?fj BY in 2. 25W M ,Gm

advertisement

July 6, 1937.

L. s. CHADWICK

2,086,118

ADJUSTABLE SHELF FOR REFRIGERATORS OR THE LIKE

Filed Nov. 22, 1935

1F»

a,

v

/

A

?fj

2 Sheets-Sheet l

3,.

'

M

.

J

INVENTOR.

BY in 2. 25W

M ,Gm-vk Wind’

ATTORNEYS .

July 6, 1937.

2,086,118

|_. s. CHADWICK

ADJUSTABLE SHELF FOR REFRIGERATORS OR THE LIKE

Filed Nov. 22,’ 1955

2 Sheets-Sheet 2

INVENTOR,

{Lu 2.90M

BY

ATTORNEYJ.

2,086,118

Patented July .I 6, 1937

UNITED STATES PpATENT OFFICE

2,086,118

ADJUSTABLE SHELF FOR REFRIGERATORS

OR THE LIKE

Lee, S. Chadwick, Shaker Heights, Ohio, assignor

to Perfection Stove Company, Cleveland, Ohio,

a corporation of Ohio

Application November 22, 1935, Serial No. 51,128

' 3 Claims.

(Cl. 211-153)

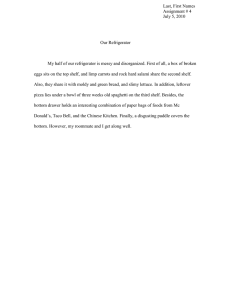

This invention is an adjustable shelf for re

front to rear, are approximately the length of

frigerators and similar enclosures in which it is

the bearing portions a and a’.

necessary or desirable to alter the spacing of the

shelves from time to time to accommodate ob

be arranged between opposed shelf supporting

jects of different heights between them.

The purpose of the invention is to provide a

'

As illustrated in Figs. 4 to '7, each shelf A may

means or ledges b in three different positions:

?rst, as shown in detail in Fig. 5, with its’ ends

simple and inexpensive construction affording a

that constitute the bearing portions a resting

wide range of adjustment and facilitating the ac

upon said means or ledges; secondly, as detailed

complishment thereof.

A typical and thoroughly practical embodiment

of the invention is illustrated in the accompany

ing drawings forming a part hereof wherein Fig. 1

is a front elevation, Fig. 2 a fragmentary plan

view, and Fig. 3 a side elevation of my improved

shelf; Fig. 4 is a front elevation of a refrigerator

incorporating the invention, and Figs. 5, 6, and 7

in Fig. 6, in a more elevated position with its

bearing portions a’ resting upon the shelf sup 10

porting means or ledges b; and, thirdly, in an

inverted position at a level below its ?rst eleva

tion with its bearing portions 0.’ again contacting

the shelf supporting means or ledges b.

15

Inasmuch as the shelf supporting means or

ledges b of each side wall 5 are spaced apart a

are sectional details through a wall of the refrig

eration compartment or enclosure and thead

distance corresponding approximately to three

times the vertical spacing of the bearing por

jacent end of the shelf, showing, respectively, the

tions 0. and a.’ of a shelf, the shelves may be 20

According to the present embodiment of the

invention, the shelf, designated generally by the

tions equally spaced apart between the high

position of the top shelf and the low position of

the bottom shelf.

Having thus described my invention, what I

20 shelf adjusted to three different elevations.

letter A, consists of a rectangular frame I, made

of a stiff, heavy gauge wire, and cross bars 2 that

25 are relatively narrow in plan but are of a depth

substantially equal to the diameter of the wire

from which the frame I is constructed, the oppo

site‘ ends of the cross bars being suitably secured

to the opposed portions of the frame I with the

30 top and bottom edges of the bars substantially

?ush with the corresponding sides of the frame

thereby to avoid a marginal obstruction to the

sliding of objects onto or off the shelf regardless

of which side of the shelf is up. The ends of the

35 frame I constitute bearing portions a.

A wide and relatively shallow U-shaped mem

ber 3, preferably constructed of material or stock

identical with that from which the frame I is

made, is secured to the underneath side of the

.40 frame (as the same is positioned in Fig. 1) a short

distance from each end thereof. The straight

central section of each member 3 constitutes a

bearing portion a’, and the same is offset lat

erally into the vertical plane of the adjacent

45 bearing portion a.

While the invention‘ is applicable to different

classes of enclosures, I have shown it in Fig. 4

as incorporated in a refrigerator B. The side

walls 5 of the refrigeration compartment 6 are

50 provided with shelf supporting means or ledges

b, the corresponding means or ledges on the op

posed walls being in the same horizontal plane,

and the adjacent ones of each wall have their

shelf supporting surfaces spaced apart preferably

5.5 three times the vertical distance between the

bearing portions 0. and a.’ of the shelves A. The

shelf supporting means or ledges b, as best shown

in Figs. 5 to 7, are desirably formed of outward

depressions of the sheet metal from which the

60 walls 5 are constructed, and, in a direction from

adjusted in the manner above described to posi

claim is:

‘

25

_

1. An invertible shelf comprising a rectangular

frame, and relatively wide U-shaped members or

rod-like material having their ends rigidly se

cured to opposed portionsof the same side of the

frame at locations inset from the ends thereof,

the central portion of each U-shaped member

being substantially parallel with and offset into

the vertical plane of the adjacent end of the

frame.

2. An invertible fabricated shelf consisting of 35

an open frame, cross members disposed between

and connected at their opposite ends to the op

posed sides of the frame, the top and bottom

surfaces of said members being substantially

?ush with the corresponding faces of the frame, 40

and relatively wide U-shaped members construct

ed of round wire having their ends secured- to

opposed portions of the same face of the frame

at locations inset from the ends thereof, the

central portion of each U-shaped member being 45

substantially parallel with and offset into the ver

tical plane of the adjacent end of the frame.

3. An invertible fabricated shelf consisting of

an open frame, cross members disposed between 50

and connected at their opposite ends to the op

posed sides of the frame, and relatively wide U

shaped members constructediof wire having their

ends rigidly secured to opposed portions of the

same face of the frame at locations inset from 55

the ends thereof, the central portion of each

U-shaped member being substantially parallel

with and offset into the vertical plane of the ad

jacent end of the frame.

LEE S. CHADWICK.

CERTIFICATE OF CORRECTION.

Patent No. 2,086, 118.

July 6,1957.

LEE S.

CHADWICK. '

It is hereby certified that error appears in the printed specification

of the above numbered patent‘requiring correction as follows: Page 1,

second column, line 27, claim 1, for the word "or" read of; and that the

said Letters Patent should be read with this correction therein that the

same may conform to the record of the case in the Patent Office.

Signed and sealed this 51st day of August, A. D. 1937.

(Seal)

Acting Commriessslilcgelirraoyiellfjatents.