dla support - Public Intelligence

advertisement

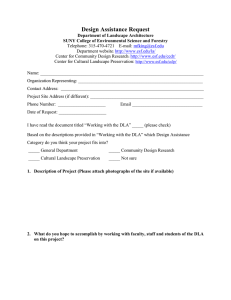

UNCLASSIFIED / FOUO DLA SUPPORT in a p Global Materiel Enterprise BG Patricia E. McQuistion Commander, Defense Supply Center Columbus Land and Maritime Demand and Supply Chains Association of the United States Army ILW Army Logistics Symposium & Exposition 17 June 2009 UNCLASSIFIED / FOUO DLA Organization Defense Supply Center C t Columbus DLA HQ Staff Theater Support Defense Supply Center C t Richmond DES Enterprise Support J-1 Human Resources Command Sergeant Major Director Chief of Staff Defense Supply Center C t Philadelphia J-3/4 Log Ops & Readiness Defense Distribution C t Center J-5 Enterprise Transformation Defense Energy S Support t Center J-6 Information Operations Defense FIELD Reutilization ACTIVITIES and Marketing Service J-7 Acquisition Management J-8 Financial Operations J-9 Joint Reserve Forces YC-3 DLA Pacific DLA Europe DLA Africa DLA Central Def Logistics Info Service YC-3 Defense Automation & Production Service Defense National Stockpile Stoc p e Center Logistics Service Activities •2 UNCLASSIFIED / FOUO Scope of Combat Support • • • • • Provides 100% of Services’ – Subsistence – Fuels – Medical supplies – Clothing & textiles – Construction & barrier materiel p p 95% of Services’ repair parts Performs federal cataloging Supports new systems provisioning Manages 3.8 million items via 8 supply chains ­ 54,000 requisitions/day ­ 8,200 contracts/day ­ 25M annual receipts and issues ­ 133M barrels of fuel sold ­ $14.6B annual in reuse/ disposals #64 Fortune 500 – above Walt Disney y #3 in Top 50 Distribution Networks * 26 Distribution Depots worldwide UNCLASSIFIED / FOUO DLA Business Model COCOMs and The operating environment shapes warfighting and sustainment Connected C d To Warfighter Demand Single Point of Accountability • BRAC • DLA Forward • Demand Planning and • Collaboration • DLA Commands Standard St d d Processes & Systems EBS Enterprise Business System DLA Customized Solutions • Performance Based Logistics • Prime Vendor • Wholesale-Retail Integration Low Cost ­ Low Cost ­ Best Value • Cost Reductions • Reduce Rate Service Enterprise Partners US TRANSPORTATION COMMAND CONTRACTOR PARTNERS UNCLASSIFIED / FOUO Supply Chain Operations Reference (SCOR) Model Supplier’s Supplier Deliver Plan Supplier Source Make Customer Deliver Source Make Deliver Source Make Deliver Customer’s Customer Source R t Return R t Return (Plan – Source – Make – Deliver – Return) • • • • DLA Enterprise Perfect Order Fulfillment Demand Plan Accuracy Attainment to Plan Cost Performance • • • • Service Needs USN/USMC: CASREPs USA: AOG, Reset, CCIR USAF: AAIP, AAIP MICAPs Material Avail, Unfilled Orders Goal Congruence in a Global Materiel Enterprise UNCLASSIFIED / FOUO DLA Fusion Center Portal • Customer Targeted Outcome (CTO) metrics programmed into the Fusion Center Portal into the Fusion Center Portal Customer Outcomes Tab – Access to detailed status information and analysis by Service and weapon system – Links outcomes to each Supply Chain partner’s contribution to those results Service Summary Page Weapons Systems Summary Page Unit Drill Down Summary Page