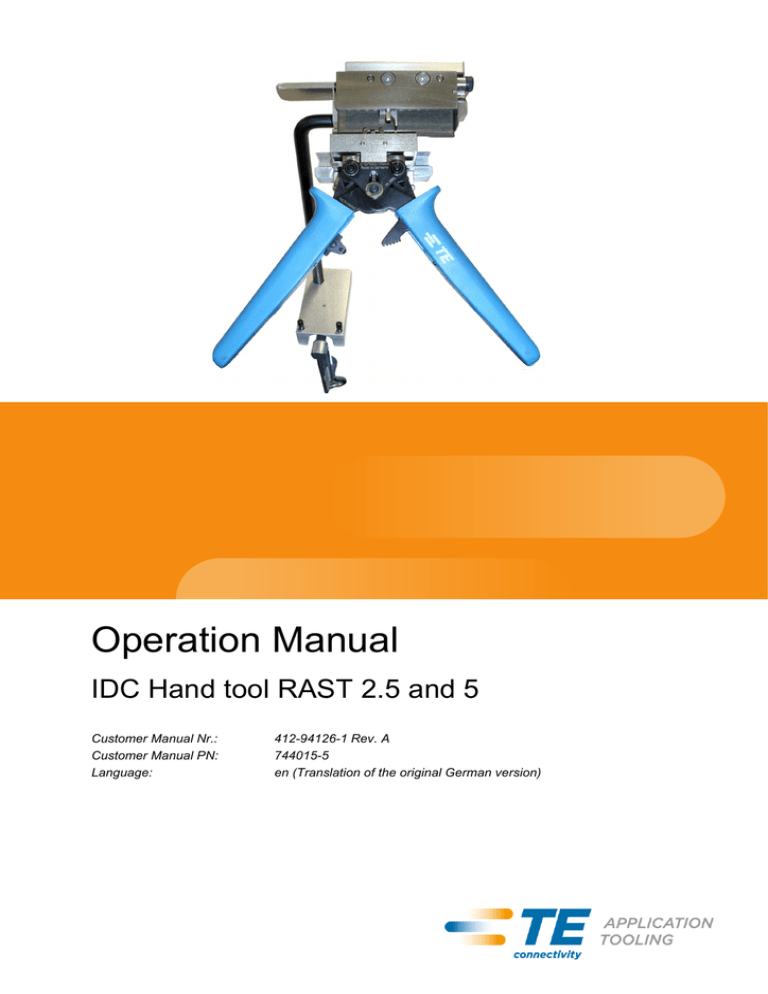

Operation Manual

IDC Hand tool RAST 2.5 and 5

Customer Manual Nr.:

Customer Manual PN:

Language:

412-94126-1 Rev. A

744015-5

en (Translation of the original German version)

IDC Hand tool RAST 2.5 and 5

The data specified above only serve to describe the product. No statements concerning a

certain condition or suitability for a certain application can be derived from our information.

The information given does not release the user from the obligation of own judgment and

verification. It must be remembered that our products are subject to a natural process of wear and aging

© This document, as well as the data, specifications and other information set forth in it, are the exclusive property of TE Connectivity Ltd.

It may not be reproduced or given to third parties without its consent.

The cover page shows a sample configuration. The delivered product may thus differ from the figure.

The original operation manual is written in German.

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

1/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

1

General information ................................................................................................... 4

1.1

Copyrights, industrial property rights......................................................................................................4

2

Using the operation manual....................................................................................... 5

2.1

Abbreviations used.................................................................................................................................5

3

General safety instructions ........................................................................................ 6

3.1

Intended use...........................................................................................................................................6

3.2

Improper use ..........................................................................................................................................6

3.3

Reasonably foreseeable misuse ............................................................................................................6

3.4

Qualification of personnel.......................................................................................................................7

3.5

Safety instructions in this document.......................................................................................................7

3.6

Adhere to the following instructions .......................................................................................................8

3.6.1

General instructions ..............................................................................................................8

3.6.2

During operation ...................................................................................................................8

3.6.3

During disposal .....................................................................................................................8

3.7

Obligations of the operator .....................................................................................................................8

4

Scope of delivery ....................................................................................................... 9

5

Product description.................................................................................................. 10

5.1

Handled connectors .............................................................................................................................10

6

Content of case ....................................................................................................... 11

