (-)1 to 9 (-)1 to 15 (-)1 to 24 (-)1 to 39 0.05 0.05 0.10 0.10 0.20 0.50 0.50 1.0 Pressure Gauge (‘C’ shaped Bourdon) PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB,SS PB,SS SS SS 0 to 0.4 0 to 0.6 0 to 1 0 to 1.6 0 to 2.5 0 to 4 0 to 6 0 to 10 0 to 16 0 to 25 0 to 40 0 to 60 0 to 100 0.01 0.01 0.02 0.05 0.05 0.10 0.10 0.20 0.50 0.50 1.0 1.0 2.0 SS SS SS SS SS SS SS 0 to 160 0 to 250 0 to 400 0 to 600 0 to 800 0 to 1000 0 to 1600 5.0 5.0 10.0 10.0 20.0 20.0 50.0 EN-837 100 mm / 150 mm in Aluminium, white background, black markings Case Diecast aluminium with screwed bezel, epoxy painted black / SS304 with bayonet bezel (SS316 on request) Phenol with screwed bezel Protection IP-68 (IS :13947 Part I) Bourdon Phosphor Bronze, SS316 Ti / SS316L, Monel Socket 22mm Square in brass, SS316, SS316 Ti / SS316L, Monel Movement Brass, SS304, SS316 Range As EN 837 (refer table 1) minimum span 0.4 kg/cm2, maximum 1600 kg/cm2 Connection 1/2" NPT (M) as standard (other optional) Accuracy ± 1% FSD (0.5% on request) Overrange 130% FSD (other on request) Suitability (-) 20°C to 80°C (service temperature) Zero adjustment Micrometer pointer (internal) Blow out disc Provided (on top) Optional IBR certification Maxima pointer NACE compliance External zero setting Integral Dampener Swivel connection to facilitate rotation and in turn positioning of pressure gauge Note Non ferrous system is recommended up to 40 kg/cm²g System Bourdon Socket PB Ph. Bronze Brass Movement Brass SS SS316 SS316 SS304 Monel Monel Monel SS304 Pressure Gauge Coil type Bourdon For range other then above please contact our design dept. Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 3 Ordering Information MODEL : BSPG OPTION MOUNTING V C S P B A +/- 0.5% Accuracy C Colour band CE CE Certificate D Dual Scale E External Zero reset (for Al, S4 and S6 case) F Flanged process connection ** I IBR L Nil M Maxima Pointer N NACE-MR-01-75 O O2 Cleaning R 150% over range U Chemical Seal Unit-Refer Catalogue CSU X Accessory - Refer Catalogue ACC Y Integral Dampener Bottom Entry, Local Mounting Back Entry, Local Mounting Bottom Entry, Surface Mounting Back Entry, Flush Panel Mounting Back Entry, Surface Mounting DIAL 10 - 100 mm 15 - 150 mm CASE PH AL S4 S6 Phenol* Die-cast Aluminium SS304 SS316 P S L M T Phosphor Bronze / Brass SS316 / SS316 SS316L / SS316L Monel / Monel SS316Ti/SS316Ti BOURDON/SOCKET UNIT A B C D E F MOVEMENT 2 - Brass 4 - SS304 6 - SS316 RANGE Refer Table 1 CONNECTION TYPE MALE / FEMALE METRIC THREADS 18 M - M 18 x 1.5 M Male 20 M - M 20 x 1.5 Female F 24 M - M 24 x 1.5 27 M - M 27 x 2 PF PF 33 M - M 33 x 2 25 1” GS Gas X X - Any other 1.1/4” 32 NS NPSM 40 1.1/2” SIZE 6 1/4” 10 3/8” 15 1/2” 20 3/4” kg/cm2 (g) Bar (g) PSI KPa mmHg Pl. specify NT NPT BP BSP BT BSPT ** For Flanged Process Connection refer the table (mentioned separately) F - FLANGED PROCESS CONNECTION ** Size Code Rating Code Facing Code 150# 300# 600# 900# A B C D RF FF RTJ LT RF FF RTJ LT 2” 50 1500# E LG LG 3” 80 2500# F ½” ¾” 1” 1½” 15 20 25 40 The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 4 www.general-gauges.com Liquid Filled Pressure Gauges MODEL : LFBSPG Features Compliance to latest EN-837 standard n Range : (-) 1 to 1600 kg/cm² n Bourdon in SS316 Ti as standard providing n better mechanical properties guaranteeing repeatability and accuracy n Accuracy ± 1% FSD (Standard), ± 0.5% FSD on request Unit of measurement - kg/cm², bar, n PSI, KPa, mbar Filling fluid - Glycerine / Silicon oil / Halo Carbon n n Rugged, liquid filled pressure gauges, especially designed for Hydraulic Systems, Pumps, Compressors, Diesel Engines, Agricultural equipment, Machine tools etc. n Excellent resistance to vibration & corrosive ambient conditions. Specifications Table 1 Ref. Standard Dial Gauge System Bar, kg/cm2 Least count Vacuum PB, SS (-)1 to 0 0.02 Compound PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS (-)1 to 0.6 (-)1 to 1.5 (-)1 to 3 (-) 1 to 5 (-)1 to 9 (-)1 to 15 (-)1 to 24 (-)1 to 39 0.05 0.05 0.10 0.10 0.20 0.50 0.50 1.0 Pressure Gauge (‘C’ shaped Bourdon) PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB,SS PB,SS SS SS 0 to 0.4 0 to 0.6 0 to 1 0 to 1.6 0 to 2.5 0 to 4 0 to 6 0 to 10 0 to 16 0 to 25 0 to 40 0 to 60 0 to 100 0.01 0.01 0.02 0.05 0.05 0.10 0.10 0.20 0.50 0.50 1.0 1.0 2.0 SS SS SS SS SS SS SS 0 to 160 0 to 250 0 to 400 0 to 600 0 to 800 0 to 1000 0 to 1600 5.0 5.0 10.0 10.0 20.0 20.0 50.0 EN-837 100 mm / 150 mm in Aluminium, white background, black markings Case SS304 with bayonet bezel (SS316 on request) Protection IP-68 (IS :13947 Part I) Bourdon Phosphor Bronze, SS316 Ti / SS316L, Monel Socket 22mm Square in brass, SS316, SS316 Ti / SS316L, Monel Movement Brass, SS304, SS316 Range As EN 837 (refer table 1) minimum span 0.4 kg/cm2, maximum 1600 kg/cm2 Connection 1/2" NPT (M) as standard (other optional) Accuracy ± 1% FSD (0.5% on request) Overrange 130% FSD (other on request) Suitability (-) 20°C to 80°C (service temperature) Zero adjustment Micrometer pointer (internal) Blow out disc Provided (on top) Optional IBR certification NACE compliance External zero setting Integral Dampener Swivel connection to facilitate rotation and in turn positioning of pressure gauge Note Non ferrous system is recommended up to 40 kg/cm²g Glycerine filled guages are not recommended for oxidising services. System Bourdon Socket PB Ph. Bronze Brass Movement Brass SS SS316 SS316 SS304 Monel Monel Monel SS304 Pressure Gauge Coil type Bourdon For range other then above please contact our design dept. Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 5 Ordering Information MODEL : LFBSPG OPTION MOUNTING V C S P B Bottom Entry, Local Mounting Back Entry, Local Mounting Bottom Entry, Surface Mounting Back Entry, Flush Panel Mounting Back Entry, Surface Mounting A C CE D E F I L N O R U +/- 0.5% Accuracy Colour band CE Certificate Dual Scale External Zero reset Flanged process connection ** IBR Nil NACE-MR-01-75 O2 Cleaning 150% over range Chemical Seal Unit-Refer Catalogue CSU X Accessory - Refer Catalogue ACC Y Integral Dampener DIAL 10 - 100 mm 15 - 150 mm CASE S4 SS304 S6 SS316 FILLING FLUID G Glycerine S Silicon oil H Halocarbon UNIT BOURDON/SOCKET P S L M T A B C D E F Phosphor Bronze / Brass SS316 / SS316 SS316L / SS316L Monel / Monel SS316Ti/SS316Ti kg/cm2 (g) Bar (g) PSI KPa mmHg Pl. specify MOVEMENT RANGE 2 - Brass 4 - SS304 6 - SS316 Refer Table 1 CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other F - FLANGED PROCESS CONNECTION ** Size Code Rating Code Facing Code 150# 300# 600# 900# A B C D RF FF RTJ LT RF FF RTJ LT 2” 50 1500# E LG LG 3” 80 2500# F ½” ¾” 1” 1½” 15 20 25 40 The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 6 www.general-gauges.com Safety Pattern- Solid Front Pr. Gauges MODEL : SFBSPG Features n Safety pattern n All SS construction Theses Pressure Gauges are well suited for the Process Industries such as Chemicals, Petro-chemicals, Energy or Gas industry, Food processing, Nuclear etc. n These version have been developed with solid baffle wall and blow out back which immediately releases in the event of accidental tube rupture . Specifications Table 1 Dial Gauge System Bar, kg/cm2 Least count Vacuum PB, SS (-)1 to 0 0.02 Compound PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS (-)1 to 0.6 (-)1 to 1.5 (-)1 to 3 (-) 1 to 5 (-)1 to 9 (-)1 to 15 (-)1 to 24 (-)1 to 39 0.05 0.05 0.10 0.10 0.20 0.50 0.50 1.0 Pressure Gauge (‘C’ shaped Bourdon) PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB,SS PB,SS SS SS 0 to 0.4 0 to 0.6 0 to 1 0 to 1.6 0 to 2.5 0 to 4 0 to 6 0 to 10 0 to 16 0 to 25 0 to 40 0 to 60 0 to 100 0.01 0.01 0.02 0.05 0.05 0.10 0.10 0.20 0.50 0.50 1.0 1.0 2.0 SS SS SS SS SS SS SS 0 to 160 0 to 250 0 to 400 0 to 600 0 to 800 0 to 1000 0 to 1600 5.0 5.0 10.0 10.0 20.0 20.0 50.0 100/150 mm, aluminium, white background, black markings Case SS304, SS316 with bayonet bezel Protection Weatherproof to IP-68 ( IS : 13947 part I )60529 Ref. standard EN 837 Bourdon SS316 Ti, SS316L, Monel Socket 22 mm Square in SS 316, SS316L, SS316 Ti, Monel Movement SS304, SS316 Range As EN 837 (refer table-1) minimum span 0.4 kg/cm2, maximum 1600 kg/cm2g Accuracy ± 1% FSD (0.5% on request) Over range 130% FSD Suitability (-) 20°C to 80°C (service temperature) Zero adjustment Micrometer pointer (internal) Optional NACE compliance Liquid filled case External zero setting mechanism Pressure Gauge Coil type Bourdon For range other then above please contact our design dept. Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 7 Ordering Information MODEL : SFBSPG OPTION MOUNTING V C B S A +/- 0.5% Accuracy C Colour band Bottom Entry, Local Mounting Back Entry, Local Mounting Back Entry, Surface Mounting Bottom Entry, Surface Mounting CE CE Certificate D Dual Scale E External Zero reset F Flanged process connection ** G Glycerine Filled Case I IBR L Nil M Maxima Pointer N NACE-MR-01-75 O O2 Cleaning R 150% over range S Silicon oil Filled Case U Chemical Seal Unit-Refer Catalogue CSU X Accessory - Refer Catalogue ACC DIAL 10 - 100 mm 15 - 150 mm CASE S4 SS304 S6 SS316 BOURDON/SOCKET P S L M T Phosphor Bronze / Brass SS316 / SS316 SS316L / SS316L Monel / Monel SS316Ti/SS316Ti MOVEMENT UNIT 2 - Brass 4 - SS304 6 - SS316 A B C D E F CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other ** For Flanged Process Connection refer the table (mentioned separately) * For surface mounting, min 20 mm gap is recommended kg/cm2 (g) Bar (g) PSI KPa mmHg specify RANGE Specify from Table 1 minimum 0 - 0.4 kg/cm2g F - FLANGED PROCESS CONNECTION ** Size Code Rating Code Facing Code 150# 300# 600# 900# A B C D RF FF RTJ LT RF FF RTJ LT 2” 50 1500# E LG LG 3” 80 2500# F ½” ¾” 1” 1½” 15 20 25 40 The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 8 www.general-gauges.com Capsule Sensing Pressure Gauges MODEL : CSPG Features n Low range with high accuracy n All SS internals n Accuracy ±1% FSD n Compact design avoids use of bulky manometers n Ingress protection class IP-67 n These Pressure Gauges are well suited for low pressure measurement. n The sensing Element Capsule, is made of 2 Stainless Steel Laser-welded Diaphragms. Specifications Table 3 Dial Range in mm WC Case Pointer Protection Capsule Socket Movement Connection Range Accuracy Over range Zero reset Blow out disc 100 mm, 150 mm Aluminium white background, black figures Diecast aluminium with screwed bezel / SS304, SS316 with bayonet bezel Light weight, balanced, aluminium IP-68 (IS : 13947 Part I ) SS316L (made of two SS 316L diaphragms laser-welded ) SS316 / SS316L Fine 1/2"NPT (M) as standard (other optional ) Refer table- 3 ±1% FSD 110% FSD Standard, Other on request Provided (Internal) Provided 0-60 0-100 0-150 0-250 0-400 0-500 0-600 0-750 0-1000 0-1600 0-2000 0-2500 0-4000 0-6000 (-)25 to (+)25 (-)40 to (+)60 (-)200 to (+)200 (-)100 to (+)100 Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 9 Ordering Information MODEL : CSPG OPTION MOUNTING V C S P B C Colour band CE CE Certificate D Dual Scale E External zero reset L Nil N NACE-MR-01-75 O O2 Cleaning X Accessory - Refer Catalogue ACC Bottom Entry, Local Mounting Back Entry, Local Mounting Bottom Entry, Surface Mounting Back Entry, Flush Panel Mounting Back Entry, Surface Mounting DIAL 10 - 100 mm 15 - 150 mm CASE UNIT AL Die-cast Aluminium S4 SS304 S6 SS316 A mm WC B specify CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” RANGE METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other Refer Table 3 The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 10 www.general-gauges.com Diaphragm Sensing Pressure Gauges MODEL : DSPG Features n Compliance to latest EN-837 standard n Range : (-) 10000 to (+)10000 mmWC Specifications Table 2 Dial 0-250 mm WC (-) 250 to 0 mm WC 0-400 mm WC (-) 400 to 0 mm WC 0-600 mm WC (-) 600 to 0 mm WC 0-1000 mm WC (-) 1000 to 0 mm WC 0-1600 mm WC (-) 1600 to 0 mm WC 0-2500 mm WC (-) 2500 to 0 mm WC 0-4000 mm WC (-) 4000 to 0 mm WC 0-6000 mm WC (-) 6000 to 0 mm WC 100/150mm, aluminium , black marking on white background Case Diecast aluminium with screwed bezel / SS304, SS316 with bayonet bezel Protection IP-68 (IS : 13947 part I) Top Flange CS/SS304/SS316 Diaphragm SS316, PTFE lined SS316 (other material optional) Bottom flange SS304/SS316, SS316 + PTFE Block, PTFE lined SS316 (other material optional) Connection 1/2" NPT (M) or flanged (specify size & rating) Range Refer table - 2 Accuracy ±2% FSD (1.6% FSD on request) Over range 120% FSD Zero adjustment Micrometer pointer Blow out disc Provided Optional 1) Flushing connection on the bottom flange to facilitate cleaning 2) Glycerine / Silicon oil filled SS304 or SS316 case 3) Solid front SS304 or SS316 case 4) Special Construction for withstand high design pressure Note 0-1.0 Bar or 0-10000 mm WC (-) 10000 to 0 mmWC Special combination for compound ranges available. 1) PTFE block construction possible in flange connection alone. 2) PTFE moulded I sections for flanged connections Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 11 Ordering Information MODEL : DSPG OPTION MOUNTING A +/- 1.6% Accuracy C Colour band CE CE Certificate D Dual Scale E External Zero reset F Flanged process connection ** FC flushing connection # G Glycerine Filled Case L Nil M Maxima Pointer N NACE-MR-01-75 O O2 Cleaning R 150% over range S Silicon Oil Filled Case X Accessory - Refer Catalogue ACC V Bottom Entry, Local Mounting S Bottom Entry, Surface Mounting V/SF Bottom Entry, Local Mounting with solid front case S/SF Bottom Entry, Bracket Mounting with solid front case DIAL 10 - 100 mm 15 - 150 mm CASE AL Die-cast Aluminium S4 SS304 S6 SS316 TOP CHAMBER C CS S4 SS304 S6 SS316 UNIT A mm WC B specify DIAPHRAGM S6 SL ST SP M4 SS316 SS316L SS316Ti SS316+PTFE Monel 400 S6 SL ST SP 16 15 SS316 SS316L SS316Ti SS316+PTFE Inconel 600 Inconel 625 HB HC TI NI TA Hastelloy B Hastelloy C Titanium Nickel Tantalum RANGE Refer Table 2 BOTTOM CHAMBER M4 HB HC TI NI F - FLANGED PROCESS CONNECTION ** Monel 400 Hastelloy B Hastelloy C Titanium Nickel Size Code Rating Code Facing Code CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” 150# 300# 600# 900# A B C D RF FF RTJ LT RF FF RTJ LT 2” 50 1500# E LG LG 3” 80 2500# F ½” ¾” 1” 1½” 15 20 25 40 METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other ** For Flanged Process Connection refer the table (mentioned separately) # Pl. conform the size for the flushing connection The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 12 www.general-gauges.com Bourdon Sensing