UNCLASSIFIED / FOUO •EPR Dashboard – April 2009 Fusion Center Land Dashboard •7 UNCLASSIFIED / FOUO DLA Demand and Supply Chains Aviation Land Richmond • Aviation Original Equipment Manufacturer (OEM) Items C&T Columbus • Gun Parts Medical Subsistence C&E Philadelphia • Valves/Hardware • Recruit Clothing • Pharmaceutical • Automotive Parts • Fluid Handling - Pipes/Tubing - Compressors - Pumps • Engines & Airframes • Aviation Supply Chain Commodities Maritime • Organizational Clothing Equipment • Institutional Feeding • Medical/Surgical Equipment • Operations Rations Energy Ft. Belvoir • Construction • Equipment • Produce • Electronics • Motors • Batteries • Packing/Gaskets g • Nuts & Washers • Wire & Cable • Converters • Electrical Connectors Enterprise Business System (EBS) FAS UNCLASSIFIED / FOUO Demand and Supply Chains Demand Chains: grouping of customers that are managed by Customer Operations “Each Customer is aligned to one, and only one, demand chain” Customer Focus Aviation Land Maritime Construction and Equipment (C&E) Clothing Cl thi and d Textiles (C&T) Medical Subsistence Supply Chains: grouping i off items/suppliers that are managed by Supplier Operations “Each Each item is aligned with one, and only one, supply chain” Supplier Focus from demand signal to order fulfillment the magic happens in the middle UNCLASSIFIED / FOUO DSCC Leadership Team Commander Deputy Commander Patricia E. McQuistion, BG Executive Director, Contracting & Acquisition q Management g Mr. James McClaugherty, SES Mr. Milton K Lewis, SES Currently deployed as the DLA Support Team h DLA S T Commander at Camp Victory, Iraq Chief of Staff Col Daniel K. Hicks, USAF YC3 Mr. Griff Warren, Deputy •10 UNCLASSIFIED / FOUO DSCC Leadership Team Land Customer Ops Land Supplier Ops COL Carl D. Bird, USA Mr Eugene Williams Mr. Williams, Deputy LTC(P) Ryan B. Kivett, USA Mr Ben Roberts Mr. Roberts, Deputy Land Supply Chain DLA Warren Ms. Ellen Dennis DLRs Maritime Customer Ops CAPT James Patton, USN Ms. Deborah Haven, Deputy Maritime Supplier Ops CAPT Roland G. Wadge, USN M P Ms. Patricia t i i A. A Shields Shi ld CDR David Peters, Deputies Maritime Supply Chain DSCC Philadelphia DLA Mechanicsburg Mr. Roger Dixon M Doug Mr. D N Nevins i DLRs DLA Norfolk Puget Team CDR Bill Nash CDR Chris Anderson Supply Storage & Distribution UNCLASSIFIED / FOUO DSCC Business Profile Our People • 2,147 Civilians; 64 Active Duty; 43 Reservists; 168 Contractors; 212 Interns Scope p of Business • 6.7M requisitions • 707K contracts/year • 1,900 1 900 contracts at $7 $7.8M/day 8M/day • 2.1M NSNs • 1,400+ weapon systems • 145,000+ customers • 7,000+ suppliers Sales Trend • FY06: $2.9B; FY07: $3.2B; FY09 Depot Level Reparables DLA-Mechanicsburg: 7,400 contracts valued at $240M supporting NAVICP DLA-Warren: 800 contracts valued at $195M supporting TACOM FY08: $3.5B Sales by Supply Chain • Land: $1.8B; Maritime: $1.7B • Foreign Military Sales: 90 nations; $280M in sales •12 UNCLASSIFIED / FOUO Forward Where Execution we are MRAP GDLS-C (LONDON, ONTARIO) PUGET SOUND NAVAL SHIPYARD (PSNSY) NAVICP-MECHANICSBURG IMF PACNORWEST LETTERKENNY (LEAD) TACOM W TACOM-Warren CECOM ASC-RI FT IRWIN MARCORSYSCOM NORFOLK