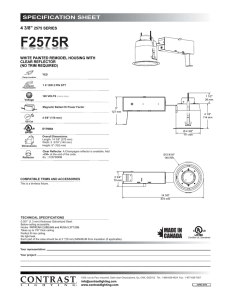

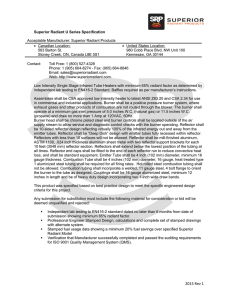

Overhead Radiant Tube Heaters - Space-Ray

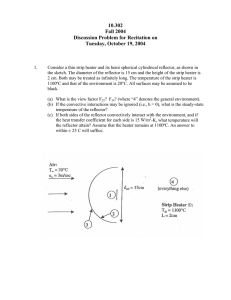

advertisement