6.1

Components overview..........................................................................................................................11

6.2

Construction of the hand tool ...............................................................................................................12

6.3

Construction of the tool heads .............................................................................................................13

6.3.1

AMP DUOPLUG 2.5 Mark II ...............................................................................................13

6.3.2

AMP DUOPLUG 2.5 Power ................................................................................................14

6.3.3

AMP multifitting Mark II.......................................................................................................15

6.3.4

AMP MONO-SHAPE Mark II ..............................................................................................16

6.3.5

AMP MONO-SHAPE Mark I ...............................................................................................17

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

2/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

7

Using the table mounting......................................................................................... 18

8

Preparation of the connector ................................................................................... 20

9

Making a connection................................................................................................ 23

9.1

AMP DUOPLUG 2.5 Mark II.................................................................................................................23

9.2

AMP DUOPLUG 2.5 Power .................................................................................................................29

9.3

AMP multifitting Mark II ........................................................................................................................34

9.4

AMP MONO-SHAPE Mark II................................................................................................................40

9.5

AMP MONO-SHAPE Mark I.................................................................................................................46

10

Maintenance and Repair ......................................................................................... 52

10.1

Daily Maintenance................................................................................................................................52

10.2

Periodically Maintenance .....................................................................................................................52

11

Disposal................................................................................................................... 53

12

Troubleshooting....................................................................................................... 54

13

Appendix ................................................................................................................. 55

13.1

Contact information ..............................................................................................................................55

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

3/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

1

General information

1.1

Copyrights, industrial property rights

© This document, as well as the data, specifications and other information set forth in it,

are the exclusive property of TE Connectivity Ltd.

It may not be reproduced or given to third parties without its consent.

This manual is exclusively meant for the carrier of the „IDC Hand tool RAST 2.5 and 5“

(in further course called “IDC Hand tool”) and its personnel for internal use only.

The additional device-specific manual includes descriptions, engineering drawings, instructions and

references, that you may not copy, reproduce or distribute without written consent neither completely

nor in parts.

If the competition try for discover and inspect this manual, we do expect the same fairness, that you

may expect from your customers in that case.

All rights, including rights created by patent grant or registration of a utility model or

design, are reserved.

Subject to change without notice. Errors and omissions excepted.

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

4/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

2

Using the operation manual

These instructions contain important information on the safe and appropriate operation and simple

troubleshooting of the hand tool.

Read these instructions completely, especially section 3 “General safety instructions”, before working

with the IDC Hand tool.

Each person entrusted with the job of operating the IDC Hand tool, must be familiar with the operation manual and strictly observe the instructions therein.

TE Connectivity Ltd. decline to accept any liability for damages that are incurred due to the fact that

the instructions in the operation manual have been disregarded.

The user is responsible for supplementing the operation manual with any instructions resulting from

current national regulations for accident prevention and protection of the environment.

Also observe the generally applicable, legal or otherwise binding regulations of the European or national legislation and the rules for the prevention of accidents and for environmental protection applicable in your country.

2.1

Abbreviations used

Abbreviation

Meaning

IDC

Isolation Displacement Connection

RAST

grid connection plug technology Rasteranschlusssteck-

PN

Part-No.

RoHS

Restriction of (the use of certain) hazardous substances

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

5/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

3

General safety instructions

The IDC Hand tool has been manufactured according to the accepted rules of current technology. There is,

however, still a risk of personal injury or damage to equipment if the following general safety instructions and

the warnings before the steps contained in these instructions are not complied with.

Read these instructions completely and thoroughly before working with the IDC hand tool.

Keep these instructions in a location where they are accessible to all users at all times.

Always include the operating instructions when you pass the IDC hand tool to third parties.

RoHS Information

Information on the presence and location of any substances subject to

RoHS (Restriction on Hazardous Substances) can be found at the following website:

http://www.tycoelectronics.com/customersupport/rohssupportcenter/

Click on “Find Compliance Status” and enter equipment part number.

3.1

Intended use

The „IDC RAST Hand tool 2.5 and 5“ has been designed to apply connectors according to the AMP specification (section 5 „Product description“) with wires following the grid connection plug technology using Insulation Displacement Technique.

It is only permitted to use the „IDC hand tool 2.5 and 5“ exclusively for repair proposes or preparation of

samples. Do not use it for serial production.