NAVAL SHIPYARD (NNSY) TACOM-RI TEST LAB WEST FT CARSON I MEF-CAMP PENDLETON COMSUBFOR FT CAMPBELL FT BRAGG II MEF- CAMP LEJEUNE FT RILEY MCLB Barstow MRAP FPII (LADSON, SC) FT HOOD Japan FT DRUM PORTSMOUTH NAVAL SHIPYARD (PNSY) MRAP NAVISTAR (WARRENVILLE, IL) PMO BREMERTON TOBYHANNA (TYAD) AMCOM FT STEWART KINGS BAY (TRF) RED RIVER (RRAD) ANNISTON S O (ANAD) ( ) SASEBO, JAPAN MRAP BAE – TVS (SEALY, TX) MCLB ALBANY/LOGCOM MRAP BAE – GSD (ANNISTON, AL) YOKOSUKA, JAPAN PEARL HARBOR NAVAL SHIPYARD (PHNSY) SCHOFIELD BARRACKS Hawaii 2600+ strong in Columbus Mechanicsburg Columbus, Mechanicsburg, Philadelphia, Norfolk, Warren plus 51 forward locations… and growing … LEGEND Fwd Exec/Maritime Fwd F d Exec/Land E /L d MRAP OEM locations Product Specialist CLSS Buyer Customer Service Rep 13 UNCLASSIFIED / FOUO DSCC BRAC/Wynne Sites Puget Sound Naval SY & Bangor IMF Warren NAVICP Mechanicsburg DLR Sites SS&D Sites DLR & SS&D Site Wynne Site Portsmouth Naval SY Tobyhanna Army Depot DSCC Columbus Aberdeen Proving Ground Norfolk Naval SY MCLB Barstow MCLB Albany (DLR & SS&D Site) Pearl Harbor Naval SY & IMF Anniston Army Depot FY 09 1Q 2Q 3Q 4Q 1Q 2Q DLR NAVICP Mech Phase I (9-Nov-08) 3Q 4Q FY 10 1Q 2Q FY 11 3Q 4Q NAVICP Mech Phase II 1Q LOGCOM TACOM Rock Island (15-Feb-09) Shipyard Kickoff SS& &D (Apr-11 ) (Apr-11) CECOM (Sept-11) Norfolk II (Jun-11) Norfolk (10 May-09) Pearl Harbor (25 April-10) Puget I/Bangor Marine Corps Kickoff 4Q 3Q (Nov 09) CCO Appt. TACOM Warren 2Q (19 Jul-09) Puget II Portsmouth (Feb 10) (Feb-10) Tobyhanna (Feb 10) MCLB Albany (Sep-09) Anniston •(NLT Sep-10) Barstow (Sep-10) MCLB (Jun-11) (Jan-Mar 11) UNCLASSIFIED / FOUO Supporting Rapid Acquisition Four Procurement Avenues of Approach 1. Acquire whole supply chains • Privatization: Tires, Gases, POL, Subsistence Prime Vendor • Microelectronics • Batteries 2. Where an end-to-end supply chain does not exist, acquire and integrate supplies and services • PBL arrangements, Integrated Logistics Partnerships, Industrial Product Support Vendors 3. Where integration g services are not required, q , acquire q strategic material with flexible response • Long-term contracts with performance requirements, strategic pp alliances supplier 4. For non-strategic material: transactional buys UNCLASSIFIED / FOUO Tire Privatization 1. Acquire whole supply chains Providers: Michelin North America, Inc. & Michelin Aircraft Tire Company 5 year contracts (currently at the beginning of year 3) Fixed price per tire supplied p p pp Annual increase based on economic price adjustment (10% CAP) Contract Requirements: • • • • • • • Worldwide Supply Chain/Inventory Management Inventory drawdown/elimination Obsolescence Management Time Definite Delivery y Standards Industrial Base Maintenance CAT** CONUS OCONUS Conflict Support Customer Support 1 2 8 3* Time Definite Delivery 2 5 12 6* Service Tailored Support − Land/Army − Aircraft/AF and Army g Cost Index Program g − Landing − Retread − Scrap Disposal …next 3 10 30 Expedited 2* 5* 12* efforts are microelectronics and batteries… •16 UNCLASSIFIED / FOUO 2. Acquire & Integrated Logistics Partnerships aka Customer Pay integrate supplies and services Demand forecasting