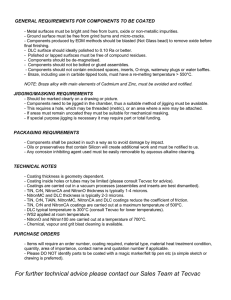

Diamond-Like carbon coatings for

advertisement