Pr. Gauges - 250mm MODEL : BSPG25 Features Compliance to latest EN-837 standard n Range : (-) 1 to 1600 kg/cm² n Bourdon in SS316 Ti as standard providing n better mechanical properties guaranteeing repeatability and accuracy n Accuracy ± 1% FSD (Standard), ± 0.5% FSD on request Unit of measurement - kg/cm², bar, PSI, KPa, mbar n Specifications Table 1 Ref. Standard Dial Gauge System Bar, kg/cm2 Least count Vacuum PB, SS (-)1 to 0 0.02 Compound PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS (-)1 to 0.6 (-)1 to 1.5 (-)1 to 3 (-) 1 to 5 (-)1 to 9 (-)1 to 15 (-)1 to 24 (-)1 to 39 0.05 0.05 0.10 0.10 0.20 0.50 0.50 1.0 Pressure Gauge (‘C’ shaped Bourdon) PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB,SS PB,SS SS SS 0 to 0.4 0 to 0.6 0 to 1 0 to 1.6 0 to 2.5 0 to 4 0 to 6 0 to 10 0 to 16 0 to 25 0 to 40 0 to 60 0 to 100 0.01 0.01 0.02 0.05 0.05 0.10 0.10 0.20 0.50 0.50 1.0 1.0 2.0 SS SS SS SS SS SS SS 0 to 160 0 to 250 0 to 400 0 to 600 0 to 800 0 to 1000 0 to 1600 5.0 5.0 10.0 10.0 20.0 20.0 50.0 EN-837 250 mm in Aluminium, white background, black markings Case Diecast aluminium with screwed bezel, epoxy painted black / SS304 with screwed bezel (SS316 on request) Protection IP-68 (IS :13947 Part I) Bourdon Phosphor bronze, SS316 Ti / SS316L, Monel Socket 22mm Square in brass, SS316, SS316 Ti / SS316L, Monel Movement Brass, SS304, SS316 Range As EN 837 (refer table 1) minimum span 0.4 kg/cm2, maximum 1600 kg/cm2 Connection 1/2" NPT (M) as standard (other optional) Accuracy ± 1.0% FSD standard (± 0.5% FSD on request) Overrange 130% FSD (other on request) Suitability (-) 20°C to 80°C (service temperature) Zero adjustment Micrometer pointer (internal) Blow out disc Provided (on top) Optional IBR certification NACE compliance Swivel connection to facilitate rotation and in turn positioning of pressure gauge Integral Dampener Note Non ferrous system is recommended up to 40 kg/cm²g System Bourdon Socket PB Ph. Bronze Brass Movement Brass SS SS316 SS316 SS304 Monel Monel Monel SS304 Pressure Gauge Coil type Bourdon For range other then above please contact our design dept. Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 13 Ordering Information MODEL : BSPG25 OPTION MOUNTING V C S P B Bottom Entry, Local Mounting Back Entry, Local Mounting Bottom Entry, Surface Mounting Back Entry, Flush Panel Mounting Back Entry, Surface Mounting A C CE D E F I L N O R U +/- 0.5% Accuracy Colour band CE Certificate Dual Scale External Zero reset Flanged process connection ** IBR Nil NACE-MR-01-75 O2 Cleaning 150% over range Chemical Seal Unit-Refer Catalogue CSU X Accessory - Refer Catalogue ACC Y Integral Dampener CASE AL Die-cast Aluminium S4 SS304 S6 SS316 BOURDON/SOCKET P S L M T Phosphor Bronze / Brass SS316 / SS316 SS316L / SS316L Monel / Monel SS316Ti/SS316Ti UNIT MOVEMENT A B C D E F 2 - Brass 4 - SS304 6 - SS316 CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other ** For Flanged Process Connection refer the table (mentioned separately) kg/cm2 (g) Bar (g) PSI KPa mmHg Pl. specify RANGE Refer Table 1 F - FLANGED PROCESS CONNECTION ** Size Code Rating Code Facing Code 150# 300# 600# 900# A B C D RF FF RTJ LT RF FF RTJ LT 2” 50 1500# E LG LG 3” 80 2500# F ½” ¾” 1” 1½” 15 20 25 40 The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 14 www.general-gauges.com Receiver Gauges MODEL : RG Features n Suitable for receiving pneumatic signals of level and flow transmitters n Compliance to latest EN-837 standard n Input Range : 0.2 to 1 kg/cm² OR 3 to 15 psi n Accuracy ± 1% FSD Specifications Ref. Standard Dial EN-837 100 mm / 150 mm in Aluminium, white background, black markings Case Diecast aluminium with screwed bezel, epoxy painted black / SS304 with bayonet bezel (SS316 on request) Phenol with screwed bezel Protection IP-68 (IS :13947 Part I) Bourdon Phosphor Bronze, SS316 Ti / SS316L Socket 22mm Square in brass, SS316, SS316 Ti / SS316L Movement Brass, SS304, SS316 Input Range 0.2 to 1 kg/cm² OR 3 to 15 PSI Scale 0 - 100% Linear OR 0 - 10 Sq. root OR 0 - 100% Sq. root Connection 1/2" NPT (M) as standard (other optional) Accuracy ± 1% FSD Overrange 130% FSD (other on request) Suitability (-) 20°C to 80°C (service temperature) Zero adjustment Micrometer pointer (internal) Blow out disc Provided (on top) System Bourdon Socket PB Ph. Bronze Brass Movement Brass SS SS316 SS316 SS304 Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 15 Ordering Information MODEL : RG INPUT RANGE MOUNTING V C S P B Bottom Entry, Local Mounting Back Entry, Local Mounting Bottom Entry, Surface Mounting Back Entry, Flush Panel Mounting Back Entry, Surface Mounting 1 0.2 - 1 kg/ cm² 2 0.2 - 1 Bar 3 3 - 15 PSI SCALE 1 2 3 4 DIAL 10 - 100 mm 15 - 150 mm 0 - 100% Linear 0 - 10 Sq. root 0 - 100% Sq. root Other - Pl. Specify CASE PH AL S4 S6 Phenol* Die-cast Aluminium SS304 SS316 OPTION CE CE Certificate L N O R S X BOURDON/SOCKET P S L T Phosphor Bronze / Brass SS316 / SS316 SS316L / SS316L SS316Ti/SS316Ti Nil NACE-MR-01-75 O2 Cleaning 150% over range Integral Dampner Accessory - Refer Catalogue ACC MOVEMENT 2 - Brass 4 - SS304 6 - SS316 CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 16 www.general-gauges.com Absolute Pressure Gauges MODEL : APG Why Absolute Pressure Gauge? The atmospheric pressure varies from place to place depending up on the altitude of the location and prevailing weather conditions. In such variable conditions, precise pressure measurement can be arrived only if a fixed (un-changing) reference point is established. For this purpose we have developed element of Twin Bellows, one of the same is totally evacuated and sealed, which shall be the reference point for calibration i.e. Absolute Zero. These twin bellows are connected through a special type of movement, by which any change in the atmospheric pressure is compensated, and thereby the gauge gives the absolute pressure irrespective of the location. Features Compliance to latest EN-837 standard n Range : 760-0 mmHg n Capsule/Bellow in SS316 as standard providing n better mechanical properties guaranteeing repeatability and accuracy Accuracy ± 1% FSD n Unit of measurement - mmHg, mmWC n Specifications Ref. Standard Dial EN-837 150 mm in Aluminium, white background, black markings Case Diecast aluminium / Ss304 / SS316 with screwed bezel Protection IP-68 (IS :13947 Part I) Sensor Capsule / Bellow in SS316 Socket 22mm Square in SS316 Movement Brass, SS304, SS316 Connection 1/2" NPT (M) as standard (other optional) Accuracy ± 1% FSD Overrange 130% FSD (other on request) Suitability (-) 20°C to 80°C (service temperature) Zero adjustment External Optional NACE compliance Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 17 Ordering Information MODEL :APG OPTION MOUNTING V C S P B D Dual Scale N NACE-MR-01-75 Bottom Entry, Local Mounting Back Entry, Local Mounting Bottom Entry, Surface Mounting Back Entry, Flush Panel Mounting Back Entry, Surface Mounting X Accessory - Refer Catalogue ACC UNIT DIAL A B C D E F 15 - 150 mm CASE AL Die-cast Aluminium S4 Ss304 S6 SS316 kg/cm2 (a) Bar (a) PSI KPa mmHg(a) Pl. specify RANGE Refer Table 1 CAPSULE/BELLOW SS316 MOVEMENT 2 - Brass 4 - SS304 6 - SS316 CONNECTION TYPE MALE / FEMALE METRIC THREADS 18 M - M 18 x 1.5 M Male 20 M - M 20 x 1.5 Female F 24 