and problem prevention was poor – daily “war room” to fix issues Multiple parts missing on vehicles 1300+ “G” coded d d vehicles hi l Valued at $70M “G” Coded vehicles expensive to fix Depot challenges: Depot challenges • Uncoordinated, and multiple sources of supply • Had to resource buyers and expediters • Took many depot resources to order, receive, store, Took many depot resources to order receive store fabricate, and move stock to the production line •17 UNCLASSIFIED / FOUO After Customer Pay 2. Acquire & integrate supplies and services Defense AT&L Article – Jan-Feb 2009 “ Before Customer Pay, we went for about three months without “ producing a single vehicle that had 100 percent parts. Today, we go about three months without a single vehicle missing a single part.” --Dr. John Gray Sales Data DLA AMG TOTAL MAY 09 $13 7 M $13.7 M $6 6M $6.6M $20 3M $20.3M Availability: APRIL $13M $5.5M $18.5M MAY $11M $7M $18M Cost Savings: RRAD $1,582,000 LEAD $1,102,722 MARCH 99 99999% 99.99999% …next efforts are USMC and other TACOM fleets… 18 UNCLASSIFIED / FOUO Fleet Automotive Support Initiatives ((FASI)) 2. Acquire & integrate supplies and services • FASI-Regional – Program Benefits – Customer-focused contracts by region for Army and USMC CONUS bases – Shared DLA and contractor management of supplies – Supply chain management, parts acquisition, forecasting, obsolescence management, quality assurance and customer service reps – Reduced government inventory investment, customer costs, and administrative lead time Inventory holding costs avoided $37.8M Total • FASI-Global – Program Benefits – – – – 100% contractor management of supplies Reduces DLA inventory investment and customer costs Improved end-to-end supply chain visibility Supply chain management, parts acquisition, forecasting, obsolescence g , quality q y assurance,, and customer service reps p management, – Shared Savings Clause Savings Due to Improved Pricing: $37.7M Annually UNCLASSIFIED / FOUO Industrial Product Support 2. Acquire & integrate supplies and services Integrated logistics solution for line-side bench stock at: Anniston Army Depot R d Ri Red River A Army Depot D t Tobyhanna and Letterkenny Army Depots Program Goals: • Improved reliability and responsiveness • Supply Chain Management, Parts Acquisition, Bin Management, • Forecasting, Obsolescence Management, Customer Service Reps, Kitting, and Quality Assurance • Single point accountability • 99.85% Bin Fill Rate …next efforts are umbrella contract to implement more rapidly at other locations… UNCLASSIFIED / FOUO DSCC FY08 Contract Land Suppliers Dollars Award A d Actions Manual $492,596,874 27% LTC $1,188,605,344 66% PACE $131,902,831 7% Manual 52,880 11% PACE , 26,372 5% LTC 401,477 84% LTC = Long Term Contracts 3. Establish long­term contracts Maritime Suppliers LTC $484,067,676 33% Manual $684,802,189 $ , , 47% PACE $289,959,628 20% LTC 151,243 151 243 49% Manual 86,306 28% PACE 70,687 23% PACE = Procurement Automated Contracting Evaluation UNCLASSIFIED / FOUO Top DLA & MILSVC Suppliers 3. Establish long­term contracts Synergy across Military Services – opportunities to leverage DoD buying power DLA Strategic Partners General