The IDC hand tool is not a product in terms of the EU-Machinery Directive 2006/42/EG.

Intended use includes having read and understood these instructions, especially

section 3 “General safety instructions”.

Application Notes:

Cumulative Trauma Disorders can result from a prolonged use of manually powered hand tools.

TE Connectivity Ltd. hand tools are intended for occasional use and low volume applications.

For extended use or production operations TE Connectivity Ltd. offers a wide selection of

powered application equipment.

3.2

Improper use

Any use of the IDC RAST hand tool other than described in section 3.1“Intended use” is considered as

improper.

3.3

Reasonably foreseeable misuse

Any attempt to use the IDC hand tool with other than the specified connectors, described in

section 3.1 “Intended use” is considered as a reasonable foreseeable misuse.

Moreover, the IDC hand tool may used exclusively within the limits of its intended use

(section 3.1 “Intended use”).

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

6/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

3.4

Qualification of personnel

In order to ensure operating safety, these activities may therefore only be carried out by qualified

technical personnel or an instructed person under the direction and supervision of qualified personnel.

Qualified personnel are those who can recognize possible hazards and institute the appropriate safety

measures due to their professional training, knowledge, and experience, as well as their understanding of

the relevant conditions pertaining to the work to be done. Qualified personnel must observe the rules

relevant to the subject area.

3.5

Safety instructions in this document

Type of risk!

Consequences

Precautions

Safety sign (warning triangle): Draws attention to the hazard

Signal word: Identifies the degree of hazard

Type of danger: Identifies the type or source of the hazard

Consequences: Describes the consequences of non-compliance

Precautions: States how the hazard can be prevented

The signal words have the following meaning:

Signal word

Application

Indicates an imminently hazardous situation which, if not avoided,

will certainly result in serious injury or even death.

Indicates a potentially hazardous situation, which, if not avoided,

could result in serious injury or even death.

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury or damage to equipment.

If this information is disregarded, it may result in machine malfunction or breakdown.

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

7/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

3.6

Adhere to the following instructions

3.6.1

General instructions

Observe the regulations for accident prevention and environmental protection for the country where

the product is used and at the workplace.

Exclusively use the IDC hand tool in good technical order and condition.

Check the IDC hand tool for visible defects, for example missing parts in set case or

broken parts.

You must generally not modify or retrofit the product.

Only use the product appropriate to the intended use described in this manual.

Person who assemble, operate, disassemble or maintain the machine must not

consume any alcohol, drugs or pharmaceuticals that may affect their ability to

respond.

Before putting the IDC Hand tool into operation, it is always important to check whether all devices

are at hand and functioning correctly.

The warranty only applies to the delivered configuration. The warranty will not apply if the product

is incorrectly assembled, not used as intended and/or handled improperly.

If the IDC hand tool is apparently damaged or do not work proper, you must send it in for repairs

(section 13.1 „Contact Information”).

3.6.2

During operation

Only persons who have been authorized by the operator may be granted access to the direct

operating range.

3.6.3

During disposal

For environmentally friendly disposal please observe the notes in section 11 ”Disposal”.

3.7

Obligations of the operator

The operator of the TE Connectivity Ltd. products is bound to provide for personnel training on a regular

basis regarding the following subjects:

Observation and use of the operating instructions and the legal regulations

Intended use and operation of the IDC hand tool.

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

8/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

4

Scope of delivery

The scope of delivery includes following parts:

1 transport case containing

misc. tools (section 6.1 ”Components overview”)

1 operating manual

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

9/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

5

Product description

Depending on the application the IDC Hand tool has been designed to apply connectors

(according to the TE specification) (section 5 „Product description“) with wires using Insulation Displacement

Technique (RAST 2.5 and 5).

It is only permitted to use the „IDC hand tool 2.5 and 5“ only for repair proposes or preparation of samples.

Do not use it for serial production.

