RENEWABlE ENERGY WIND / SOlAR TRANSFORMERS

advertisement

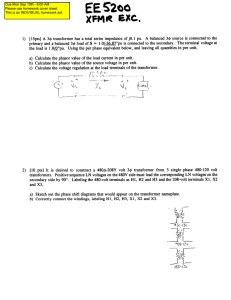

VIRGINIA TRANSFORMER Precisely Your Power Solution RENEWABlE ENERGY WIND / SOlAR TRANSFORMERS long life, reliability, VAlUE Virginia Transformer has over three decades of experience in the custom design and manufacturing of power transformers. That experience extends across every conceivable market – utility, industrial, commercial, alternative energy, marine/offshore, transit, data centers. Anywhere that electrical power needs to be generated, transmitted or distributed, you’ll find VT transformers in operation. We offer solutions for the widest range of markets and applications of any power transformer company in North America. Whatever your particular needs are, we can provide Precisely Your Power Solution. The history of Virginia Transformer is one of custom transformer designing. We began manufacturing transformers for the mining industry, and these liquid-filled and dry type transformers had to be designed to meet very low profile construction standards and to operate reliably in extremely harsh, high-temperature environments. The knowledge gained from these early projects guided Virginia Transformer in the development of numerous design innovations. As our product line has, and continues to expand, we continue to produce innovative solutions for power transformer applications developing the best possible transformer to meet our customers’ specific needs. Virginia Transformers experience, expertise and ingenuity continue to expand and develop along with the breadth of our product range. VT has moved to the forefront of transformer design for alternative energy projects, and has become the manufacturer of choice for numerous wind farm projects. We continually improve the efficiency of our processes throughout our facilities. Virginia Transformer remains committed to providing comprehensive solutions for all your power needs with the shortest lead times in the industry, and the highest quality and reliability available. GENERATING WIND POWER COLLECTOR TRANSFORMER GSU PAD MOUNT TRANSFORMER (at base of turbine) PHOTOVOLTAIC MODULES TRANSFORMER TO GRID GENERATING SOLAR POWER INVERTER PAD MOUNT TRANSFORMER GSU STEP UP TRANSFORMER TRANSFORMER TO GRID • Edom Hills / Desert Springs, CA / 15 MVA • Roe Heights, SD / 17 MVA (LTC) • Hilo, HI / 15 MVA (LTC) • Prince Edward Island / 30 MVA • Wolverine Creek Wind Farm / Idaho Falls, ID 45/60/76 MVA • Bangore ME. / 37.5 MVA (LTC) • UPC Wind / Prattsburgh, NY / 39 MVA • Ciambro / Stretton, ME / Grounding Transformer WIND APPlICATIONS Virginia Transformer’s new generation line of Wind/Solar GSU Pad Mounted Transformers are designed to outlast the life of the wind turbine – up to a 30 year life without replacement. This could impact the potential lost revenue/O & M costs over the life of a typical wind farm by more than 15% up to $8-10 Million. Typical “Distribution Type” Transformers, as presently used by the industry, are experiencing an abnormal rate of premature failures due to the partial discharge and harmonics created by the new Type 3/4 Turbines. Some transformers are failing in as little as 5-6 years, with no warranty provisions. This could lead to replacing transformers 4-5 times during the life of the turbine (25 - 30 years) – A hidden expense and lost revenue when calculating future O & M costs of operation. And the wind farm owner may not be aware of this cost when negotiating its’ PPA contract. Not only the cost of the transformers but also the labor and downtime, plus associated expenses and lost revenue. Virginia Transformer has developed special methods to eliminate potential problems in transformers used in wind applications. The magnetics of the transformer are designed in which the harmonics are absorbed/ameliorated. Special shields provide further filtering of the harmonics from passing from one side to the other. Specially designed windings and cooling arrangements take away the effects of hotspots and increase the life of the transformer substantially. WIND TRANSFORMER SPECS SPECIFICATION Pad Mounted, loop-Feed, WIND TURBINE WIND TURBINE GENERATOR GENERATOR GENERATOR GENERATOR INVERTER INVERTER INVERTER INVERTER FIl TER FIl TER Y/A Y/A (1 - 3) MVA WIND TURBINE TRANSFORMER www.vatransformer.com FIl TER FIl TER Y/A Y/A (1 - 3) MVA WIND TURBINE TRANSFORMER (1 - 3) MVA WIND TURBINE TRANSFORMER COll ECTOR TRANSFORMER COll ECTOR TRANSFORMER TO GRID GRID TIE TRANSFORMER TO GRID KVA: 1700 2200 2600 or as specified Secondary Kv: 34.5 Primary V: 690V Z:5.75% subject to ANSI tolerance Windings: CU / Al Efficiency: > 99.4 - 99.5% losses: low losses for Nll (Apprx. 2350 W), ll can be slightly higher (Approx. 