Electric Boeing Textron Oshkosh Honeywell Rolls Royce AM General G d i h Corp Goodrich C Parker Hannifin Sikorsky Hamilton Sundstrand Dresser Rand Eaton Corp Canadian Commercial Corp Pratt & Whitney Northrop Grumman Lockheed Martin General Dynamics BAE Systems Smiths Aerospace Raytheon Moog United Defense LP/BAE Alcoa Global Fasteners Aircraft Braking Systems Warren Pumps p Avibank York Air Force General Electric United Technologies Dynamic Gunver Technologies GKN Aerospace Rolls Royce Parker Hannifin Kaiser Electronics N th Northrop G Grumman Raytheon Goodrich Corp Hamilton Sundstrand CFM International BAE Systems Honeywell Boeing AAR Parts Trading Inc EFW Inc Military Service Top Vendors (2003-2005) Army Navy Goodyear General Electric AM General Bell Boeing Joint Project Office Boeing Boeing Lockheed Martin Sikorsky Oshkosh All Tools Inc Purdy Corp Raytheon Honeywell Lockheed Martin G General l Electric El t i B ll Helicopter/Textron Bell H li t /T t Bell Helicopter/Textron Hamilton Sundstrand DRS Optronics Rolls Royce General Dynamics Canadian Commercial Corp. Raytheon Northrop Grumman Pacific Harness and Cable BAE Systems Sikorsky United Technologies CE Niehoff & Co L-3 Communications Fenn Manufacturing Hutchinson Industries GTA Containers Cummins Inc Significant Overlap in Top Suppliers Marine Corps Canadian Commercial Corp Raytheon Ronal Industries Rodelco Electronics Mantech Systems Engineering Lockheed Martin L-3 Communications N th Northrop G Grumman Centron Industries Wendon Company Carleton Life Support Systems Harris Corp Detroit Diesel Oshkosh Aegis Power Systems Communications & Power Industries Sensis Corp System Technical Support Corp General Dynamics DLA Unique Air Force Unique Army Unique Navy Unique M i Corps Marine C Unique U i DLA/Military Service Common Supplier UNCLASSIFIED / FOUO 4. Transactional DLA Support to MRAP buys Æ LTCs We broke the mold in provisioning and sustainment Parts Support Strategy: Original Plan vs Actual Incremental CLS transition to organic, based on NSN assignment and theater requisitions FY08 FY09 FY10 2QTR 3QTR 4QTR 1QTR 1QTR Provisioning Phase I: Forecasted & Demand Driven Parts Phase II: •Type II NSNs (CAGE & PN) assigned for ASL/PLL •Obtain TECH Data 4QTR 3QTR 2QTR 1QTR 2QTR Complete Weapon System •Long Term Contracts (Sole Source & Competitive) •Type I NSNs (Fully Described) Assignment/Identification Army G4 direction: Enable units to order via NSN using tactical STAMIS O Organic i Supply S l System S t (MILSTRIP) NSN Requisitions R i iti 2008 MAR APR MAY JUNE 2009 JULY PHASE 1 Air Conditioning Parts (258 NSNs) Planning began in Spring 08 Undefinitized Contract Actions (UCA) Issued May08 – deliveries through FY08 AUG SEP OCT PHASE 2 Over 5000 NSNs (OEM) Planning in June 08 UCA’s issued in July 08 Deliveries continue in 2009 NOV DEC JAN FEB PHASE 3 Long term contracts (up to 19K NSNs) Market Survey began Oct 2008 ID new LTCs and adds to current Award by Sep 09 UNCLASSIFIED / FOUO 156 dedicated to MRAP DLA MRAP Team Customer Side Deployed DLA Support Teams (DST) • Iraq (OIF) • COL Carl Bird & Eugene Williams (Land DCO) • LTC Joan Sweeny, Land Readiness Room - (with team of 7) MRAP Program Mgt. • Dan