5.1

Handled connectors

Following connectors of the type „RAST 2.5“ and „RAST 5“ are used:

RAST 5

RAST 2.5

Connector

TE specification

PN

tool case

(ref. Fig. 1)

AMP DUOPLUG 2.5 Mark II

114-18467-0

1-1579012-1

AMP DUOPLUG 2.5 Power

114-18458-0

1-1579012-2

AMP multifitting Mark II

114-18288

1-1579012-6

AMP MONO-SHAPE Mark II

114-20104

1-1579012-5

114-20016 (TAB)

AMP MONO-SHAPE Mark I

1-1579012-4

114-20018 (PC)

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

10/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

6

Content of case

6.1

Components overview

Fig. 1: Components overview

1 Set of socket head wrenches

5 Side cutter (latching rib)

2 IDC- RAST Hand tool with

tool head and adapter

6 End cutter (Keying rib)

3 Table clamp piece

7 Bracket

4 Transport case

8 Cutter knife

This operating manual is stored in the inner shed of the transport case.

Pull the foam piece by using the clip (arrow).

The operating manual will find behind the foam piece.

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

11/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

6.2

Construction of the hand tool

The Hand tool consists of the movable handle with the guidance and the stuffer (4), the adapter (5), the

table mounting consists of the table clamp piece (2) and the bracket (3) as well as the tool head consists of

the holding fixture with connector clamping (1).

Fig. 2: Hand Tool Design (similarly)

1

Holding fixture incl. Connector clamping

2

Table clamp piece

3

Bracket

4

Guidance incl. Stuffer unit

5

Adapter

CAUTION!

Damage to property! Stuffer damage hazard!

Strictly observe to exchange the complete tool head.

The fixture including the connector clamping may only use in combination with the

appropriate provided gripper.

A combination of a holding fixture with a guidance of another type will probably crash and will

cause a damage of the stuffer!

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

12/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

6.3

Construction of the tool heads

6.3.1

AMP DUOPLUG 2.5 Mark II

Fig. 3: Tool Head Design AMP DUOPLUG 2.5 Mark II

1

Chamber’s exterior fixation, static

4

Stuffer

2

Press bar for connector’s fixation

5

Tool head /

guidance incl. stuffer unit

3

Chamber fixation

6

Forked sleeve for

Chamber fixation

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

13/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

6.3.2

AMP DUOPLUG 2.5 Power

Fig. 4: Head Design AMP DUOPLUG 2.5 Power

1

Tool head /

guidance incl. stuffer unit

4

Tool head / holding fixture incl.

connector clamping

2

Stuffer

5

Press bar for connector’s fixation

3

Chamber’s exterior fixation,

static

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

14/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

6.3.3

AMP multifitting Mark II

Fig. 5: Tool Head Design AMP multifitting Mark II

1

Locking screw

6

Chamber fixation

2

Tool head / holding fixture incl. 7

connector clamping

Forked sleeve for

Chamber fixation

3

Chamber’s exterior fixation,

static foldaway

8

Stuffer

4

Chamber’s exterior fixation,

adjustable

9

Tool head / guidance incl. stuffer

unit

5

Gauge piece resp. snap-fitting

of the connector’s width

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

15/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

6.3.4

AMP MONO-SHAPE Mark II

Fig. 6: Tool Head Design AMP MONO-SHAPE Mark II

1

Locking screw

6

Chamber fixation

2

Tool head / holding fixture incl. 7

connector clamping

Forked sleeve for

Chamber fixation

3

Chamber’s exterior fixation,

static, foldaway

8

Stuffer

4

Chamber’s exterior fixation,

adjustable

9

Tool head /

guidance incl. stuffer unit

5

Gauge piece resp. snap-fitting

of the connector’s width

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

16/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

6.3.5

AMP MONO-SHAPE Mark I

Fig. 7: Tool Head Design AMP MONO-SHAPE Mark I

1

Locking screw

2

Tool head / holding fixture incl. 7

connector clamping

Chamber fixation

3

Compensation bar for type

“PC”

(9.5 „AMP MONO-SHAPE

Mark I“)

8

Stuffer

4

Chamber’s exterior fixation,

static, foldaway

9

Tool head /

guidance incl. stuffer unit

5

Chamber’s exterior fixation,

adjustable

10 Forked sleeve for

Chamber fixation

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

6

Gauge piece resp. snap-fitting of

the connector’s width

17/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

7

Using the table mounting

For assistance the hand tool can be fixed on a work table, so you can use both the hands to work.

Attach the table mounting (1 / see page 11) to an appropriate place.

Insert the bracket into the mounting bore (arrow) of the bracket (2) and fix it by the locking screw

placed on the face of the table mounting.

Fig. 8: Fastening the fixture

Place the hand tool with its mounting hole onto the free end of the bracket (arrow) and fix it by using the two locking screws placed in the adapter plate.