M - M 24 x 1.5 27 M - M 27 x 2 PF PF 33 M - M 33 x 2 25 1” GS Gas X X - Any other 1.1/4” 32 NS NPSM 40 1.1/2” SIZE 6 1/4” 10 3/8” 15 1/2” 20 3/4” NT NPT BP BSP BT BSPT ** For Flanged Process Connection refer the table (mentioned separately) F - FLANGED PROCESS CONNECTION ** Size Code Rating Code Facing Code 150# 300# 600# 900# A B C D RF FF RTJ LT RF FF RTJ LT 2” 50 1500# E LG LG 3” 80 2500# F ½” ¾” 1” 1½” 15 20 25 40 The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 18 www.general-gauges.com Master Pressure Gauges MODEL : MPG Features n Accuracy class ± 0.25% n Rugged construction n 1.2 fold overrange capability n Traceability to national/international standard / laboratory Table 1 Specifications Ref. Standard EN 837 Normal size 150 mm / 250 mm Case Diecast aluminium / SS304 Bezel Aluminium / SS304 Dial Anti parallax mirror type, white, with black markings. Window Instrument glass Pointer Balanced knife edge Measuring element Bourdon in SS316 Ti Movement Precision brass, jewel bearings Connection 1/2" NPT (M), bottom or back eccentric in brass or SS316 Range 760 mm Hg Vac upto 600 bar g (Refer table -1 of Bourdon Sensing Pressure Gauge ) Scale Bar (g), kg/cm2g, PSI (dual scale) Accuracy ± 0.25% Overrange 1.2 times maximum rating for short duration Suitability Media up to 50°C ambient (-) 25°C to 60°C Option Pressure comparator bench can be supplied. Pressure comparator bench consists of pressure raising by screw press, reservoir for filling the system. The pressure is released to atmosphere by opening valve between reservoir and the system after screw press has been reversed to lower pressure. It has maintenance free operation. Range Bar, kg/cm2 least Count NG 150 NG250 (-)1 to 0 0.005 0.005 (-)1 to 0.6 0.01 0.005 (-)1 to 1.5 (-)1 to 3 (-) 1 to 5 (-)1 to 9 (-)1 to 15 (-)1 to 24 (-)1 to 39 0 to 1 0 to 1.6 0 to 2.5 0 to 4 0 to 6 0 to 10 0 to 16 0 to 25 0 to 40 0 to 60 0 to 100 0.02 0.02 0.05 0.05 0.1 0.2 0.2 0.005 0.01 0.02 0.02 0.05 0.05 0.1 0.2 0.2 0.5 0.5 0.01 0.02 0.02 0.05 0.05 0.1 0.2 0.005 0.005 0.01 0.02 0.02 0.05 0.05 0.1 0.2 0.2 0.5 0 to 160 1.0 0.5 0 to 250 2.0 1.0 0 to 400 2.0 2.0 0 to 600 5.0 2.0 Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 19 Ordering Information MODEL : MPG OPTION MOUNTING V C S P B CE CE Certificate P Pressure Comparator Bench X Accessory - Refer Catalogue ACC Bottom Entry, Local Mounting Back Entry, Local Mounting Bottom Entry, Surface Mounting Back Entry, Flush Panel Mounting Back Entry, Surface Mounting UNIT DIAL A B C D E F 15 - 150 mm 25 - 250 mm CASE AL Die-cast Aluminium S4 SS304 RANGE CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” kg/cm2 (g) Bar (g) PSI KPa mmHg specify METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other Refer Table 1 The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 20 www.general-gauges.com Indicating Pressure Switches MODEL : IPSH Features Combination of indication and switch n Choice of electrical contacts and microswitch n One or two contacts possible n Switch setting throughout the range externally n High repeatability and low hysteresis n Weatherproof or Flameproof housing n Mil connector provided optionally. n Table 1 Specifications Dial Case Protection Bourdon Socket Movement Connection Range Accuracy Overrange Blow out disc Zero reset Contacts Accessory 100 mm / 150 mm, aluminium, white background, black markings Diecast aluminium with screwed bezel SS304, SS316 with bayonet bezel Weatherproof to IP - 68 (IS 13947 part I) Flameproof to IIA IIB (equivalent to NEC C1. I, Div. 2, Gr. C & D) SS316 Ti, Monel, Phosphor Bronze, SS316L SS316, Monel, brass, SS316L, SS316 Ti SS304 for SPST, brass (with SPDT microswitch) 1/2" NPT (M) as standard (-)1 to 1600 kg /cm2 minimum span of 4 kg/cm2 (only standard ranges as mentioned under table 1 ± 1% FSD for indication ± 2% FSD for switching 130% FSD Provided Provided (Micrometer Pointer) 1SPST, single, normally open, closing on rise in pressure or vice versa, rated 30VA @ 230V AC 2 SPST, two contacts , independently adjustable, one normally open, other normally closed or both normally open or both normally closed, rated 30VA @ 230V AC 1SPDT, single microswitch, adjustable over entire range, rated 5 amp @ 230V AC (3A @ 28 VDC) 2SPDT, double microswitch, adjustable over entire range, rated 5 amp @ 230V AC (3A @ 28 VDC) Relay for the contact assembly to suit 5 amp @ 230V AC, separately mounted. System Bar, kg/cm2 Least count Compound PB, SS (-)1 to 3 0.10 PB, SS PB, SS PB, SS PB, SS PB, SS (-) 1 to 5 (-)1 to 9 (-)1 to 15 (-)1 to 24 (-)1 to 39 0.10 0.20 0.50 0.50 1.0 PB, SS PB, SS PB, SS PB, SS PB,SS PB,SS SS SS 0 to 4 0 to 6 0 to 10 0 to 16 0 to 25 0 to 40 0 to 60 0 to 100 0.10 0.10 0.20 0.50 0.50 1.0 1.0 2.0 Pressure Gauge (‘C’ shaped Bourdon) Pressure SS 0 to 160 5.0 Gauge Coil type Bourdon SS SS SS SS SS SS 0 to 250 0 to 400 0 to 600 0 to 800 0 to 1000 0 to 1600 5.0 10.0 10.0 20.0 20.0 50.0 For range other then above please contact our design dept. Notes Benefits of Microswitch type over contact assembly n Microswitch is rated 5 amp @ 230 VAC (3A @ 28 VDC). Hence use of relay is not required n Microswitch offered as a combination of movement and switch is procured from Internationally reputed vendor. n Microswitch assembly provides better switching accuracy and repeatability Gauge 1) 2) 3) 4) Electrical contact assembly is not offered in flameproof version. Flameproof version available only in diecast aluminium case. Non- ferrous system is recommended up to 40 kg/cm2 Pressure switch can also be offered with chemical seal pressure gauges in weatherproof and flameproof cases. 5) Surface mounted flameproof housing with chemical seal pressure gauge is available with capillary. n Compact design. Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 21 Ordering Information MODEL : IPSH OPTION MOUNTING V C S P B A 1 SPDT B 2 SPDT C Colour band CE CE Certificate D Dual Scale F Flanged Process connection ** H Flameproof housing # I 1 SPST J 2 SPST L Nil N NACE-MR-01-75 R Relay U Chemical Seal Unit-Refer Catalogue CSU X Accessory - Refer Catalogue ACC Bottom Entry, Local Mounting Back Entry, Local Mounting Bottom Entry, Surface Mounting Back Entry, Flush Panel Mounting Back Entry, Surface Mounting DIAL 10 - 100 mm 15 - 150 mm CASE AL Die-cast Aluminium S4 SS304 S6 SS316 BOURDON/SOCKET P S L M T Phosphor Bronze / Brass SS316 / SS316 SS316L / SS316L Monel / Monel SS316Ti / SS316Ti UNIT A B C D E F MOVEMENT 2 - Brass 4 - SS304 6 - SS316 kg/cm2 (g) Bar (g) PSI KPa mmHg Specify CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” RANGE METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other Refer Table 1 ** For Flanged Process Connection refer the table (mentioned separately) # Flame proof housing available in 100 mm dia dial and in aluminium cast only. The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 22 www.general-gauges.com Hygiene Gauges MODEL : HYG Features Designed for pressure measurement in Sanitary application n n Designed compliance to International Dairy Federation Compliance to latest EN-837 standard n Range : (-) 1 to 40 kg/cm² n n Accuracy ± 1% FSD (Standard), ± 0.5% FSD on request Unit of measurement - kg/cm², bar, n PSI, KPa, mbar Micrometer pointer n Hygiene Gauges designed for