Bohn, PM Don DiGuardi (SCPOC) • John Dreska, Dep PM (with Team of 6) • Afghanistan (OEF) • Kuwait DDC/DDRT Support Team of 5 DLIS DST Spt Team of 10 T Team off 2 Team of 2 Team of 5 Matrixed Support DLA FWD DDC Troop DLIS Management g Cherokee Buy Team Team of 2 Team of 20 MRAP IST – Support Div LTC Team Team of 51 Team of 4 Contract Admin. Team Team of 15 FPII Contract Admin Gina Robinson Navistar GDLS‐ GDLS‐C BAE‐ BAE‐TVS BAE BAE‐‐GSD Linda Combs Shelia Robbins OEM Liaisons Darrell Kem Cheryl Abercrombie­ Beckett MSGT Mike Luetkeman TBD Delores Gang SRM Pauline Buck Pauline Buck Pauline Buck TBD Pauline Buck Ken Glidden TBD Rick Bailey Provisioning Tom Stoner TBD ARMY Rob Osborn Terry McArthur USMC Tom Stoner Yvonne Bozek Sue Pavlak Marsha Christoph UNCLASSIFIED / FOUO NSN's Identified as MRAP over time Of th the 23 23,649 649 MRAP NSN's NSN' JUN09 Fe b07 M ar A p M r ay Ju n 1.8K NIINs removed, 77% are Obsolete Parts 9 141 w/ SOH 9,141 SOH > 0 Cumulative 11000 10000 9000 8000 7000 6000 5000 4000 3000 2000 1000 0 DL LA NIINs w/ SO OH > 0 Army USMC Other Tot. Documents Shipped 07 M ar A p M r ay Ju n Ju A l ug S ep O ct N ov Ja De n c -0 8 Fe b M ar A p M r ay Ju n Ju A l ug S ep O ct N ov Ja Dec n -0 9 Fe b M ar A p M r ay Ju n 9717 12000 eb 827 75000 70000 65000 60000 55000 50000 45000 40000 35000 30000 25000 20000 15000 10000 5000 0 F 1799 C Cumulative l ti DLA Inventory I t Build B ild O Over ti time Total Cus stomer Orders s Shipped Orders Shipped Ju A l ug S ep O c N t ov JaDe n- c 08 Fe b M ar A p M r ay Ju n Ju A l ug S ep O c N t ov JaDe n- c 09 Fe b M ar A p M r ay Ju n 7000 6500 6000 5500 5000 4500 4000 3500 3000 2500 2000 1500 1000 500 0 UNCLASSIFIED / FOUO MRAP Readiness Tracker Benefits: • Early Detection of NMC Drivers • Facilitates E E-Buy Buy Management • Detailed History of NMC Parts • Collaboration Tool • Performance Tracking (Internet Based Tool) Part: Nomen: Dog Door Hatch (Example) Quick Search by NIIN, Document, or Vehicle S i l Number Serial N b Weekly Inputs: •MRAP 026 (OIF & OEF) •MERIT USMC NMC DOCS Users: • Army, Navy, AF, & Marines • DLA DSTs & DLA PM MRAP Phase 2 Improvements: • Feed of RFID Tracking Data Promotes Fast Triage for DLA MRAP Critical Parts UNCLASSIFIED / FOUO MRAP Sustainment DLA MRAP NSNs & Army SSA Statistics as of 11 Jun SSA Supporting Scorpion Cascade 1900 1800 Kuwait 1700 1600 1500 1400 1300 1200 1100 1000 900 800 700 600 500 400 300 200 100 0 Afghanistan Iraq W7Z WKQ W1P W0F W0P W2W W8D W8G W29 W2E W2Z W31 WDT WES WJE WKU WLA WP3 WP6 WP7 WQ6 WVE WVZ W1C W3F RO > 0 (DLA MRAP 01 JJun 09) 1249 553 739 439 725 744 1247 1763 535 858 749 1040 689 952 938 478 878 1394 792 1827 1219 932 1103 1272 237 RO > 0 (DLA MRAP 08 Jun 09) 1254 553 742 444 756 744 1245 1767 535 853 752 1044 691 951 936 484 879 1316 791 1851 1223 929 1108 1278 241 RO > 0 (DLA MRAP SOH > 0) 1133 517 629 380 602 619 1003 1456 484 754 672 900 620 815 838 380 777 1186 682 1629 1091 822 RO > 0 (SSA Q_OH > 0) 1067 535 656 401 661 610 1124 1501 468 778 703 943 617 896 895 419 787 1216 726 1729 1153 829 1026 1216 224 10 17 26 39 26 12 30 23 16 14 20 28 RO > 0 ZBal w /Due Out 59 RO > 0 ZBal w /Due In 59 4 10 17 26 39 26 81 0 26 12 30 23 16 