Fig. 9: Fastening the hand tool

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

18/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Fix the bracket in the requested position by using the two clamp screw of the adapter(arrow).

Fig. 10: Fixation of the bracket

The complete hand tool is exemplary displayed in Fig. 11.

Fig. 11: Complete hand tool with table mounting

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

19/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

8

Preparation of the connector

The preparation of the connector will be shown exemplarily by using the AMP multifitting Mark II and

applies analogously to all similar products listed in 5.1 „Handled Connectors“.

The connectors will be delivered exclusively linked on strip.

Fig. 12: Condition of the connectors at delivery

Fig. 13: Bundled connectors

1

Cover

3

Latching rib

2

Connector

4

Keying rib

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

20/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Pull up the connector to be separated against the cover of the fitting connector. By slightly tilting

and a sufficient force both the latching ribs gets released and disconnect the connector.

Strictly observe not to damage the connectors when separating it!

Separate the connector’s cover in consideration of its specification by moving it back and forth or

alternatively by using the cutter knife.

Fig. 14: Removing of cover

CAUTION!

Risk of injury (cuts from sharp edges)!

Strictly wear protective gloves when doing the cutting work described subsequent

Remove the latching ribs by using the side cutter (PN 658170-2) according to the

respective specification.

Types 114-20016 „AMP MONO-SHAPE MK I (TAB)” and 11420018 „AMP MONO-SHAPE MK I (PC)” do not have any

latching ribs to cut-off!

Fig. 15: Cutting-off latching ribs

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

21/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Remove the keying ribs according to the respective specification by using the end

cutter (PN 539601-3).

Fig. 16: Cutting-off keying ribs

Ready-to-use connector:

Fig. 17: Ready-to-use connector

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

22/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

9

Making a connection

9.1

AMP DUOPLUG 2.5 Mark II

Insert the prepared connector into the check rail between the stuffer unit and holding fixture incl.

connector clamping.

Fig. 18: Inserting connector

Press down the clamping bar (1) for an easier handling.

Push the connector (3) into the check rail against the fixation (2). The gripper has to be opened.

Fig. 19: Positioning connector to fixation

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

23/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Move the transport unit to positioning the connector’s IDC contacts straight to the stuffer.

Fig. 20: Positioning of the connector

Make sure that the transport unit is explicit engaged.

An attempt of clamping using an incorrect engaged transport unit will damage

the stuffer!

Move the forked sleeve (1) to the left (arrow), so that the green marker (2) appears.

This moves the chamber fixation in its functional position.

At once the gripper is getting released.

Fig. 21: Positioning of chamber fixation

Make sure that the green marker appears.

If it is not visible, the gripper is blocked against pinching!

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

24/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Feed the end of the insulted wire to the IDC contact, so the wire rests flush with the bottom face

(arrow) of the connector. Check the correct position of the wire.

The gripper still remains open.

Make sure that the chamber fixation is arranged in its functional position.

This has to be in any case before executing the contacting!

The positioning of the wire above the IDC contact has a major impact on the

quality of contacting!

Therefore check the correct position of the wire!

Pinch the gripper.

Fig. 22: Pinching the gripper

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

25/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

The stuffer heads for the IDC contact.

The chamber’s exterior fixation protects the chamber’s side walls against unintended deformation.

The stuffer inserts the wire into the IDC contact, where the wire is insulated and fixed.

Fig. 23: Pressing of stuffer

Loosening the gripper.

Fig. 24: Loosening the gripper

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

26/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Move the forked sleeve (1) to the right (arrow), so that the red marker (2) appears.

This lifts out the chamber fixation from its functional position.

At once the gripper is getting blocked against pinching.

Fig. 25: Blocking the gripper

Make sure that the red marker appears.

Only in this position the gripper is blocked against pinching!!

Repeat the positioning of the stuffer below the insulation displacement termination to be handled by

means of the guidance, the locking of the chamber fixation by means of the forked sleeve, the

feeding of the insulated wire, the pinching and loosening of the gripper as well as the release of the

chamber fixation for all chambers to be provided with a wire.

After finishing the process press down the press bar and pull off the connector.

Do not tension the wires due to damaging the contacting!

Fig. 26: Removing the connector

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

27/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Put the cover onto the connector considering the respective specifications and press it in.