pressure measurement in Sanitary application in accordance with International Dairy Federation (IDF) requirements in pharmaceutical, dairy, biotechnology, food & beverages industries. Specifications Ref. Standard Dial EN-837 100 mm / 150 mm in Aluminium, white background, black markings Case SS304 with bayonet bezel (SS316 on request) Protection IP-68 (IS :13947 Part I) Diaphragm SS 316 L welded Movement SS304 Range Minimum (-)1 to 5 kg/cm², Maximum 0 - 40 kg/cm² Filling Fluid Silicon oil Accuracy ± 1% FSD (0.5% on request) Overrange 130% FSD (other on request) Suitability (-) 20°C to 80°C (service temperature) Zero adjustment Micrometer pointer (internal) Blow out disc Provided (on top) Optional NACE compliance External zero setting Glycerine filled case Triclover clamp SMS fittings Gasket Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 23 Ordering Information MODEL : HYG INPUT RANGE DIAL 10 - 100 mm 15 - 150 mm CASE S4 SS304 S6 SS316 RANGE Pl. specify A B C D E F kg/cm2 (g) Bar (g) PSI KPa mmHg Pl. specify OPTION A +/- 0.5% Accuracy C Colour band CE CE Certificate D Dual Scale E External Zero reset G Glycerine Filled Case S SMS Fitting T Triclover Clamp L Nil M Maxima Pointer N NACE-MR-01-75 O O2 Cleaning R 150% over range The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 24 www.general-gauges.com Bourdon Sensing Pr. Gauges-40-50-63 MODEL : SMBSPG Features n Designed to fulfill most industrial requirements as well as commercial n Range : (-) 1 to 600 kg/cm² n Bourdon in SS316 as standard n Accuracy ± 2% FSD n Unit of measurement - kg/cm², bar, PSI n Pressure Gauges are developed for OEM applications in compressed gases. Lubricating circuits etc. Table 1 Specifications Dial Case Movement Range Accuracy Overrange Suitability Blow out disc Optional Note 40 mm / 50 mm / 63 mm in Aluminium, white background, black markings Pressed Steel, epoxy painted black SS304 with bayonet bezel Brass, SS304 (refer table 1) minimum span 1 kg/cm2, maximum 600 kg/cm2 ± 2% FSD 130% FSD (-) 20°C to 60°C for ferrous system (service temperature) (-) 20°C to 60°C for non-ferrous system (service temperature) Provided (on top) Glycerine filled case (in SS case) Integral Dampner Swievel connection to facilitate rotation and in turn positioning of pressure gauge 1) 40 mm panel mounted gauge will be provided with bracket mounting and 50 mm & 63 mm with front flange 2) Non ferrous system is recommended up to 40 kg/cm² System Bourdon Socket PB Ph. Bronze Brass Brass SS SS316 SS316 SS304 Gauge System Bar, kg/cm2 Vacuum PB, SS (-)1 to 0 Compound PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS (-)1 to 0.6 (-)1 to 1.5 (-)1 to 3 (-) 1 to 5 (-)1 to 9 (-)1 to 15 (-)1 to 24 (-)1 to 39 Pressure Gauge (‘C’ shaped Bourdon) PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB, SS PB,SS PB,SS SS SS 0 to 0.4 0 to 0.6 0 to 1 0 to 1.6 0 to 2.5 0 to 4 0 to 6 0 to 10 0 to 16 0 to 25 0 to 40 0 to 60 0 to 100 SS SS SS SS 0 to 160 0 to 250 0 to 300 0 to 350 Movement Pressure Gauge Coil type Bourdon Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 25 Ordering Information MODEL : SMBSPG OPTION MOUNTING V C S P B Bottom Entry, Local Mounting Back Entry, Local Mounting Bottom Entry, Surface Mounting Back Entry, Flush Panel Mounting Back Entry, Surface Mounting 04 - 40 mm 05 - 50 mm D G L S X Dual Scale Glycerine filled case Nil A B C F kg/cm2 (g) Bar (g) PSI Pl. specify DIAL Integral Dampner Accessory - Refer Catalogue ACC 06 - 63 mm UNIT CASE PS Pressed Steel SS Stainless Steel RANGE BOURDON/SOCKET P Phosphor Bronze / Brass S SS316 / SS316 Refer Table 1 MOVEMENT F - FLANGED PROCESS CONNECTION ** 2 - Brass 4 - SS304 Size Code Rating Code Facing Code CONNECTION SIZE 4 6 10 15 20 25 32 40 1/8” 1/4” 3/8” 1/2” 3/4” 1” 1.1/4” 1.1/2” TYPE NT NT BP BT PF GS NS NPT NPT BSP BSPT PF Gas NPSM MALE / FEMALE METRIC THREADS 18 M - M 18 x 1.5 M Male 20 M - M 20 x 1.5 F Female 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other 150# 300# 600# 900# A B C D RF FF RTJ LT RF FF RTJ LT 2” 50 1500# E LG LG 3” 80 2500# F ½” ¾” 1” 1½” 15 20 25 40 The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 26 www.general-gauges.com Chemical / Diaphragm Seal Unit MODEL : CSU Features Where isolation is essential n Corrosive process fluid. n Process fluid having sediments or is viscous. n Process fluid has a tendency to solidify, freeze or crystallise at lower temperatures which may block the sensing element. n Process fluid is hazardous. n The diaphragm seal transmits process pressure to the instrument through a diaphragm. The instrument side of the diaphragm is filled with appropriate fluid. As liquids are incompressible, pressure is hydraulically transmitted to the pressure sensing element. n Proper selection of diaphragm seal is important after reviewing the application. Specifications The generally offered MOC is as follows : Upper housing : CS, SS304. SS316 Diaphragm : SS316L, PTFE, PTFE coated, Titanium, Hastelloy B, C, Nickel, Monel, Tantalum Lower housing : SS304, SS316, SS304L, SS316L,Titanium, Nickel, PTFE coated / lined, PTFE block, Hastelloy B, C. Filling Fluid : Name Application range Silicone oil(-) 40°C to 200°C Fluorolube(-) 50°C to 150°C Glycerine0 to 80°C Paraffine0 to 85°C DC-704 0 to 339°C Halocarbon(-) 25°C to 225°C Food grade oil 0 to 150°C Water 20 to 80°C Note : 1) Purchaser must confirm the suitability of the MOC suggested. 2) Capillary for remote seal can be offered. Different types of diaphragm seal offered: 1) 2) 3) 4) 5) 6) 7) Direct mounted Inline flow through type with flanged connection. Inline flow through type (jacketed) Inline flow through type (weld in) Extended diaphragm seal Pan cake type diaphragm seal I-Section type Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 27 Dimensions 1) In-line flow through type (End connection flanged) For application in Waste Water, Pulp & Paper, Synthetic Fibre, where fluid is viscous and will contain solid undissolved particles. 2) In-line flow through type (Jacketed) For applications where process fluid is likely to solidify as temperature reduces. Jacketing provided for steam or thermic fluid. (End connection - weld in shown above) 3) In-line Flow through type (Weld in) End pipe suitable for butt welding to the process pipe. For application in Waste Water, Synthetic Fibre, Pulp & paper, etc. 4) Extended diaphragm seal Diaphragm flushed to the process. Extension depends upon nozzle standout. Allows mounting in insulated vessels or pipelines. 