13600W)* * loss fig. based on a 1600 KVA pad mounted transformer load loss temperature: 85º C BIl: HV-200 KV, lV - 30 KV Vector Group: Delta/grounded Wye Frequency: 60 HZ Average winding Temp Rise: 65º C Fluid: Mineral Oil / FR3 / Beta Fluid Mechanical HV and lV compartments are separated by a mechanical barrier. lV on Right and HV on left when viewed from front. lV compartment door flat panel design HV door open only after lV door is opened Dimensions: Height 75”, width 75”, Depth 35” (all dimensions approximate depending on KVA.) Compartment depth: C57.12.34 HV bushings: loop feed 6 bushings 600 A lV bushings: 3 suitable for 30 KV BIl DETC: + 5% to -5% in 2.5% steps Gauges: PRD, Pressure level indicator, llG, Drain and filter valve, oil sampling valve WIND TURBINE WIND TURBINE PA SoLar Park, 9/11.5 MVA, 69 kV Nesquehoning, PA ALPaugh N. SoLar Farm, 15/16.8/20/22.4 MVA, 117.5 kV, 8 kV 33/44/55 MVA, 117.5 kV Alpaugh, CA FRV SOLAR FARM, 12/16/20 MVA, 46 kV (Step up) Marana, AZ GREATER SANDHILL SOLAR FARM, 12/16/20 MVA, 69 kV Mosca, CO KALAELOA SOLAR II Project (Sunpower), 5 MVA, 46 kV Oahu, HI AVENAL SOLAR FARM (2), 15/20/25 MVA, 73 kV Avenal City, CA GRAYBAR/ROSENDIN ELECTRIC (2), 35/46.667/58.333 MVA, 115 kV Puerto Rico SOlAR APPlICATIONS Virginia Transformer Corp. has been designing and building power transformers for Solar applications for over ten (10) years. New figures released by SEIA (Solar Energy Industries Association) state that the total MW of projects under construction and under development as of the end of 2012 is around 30,265 MW in the U.S. alone and still climbing. This represents a growth rate of 85% from an installation perspective over the year 2011. The U.S. happens to be the fourth largest solar market in the world and is expected to grow even further. Virginia Transformer understands the needs of the solar developers and has successfully designed and shipped transformers for power distribution applications in a solar farm using PV modules in North America. We have been successfully meeting the stringent specifications of customers like NPI, Recurrent Energy, and have a design which precisely fits these applications. The transformers are specially designed with low losses but high efficiency standards to meet the industry’s stringent demands. Our design of these transformers accommodates the additional thermal heating due to harmonics in the current (even up to K factor =20) during DC to AC conversion of solar energy power plants. Since Virginia Transformer boasts some of the best lead times for these transformers in the industry, this is a major benefit for the developers to meet start up commitments. VTC also has embarked on designing small GSU’s for inverter house applications with special K factor and with environmentally friendly fluid like FR3. The units meet ANSI/NEMA as well as international standards and confirm to low losses and high efficiency standards. Virginia Transformer is already working with some leading manufacturers of inverter houses as a preferred OEM manufacturer of small GSU’s. All of our transformers are designed with the same care to ensure that it has a long life that meets the requirements for a full life cycle which may be anywhere from 25 - 30 years. SOlAR TRANSFORMER SPECS SPECIFICATION Solar Application Transformer Rating: 1 MVA 1.5 MVA 2 MVA or as specified Temp. Rise: 65º C Cooling Class: KNAN / ONAN Frequency: 60 HZ Duty Cycle: Designed for Step Up Operation Insulating Fluid: FR3 / Mineral Oil / BETA Altitude: Designed for operation at 1000Mt (3300 ft) above Sea level Sound level: NEMA TR1 Standard Efficiency Standard: CSA, ANSI Harmonic K Factor: None Primary Voltage: 27.6 KV, 36.5 KV or any others BIl: 150 KV KV Class: 35 KV Primary Configuration: Dead Front Primary Configuration: loop Feed Taps: 2 - 2.5% taps above and 2 - 2.5% taps below nominal Tap Changer: 100 A 5 position tap changer Primary Bushings: 600 Amp 35 KV Copper deadbreak one piece bushing (6) load Break Switching: 300 A two position break switch Arrestors: under oil, 3 Fuses: Cartridge fusing (3) in series with partial range current limiting fuses Secondary Voltage: 480 V 690 V BIl: 30 KV Secondary KV Class: 1.2 KV Secondary Bushings: Integral Aluminum & 12 hole spade bushings (4) Secondary Configuration: live front Coating: ANSI 61 Grey / or as specified PHOTOVOl TAIC MODulE 1 PHOTOVOl TAIC MODulE 2 INVERTER INVERTER FILTER FIl TER PHOTOVOl TAIC MODulE 3 PHOTOVOl TAIC MODulE 4 INVERTER INVERTER FIl TER FIl TER TRANSFORMER TRANSFORMER COLLECTOR TRANSFORMER GRID TIE TRANSFORMER TO GRID Virginia Transformer is a leader in custom power transformers engineered precisely for your application and optimized for performance and long life. Corporate Office 220 Glade View Drive Roanoke, VA 24012 540.345.9892 Fax 540.342.7692 VTC-U 3770 Poleline Rd. Bldg. #37 Pocatello, ID 83201 208.238.0720 Fax 208.238.1678 VTC-W Complejo Industrial Chihuahua Ave. Homero #3307 Chihuahua, Mexico 52.614.483.0000 Fax 52.614.481.4900 VTC-I Engineering Procurement Facility Delhi, India Field Service – Installation Maintenance Spare Parts (Available optionally after delivery) 1-800-882-3944 24/7/365 www.vatransformer.com For Sales assistance please contact our Corporate Sales Office 540.345.9892 Visit www.vatransformer.com to find the name and contact information for local sales representative Information included in this catalog was believed correct at the time of printing. Virginia Transformer Corporation reserves the right to discontinue products or change specifications without prior notification. © 1-2013 Virginia Transformer Corp