The cover has to be in the correct position. Use an appropriate tool if applicable.

Fig. 27: Pressing in the cap

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

28/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

9.2

AMP DUOPLUG 2.5 Power

Insert the prepared connector into the check rail between the stuffer unit and the transport unit.

Fig. 28: Inserting connector

Press down the clamping bar (1) for an easier handling.

Pull the connector (3) into the check rail against the contact support (2).

The gripper must be opened.

Fig. 29: Positioning connector to fixation

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

29/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Move the transport unit to positioning the connector’s IDC contacts straight to the stuffer.

Fig. 30: Positioning of stuffer

Make sure that the transport unit is explicit engaged. An attempt of clamping

using an incorrect engaged transport unit will damage the stuffer.

Feed the end of the insulted wire to the IDC contact, so the wire rests flush with the bottom face

(arrow) of the connector. Check the correct position of the wire.

The gripper still remains open.

Fig. 31: Insertion of wire

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

30/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Pinch the gripper.

Fig. 32: Pinching the gripper

The stuffer and the chamber fixation head for the IDC contact. The stuffer inserts the wire into the

IDC contact, where the wire is insulated and fixed.

NOTE!

This AMP DUOPLUG 2.5 Power – Tool Head comes with NO

chamber fixation protecting the side walls!

Fig. 33: Pressing of stuffer

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

31/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Loosening the gripper.

Fig. 34: Loosening the gripper

Repeat the positioning of the stuffer below the insulation displacement termination to be handled by

means of the guidance, the feeding of the insulated wire as well as the pinching and loosening of

the gripper for all chambers to be provided with a wire.

After finishing the process press down the press bar and pull off the connector.

Do not tension the wires due to damaging the contacting!

Fig. 35: Removing the connector

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

32/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Put the cover onto the connector considering the respective specifications and press it in.

The cover has to be in the correct position. Use an appropriate tool if applicable.

Fig. 36: Pressing in the cap

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

33/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

9.3

AMP multifitting Mark II

Fold up the foldaway fixation to insert the connector into the guidance.

Insert the prepared connector into the check rail between the stuffer unit and the transport unit.

Fig. 37: Inserting connector

Fold down the foldaway fixation.

Move the adjustable chamber’s fixation (1) against the connector (3).

The gripper has to be open.

Fig. 38: Positioning connector to fixation

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

34/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Make sure that the chamber fixations are in the right position.

Misplaced chamber fixations will cause a negative impact on the quality of

contacting!

Move the transport unit to positioning the connector’s IDC contacts straight to the stuffer.

Fig. 39: Positioning of stuffer

Make sure that the transport unit is explicit engaged.

An attempt of clamping using an incorrect engaged transport unit will

damage the stuffer!

Move the forked sleeve (1) to the left (arrow), so that the green marker (2) appears.

This moves the chamber fixation in its functional position.

At once the gripper is getting released.

Fig. 40: Positioning of fixation

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

35/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Make sure that the green marker appears.

If it is not visible, the gripper is blocked against pinching!

Feed the end of the insulted wire to the IDC contact, so the wire rests flush with the bottom face

(arrow) of the connector. Check the correct position of the wire.

The gripper still remains open.

Make sure that the chamber fixation is arranged in its functional position.

This has to be in any case before executing the contacting!

The positioning of the wire above the IDC contact has a major impact on the

quality of contacting!

Therefore check the correct position of the wire!

Pinch the gripper.

Fig. 41: Pinching the gripper

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

36/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

The stuffer heads for the IDC contact.

The chamber’s exterior fixation protects the chamber’s side walls against unintended deformation.

The stuffer inserts the wire into the IDC contact, where the wire is insulated and fixed.

Fig. 42: Pressing of stuffer

Loosening the gripper.

Fig. 43: Loosening the gripper

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

37/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Move the forked sleeve (1) to the right (arrow), so that the red marker (2) appears.

This lifts out the chamber fixation from its functional position.

At once the gripper is getting blocked against pinching.

Fig. 44: Blocking the gripper

Make sure that the red marker appears.

Only in this position the gripper is blocked against pinching!

Repeat the positioning of the stuffer below the insulation displacement termination to be handled by

means of the guidance, the locking of the chamber fixation by means of the forked sleeve, the

feeding of the insulated wire, the pinching and loosening of the gripper as well as the release of the

chamber fixation for all chambers to be provided with a wire.