28 5) Pan Cake type diaphragm seal Sandwiched between loose flange (back-up flange) and nozzle flange. For fluids which are corrosive, contaminated, etc. www.general-gauges.com Ordering Information MODEL : CSU OPTION CE CE Certificate F Flanged process connection ** FC Flushing connection FR Flushing Ring L Nil O O2 Cleaning P Capillary for mounting "S" * W Welded Diaphragm MOUNTING DM Direct mounted IF Inline flow through type with flanged connection. IJ Inline flow through type (jacketed) IJ Inline flow through type (weld in) ED Extended diaphragm seal PC Pan cake type diaphragm seal IS I-Section type FILLING FLUID S F G P D H V W TOP CHAMBER C CS S4 SS304 S6 SS316 DIAPHRAGM S6 SL ST SP S1 HB HC SS316 SS316L SS316Ti SS316+PTFE SS321 Hastelloy B Hastelloy C S6 SL ST SP S1 M4 SS316 SS316L SS316Ti SS316+PTFE SS321 Monel 400 M4 Monel 400 TI Titanium NI Nickel TA Tantalum SI Silver GP Gold Plated GL Gold PT PTFE F - FLANGED PROCESS CONNECTION ** Size Code Rating Code Facing Code 150# 300# 600# 900# A B C D RF FF RTJ LT RF FF RTJ LT 2” 50 1500# E LG LG 3” 80 2500# F ½” ¾” 1” 1½” BOTTOM CHAMBER 18 Incoloy 800 HB HC TI NI TA Silicone oil Fluorolube Glycerine Paraffine DC-704 Halocarbon Food grade oil Water Hastelloy B Hastelloy C Titanium Nickel Tantalum 15 20 25 40 CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other * Length of capillary to be specified in bracket e.g. P (3) i.e. 3 mtr. capillary ** For Flanged Process Connection refer the table (mentioned separately) The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. www.general-gauges.com 29 Accessories MODEL :ACC Snubber Syphon Two way isolation valve Pulsation dampener for pulsating services, or where vibration exists, on pump discharge lines, for dampening erratic pressures. Available in materials such as CS, SS304, SS316, Monel standard connection 1/2” NPT(F) x 1/2” NPT(M) (please specify other connection) For lowering the service temperature so that guage is exposed to lower temperature (i.e. <600C). Generally offered in 1/2” sch, 40 or 80 size (other sizes also can be offered on request). Two types - U type and pig tail type are mainly offered, as customer desires. Available in material like CS (A106), SS304 SS316, P11 etc. IBR Certification - Wherever applicable is offered. Standard connection ½” NPT(F) x 1/2” NPT(M). Butt welded (plain) connection also can be offered. Simple needle type isolation valve used for isolating (separating) process from the gauge. Available in CS, SS304, SS316. Standard connection is ½” NPT(F) x 1/2” NPT(M). Request for other requirements. Gauge saver Three way isolation valve Swivelling adaptor or gauge union Used where maximum pressure (or design pressure) exceeded to the overrange pressure of the gauge. Minimum setting, generally offered is 1 kg/cm2g. Request for lower settings. Normally offered in SS316 & Monel. Other material on request. Standard connection offered is ½” NPT. Isolates the gauge from the process and has drain facility. Available normally in SS316 (other material on request). Standard connection of 1/2” NPT(F) x 1/2” NPT(F) x 1/2” NPT(M). (Please specify other requirement like 1/2” BSP or M20 x 1.5 etc.) Facilitates positioning of the gauge while installation. Generally offered in the same material as that of socket i.e. SS304, SS316, Monel. Other material can be offered on request. 30 www.general-gauges.com Ordering Information MODEL : ACC ACCESSORY SN Snubber SYP Pig Tail Type Syphon SYU “U” Type Syphon GS Gauge Saver GA Gauge Adaptor BB Block & Bleed Valve 2W Two Way Isolation Valve 3W Three Way Isolation Valve SW Swivelling adaptor 2V Two Valve Manifold 3V Three Valve Manifold 5V Five Valve Manifold PROCESS CONNECTION Pl. Specify I L N O OPTION IBR Nil NACE-MR-01-75 O2 Cleaning MATERIAL CS S4 S6 SL M4 F Carbon Steel SS304 SS316 SS316L Monel Pl. Specify INSTRUMENT CONNECTION Pl. Specify The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. www.general-gauges.com 31 NOTES AN ISO 9001:2000 COMPANY DIFFERENTIAL PRESSURE GAUGES 35 37 Differential Pressure GaugesBellow Type Differential Pressure GaugesDiaphragm Type 43 41 Differential Pressure GaugesCapsule Type Differential Pressure GaugesMagnehelic Type 39 Differential Pressure GaugesBellow- Diaphragm Type 45 Indicating Differential Pressure Switch 49 In House Facilities 47 Flow Indicator 34 50 Convertion Chart www.general-gauges.com Differential Pr. Gauges - Bellow Type MODEL : DPG-B Features n Bellow type construction n Referance Standard: EN - 837 n All SS internals n Screwed / Flanged connection n Chemical seal unit (optional) for process suitability n Accuracy ± 1% FSD Microswitch type contacts as required n A set of two stainless steel bellows mounted on a force balance n enables direct reading of the actual differential pressure. n Each bellow of the pressure Gauge can withstand the full static pressure without any damage or shifting being caused to the instrument. Specifications Dial Case & Bezel Window Pointer Sensing Other wetted parts Movement Connection Range Static Pressure Accuracy Blow out disc Temperature suitability Optional 6"(150mm) Diecast aluminium / SS304 / SS316, weatherproof to IP-68 (IS:13947 Part 1) Toughened Glass with rubber ring Light weight, micrometer adjustable Bellow in SS316L SS316 L SS304 / SS316 ½" NPT (M) as standard (other on request) Minimum 0 to 1000 mm WC Upto 60 kg/cm2g, Higher Static Pressure on request ± 1% FSD Provided (top of the case) (-) 20°C to 80°C Chemical seal unit Liquid filled case Microswitch type contacts (5 Amp @ 230 VAC) External zero mechanism Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 35 Ordering Information MODEL : DPG-B OPTION MOUNTING CE E G S N O D L P U CE Certificate External zero Adjustment Glycerin Filled Case Silicon Oil Filled Case NACE-MR-01-75 O2 Cleaning Dual Scale Nil 2" Pipe Mounting Bracket Chemical Seal Unit-Refer Catalogue CSU X Accessory - Refer Catalogue ACC S Bottom Entry, Surface Mounting P Back Entry, Panel Mounting Y Yoke Mounting (2" pipe mounting) DIAL 15 - 150 mm CASE AL Die-cast Aluminium S4 SS304 S6 SS316 BELLOW S6 SS316 L STATIC PRESSURE MOVEMENT A SS304 B SS316 Please Specify UNIT CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other A B C D E kg/cm2 (g) Bar (g) PSI KPa mmHg RANGE Please Specify The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 36 www.general-gauges.com Differential Pr. Gauges - Diaphragm Type MODEL : DPG-D Features n Diaphragm (double diaphragm design) type construction n Static pressure upto 100 kg/cm2 (higher static pressure on request upto 300 Kg/cm²) n Referance Standard: EN - 837 n All SS internals n Screwed / Flanged connection n Accuracy ± 2% FSD (1.6% FSD on request - assending side) Specifications Dial Case & Bezel Window Pointer Sensing Other wetted parts Movement Connection Range Static Pressure Accuracy Blow out disc Temperature suitability 4" / 6" Nominal Diecast aluminium / SS304 / SS316, weatherproof to IP-68 (IS:13947 Part 1) Toughened Glass with rubber ring Light weight, micrometer adjustable Diaphragm in SS316 / SS316L / Monel / Titanium / Hastelloy C SS316 / SS316L / Monel / Titanium / Hastelloy C SS304 ½" NPT (M) as standard (other on request) Minimum 0 to 600 mm WC Upto 100 kg/cm2g max. (Higher static pressure on request) ± 2% FSD (1.6 % FSD on request) Provided (top of the case) (-) 20°C to 80°C Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 37 Ordering Information MODEL : DPG-D OPTION MOUNTING CE N O D L P X S Bottom Entry, Surface Mounting P Back Entry, Panel Mounting Y Yoke Mounting (2" pipe mounting) DIAL 10 - 100 mm 15 - 150 mm CASE CE Certificate NACE-MR-01-75 O2 Cleaning Dual Scale Nil 2" Pipe Mounting Bracket Accessory - Refer Catalogue ACC STATIC PRESSURE AL Die-cast Aluminium S4 SS304 S6 SS316 Please Specify UNIT DIAPHRAGM A B C D E S6 SS316 HC Hastelloy C - 276 HB Hastelloy B M Monel 400 L SS316L T Titanium kg/cm2 (g) Bar (g) PSI KPa mmHg RANGE Please Specify MOVEMENT A SS304 B SS316 CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 38 www.general-gauges.com Diff. Pr. Gauges-Bellow