14 20 28 7 25 43 29 24 25 13 8 Where DLA SOH = 0 60 5 26 21 37 51 36 121 15 37 17 46 32 21 20 31 41 35 36 61 34 37 35 29 9 % ASL Zero Balance 15% 3% 12% 10% 13% 18% 10% 15% 13% 9% 7% 10% 11% 6% 4% 13% 10% 8% 8% 7% 6% 11% 7% 5% 7% % ASL Zero Bal w /DO 5% 1% 1% 3% 2% 3% 2% 1% 4% 1% 3% 2% 2% 3% 2% 1% 3% DA Standard is 8% 4 4% 3% 5% 26 2% 81 5% RO > 0 (DLA MRAP 01 Jun 09) RO > 0 (SSA Q_OH Q OH > 0) Where DLA SOH = 0 0 0% 3% RO > 0 (DLA MRAP 08 Jun 09) RO > 0 ZBal w/Due Out % ASL Zero Balance 3% 7 25 43 29 24 939 1013 211 25 RO > 0 (DLA MRAP SOH > 0) RO > 0 ZBal w/Due In % ASL Zero Bal w/DO 280 SSA Zero Bal DLA MRAP NIIN’s where SSA RO > 0 13 8 USA 737 USMC 395 USAF 149 USN 44 UNCLASSIFIED / FOUO KEY Army/Marine Corps MRAP Home Station Training 30 USAF 65 DDDE Lewis USN Hohenfels/ JMTC McCoy 30 40 Drum 30 30 29 Palms Carson DDJC 145 Riley Ft LW 40 Bliss 6 Wainwright Richardson Hawaii 44 6 Kaneohe Bay 11 30 RRAD/MTT 40 30 Hood Polk/JRTC & FSF-TT 4 RRAD/USMC Bragg 30 Shelby 16 Schofield Bks Dix Campbell Sill Pendleton 30 30 30 Irwin/NTC DDSP Atterbury 30 60 Alaska USMC Germany Total = 1,325 91 USA 96 Lejeune Stewart 2 Japan Camp Fuji 90 DLA Depots with MRAP Parts 46 Okinawa 28 UNCLASSIFIED / FOUO Organic Manufacturing Why use Organic Manufacturing? • • • • • • • Contractor Performance History No­source/No offers received Non­responsive Technically unacceptable Previously made by an organic Emergency Supply Operation Center l Diminishing Manufacturing Source 5. Organic sources Army Industrial Sites Supported Anniston Army Depot Letterkenny Army Depot Red River Army Depot Tobyhanna Army Depot Joint Manufacturing & Tech Center Army Organic Contracts FY08 JMTC: 23 Projects, $6.5M ARDEC: 1 Project, $1.9M Rules: • Must have approved Organic source • Public (organic) and Private sources can not compete against each other for awards! p g Exceptions: • Price: quoted price is formally determined to be unacceptable. • Delivery: quoted delivery time frame does D li t d d li ti f d not meet customer requirements. Army Organic Sites FY09 JMTC: 11 Projects, $2.6M ARDEC: 5 Projects, $72K TYAD: 1 Project, $7K Examples: M2 machine gun parts, other small arms, wiring harnesses and cables wiring harnesses and cables Intent: Use Organic Manufacturing capabilities to solve critical supply issues on •troubled NSNs. UNCLASSIFIED / FOUO Personal Lessons Learned • Early and continuous collaboration on requirements pays off • Understanding supply chain roles and responsibilities is g pp y p critical (e.g., engineering support, cataloging, provisioning) • Aligning metrics among DLA, TRANSCOM, the Services, and Suppliers is the path to continuous improvement of the end­ to­end supply chain • Post award actions for privatization, ILP, and IPV­type contracts requires program management structure • St Stay inextricably linked with warfighting and industrial i t i bl li k d ith fi hti d i d t i l activities requirements and routinely translate those to Suppliers Supply Chain TTP = Trust, Transparency, and Partnering UNCLASSIFIED / FOUO Opportunities in DLA • 20,805 Civilians , • 519 Active Duty Military y • 754 Reserve Military • Located in 48 States/28 Countries UNCLASSIFIED / FOUO 32