After finishing the process press down the press bar and pull off the connector.

Do not tension the wires due to damaging the contacting!

Fig. 45: Removing the connector

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

38/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Put the cover onto the connector considering the respective specifications and press it in.

The cover has to be in the correct position. Use an appropriate tool if applicable.

Fig. 46: Pressing in the cap

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

39/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

9.4

AMP MONO-SHAPE Mark II

Fold up the foldaway fixation to insert the connector into the guidance.

Insert the prepared connector into the check rail between the stuffer unit and the transport unit.

Fig. 47: Inserting connector

Fold down the foldaway fixation (1).

Move the adjustable chamber’s fixation (3) against the connector (2).

The gripper has to be open.

Fig. 48: Positioning connector to fixation

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

40/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Make sure that the chamber fixations are in the right position.

Misplaced chamber fixations will cause a negative impact on the quality of

contacting!

Move the transport unit to positioning the connector’s IDC contacts straight to the stuffer.

Fig. 49: Positioning of stuffer

Make sure that the transport unit is explicit engaged.

An attempt of clamping using an incorrect engaged transport unit will

damage the stuffer!

Move the forked sleeve (1) to the left (arrow), so that the green marker (2) appears.

This moves the chamber fixation in its functional position.

At once the gripper is getting released.

Fig. 50: Positioning of fixation

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

41/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Make sure that the green marker appears.

If it is not visible, the gripper is blocked against pinching!

Feed the end of the insulted wire to the IDC contact, so the wire rests flush with the bottom face

(arrow) of the connector. Check the correct position of the wire.

The gripper still remains open.

Make sure that the chamber fixation is arranged in its functional position.

This has to be in any case before executing the contacting!

The positioning of the wire above the IDC contact has a major impact on the

quality of contacting!

Therefore check the correct position of the wire!

Pinch the gripper.

Fig. 51: Pinching the gripper

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

42/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

The stuffer heads for the IDC contact.

The chamber’s exterior fixation protects the chamber’s side walls against unintended deformation.

The stuffer inserts the wire into the IDC contact, where the wire is insulated and fixed.

Fig. 52: Pressing of stuffer

Loosening the gripper.

Fig. 53: Loosening the gripper

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

43/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Move the forked sleeve (1) to the right (arrow), so that the red marker (2) appears.

This lifts out the chamber fixation from its functional position.

At once the gripper is getting blocked against pinching.

Fig. 54: Blocking the gripper

Make sure that the red marker appears.

Only in this position the gripper is blocked against pinching!

Repeat the positioning of the stuffer below the insulation displacement termination to be handled by

means of the guidance, the locking of the chamber fixation by means of the forked sleeve, the

feeding of the insulated wire, the pinching and loosening of the gripper as well as the release of the

chamber fixation for all chambers to be provided with a wire.

After finishing the process press down the press bar and pull off the connector.

Do not tension the wires due to damaging the contacting!

Fig. 55: Removing the connector

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

44/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Put the cover onto the connector considering the respective specifications and press it in.

The cover has to be in the correct position. Use an appropriate tool if applicable.

Fig. 56: Pressing in the cap

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

45/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

9.5

AMP MONO-SHAPE Mark I

This tool head can handle to types of connectors:

Type „TAB“ according to specification 114-20016 and Type „PC“ according to specification 11420018. Handling type “PC” a compensation bar (arrow) has to be adopted into the tool head to

compensate the “TAB”-Type’s different stack height. When handling Type “TAB” the compensation

bar must be removed by pulling out sideways.

Fig. 57: Compensation bar

Fold up the foldaway fixation to insert the connector into the guidance.

Insert the prepared connector into the check rail between the stuffer unit and the transport unit and

fold down the foldaway fixation (1).

Move the adjustable chamber’s fixation (3) against the connector (2).

The gripper has to be open.

Fig. 58: Positioning connector to fixation

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

46/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Make sure that the chamber fixations are in the right position.

Misplaced chamber fixations will cause a negative impact on the quality of

contacting!

Move the transport unit to positioning the connector’s IDC contacts straight to the stuffer.

Fig. 59: Positioning of the connector

Make sure that the transport unit is explicit engaged.

An attempt of clamping using an incorrect engaged transport unit will damage the stuffer!

Move the forked sleeve (1) to the left (arrow), so that the green marker (2) appears.