Diaphragm Type MODEL : DPG-BD Features n Bellow- Diaphragm type construction n Static pressure upto 40 kg/cm2 (Max.) n All SS internals n Screwed / Flanged connection n Accuracy ± 1% FSD n Unit of measurement - mbar, mmWC, kpa n IP-67 Protection n For measurement of small differential Pressures at high static Pressure. Specifications Dial Case & Bezel Window Pointer Sensing Element Other wetted parts Movement Connection Range Static Pressure Accuracy Blow out disc Temperature suitability 4" / 6" Nominal SS304 / SS316, weatherproof to IP-68 (IS:13947 Part 1) Toughened Glass with rubber ring Micrometer pointer Bellow- Diaphragm in SS316 SS316 SS304 ½" NPT (M) as standard (other on request) Minimum 0 to 250 mm WC Upto 40 kg/cm2g max. ± 1% FSD Provided (top of the case) (-) 20°C to 80°C Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 39 Ordering Information MODEL : DPG-BD OPTION MOUNTING CE D L N O P X S Bottom Entry, Surface Mounting Y Yoke Mounting (2" pipe mounting) DIAL 10 - 100 mm 15 - 150 mm CASE AL Die-cast Aluminium S4 SS304 S6 SS316 STATIC PRESSURE Please Specify BELLOW DIAPHRAGM UNIT S6 SS316 A B C D E MOVEMENT A SS304 B SS316 CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” CE Certificate Dual Scale Nil NACE-MR-01-75 O2 Cleaning 2" Pipe Mounting Bracket Accessory - Refer Catalogue ACC METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other kg/cm2 (g) Bar (g) PSI KPa mmHg RANGE Please Specify The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 40 www.general-gauges.com Differential Pr. Gauges-Capsule Type MODEL : DPG-C Features n Low differential pressure measurement with high accuarcy n Sensing element- Capsule in SS316L n Screwed connection n Accuracy ± 1% FSD n General stainless steel capsule differential pressure gauges are designed for measuring small differential pressures on clean & dry air or gas system Specifications Dial Case & Bezel Window Sensing Connection Range Static Pressure Accuracy Temperature suitability 4"(100mm) / 6"(150mm) SS304 / SS316, weatherproof to IP-68 (IS:13947 Part 1) Toughened Glass with rubber ring Capsule in SS316L ½ " NPT (M) as standard (other on request) Any range between 0 to 60 mm WC to 0 to 1000 mmWC 10 times the range ± 1% FSD (-) 20°C to 80°C Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 41 Ordering Information MODEL : DPG-C OPTION MOUNTING CE N O X S Bottom Entry, Surface Mounting V Bottom Entry, Local Mounting DIAL 10 - 100 mm 15 - 150 mm STATIC PRESSURE CASE 10 Times range S4 SS304 S6 SS316 UNIT CAPSULE L CE Certificate NACE-MR-01-75 O2 Cleaning Accessory - Refer Catalogue ACC E F SS316L MOVEMENT mmWC Pl. specify RANGE A SS304 B SS316 Please Specify CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 42 www.general-gauges.com Differential Pr. Gauges-Magnehelic Type MODEL : DPG-M Features n Magnet-Viton Diaphragm type construction n Static pressure 35 bar & 100 bar n Body block - SS / AL. n Screwed connection n Accuracy ± 2% FSD (Ascending) n Glycerine filled case as an option n Unit of measurement - Kg / cm², bar, mmWC n IP-67 Protection Specifications Dial Case & Bezel Sensing Body Material Magnet Spring Connection Range Static Pressure Accuracy Blow out disc Temperature suitability Optional 4" / 6" Nominal SS 304 weatherproof to IP-65 (IS:13947 Part 1) Diaphragm in Vitom Aluminium / SS304 /SS316 Ceramic SS316 ¼" NPT (F) as standard (other on request) As customer requires (Minimum 0 to 100 mm WC) 35 bar & 100 bar ± 2% FSD (on Ascending Side) Provided (top of the case) (-) 20°C to 80°C Switching : SPST Voltage : 230V AC/DC (max) Rating Switch : 1SPST & 2 SPST Capacity : 30 VA AC/DC (max) Current : 1 A (max) Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 43 Ordering Information MODEL : DPG-M OPTION MOUNTING CE D I J L P X L Local (Direct) Mounting P Panel Mounting DIAL 10 - 100 mm 15 - 150 mm CASE S4 SS304 STATIC PRESSURE DIAPHRAGM Please Specify V Viton MOVEMENT UNIT A SS304 B SS316 CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” CE Certificate Dual Scale 1 SPST 2 SPST Nil 2" Pipe Mounting Bracket Accessory - Refer Catalogue ACC METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other A B C D E kg/cm2 (g) Bar (g) PSI KPa mmHg RANGE Please Specify The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 44 www.general-gauges.com Indicating Differential Pressure Switch MODEL : IDPS GENERAL has been designing and manufacturing high quality Diaphragm / Bellow Type Differential pressure indicating switches to suit to most of the industrial application for accurate control of the process equipments. Rigorous and continuous tests are conducted for design and quality conformance. n Indicating Differential Pressure Switches are design to use in Pumps, Compressors, Lubrication Systems, Turbines, Generators, Boilers, Furnances etc. in industries such as Chemical, Fertiliser, Ferrous & Non-ferrous metal, Pulp & Paper, Power, Waste Water Treatment, Refinery & Petrochemical, Synthetic Fibre, etc. Specifications Sensing Element Case Cable Entry Switch Movement Set Point Mounting Process Connection Range Indication Accuracy Switching Accuracy Repeatability Process Temperature Calibration : SS316L diaphragm or bellow : Diecast aluminium, epoxy painted, weatherproof to IP-68 (IS:13947 Part I) or flameproof to I, IIA, IIB (equivalent to NEC CI. 1 Gr C & D) SS304 / SS316 optionally : ½” NPT (F) : I SPDT / 2 SPDT. Snap acting micro-switch (DPDT on request) Rated 5A @ 230 VAC (3A @ 28 VDC) : Brass : Adjustable throughout the range : Surface Mounting / Pipe, also available with Remote Seal : 1/2” NPT (M) as standard. Other connections optionally : As customer requires (minimum 0 to 1000 mm WC) : ±1% FSD : ±1.5 - 2% FSD : 1% FSD : (-)20°C to 60°C for SS wetted parts : All switches are individually calibrated Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 45 Ordering Information TYPE : IDPS OPTION MOUNTING A B CE E N O D L P U 1SPDT 2SPDT CE Certificate External zero Adjustment NACE-MR-01-75 O2 Cleaning Dual Scale Nil 2" Pipe Mounting Bracket Chemical Seal Unit-Refer Catalogue CSU X Accessory - Refer Catalogue ACC S Bottom Entry, Surface Mounting P Back Entry, Panel Mounting Y Yoke Mounting (2” pipe mounting) DIAL 15 - 150 mm CASE AL Die-cast Aluminium S4 SS304 S6 SS316 DIAPHRAGM / BELLOW S6 SS316 Static Pressure Please Specify MOVEMENT Brass UNIT A B C D E CONNECTION TYPE SIZE MALE / FEMALE 6 1/4” NT NPT M Male 10 3/8” BP BSP F Female 15 1/2” BT BSPT 20 3/4” PF PF 25 1” GS Gas 32 1.1/4” NS NPSM 40 1.1/2” METRIC THREADS 18 M - M 18 x 1.5 20 M - M 20 x 1.5 24 M - M 24 x 1.5 27 M - M 27 x 2 33 M - M 33 x 2 X X - Any other kg/cm² (g) Bar (g) PSI KPa mmHg RANGE Please Specify F - FLANGED PROCESS CONNECTION ** Size Code Rating Code Facing Code 150# 300# 600# 900# A B C D RF FF RTJ LT RF FF RTJ LT 2” 50 1500# E LG LG 3” 80 2500# F ½” ¾” 1” 1½” 15 20 25 40 The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 46 www.general-gauges.com Flow Indicator MODEL : FI Features n Differential Pressure across Orifice Plate Asembly n Weld Neck Flange connection n Unit of measurement direct in terms of flow unit n Weatherproof to IP – 67 (IS 13947 Part 1) Specifications Orifice Plate Assembly Design Types Plate material Orifice Bore Tab Plate Vent / Drain Flange