This moves the chamber fixation in its functional position.

At once the gripper is getting released.

Fig. 60: Positioning of chamber fixation

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

47/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Make sure that the green marker appears.

If it is not visible, the gripper is blocked against pinching!

Feed the end of the insulted wire to the IDC contact, so the wire rests flush with the bottom face

(arrow) of the connector. Check the correct position of the wire.

The gripper still remains open.

Make sure that the chamber fixation is arranged in its functional position.

This has to be in any case before executing the contacting!

The positioning of the wire above the IDC contact has a major impact on the

quality of contacting!

Therefore check the correct position of the wire!

Pinch the gripper.

Fig. 61: Pinching the gripper

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

48/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

The stuffer heads for the IDC contact.

The chamber’s exterior fixation protects the chamber’s side walls against unintended deformation.

The stuffer inserts the wire into the IDC contact, where the wire is insulated and fixed.

Fig. 62: Pressing of stuffer

Loosening the gripper.

Fig. 63: Loosening the gripper

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

49/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Move the forked sleeve (1) to the right (arrow), so that the red marker (2) appears.

This lifts out the chamber fixation from its functional position.

At once the gripper is getting blocked against pinching.

Fig. 64: Blocking the gripper

Make sure that the red marker appears.

Only in this position the gripper is blocked against pinching!

Repeat the positioning of the stuffer below the insulation displacement termination to be handled by

means of the guidance, the locking of the chamber fixation by means of the forked sleeve, the

feeding of the insulated wire, the pinching and loosening of the gripper as well as the release of the

chamber fixation for all chambers to be provided with a wire

After finishing the process press down the press bar and pull off the connector.

Do not tension the wires due to damaging the contacting!

Fig. 65: Removing the connector

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

50/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

Put the cover onto the connector considering the respective specifications and press it in.

The cover has to be in the correct position. Use an appropriate tool if applicable.

Fig. 66: Pressing in the cap

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

51/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

10

Maintenance and Repair

10.1

Daily Maintenance

For the daily maintenance following steps has to be taken by the responsible operator:

Clean up the tool from dust, humidity and other residues by means of a clean, soft scrubber or a lintfree cloth

never use rigorous or abrasive mediums to avoid damaging the tool.

Make sure the mounting pins of the tool pinch are inserted and fixed by lock washers.

All pins, pivot points and bearing surfaces must be provided with a high-quality SAE20 motor oil.

Avoid excessive lubrication.

If the hand tool is no longer required, pinching the gripper and store the hand tool dry and clean in

the transport case (6.1 “Components overview”).

10.2

Periodically Maintenance

Depending on the degree of utilisation an inspection of the RAST hand tool should be done by an

appropriate qualified personnel.

Make sure the mounting pins of the tool pinch are inserted and fixed by lock washers.

Pinching the gripper until the mechanism of the lever brace released resp. opened and leave the

gripper opened.

Do not loose the gripper too fast and completely to avoid damaging the tool head‘s springs.

Check the hand tool on abrasions and damaging, in particularly in the field of the crimper and all

pivot points.

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

52/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

11

Disposal

Careless disposal of the applicator lead to pollution of the environment.

In case of disposal, please send the hand tool and ist components back to the address specified in

section 13.1 “Contact information”.

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

53/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

12

Troubleshooting

If the engagement of the holding fixture incl. connector clamping is not positioned correctly, the

stuffer will drive against the connector.

Due to that the connector will get damaged (arrow).

Fig. 67: Damaging of connector

If the gripper gets jammed you must not keep on pushing the gripper in no way but use the extraction mechanism (arrow).

Fig. 68: Extraction Mechanism

In case of damage in every way, that have an impact on the gripper’s function etc. the gripper has

to send in for repairs (see section 13.1 “Contact information”).

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

54/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5

IDC Hand tool RAST 2.5 and 5

13

Appendix

13.1

Contact information

TE Connectivity

c/o Schenck Technologie- und Industriepark GmbH

Landwehrstr. 55 / Gebäude 83

64293 Darmstadt

Field Service EMEA@te.com

GATD Kundendienst-Hotline: +49-6151-607-1518

©2009 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

TE logo and Tyco Electronics are trademarks.

55/ 55

*Trademark. Other products, logos, and company names used are the property of their respective owners.

Operation Manual

744015-5