Union Pressure Tappings Gasket Studs / Nuts Jack Screw Conforms to ISA RP 3.2 , DIN 1952 , BS 1042, ISO-5167 Square edge concentric, Quadrant edged, Conical entrance, Eccentric, Segmental SS304 , SS316 , SS316L as standard. Hastelloy-C , Monel , PP , PVC , PTFE coated , etc. can be given on request. In accordance with ISO-5167, BS-1042, ASME MFC 3M, R.W.Miller, L.K.Spink, AGA-3 In the same material as plate & is welded to orifice plate. Tag plate integral to the Orifice plate (i.e. without welding) can also be offered as a special case. Vent or Drain holes are provided as per customer’s requirement. Not drilled for orifice bores smaller than 25.4 mm Weld neck, Slip on, Threaded, Socket welded with RF or RTJ facing Orifice flanges are in accordance with ANSI B16.36 with minimum flange rating of 300# for sizes up to 8” or male - female flanges in accordance with ANSI B16.5. Corner tappings are recommended for sizes upto 1 ½”; Flange taps from 2" to 16" ; D – D/2 taps for higher sizes. CAF as per IS: 2712 Gr 0/1 , SS spiral wound + CAF , SS spiral wound + Grafoil, SS spiral wound + PTFE are normally supplied as per process requirement. Other materials available on request. For RTJ flanges , the plate is fixed on the plate holder. The plate holder is in Soft Iron material & acts as a gasket . ASTM A193 Gr.B7/A-194 Gr.2H as standard, Other material on request. Carbon Steel ( C1038 heat treated ) Flow Indicator Dial Case & Bezel Window Pointer Sensing Other wetted parts Movement Connection Range Static Pressure Accuracy Blow out disc Temperature suitability Optional 6"(150mm) Diecast aluminium / SS304 / SS316, weatherproof to IP-67 (IS:13947 Part 1) Toughened Glass with rubber ring Light weight, micrometer adjustable Bellow in SS316L SS316 L SS304 / SS316 ½" NPT (M) as standard (other on request) Minimum 0 to 1000 mm WC Upto 60 kg/cm2g, Higher Static Pressure on request ± 1% FSD Provided (top of the case) (-) 20°C to 80°C Three Valve Manifold in SS316, suitable SS tubing and associated instrument fittings Under Technical Collaboration with M/s. Gauges Bourdon, U.K. www.general-gauges.com 47 Ordering Information MODEL : FI Flow Range TYPE OF ORIFICE PLATE SC Square Edge Concentric QC Quadrant Edge Concentric CC Conical Entrance EC Eccentric SE Segmental PLATE MATERIAL S4 S6 SL ST SP S1 M4 SS304 SS316 SS316L SS316Ti SS316+PTFE SS321 Monel 400 1 2 3 4 5 3.18mm 6.35mm 9.52mm 12.7mm Please Specify PP Poly Porpley HB HC TI PF TA Hastelloy B Hastelloy C Titanium PTFE Tantalum PLATE THICKNESS Please Specify STATIC PRESSURE Please Specify UNIT A B C D E kg/cm2 (g) Bar (g) Psig KPa mmHg RANGE Please Specify FLANGE DETAILS Type Weld Neck / Slip on / Threaded / Socket Weld Size Schedule Rating Facing ½ Inch to 24 Inch Please Specify 150# / 300# / 600# / 900# / 1500# / 2500# RF / RTJ Material Please Specify The recommendations made in this catalogue are to be used as intended guide. No guarantee of material can be undertaken since other factors may affect the performance. We reserve the right to change the specifications mentioned in this catalogue without any notice as improvements & development is a continuous process at General. Responsibility of typographical errors is specifically disclaimed. 48 www.general-gauges.com In House Facilities In-House testing facilities for Pressure Gauges Pressure Gauges, Differential Pressure Gauges and Pressure Switches are manufactured in technical collaboration with M/s Gauges Bourdon, U.K. The same are manufactured and tested in accordance with EN : 837 standard. According to the said international standard, following tests are carried out to ensure the quality of Pressure Gauges. We can carry out following tests-In-House-at our manufacturing plant. 1. Visual Inspection 9. Effects of Mechanical Shock 2. Dimensional Verification 10. Endurance test with Steady Pressure 3. Accuracy Test 11. Endurance test with Over Pressure 4. Hysteresis Test 12. Endurance test with Cyclic Pressure 5. Leak Test 13. Safety Blow-out Test 6. Influence of Mounting Position 14. Thermal stability test at rated temperature 7. Degree of Protection 15. Temperature effect test 8. Effects of Mechanical Vibration 16. Energy release test www.general-gauges.com 49 50 0.000097 0.000967 0.00425 0.968 0.03342 0.001316 0.01316 0.000987 0.987 0.00001 0.001421 0.01421 0.0625 14.22 0.4912 0.01934 0.1934 0.0145 14.504 0.000145 9.869 0.00246 0.0361 145.04 1 14.7 0.00987 0.0681 1 0.14504 atms. psi 4019 4.019 0.00402 401.9 0.4012 5.358 0.536 13.61 394.1 1.732 0.3937 0.0394 1 407.2 27.71 “WC 102,074 102.07 0.102 10,210 10.21 136.1 13.61 345.7 10001 43.986 10 1 25.4 10,343 703.8 mm WC 10,207 10.207 0.0102 1021 1.021 13.61 1.361 34.57 1000.1 4.4 1 0.1 2.54 1,034.30 70.38 cm 2321 2.321 0.00232 232.1 0.2321 3.1 0.31 7.858 227.6 1 0.227 0.0227 0.5775 235.1 16 oz/in² WC 10.2 0.0102 0.00001 1.02 0.00102 0.0136 0.00136 0.0345 1 0.0044 0.001 0.0001 0.00254 1.033 0.0704 Kg/cm² 295.3 0.295 0.000295 29.53 0.0295 0.394 0.0394 1 28.96 0.1273 0.0289 0.00289 0.0735 29.92 2.036 “Hg 7500 7.5 0.0075 750 0.75 10 1 25.4 735.6 3.232 0.735 0.0735 1.866 760 51.715 mm 750 0.75 0.00075 75 0.075 1 0.1 2.54 73.56 0.3232 0.0735 0.00735 0.187 76 5.17 cm Hg Hg 10,000 10 0.01 1,000 1 13.33 1.333 33.86 980.7 4.31 0.98 0.098 2.488 1013 68.95 mbar 10 0.01 0.00001 1 0.001 0.01333 0.001333 0.0339 0.981 0.00431 0.00098 0.000098 0.00249 1.013 0.0689 bar 1,000,000 1,000 1 100,000 100 1,333 133.3 3,386 98,067 431 98 9.8 248.8 101,325 6,895 Pa To convert pressure from one unit to another: 1. Start at column heading with units to convert from. 2. Move down the same column to number “1”. 3. Move across this row to the column with units heading you are converting to. 4. Multiply the number in this table cell times the amount you are converting from to get the new value in converted units. 1,000 1 0.001 100 0.1 1.333 0.1333 3.386 98.07 0.431 0.098 0.0098 0.249 101.3 6.895 KPa (N/m²) 1 0.001 0.000001 0.1 0.0001 0.00133 0.000133 0.00339 0.0981 0.00043 0.0001 0.00001 0.00025 0.1013 0.0069 MPa Convertion Chart www.general-gauges.com www.general-gauges.com 51 52 www.general-gauges.com HEAD OFFICE: 194/195, Gopi Tank Road, Mahim, Mumbai - 400016. Tel: 022-24454387, 24449177 Fax: 24463507 E-mail: info@general-gauges.com Website: www.general-gauges.com visit our AV presentation on www.general-gauges-corporatefilm.com PLANT: Gauges Bourdon(I) Pvt. Ltd. (Under technical collaboration with M/s. Gauges Bourdon, U.K.) 4, 5, 6 Jawahar Co-op Industrial Estate, Kamothe, Panvel- 410209. Tel: 022-27421095, 27421903, 27423744, 27423745 Fax: 27421901 E-mail: gbipl@bom8.vsnl.net.in BANGALORE: ‘B’ Wing - 1005, Mittal Tower, M G Road – 560001. Telefax : 080-41510946 E-mail: gicbangalore@generalinstruments.net CHENNAI: 7, Block AD, II Avenue, Anna Nagar - 600040 Ph: 044-26211763 Fax: 26203910 E-mail: gicchennai@generalinstruments.net NEW DELHI: 511, Eros Apartments, 56, Nehru Place -110019 Ph: 011-26433201 Fax: 41607464 E-mail: gicdelhi@generalinstruments.net VADODARA: 715, Yashkamal Building, Tilak Road - 390005 Ph: 0265-22235192 Telefax: 22362475 E-mail: gicbaroda@generalinstruments.net OVERSEAS NETWORK: AUSTRALIA BANGLADESH CANADA FRANCE GERMANY KUWAIT MALAYSIA SINGAPORE THAILAND UAE UK USA www.enggcatalogueservices.com BRANCHES: